Dried Aluminum Hydroxide Gel Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439423 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Dried Aluminum Hydroxide Gel Market Size

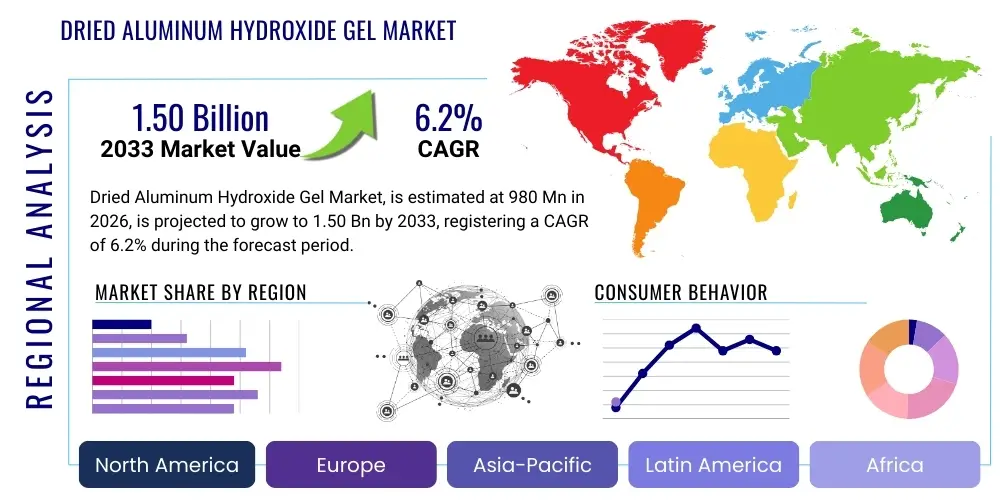

The Dried Aluminum Hydroxide Gel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 980 Million in 2026 and is projected to reach USD 1.50 Billion by the end of the forecast period in 2033.

Dried Aluminum Hydroxide Gel Market introduction

The Dried Aluminum Hydroxide Gel Market encompasses a versatile inorganic compound widely recognized for its unique chemical properties and extensive applications across various industries. Dried aluminum hydroxide gel, often abbreviated as DAHG, is primarily composed of aluminum oxide and water, appearing as a white, amorphous powder or granular substance. Its significance stems from its excellent acid-neutralizing capabilities, high surface area, and adsorbent characteristics, making it a critical ingredient in a multitude of products.

Key applications for DAHG span pharmaceuticals, chemicals, and industrial sectors. In pharmaceuticals, it is most prominently used as an active ingredient in antacids to alleviate symptoms of heartburn, indigestion, and acid reflux by neutralizing stomach acid. Its non-systemic action and low toxicity make it a preferred choice for such formulations. Beyond antacids, DAHG also finds utility in certain vaccine adjuvants and as a desiccant or adsorbent in drug manufacturing processes, where its ability to absorb moisture and impurities is highly valued.

Driving factors for this market include the escalating global prevalence of gastrointestinal disorders, such as GERD and peptic ulcers, which necessitate effective acid-reducing treatments. Furthermore, the increasing demand for flame retardants in various materials, particularly in the construction and electronics industries, significantly contributes to market expansion. Its role as a raw material in other chemical processes and the growing awareness regarding health and wellness, prompting consumers to seek over-the-counter remedies, further underscore the market's robust growth trajectory.

Dried Aluminum Hydroxide Gel Market Executive Summary

The Dried Aluminum Hydroxide Gel (DAHG) market is characterized by dynamic business trends, evolving regional demands, and significant growth within key application segments. Business trends indicate a strong emphasis on product purity and particle size customization, driven by stringent regulatory requirements in the pharmaceutical sector and specific performance needs in industrial applications. Manufacturers are increasingly investing in advanced drying and milling technologies to produce DAHG with enhanced physical and chemical properties, ensuring superior efficacy and broader applicability. Strategic partnerships and mergers among key players are also prevalent, aiming to consolidate market share, optimize supply chains, and leverage synergistic capabilities to meet diverse customer demands effectively.

Regionally, the market exhibits varied growth patterns and consumption landscapes. Asia Pacific continues to emerge as a dominant force, fueled by rapid industrialization, expanding pharmaceutical manufacturing bases, and a burgeoning population experiencing a higher incidence of gastrointestinal ailments. Countries like China and India are at the forefront of both production and consumption, benefiting from lower manufacturing costs and growing domestic demand. North America and Europe represent mature markets with stable demand, primarily driven by established pharmaceutical industries and stringent safety regulations promoting the use of non-halogenated flame retardants. Latin America and the Middle East & Africa are showing promising growth, attributed to improving healthcare infrastructure and increasing investments in industrial and chemical sectors.

Segment-wise, the pharmaceutical application segment remains the largest and most critical revenue generator, predominantly due to the pervasive use of DAHG in antacid formulations. The continuous rise in lifestyle-related digestive disorders and an aging global population ensures sustained demand for pharmaceutical-grade DAHG. Concurrently, the flame retardant segment is experiencing substantial growth, propelled by increasing fire safety regulations and the need for non-toxic, environmentally friendly alternatives to traditional halogenated flame retardants in plastics, coatings, and textiles. Other segments, including adsorbents, ceramics, and cosmetics, also contribute to the market's diversity, driven by specialized technical requirements and ongoing innovation in product development.

AI Impact Analysis on Dried Aluminum Hydroxide Gel Market

The Dried Aluminum Hydroxide Gel (DAHG) market, traditionally rooted in chemical and pharmaceutical manufacturing, is poised for significant transformation through the integration of Artificial Intelligence (AI) technologies. Common user questions related to AI's impact revolve around how it can enhance production efficiency, improve product quality, optimize supply chains, accelerate research and development of new applications, and predict market trends. Stakeholders are keen to understand how AI can lead to more sustainable and cost-effective manufacturing processes, ensuring consistent product specifications and reducing waste. Concerns often include the initial investment cost, data privacy, and the need for specialized skills to implement and manage AI systems, alongside expectations for revolutionary advancements in material science and operational intelligence within the DAHG domain.

- AI can optimize production processes by monitoring real-time data from various stages such as precipitation, filtration, and drying, identifying anomalies and recommending adjustments to maintain optimal conditions for yield and purity.

- Predictive analytics powered by AI can forecast demand patterns more accurately, enabling manufacturers to optimize inventory levels, reduce waste, and manage production schedules efficiently to meet market needs.

- Quality control can be significantly enhanced through AI-driven image analysis and sensor data processing, allowing for precise detection of impurities or deviations in particle size and morphology, ensuring consistent product quality.

- AI accelerates research and development by simulating molecular interactions and predicting the performance of new DAHG formulations or modifications for specific applications, thus reducing the time and cost associated with experimental trials.

- Supply chain management benefits from AI by optimizing logistics, predicting potential disruptions, and identifying the most cost-effective and reliable sourcing channels for raw materials like bauxite and caustic soda, improving resilience.

- Maintenance of manufacturing equipment can be transformed by AI-driven predictive maintenance, which analyzes machine performance data to anticipate potential failures, thereby minimizing downtime and extending equipment lifespan.

- Market analysis and competitive intelligence are bolstered by AI algorithms that can process vast amounts of market data, identify emerging trends, analyze competitor strategies, and inform strategic business decisions for market expansion.

DRO & Impact Forces Of Dried Aluminum Hydroxide Gel Market

The Dried Aluminum Hydroxide Gel (DAHG) market is influenced by a complex interplay of drivers, restraints, and opportunities, alongside broader impact forces that shape its trajectory. A primary driver is the expanding pharmaceutical sector, particularly the rising global prevalence of gastrointestinal disorders such as GERD and indigestion. DAHG's established efficacy as a safe and effective antacid makes it indispensable in over-the-counter and prescription medications. Concurrently, increasing awareness and stringent regulations regarding fire safety in building and construction, automotive, and electronics industries are fueling the demand for non-halogenated flame retardants, where DAHG offers a viable and environmentally friendly solution. The growing disposable income in emerging economies also contributes to higher healthcare spending and consumption of personal care products, where DAHG finds minor applications.

However, the market faces several significant restraints. Volatility in the prices of key raw materials, such as bauxite and caustic soda, can directly impact production costs and profit margins for DAHG manufacturers. Furthermore, the availability of alternative acid neutralizers and flame retardants, including magnesium hydroxide, calcium carbonate, and various organic compounds, presents competitive pressure, limiting market growth. Stringent regulatory frameworks, particularly in the pharmaceutical sector, regarding purity standards, manufacturing practices, and product labeling, impose compliance burdens and can slow down market entry for new products or players. Supply chain disruptions, exacerbated by geopolitical tensions or global health crises, can also impede consistent raw material procurement and product distribution.

Despite these challenges, numerous opportunities exist for market expansion. The development of novel applications for DAHG in areas such as advanced ceramics, catalysts, and water treatment offers untapped growth potential. Investing in research and development to produce DAHG with enhanced properties, such as improved dispersibility, higher surface area, or tailored particle size, can open new revenue streams. Furthermore, the growing demand for sustainable and eco-friendly products creates an opportunity for DAHG as a non-toxic, naturally derived ingredient in various industrial applications. Geographic expansion into underserved or rapidly industrializing regions, coupled with strategic collaborations for product innovation and market penetration, can also unlock substantial value for market participants.

Segmentation Analysis

The Dried Aluminum Hydroxide Gel market is intricately segmented to provide a granular understanding of its diverse applications, forms, and end-use industries. This segmentation is crucial for stakeholders to identify key growth areas, tailor product offerings, and formulate effective market penetration strategies. The primary segmentation typically considers factors such as the grade of the product, the form in which it is supplied, its specific applications, and the major end-use sectors that consume DAHG. Each segment responds to unique market drivers and regulatory landscapes, influencing demand and supply dynamics across the globe.

- By Grade:

- Pharmaceutical Grade: Characterized by high purity and strict quality control, suitable for human consumption in antacids and medical formulations, adhering to pharmacopoeial standards.

- Technical Grade: Used in industrial applications like flame retardants, catalysts, and adsorbents, with less stringent purity requirements compared to pharmaceutical grade but still demanding consistent physical properties.

- By Form:

- Powder: Fine, amorphous particles offering high surface area, preferred for applications requiring easy dispersion or dissolution, such as antacid tablets and flame retardant composites.

- Granular: Larger particles, often used where flowability and reduced dusting are critical, or in specific industrial processes.

- Tablets/Pellets: Pre-formed dosage forms, primarily for pharmaceutical antacid products, offering convenience and controlled release.

- By Application:

- Antacids: The largest application segment, leveraging DAHG's acid-neutralizing properties to relieve heartburn and indigestion.

- Flame Retardants: Utilized in plastics, rubber, coatings, and textiles to suppress or delay the spread of fire, acting as a smoke suppressant and heat sink.

- Adsorbents and Desiccants: Employed in purification processes, gas drying, and as carriers for catalysts due to its high surface area and porous structure.

- Cosmetics and Personal Care: Minor applications in deodorants, antiperspirants, and some skincare products for its astringent and absorbent properties.

- Chemical Intermediates: Used in the synthesis of other aluminum compounds and specialty chemicals.

- Others: Includes applications in ceramics, paper, water treatment, and specialized industrial uses.

- By End-Use Industry:

- Pharmaceuticals: Manufacturers of OTC and prescription drugs for gastrointestinal health.

- Chemical Manufacturing: Producers of various aluminum-based chemicals, catalysts, and industrial agents.

- Building & Construction: Manufacturers of fire-resistant materials, insulation, and coatings.

- Plastics & Polymers: Producers of flame-retardant plastics for electronics, automotive, and consumer goods.

- Personal Care & Cosmetics: Formulators of skincare, oral care, and deodorizing products.

- Water Treatment: Utilized in flocculation and purification processes.

Value Chain Analysis For Dried Aluminum Hydroxide Gel Market

The value chain for the Dried Aluminum Hydroxide Gel (DAHG) market begins with the procurement of raw materials and extends through various processing stages to the final distribution channels reaching diverse end-use industries. Upstream analysis highlights the critical role of bauxite mining and the chemical processing of bauxite to produce aluminum hydroxide. Key raw materials include bauxite, which is processed to alumina, then further refined to aluminum trihydrate (ATH) or aluminum hydroxide. Caustic soda and sulfuric acid are also essential for the precipitation and washing steps in the manufacturing of high-purity DAHG. Suppliers of these primary chemicals form the foundational layer of the value chain, and their pricing, quality, and supply consistency significantly impact the overall production costs and market competitiveness of DAHG manufacturers.

Following raw material procurement, the manufacturing process involves several complex steps including precipitation, washing, filtration, and critically, drying to produce the desired dried gel form. This stage often includes specialized equipment for spray drying or flash drying to achieve specific particle sizes, surface areas, and moisture content, which are crucial for the functional performance of DAHG in different applications. Manufacturers often invest heavily in quality control measures to ensure that the DAHG meets stringent industry standards, especially for pharmaceutical-grade products. This midstream segment is characterized by technological expertise and process optimization, aiming to produce DAHG with tailored physical and chemical properties to cater to the diverse needs of downstream industries.

Downstream analysis focuses on the distribution channels and the ultimate end-users. Once produced, DAHG is distributed through a combination of direct sales and indirect channels. Direct sales are common for large volume buyers, particularly pharmaceutical companies or major chemical manufacturers, where long-term contracts and technical support are paramount. Indirect channels involve a network of distributors and agents specializing in chemical and pharmaceutical ingredients. These intermediaries play a vital role in market penetration, particularly for smaller customers or those in geographically diverse regions, by managing warehousing, logistics, and technical sales support. The end-users, predominantly pharmaceutical companies (for antacids), chemical manufacturers (for flame retardants and catalysts), and to a lesser extent, cosmetics and water treatment sectors, drive the final demand, with their specific requirements dictating product specifications and innovation within the DAHG market.

Dried Aluminum Hydroxide Gel Market Potential Customers

The Dried Aluminum Hydroxide Gel (DAHG) market caters to a broad spectrum of potential customers across various industries, each with specific requirements and applications for the product. The most significant customer segment comprises pharmaceutical companies, particularly those involved in the production of over-the-counter (OTC) and prescription medications for gastrointestinal health. These companies utilize DAHG primarily as an active ingredient in antacids to neutralize stomach acid, treating conditions such as heartburn, acid indigestion, and peptic ulcers. The demand from this sector is driven by the global prevalence of digestive disorders, an aging population, and increasing consumer reliance on self-medication for common ailments, making pharmaceutical manufacturers a cornerstone of the DAHG market.

Another substantial customer base includes chemical manufacturers and polymer processors that integrate DAHG into their products as a non-halogenated flame retardant and smoke suppressant. This is particularly critical in industries like building and construction (for fire-resistant panels, coatings, and insulation), electronics (for casings and components), and automotive (for interior parts). These customers seek DAHG for its ability to release water molecules when heated, cooling the substrate and diluting combustible gases, while also forming a protective char layer. The increasing regulatory pressure to reduce halogenated compounds due to environmental and health concerns further solidifies DAHG's position as a preferred additive for these industries, expanding its customer reach significantly.

Beyond these primary sectors, other potential customers include cosmetic and personal care product manufacturers, who use DAHG in formulations such as deodorants, antiperspirants, and certain skincare products for its absorbent and astringent properties. Water treatment facilities represent another niche segment, where DAHG derivatives can be used as coagulants or adsorbents for removing impurities. Additionally, manufacturers in the ceramics industry, as well as those producing catalysts and specialized chemical intermediates, also constitute potential buyers. These diverse end-users collectively contribute to the sustained demand for DAHG, each seeking specific grades, particle sizes, and purities tailored to their unique processing and product performance requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 980 Million |

| Market Forecast in 2033 | USD 1.50 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Huber Engineered Materials, Sumitomo Chemical Co., Ltd., J.M. Huber Corporation, Almatis GmbH, R.S. Minerals, MAL - Mineralis Alumina GmbH, Nabaltec AG, Sasol Ltd., Showa Denko K.K., Shandong Aluminum Company Limited, Zhongshan Aluminum Industry Co., Ltd., Zibo Aluminum Industry Co., Ltd., Spectrum Chemical Manufacturing Corp., Noah Technologies Corporation, Merck KGaA, Avantor, Thermo Fisher Scientific Inc., W. R. Grace & Co., AkzoNobel N.V., Clariant AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dried Aluminum Hydroxide Gel Market Key Technology Landscape

The key technology landscape for the Dried Aluminum Hydroxide Gel (DAHG) market is centered on optimizing production efficiency, enhancing product purity, and tailoring physical properties to meet diverse application requirements. The manufacturing process typically involves a controlled precipitation reaction of an aluminum salt with a base, followed by a series of washing, filtration, and drying steps. Advanced precipitation techniques are crucial for controlling particle size distribution and morphology, directly impacting the gel's reactivity and surface area, which are vital for its functionality as an antacid or adsorbent. Manufacturers employ sophisticated reactor designs and precise control over temperature, pH, and reactant addition rates to achieve desired characteristics and ensure consistent batch quality.

Following precipitation, the drying phase is paramount for producing the "dried" gel. Technologies such as spray drying, flash drying, and tray drying are commonly employed. Spray drying is particularly favored for producing fine, spherical particles with excellent flowability and dispersibility, which is highly beneficial for pharmaceutical formulations and homogeneous dispersion in polymer matrices for flame retardancy. These drying methods are continually being refined to minimize energy consumption, prevent agglomeration, and preserve the gel's amorphous structure and high surface area, which are essential for its therapeutic and industrial efficacy. Innovations in drying aim to reduce processing time while ensuring uniform moisture content throughout the batch.

Furthermore, post-processing technologies play a significant role in customizing DAHG for specific end-uses. This includes advanced milling and grinding techniques to achieve ultra-fine particle sizes, which can enhance reactivity and improve dispersion in complex formulations. Surface modification technologies, though less common, are also explored to alter the surface chemistry of DAHG, potentially improving compatibility with organic polymers or enhancing its adsorption selectivity. Quality assurance technologies, involving analytical techniques like X-ray diffraction (XRD), scanning electron microscopy (SEM), particle size analyzers, and atomic absorption spectroscopy (AAS), are indispensable for verifying product purity, crystallinity, and elemental composition, ensuring that DAHG meets stringent industry standards and customer specifications.

Regional Highlights

- North America: This region represents a mature market for Dried Aluminum Hydroxide Gel, characterized by stable demand from well-established pharmaceutical and chemical industries. The United States and Canada are key contributors, driven by a high prevalence of gastrointestinal disorders and stringent fire safety regulations promoting the use of flame retardants. Innovation in pharmaceutical formulations and advanced material science also contributes to sustained, albeit moderate, growth.

- Europe: The European market demonstrates consistent demand, influenced by a robust healthcare sector, strong emphasis on environmental regulations, and a focus on sustainable chemical solutions. Countries like Germany, France, and the UK are prominent consumers, particularly in pharmaceutical manufacturing and the production of flame-retardant polymers. Regulatory pressures for non-halogenated alternatives provide a strong impetus for DAHG adoption.

- Asia Pacific (APAC): APAC is the fastest-growing and largest market for Dried Aluminum Hydroxide Gel, propelled by rapid industrialization, expanding healthcare infrastructure, and a burgeoning population. China and India are at the forefront, witnessing substantial growth in pharmaceutical production, construction activities, and the manufacturing of consumer electronics. Lower production costs and increasing domestic demand contribute significantly to the region's dominance.

- Latin America: The Latin American market for DAHG is showing promising growth, primarily due to improving economic conditions, increasing investments in healthcare, and the expansion of industrial sectors. Brazil and Mexico are leading the demand, driven by a growing middle class and enhanced access to pharmaceutical products. The region offers significant untapped potential for market players seeking expansion opportunities.

- Middle East and Africa (MEA): This region is experiencing nascent but accelerating growth in the Dried Aluminum Hydroxide Gel market. Infrastructure development projects, growing pharmaceutical imports and local production, and increasing awareness of health and safety standards are key drivers. Countries in the GCC region and South Africa are emerging as significant consumers, with demand expected to rise as industrialization and healthcare facilities continue to expand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dried Aluminum Hydroxide Gel Market.- Huber Engineered Materials

- Sumitomo Chemical Co., Ltd.

- J.M. Huber Corporation

- Almatis GmbH

- R.S. Minerals

- MAL - Mineralis Alumina GmbH

- Nabaltec AG

- Sasol Ltd.

- Showa Denko K.K.

- Shandong Aluminum Company Limited

- Zhongshan Aluminum Industry Co., Ltd.

- Zibo Aluminum Industry Co., Ltd.

- Spectrum Chemical Manufacturing Corp.

- Noah Technologies Corporation

- Merck KGaA

- Avantor

- Thermo Fisher Scientific Inc.

- W. R. Grace & Co.

- AkzoNobel N.V.

- Clariant AG

Frequently Asked Questions

What is Dried Aluminum Hydroxide Gel (DAHG) primarily used for?

Dried Aluminum Hydroxide Gel (DAHG) is primarily utilized in the pharmaceutical industry as an active ingredient in antacids to neutralize stomach acid, providing relief from heartburn, indigestion, and acid reflux. It is also extensively used as a non-halogenated flame retardant in plastics, coatings, and textiles, and finds applications as an adsorbent, desiccant, and in cosmetics.

How is Dried Aluminum Hydroxide Gel produced?

DAHG is produced through a controlled precipitation process where an aluminum salt reacts with a base to form aluminum hydroxide slurry. This slurry undergoes a series of washing, filtration, and critical drying steps, often using techniques like spray drying or flash drying, to yield a fine, amorphous powder or granular product with specific purity and particle size characteristics.

What are the key factors driving the growth of the DAHG market?

The key drivers for the DAHG market include the rising global prevalence of gastrointestinal disorders, which fuels demand for antacids, and the increasing adoption of non-halogenated flame retardants due to stringent fire safety regulations and environmental concerns. Additionally, the expansion of the pharmaceutical industry and growing health consciousness significantly contribute to market growth.

What challenges does the Dried Aluminum Hydroxide Gel market face?

The DAHG market faces challenges such as volatility in the prices of raw materials like bauxite and caustic soda, which can impact production costs. Competition from alternative acid neutralizers and flame retardants, stringent regulatory requirements, particularly in pharmaceuticals, and potential disruptions in the global supply chain also pose significant restraints.

Which geographical region dominates the Dried Aluminum Hydroxide Gel market?

The Asia Pacific (APAC) region currently dominates the Dried Aluminum Hydroxide Gel market. This is primarily attributed to rapid industrialization, the significant expansion of pharmaceutical manufacturing, increasing construction activities, and a large population base contributing to higher demand for both pharmaceutical and industrial applications of DAHG, particularly in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager