Dough Conditioners Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438725 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Dough Conditioners Market Size

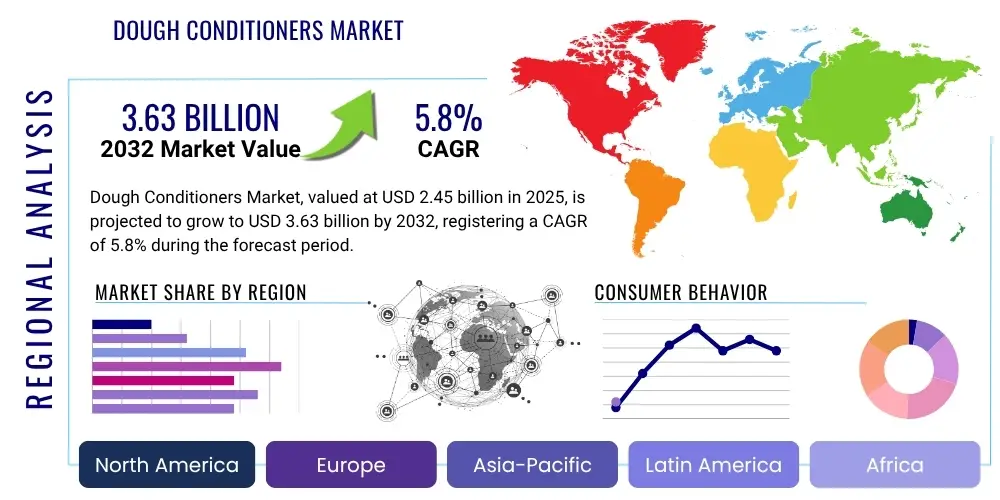

The Dough Conditioners Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Dough Conditioners Market introduction

The Dough Conditioners Market encompasses a broad range of functional ingredients designed to enhance the physical and chemical properties of dough, ultimately improving the quality, consistency, and shelf life of baked goods. These ingredients are crucial in modern commercial baking, addressing challenges such as variability in flour quality, high-speed processing demands, and the need for extended freshness. Dough conditioners function by strengthening the gluten network, accelerating fermentation, and improving gas retention, leading to better volume, finer crumb structure, and increased tolerance to mechanical handling. The primary components driving this market include enzymes (like amylases and lipases), emulsifiers (such as DATEM and SSL), and oxidizing or reducing agents (like ascorbic acid).

The core application of these conditioners spans across mass-produced baked goods, including standard loaf bread, specialty breads, rolls, biscuits, and confectionery products. Rapid urbanization and the corresponding increase in demand for convenient, packaged foods, particularly in developing economies, are major propellers for market growth. Furthermore, shifting consumer preferences towards specialized bread types, such as whole grain, gluten-free, or high-fiber variants, necessitate the use of advanced conditioning systems to maintain desirable textural attributes that might otherwise be compromised by non-traditional ingredients.

The ongoing trend toward "clean label" ingredients represents a significant evolutionary pressure on the industry, driving innovation toward natural, enzyme-based solutions that can replace traditional chemical agents like potassium bromate or azodicarbonamide (ADA), which face increasing regulatory scrutiny globally. The benefits derived from optimal dough conditioning—including reduced processing time, minimized waste, and improved final product characteristics—cement its indispensable role in the modern food manufacturing sector, securing its continued robust growth throughout the forecast period.

Dough Conditioners Market Executive Summary

The Dough Conditioners Market is characterized by robust growth, primarily fueled by the soaring global demand for packaged and processed baked goods, coupled with technological advancements in enzyme engineering. Business trends show a distinct pivot toward natural and enzyme-based conditioners, driven by consumer preference for clean label products and stringent food safety regulations, particularly in North America and Europe. Key market players are heavily investing in R&D to develop novel ingredient blends that offer multi-functional benefits, such as optimizing dough machinability while simultaneously extending product freshness without requiring artificial additives. Consolidation through strategic mergers and acquisitions is also prevalent, as companies seek to expand their ingredient portfolios and geographic reach, especially into high-growth Asian markets.

Regionally, Asia Pacific (APAC) is emerging as the fastest-growing market, largely due to rapid urbanization, increasing per capita consumption of Western-style baked goods, and the expansion of organized retail chains and industrial bakeries in countries like China and India. North America and Europe, while mature, remain dominant in terms of value, driven by high adoption rates of premium and specialized baking technologies and a strong emphasis on consistent product quality and sophisticated supply chain management. European trends are strongly shaped by the EU’s ‘Farm to Fork’ strategy, pushing manufacturers towards sustainable and locally sourced conditioning ingredients. Latin America and MEA exhibit potential, primarily driven by investments in local manufacturing capabilities and the rising availability of convenience food options.

Segment trends highlight the enzyme category as the most dynamic segment, with Amylases, Lipases, and Proteases dominating innovation due to their natural origin and efficacy in gluten modification and texture improvement. Within applications, commercial bread production remains the largest consumer base, although specialty applications like frozen dough products and pizza bases are experiencing accelerated growth due driven by the Quick Service Restaurant (QSR) sector and at-home baking convenience trends. The shift from powder to encapsulated or liquid forms is also noted, offering benefits in dosage accuracy and ease of integration into automated industrial mixing processes, streamlining manufacturing operations across various scales.

AI Impact Analysis on Dough Conditioners Market

Common user questions regarding AI’s impact on the Dough Conditioners Market center on predictive quality control, optimization of complex ingredient blends, and personalized product development. Users frequently inquire about how AI can analyze fluctuating raw material quality (especially flour protein content) in real-time to automatically adjust conditioner dosages, thereby ensuring consistent dough performance and reducing batch variability—a critical concern for industrial bakers. Furthermore, there is significant interest in Generative AI’s capability to model complex interactions between enzymes, emulsifiers, and flour types, allowing manufacturers to rapidly formulate custom conditioner systems optimized for specific baking processes (e.g., long fermentation vs. rapid proofing) or regional climatic conditions. Users also anticipate AI being used for advanced supply chain forecasting, helping conditioner suppliers manage inventory and volatile pricing of key raw materials like specialized enzymes or agricultural derivatives, thereby stabilizing overall production costs and improving market efficiency. The key themes are focused on leveraging AI for precision, efficiency, and advanced formulation discovery.

- AI-Powered Predictive Quality Control: Real-time adjustment of conditioner ratios based on incoming flour analysis (moisture, protein, ash content), minimizing processing errors and waste.

- Optimized Recipe Formulation: Utilizing machine learning algorithms to simulate and predict the synergistic effects of multi-component conditioner blends, accelerating R&D cycle times for new products.

- Supply Chain and Inventory Management: AI forecasting models predict demand fluctuations for specific conditioners and optimize enzyme production schedules, mitigating potential ingredient shortages.

- Automated Process Monitoring: Integrating sensors and AI vision systems on production lines to monitor dough rheology and automatically adjust mixing times or proofing parameters based on the conditioner's performance.

- Personalized Baking Solutions: Developing AI-driven platforms that recommend or formulate bespoke conditioning systems tailored to individual client bakery requirements, specific equipment, or desired final product texture.

DRO & Impact Forces Of Dough Conditioners Market

The Dough Conditioners market is significantly influenced by a dynamic interplay of market drivers, strict regulatory restraints, and technological opportunities, all contributing to its long-term trajectory. Key drivers include the massive global proliferation of commercial and industrial bakeries, which rely entirely on conditioners to maintain high-volume production speed and uniformity, alongside the consumer-driven push for highly convenient, shelf-stable baked goods that require functional ingredients to extend freshness and prevent staling. Conversely, the market is restrained by the growing consumer skepticism and regulatory scrutiny surrounding synthetic chemical additives, forcing major reformulation efforts and increasing R&D costs associated with achieving ‘clean label’ compliance, particularly in Western markets. The impact forces indicate a strong push toward natural and biotechnological solutions.

A primary opportunity lies in the rapid technological advancement of enzyme engineering, allowing manufacturers to create highly specific and efficient biocatalysts (enzymes) that deliver superior performance attributes compared to traditional chemical conditioners, often enabling cleaner ingredient decks. Furthermore, significant untapped market potential exists in emerging economies in APAC and Latin America, where the shift from traditional baking methods to industrial production is accelerating, creating massive scale-up opportunities for global ingredient suppliers. Overcoming the initial high cost associated with advanced enzyme manufacturing and educating industrial users in these emerging regions about the optimized application of these complex ingredients remain crucial challenges.

The overall impact force leans towards growth, driven by necessity; modern industrial baking cannot function efficiently without robust conditioning systems. However, this growth is channeled specifically into segments that align with consumer trust and health trends. Manufacturers that successfully navigate the transition away from chemical oxidizers towards innovative, enzyme-based, or plant-derived emulsifiers are poised for long-term market leadership. Regulatory environments, particularly those focusing on transparency and minimal processing, act as a continuous filtering mechanism, eliminating outdated ingredients and promoting the adoption of advanced, safe functional solutions.

Segmentation Analysis

The Dough Conditioners Market is primarily segmented based on the ingredient type, the application (type of baked good), and the form of the conditioner (powder, liquid, paste). This segmentation reflects the highly technical nature of the industry, where performance is intrinsically linked to the chemical composition and delivery format of the functional agent. Ingredient type is the most critical axis, detailing the specific mechanism by which the ingredient modifies dough—whether through gluten strengthening (oxidizing agents/enzymes), dough softening (reducing agents), or improved gas retention and anti-staling (emulsifiers). The selection of the appropriate conditioner blend is entirely dependent on the desired end product characteristics and the specific manufacturing process used by the bakery.

By application, the commercial bread segment holds the largest market share globally due to the sheer volume of production, though specialty segments like pizza doughs, frozen products, and cakes and pastries exhibit higher growth rates, driven by consumer demand for convenience and ready-to-eat solutions. These specialized applications often require more customized and potent conditioning systems to withstand freezing, thawing, or aggressive mechanical mixing. The increasing precision required in industrial baking is driving a trend toward multi-functional blends, where various ingredients are combined to achieve multiple performance benefits simultaneously, such as improved shelf life and enhanced dough stability during high-speed production, thereby simplifying the inventory and handling processes for industrial users.

- By Ingredient Type:

- Enzymes (Amylases, Lipases, Proteases, Glucose Oxidase)

- Emulsifiers (DATEM, Sodium Stearoyl Lactylate (SSL), Monoglycerides, Lecithin)

- Oxidizing Agents (Ascorbic Acid, Azodicarbonamide (ADA - diminishing))

- Reducing Agents (L-Cysteine, Sodium Metabisulfite)

- Other Ingredients (Minerals, Yeast Nutrients)

- By Application:

- Bread (Loaf Bread, Rolls, Buns)

- Biscuits & Cookies

- Cakes & Pastries

- Pizza Doughs & Flatbreads

- Other Baked Goods (Donuts, Waffles)

- By Form:

- Powder

- Liquid

- Paste

Value Chain Analysis For Dough Conditioners Market

The value chain for the Dough Conditioners Market is complex and starts with the sourcing of specialized raw materials, primarily agricultural products (wheat, soy, palm, sunflower for emulsifiers) and biotechnological inputs (microorganisms for enzyme production). The upstream segment is dominated by specialized chemical and biochemical manufacturers who invest heavily in fermentation technology and extraction processes to produce high-purity functional ingredients like high-performance enzymes or food-grade emulsifiers. Quality control at this stage is paramount, as the efficacy of the final conditioner blend depends directly on the concentration and stability of these core active ingredients. Price volatility in agricultural commodities and the patent landscape surrounding novel enzyme strains significantly influence the cost structure of the final product.

Midstream activities involve the blending, formulation, and encapsulation of these raw functional ingredients into proprietary conditioner systems. Ingredient suppliers, often possessing deep application knowledge, custom-design blends optimized for specific climates, flours, and baking technologies (e.g., specific conditioner for a short-time dough process vs. a sponge-and-dough process). The trend toward clean label solutions has intensified this processing stage, requiring sophisticated encapsulation technologies to ensure ingredient stability and controlled release during the mixing and baking phases. This stage adds significant value through intellectual property and specialized manufacturing techniques.

Distribution channels are multifaceted, utilizing both direct and indirect methods. Large, multinational conditioner manufacturers often employ direct sales teams and dedicated technical service staff to engage with major industrial bakeries, offering bespoke formulation advice and technical support. Indirect channels, involving regional distributors and specialized ingredient brokers, serve smaller and medium-sized bakeries, ensuring market penetration in less consolidated regions. The shift towards e-commerce platforms is slowly impacting the distribution of standard, off-the-shelf blends, although complex, customized solutions still require high-touch technical support and direct interaction, underlining the importance of the technical sales force in the downstream segment.

Dough Conditioners Market Potential Customers

Potential customers for dough conditioners primarily consist of entities involved in high-volume production of flour-based consumer goods, where consistency, scalability, and shelf life extension are critical operational requirements. The largest segment includes industrial bakeries that produce packaged loaf bread, rolls, and buns for mass market distribution. These customers require highly standardized and potent conditioning systems to ensure that thousands of units produced daily maintain uniform texture, volume, and freshness across various production runs, regardless of minor variations in flour quality or environmental factors.

The second major customer group encompasses manufacturers of specialized baked goods, including frozen dough producers, pizza base manufacturers, and cake and pastry wholesalers. These clients often demand highly specific conditioners capable of addressing unique challenges, such as enzyme systems that maintain integrity through freezing and thawing cycles or emulsifiers designed to prevent fat migration in complex laminated pastry products. The Quick Service Restaurant (QSR) sector and large in-store supermarket bakeries also represent significant end-users, seeking tailored solutions that minimize labor time and maximize the quality of freshly baked products offered to consumers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kerry Group, ADM, Corbion, DuPont (Danisco), Lesaffre, Puratos, Lallemand, BASF, DSM, AB Mauri, Döhler, Bakels, Novozymes, AAK, Ingredion, Caldic B.V., Palsgaard A/S, Associated British Foods, Wacker Chemie AG, Takeda Pharmaceutical. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dough Conditioners Market Key Technology Landscape

The Dough Conditioners market is deeply integrated with advancements in biotechnology and precision food chemistry. The leading technology shaping the market is modern enzyme engineering and production, which utilizes microbial fermentation and genetic modification to create highly specific and thermo-stable enzymes (such as novel fungal alpha-amylases or specialized lipases). These biotechnologically produced ingredients offer superior functional properties—like improved dough stability and significant anti-staling effects—at lower inclusion rates compared to older chemical additives. This technological shift is fundamental to meeting the clean label demands, as enzymes function as processing aids that are often deactivated during baking and do not require labeling as final product ingredients, making them highly desirable for manufacturers aiming for consumer acceptance.

Another critical technological area involves microencapsulation and advanced blending techniques. Encapsulation technology is employed to coat sensitive or potent ingredients, such as certain oxidizing agents or reducing agents, ensuring they are released only at the optimal moment during the mixing or proofing process. This controlled release mechanism enhances the ingredient's efficiency, prevents premature reaction, and improves the overall stability and predictability of the conditioning system. Advanced blending utilizes precise, computerized dosing and mixing equipment to create homogenous, complex, multi-component functional blends, which is crucial for delivering custom, high-performance conditioning solutions consistently to large-scale industrial clients.

Furthermore, analytical rheology tools and rapid testing technologies are essential components of the market’s technological landscape. Industrial manufacturers rely on instruments like Farinographs and Rheometers to quickly assess flour quality and dough characteristics, allowing for instantaneous adjustments to conditioning formulas. The integration of sensor technology and data analytics in industrial bakeries, combined with supplier technical support, forms a feedback loop that drives continuous refinement of conditioner formulations. This focus on real-time data analysis ensures that the conditioner systems remain effective even as environmental or raw material inputs fluctuate, securing optimal performance and minimizing production risks for high-volume manufacturers.

Regional Highlights

- Asia Pacific (APAC) Market Dominance and Growth Trajectory: APAC is forecast to be the fastest-growing region in the Dough Conditioners Market, driven primarily by the colossal population base, increasing disposable incomes, and the rapid westernization of dietary habits. This region is witnessing a significant shift from traditional home-baking to the consumption of packaged, industrially produced baked goods. Countries like China, India, and Indonesia are undergoing massive infrastructure development, supporting the expansion of large-scale commercial bakeries and international Quick Service Restaurants (QSRs), all of which require reliable, high-performance dough conditioners. Local manufacturers are focusing on adapting conditioner formulations to the region's diverse wheat varieties and high-humidity environments, leading to substantial localized R&D efforts. The adoption rate of advanced enzyme technology is accelerating here, often bypassing the heavy use of older chemical systems prevalent in historical Western markets, positioning APAC as a key future growth hub.

- North America Market Maturity and Innovation Focus: North America holds a substantial share of the global market value, characterized by mature, highly automated industrial baking processes and a strong consumer focus on health and clean labels. This region is the primary driver for innovation in natural and functional ingredients, specifically demanding non-GMO, organic, and highly efficient enzyme systems. The stringent regulatory landscape, combined with powerful retailer specifications regarding ingredient transparency, forces suppliers to continuously optimize formulas. The high penetration of specialty bread (e.g., artisanal, ancient grain, gluten-free) necessitates complex, tailor-made conditioning solutions to manage non-traditional dough structures, thereby maintaining high demand for premium, high-value functional ingredients. Manufacturers in this region focus on optimizing logistics and ensuring the stability of sophisticated blends throughout the extensive North American supply chain.

- Europe Market Regulation and Sustainability Mandates: The European market is defined by rigorous food safety standards and an intense focus on sustainability and traceability, largely influenced by European Union regulations like the 'Farm to Fork' strategy. This environment favors ingredients with clear provenance and minimal processing. Demand for chemical oxidizing agents has declined sharply, replaced almost entirely by advanced enzyme systems and plant-derived emulsifiers (such as those based on sunflower or rapeseed). Western European countries (Germany, France, UK) are major consumers, utilizing conditioners heavily in both industrial production and high-quality artisan baking. The market's competitive edge lies in offering traceable, certified, and environmentally conscious conditioning solutions, pushing R&D towards fermentation-based, sustainable ingredient sourcing and reduction of environmental footprint in ingredient production.

- Latin America and Middle East & Africa (LAMEA) Emerging Demand: While smaller in market size, LAMEA presents significant potential. Latin America's growth is spurred by rapid urbanization and the expansion of the middle class, increasing the demand for convenient, packaged bread and fast-food products. Investment in domestic food processing capabilities in countries like Brazil and Mexico is boosting the need for consistent, reliable dough conditioners. In the Middle East and Africa, market expansion is linked to demographic growth, rising tourism, and foreign investment in food manufacturing. Challenges related to high temperatures, supply chain infrastructure, and differing regulatory frameworks across various countries mean that conditioner systems must be exceptionally robust and adaptable to localized flour and processing conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dough Conditioners Market.- Kerry Group

- Archer Daniels Midland Company (ADM)

- Corbion N.V.

- DuPont (Danisco)

- Lesaffre

- Puratos Group

- Lallemand Inc.

- BASF SE

- Koninklijke DSM N.V.

- AB Mauri

- Döhler GmbH

- Bakels Group

- Novozymes A/S

- AAK AB

- Ingredion Incorporated

- Caldic B.V.

- Palsgaard A/S

- Associated British Foods plc

- Wacker Chemie AG

- Takeda Pharmaceutical Company Limited (Food Ingredients Division)

Frequently Asked Questions

Analyze common user questions about the Dough Conditioners market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary functional roles of dough conditioners in industrial baking?

Dough conditioners serve three main functions: enhancing dough rheology (improving elasticity and machinability), stabilizing the gluten network (increasing volume and structure), and improving the shelf life and anti-staling properties of the finished product, which is critical for packaged goods distribution.

How is the market shifting in response to clean label trends?

The market is rapidly shifting away from synthetic chemical conditioners like ADA and potassium bromate. The primary replacement solution involves enzyme-based conditioners (amylases, lipases) and natural emulsifiers, which offer high functionality while aligning with consumer demands for recognizable and minimal ingredients.

Which ingredient type holds the largest growth potential?

Enzymes, specifically engineered amylases and lipases, hold the largest growth potential. Biotechnological advancements allow for the creation of highly efficient, targeted biocatalysts that provide superior performance in gluten modification and texture preservation compared to traditional chemical agents, driving their adoption globally.

What major regulatory factors influence the Dough Conditioners Market?

Key regulatory factors include ingredient approval status (e.g., FDA and EFSA regulations on specific additives), maximum usage limits, and mandatory labeling requirements. The general trend across mature markets is towards strict regulation or outright banning of older chemical oxidizers, favoring natural and processing aids.

Why is the Asia Pacific region experiencing accelerated growth in this market?

APAC's accelerated growth is attributed to rapid urbanization, increasing consumption of packaged bread and Western-style foods, and significant investment in large-scale industrial bakery infrastructure. This structural shift from decentralized, traditional baking to centralized, high-volume production creates massive, immediate demand for functional conditioning ingredients.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager