Dot Peen Marking Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440565 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Dot Peen Marking Machines Market Size

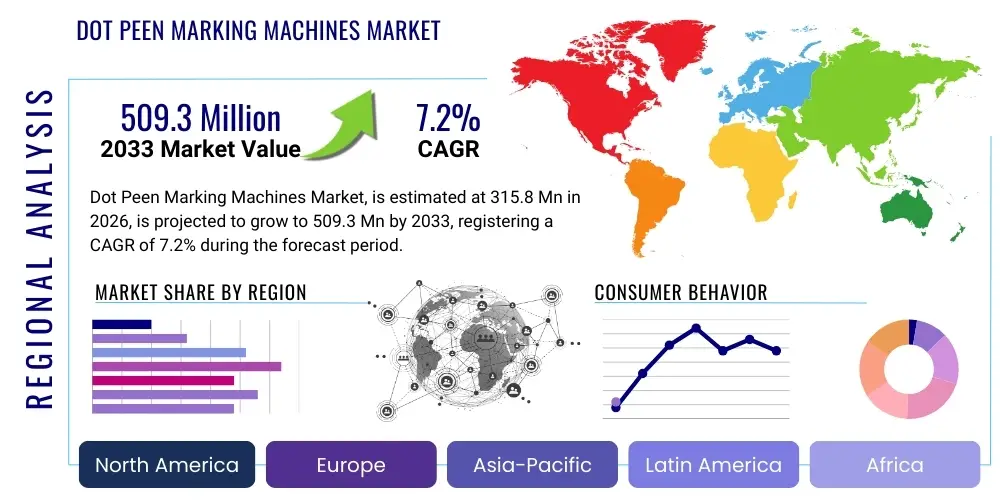

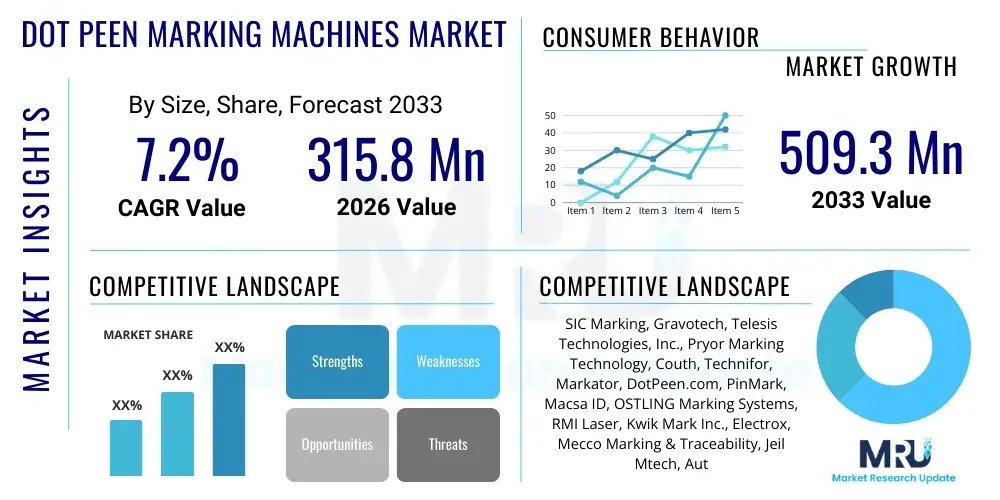

The Dot Peen Marking Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 315.8 million in 2026 and is projected to reach USD 509.3 million by the end of the forecast period in 2033.

Dot Peen Marking Machines Market introduction

The Dot Peen Marking Machines Market encompasses the global industry involved in the manufacturing, distribution, and sales of equipment designed for permanent marking of various materials through a series of indentations (dots). These machines utilize a hardened pin to strike the surface of a material, creating precise and indelible marks. This technology is widely favored for its ability to produce highly durable marks, resistant to abrasion, chemicals, and extreme temperatures, making it ideal for traceability, anti-counterfeiting, and identification purposes across diverse industrial applications. Key products include portable, benchtop, and integrated systems, each tailored to specific operational needs and production environments, from small batch marking to high-volume assembly lines.

Major applications of dot peen marking machines span critical sectors such as automotive for VIN and component marking, aerospace for part identification and compliance, medical devices for surgical tool traceability, and general manufacturing for serial numbers, logos, and data matrix codes on metals, plastics, and other hard materials. The inherent benefits of dot peen marking, including its low operational cost compared to alternatives like laser marking, its versatility in marking various material hardnesses, and the creation of permanent, readable marks, contribute significantly to its widespread adoption. This method ensures that critical information remains intact throughout a product's lifecycle, supporting stringent regulatory requirements and quality control standards across numerous industries. The rise in demand for robust product identification and tracking solutions across global supply chains continues to solidify its market position.

The market is primarily driven by an increasing emphasis on product traceability and authentication due to escalating regulatory mandates and a growing global concern over counterfeit goods. Industries such as automotive and aerospace require absolute certainty in part provenance and lifespan tracking, which dot peen marking reliably provides. Furthermore, the global expansion of industrial automation and the integration of marking solutions into lean manufacturing processes contribute substantially to market growth, as companies seek efficient and cost-effective methods for permanent identification. The enduring need for durable, machine-readable codes on components, coupled with advancements in machine capabilities such as improved accuracy, speed, and connectivity, further propels the market forward, addressing the evolving demands of modern manufacturing ecosystems.

Dot Peen Marking Machines Market Executive Summary

The Dot Peen Marking Machines Market is currently experiencing robust growth, propelled by several key business trends including the widespread adoption of Industry 4.0 principles, increasing automation in manufacturing, and a growing global focus on supply chain transparency and anti-counterfeiting measures. Businesses are increasingly investing in integrated marking solutions that can seamlessly connect with existing production lines, MES (Manufacturing Execution Systems), and ERP (Enterprise Resource Planning) systems to enhance data accuracy and operational efficiency. There is a discernible trend towards more intelligent, portable, and user-friendly machines, driven by the need for flexibility in diverse production environments and the demand for marking solutions that can handle increasingly complex data requirements. Customization of marking parameters and integration with robotic systems for automated handling are also significant drivers shaping current business strategies within the market, pushing manufacturers to innovate beyond traditional standalone units.

Regional trends indicate strong growth in Asia Pacific, particularly in countries like China, India, and Southeast Asian nations, where rapid industrialization, burgeoning automotive and electronics manufacturing sectors, and a large export-oriented production base are fueling demand for robust marking solutions. North America and Europe continue to be mature markets, characterized by high adoption rates in advanced manufacturing, aerospace, and medical device industries, driven by strict regulatory compliance and high-value product traceability requirements. These regions are also leading in the integration of smart manufacturing technologies and automation, which further drives the demand for sophisticated dot peen systems capable of real-time data exchange. Emerging economies in Latin America and the Middle East & Africa are showing promising growth, albeit from a smaller base, as industrial infrastructure develops and local manufacturing capabilities expand, creating new opportunities for market penetration and application.

Segmentation trends reveal significant shifts within the market. By type, pneumatic dot peen markers continue to dominate due to their robustness and versatility, though electromagnetic systems are gaining traction for applications requiring quieter operation and finer control. In terms of operation, portable dot peen machines are seeing increased demand for their flexibility in marking large or immobile parts, while integrated systems are becoming indispensable for high-volume, automated production lines. Application-wise, VIN marking in the automotive industry and UID (Unique Identification) marking in aerospace and defense remain critical segments, alongside general part marking for industrial components. End-user industries such as automotive, aerospace & defense, and general manufacturing represent the largest shares, consistently requiring permanent and reliable marking for compliance, quality control, and brand protection, with the medical device sector showing accelerated growth due to stringent traceability regulations.

AI Impact Analysis on Dot Peen Marking Machines Market

User questions regarding AI's impact on the Dot Peen Marking Machines Market frequently revolve around how artificial intelligence can enhance existing marking processes, improve precision and efficiency, and integrate with broader smart factory ecosystems. Common inquiries explore the potential for AI to optimize marking parameters based on material properties, predict maintenance needs of marking pins, enable more sophisticated quality control through vision systems, and facilitate real-time data analysis for process improvement. Users are also keen to understand how AI can drive greater automation, especially in complex marking tasks, and how it might contribute to a more adaptive and autonomous manufacturing environment, moving beyond simple static marking sequences to dynamic, data-driven operations. The overarching themes are efficiency, precision, predictive capabilities, and seamless integration within Industry 4.0 frameworks.

- AI-powered vision systems for enhanced mark verification and quality control, detecting defects and ensuring compliance.

- Predictive maintenance algorithms for marking pins and machine components, reducing downtime and optimizing service schedules.

- Intelligent parameter optimization, where AI analyzes material properties and desired mark depth/clarity to automatically adjust marking settings.

- Integration with robotic systems, allowing AI to guide dot peen markers for precise, complex, and variable marking patterns on irregular surfaces.

- Real-time data analytics for process monitoring, identifying trends, and suggesting improvements in marking efficiency and consistency.

- Autonomous anomaly detection during marking operations, flagging inconsistencies that could lead to errors or material damage.

- Enhanced customization and adaptability for small batch runs, with AI quickly reconfiguring marking sequences based on design changes or product variations.

- Improved traceability and data management through AI processing of marked data, linking it to broader supply chain and inventory systems.

DRO & Impact Forces Of Dot Peen Marking Machines Market

The Dot Peen Marking Machines Market is significantly shaped by a confluence of Drivers, Restraints, and Opportunities, collectively forming the impact forces that dictate its trajectory. Key drivers include the escalating global demand for product traceability and anti-counterfeiting measures, driven by increasingly stringent regulatory mandates across sectors like automotive, aerospace, and medical devices. The pervasive trend of industrial automation and the push towards Industry 4.0 adoption further propel market expansion, as manufacturers seek integrated, efficient, and reliable permanent marking solutions within their automated production lines. The growing focus on quality control and brand protection also underscores the necessity for durable and verifiable part identification. These drivers represent the primary tailwinds, creating sustained demand across various manufacturing verticals and geographies.

However, the market also faces notable restraints. The initial high capital investment required for purchasing advanced dot peen marking systems can be a barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. Additionally, the operational complexity and the need for specialized technical expertise for machine setup, programming, and maintenance can deter some potential users. Competition from alternative marking technologies, such as laser marking and inkjet printing, which may offer different advantages in terms of speed, surface compatibility, or cost for specific applications, also poses a constraint. While dot peen offers unique benefits in durability, these alternative technologies sometimes present a more viable solution depending on the specific application requirements, impacting market share in certain niches.

Opportunities for growth are abundant and dynamic. The increasing adoption of smart factory concepts and the integration of marking machines with IoT and AI technologies present significant avenues for innovation and market penetration, allowing for more intelligent, predictive, and efficient operations. Emerging markets, with their burgeoning manufacturing sectors and developing industrial infrastructure, represent untapped potential for market expansion. The growing demand for customized products and the need for flexible marking solutions for diverse materials and part geometries also create new niches. Furthermore, continuous advancements in dot peen technology, such as improved pin durability, faster marking speeds, enhanced software capabilities, and more robust integration features, are continually expanding the range of applications and improving the cost-effectiveness of these machines, presenting attractive growth prospects for manufacturers and solution providers.

Segmentation Analysis

The Dot Peen Marking Machines Market is extensively segmented to provide a granular view of its various components and their respective contributions to the overall market landscape. This detailed breakdown allows for a comprehensive understanding of market dynamics, identifying key areas of growth, specific product preferences, and target end-user industries. Segmentation aids in strategizing product development, marketing efforts, and market entry by highlighting the unique requirements and adoption patterns across different operational types, technological specifications, and industrial applications, reflecting the diverse needs of a global manufacturing base that increasingly relies on precise and permanent identification solutions.

- By Type

- Pneumatic Dot Peen Marking Machines

- Electromagnetic Dot Peen Marking Machines

- Scuba Dot Peen Marking Machines

- By Operation

- Portable Dot Peen Marking Machines

- Benchtop (Stationary) Dot Peen Marking Machines

- Integrated (Workstation/Robot-mounted) Dot Peen Marking Machines

- By Application

- Part Marking

- VIN (Vehicle Identification Number) Marking

- Nameplate Marking

- UID (Unique Identification) Marking

- Serial Number Marking

- Logo and Branding Marking

- Data Matrix and QR Code Marking

- By End-User Industry

- Automotive

- Aerospace & Defense

- General Manufacturing

- Heavy Machinery

- Electronics & Semiconductors

- Medical Devices

- Oil & Gas

- Metal Fabrication

- Tool & Die

- Others (e.g., Construction, Railways)

Value Chain Analysis For Dot Peen Marking Machines Market

The value chain for the Dot Peen Marking Machines Market begins with upstream activities focused on the procurement of raw materials and the manufacturing of specialized components essential for the construction of these complex machines. This includes suppliers of high-grade steels and alloys for marking pins, precision electronics for controllers and software, motors, pneumatic components (for pneumatic systems), and various other mechanical and electrical parts. Manufacturers of these core components, such as hardened tool steel producers, electronic circuit board fabricators, and specialized software developers, form the foundational layer of the value chain. Their ability to deliver high-quality, durable, and technologically advanced inputs directly influences the performance and reliability of the final dot peen marking system. Relationships at this stage are critical for maintaining supply consistency, cost efficiency, and innovation in core machine technologies.

Moving downstream, the value chain encompasses the assembly, integration, distribution, and end-use of dot peen marking machines. Manufacturers of dot peen systems integrate all the sourced components, develop proprietary software interfaces, and conduct rigorous testing to ensure product quality and performance. The distribution channels play a crucial role in reaching the diverse customer base. This typically involves a combination of direct sales, where manufacturers sell directly to large industrial clients or for complex, customized solutions, and indirect channels, which include a network of authorized distributors, resellers, and system integrators. These intermediaries provide local sales support, technical service, and often integrate the marking machines into larger automated production lines or robotic cells, adding significant value through specialized installation and configuration services tailored to specific customer needs and industry requirements. The choice of distribution channel often depends on the geographic reach, market segment, and level of technical support required by the end-user, ensuring comprehensive market coverage and customer satisfaction.

The final stage of the value chain involves the end-users—the diverse industries and companies that purchase and operate dot peen marking machines. These end-users, spanning automotive, aerospace, medical devices, and general manufacturing, are the ultimate beneficiaries of the technology, leveraging it for critical applications such such as part traceability, regulatory compliance, anti-counterfeiting, and brand identification. Post-sale activities, including technical support, maintenance services, training, and the supply of consumables (like marking pins), form an integral part of the value chain, ensuring the long-term operational efficiency and customer satisfaction. The feedback loop from end-users back to manufacturers and component suppliers is vital for continuous product improvement, innovation, and adaptation to evolving market demands, highlighting the interconnectedness of all stages in delivering value within the dot peen marking machine ecosystem.

Dot Peen Marking Machines Market Potential Customers

The potential customers for Dot Peen Marking Machines are diverse, primarily comprising end-user industries that require permanent, high-contrast, and durable marking for product identification, traceability, and regulatory compliance. These industries span a wide range of manufacturing and production environments where parts and components need indelible marks that can withstand harsh industrial conditions, chemicals, and abrasion throughout their lifecycle. Key segments include those with stringent quality control standards and legal requirements for identification, such as lot numbers, serial numbers, date codes, and unique identifiers (UIDs). The core demand originates from sectors where a robust and enduring mark is not merely a preference but a critical operational necessity for safety, accountability, and supply chain integrity.

Foremost among the potential customers is the automotive industry, which heavily relies on dot peen technology for VIN (Vehicle Identification Number) marking on chassis and frames, as well as for marking various engine components, brake parts, and other critical assemblies. The aerospace and defense sector represents another significant customer base, where stringent traceability requirements for every single part, from airframe components to engine parts, necessitate permanent marking to ensure safety, maintenance records, and regulatory compliance. Similarly, the medical device industry demands high-precision, biocompatible marking for surgical instruments, implants, and diagnostic equipment, ensuring sterility, batch traceability, and authenticity, often using smaller, more precise dot peen systems that can mark delicate surfaces without compromising material integrity.

Beyond these highly regulated sectors, general manufacturing encompasses a vast array of potential customers, including metal fabricators, tool and die manufacturers, heavy machinery producers, and electronics and semiconductor companies. These businesses utilize dot peen marking for serializing parts, branding products, creating data matrix codes for automated scanning, and marking work-in-progress components for internal tracking. The oil and gas industry also constitutes a niche but critical customer segment, requiring robust marking on pipes, valves, and drilling components that operate in extremely harsh environments. Essentially, any manufacturing entity dealing with metal, hard plastics, or similar materials that requires a permanent, machine-readable mark for tracking, quality control, or compliance purposes, represents a potential buyer for dot peen marking machines, highlighting the broad applicability and enduring demand for this technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 315.8 million |

| Market Forecast in 2033 | USD 509.3 million |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SIC Marking, Gravotech, Telesis Technologies, Inc., Pryor Marking Technology, Couth, Technifor, Markator, DotPeen.com, PinMark, Macsa ID, OSTLING Marking Systems, RMI Laser, Kwik Mark Inc., Electrox, Mecco Marking & Traceability, Jeil Mtech, Automator International, Dapra Corporation, ID Technology, Datamark Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dot Peen Marking Machines Market Key Technology Landscape

The Dot Peen Marking Machines Market is characterized by a dynamic technology landscape driven by continuous innovation aimed at enhancing marking quality, speed, versatility, and integration capabilities. At the core, the technology revolves around the marking pin mechanism, primarily categorized into pneumatic and electromagnetic systems. Pneumatic systems utilize compressed air to drive the pin, offering robust performance and deeper marks, suitable for harder materials and industrial environments. Electromagnetic systems, conversely, use an electromagnetic coil to actuate the pin, providing quieter operation, finer control, and often higher precision, making them ideal for applications requiring delicate marking or quieter work environments. Advancements in pin materials and designs are crucial for increasing durability, reducing wear, and enabling marking on a broader range of material hardnesses, contributing to reduced maintenance and extended operational lifespans of the machines.

Beyond the core marking mechanism, the technological landscape includes sophisticated control systems and software that govern the marking process. Modern dot peen machines are equipped with advanced microprocessors and intuitive human-machine interfaces (HMIs), often featuring touchscreens, that simplify programming, enable precise parameter adjustments (such as mark depth, dot spacing, and font selection), and facilitate the creation of complex marking patterns, including logos and data matrix codes. Integration capabilities are a significant technological trend, with machines designed for seamless connection with industrial networks, PLCs (Programmable Logic Controllers), robotic systems, and factory management software (MES/ERP). This connectivity allows for automated data transfer, real-time process monitoring, and integration into fully automated production lines, aligning with Industry 4.0 objectives and smart factory initiatives to maximize efficiency and data integrity across manufacturing operations.

Furthermore, portable and integrated solutions represent key technological advancements tailored to specific operational needs. Portable dot peen machines, often battery-operated and lightweight, offer unparalleled flexibility for marking large, heavy, or immovable parts directly on the shop floor or in remote locations. Integrated systems are designed for high-volume production lines, mounted on workstations or robotic arms, offering automated loading, marking, and unloading capabilities, significantly boosting throughput and consistency. The incorporation of vision systems into dot peen markers is also gaining traction, enabling automatic part recognition, mark validation, and quality control, ensuring that marks are consistently accurate and readable. These technological developments collectively aim to enhance the user experience, broaden the application scope, and improve the overall efficiency and reliability of dot peen marking operations in an increasingly automated and data-driven manufacturing world.

Regional Highlights

- North America: This region is a mature market characterized by high adoption of advanced manufacturing technologies, stringent regulatory requirements for traceability in automotive and aerospace industries, and a strong presence of key market players. The U.S. and Canada lead in innovation and industrial automation, driving demand for sophisticated, integrated dot peen marking solutions. The emphasis on high-value manufacturing and quality control further bolsters market growth.

- Europe: Europe represents another significant market, driven by its robust automotive, machinery manufacturing, and medical device sectors, particularly in Germany, France, and the UK. Strict EU regulations regarding product identification, CE marking, and anti-counterfeiting measures contribute to the steady demand for reliable dot peen marking machines. The region also benefits from a strong focus on precision engineering and Industry 4.0 initiatives.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, burgeoning manufacturing sectors in China, India, Japan, and South Korea, and a large export-oriented economy. The expansion of automotive, electronics, and general manufacturing industries, coupled with increasing investments in factory automation, creates immense opportunities for market penetration and growth. The demand for cost-effective and efficient marking solutions is particularly high.

- Latin America: This region is an emerging market for dot peen marking machines, driven by the developing industrial infrastructure and growing manufacturing bases, especially in countries like Brazil and Mexico. The automotive and general manufacturing sectors are expanding, leading to increased demand for robust identification and traceability solutions, albeit from a smaller market share compared to more developed regions.

- Middle East and Africa (MEA): The MEA market is gradually expanding, primarily influenced by investments in infrastructure, oil and gas, and manufacturing diversification initiatives in countries like Saudi Arabia and UAE. As industrialization progresses and local manufacturing capabilities grow, the need for permanent marking solutions for equipment and components is expected to rise, creating new opportunities for market development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dot Peen Marking Machines Market.- SIC Marking

- Gravotech

- Telesis Technologies, Inc.

- Pryor Marking Technology

- Couth

- Technifor

- Markator

- DotPeen.com

- PinMark

- Macsa ID

- OSTLING Marking Systems

- RMI Laser

- Kwik Mark Inc.

- Electrox

- Mecco Marking & Traceability

- Jeil Mtech

- Automator International

- Dapra Corporation

- ID Technology

- Datamark Systems

Frequently Asked Questions

Analyze common user questions about the Dot Peen Marking Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is dot peen marking and how does it work?

Dot peen marking is a direct part marking technology that uses a hard stylus or pin to indent a series of dots onto a material's surface, creating permanent alphanumeric characters, logos, or 2D data matrix codes. The pin is typically actuated by pneumatic pressure or an electromagnetic coil, striking the material repeatedly and rapidly to form the desired mark. This process is highly effective for creating durable marks that resist wear, chemicals, and extreme temperatures, making it ideal for industrial traceability and identification needs.

What materials can dot peen marking machines mark?

Dot peen marking machines are highly versatile and can permanently mark a wide range of materials, primarily metals, including steel, stainless steel, aluminum, copper, brass, and titanium. They are also effective on various hard plastics, composites, and other non-metallic surfaces that can withstand the impact of the marking pin. The ability to mark different material hardnesses and surface finishes makes dot peen technology a preferred choice across diverse manufacturing industries, from automotive to aerospace.

What are the primary advantages of dot peen marking over other marking technologies?

The primary advantages of dot peen marking include its ability to create exceptionally durable and permanent marks that are resistant to harsh environments, chemicals, and abrasion, ensuring lifelong traceability. It is also cost-effective compared to laser marking for certain applications, offers high reliability, and can mark a wide range of material hardnesses without requiring consumables like ink. Furthermore, dot peen systems are generally robust, require minimal maintenance, and can be easily integrated into existing production lines, providing a versatile and long-lasting identification solution.

How do dot peen marking machines integrate into automated production lines?

Modern dot peen marking machines are designed for seamless integration into automated production lines through various communication protocols and interfaces. They can be mounted on robotic arms, integrated into workstations, or controlled by PLCs (Programmable Logic Controllers) and factory management systems (MES/ERP). This allows for automated part handling, precise marking, and real-time data exchange, enhancing efficiency, reducing manual intervention, and ensuring consistent marking quality in high-volume manufacturing environments, aligning with Industry 4.0 principles for smart factories.

What factors should be considered when choosing a dot peen marking machine?

When selecting a dot peen marking machine, several critical factors should be considered, including the type of material to be marked and its hardness, the required mark depth and permanence, the marking speed necessary for production throughput, and the level of precision and resolution needed for the application. Additionally, operational factors like machine portability (portable, benchtop, or integrated), ease of integration with existing systems, software capabilities, budget constraints, and post-sales support are crucial. Assessing these elements ensures the chosen machine effectively meets specific application requirements and long-term operational needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager