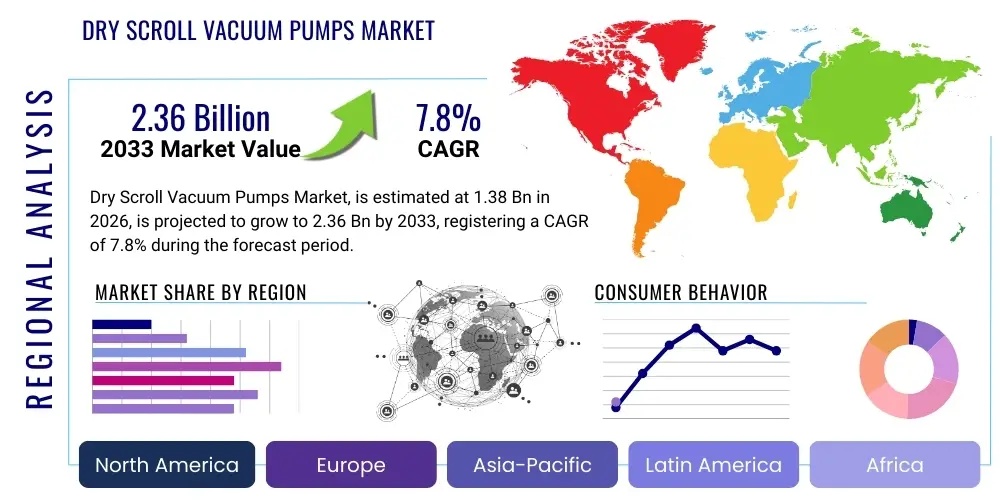

Dry Scroll Vacuum Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440087 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Dry Scroll Vacuum Pumps Market Size

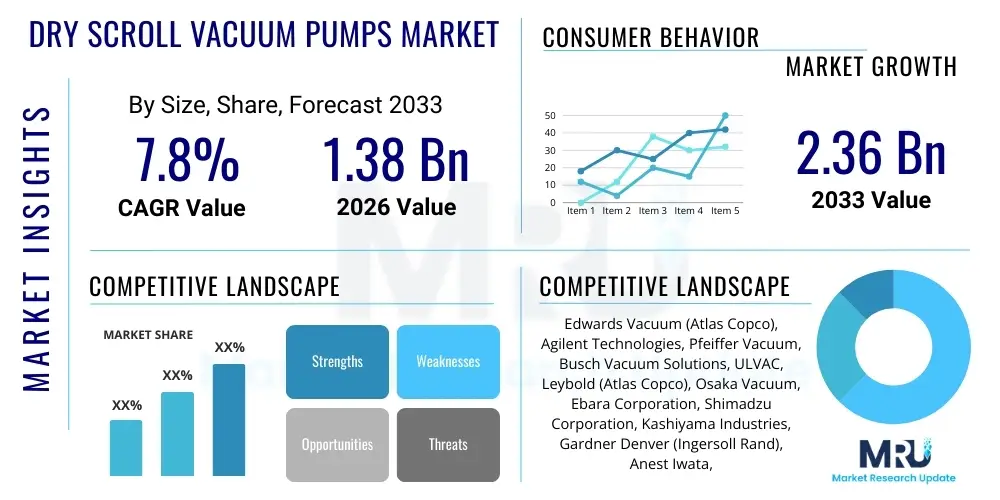

The Dry Scroll Vacuum Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.38 Billion in 2026 and is projected to reach USD 2.36 Billion by the end of the forecast period in 2033.

Dry Scroll Vacuum Pumps Market introduction

The Dry Scroll Vacuum Pumps market is a specialized segment within the broader vacuum technology industry, characterized by its reliance on an oil-free mechanism for generating vacuum. These pumps utilize two interleaved spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas, effectively creating a vacuum without the need for lubricants. This fundamental design ensures a contamination-free pumping environment, making them indispensable across a spectrum of sensitive applications where process purity is paramount.

Major applications for dry scroll vacuum pumps span critical sectors such as semiconductor manufacturing, where ultra-clean environments are essential for chip production, and advanced analytical instruments used in scientific research and quality control. They are also widely adopted in pharmaceutical and biotechnology industries for lyophilization and sterile processing, in solar panel manufacturing, and in various research and development laboratories. The inherent benefits of these pumps, including their quiet operation, low vibration, minimal maintenance requirements, and compact footprint, contribute significantly to their growing appeal.

The primary driving factors behind the market's expansion include the escalating demand for high-purity vacuum environments in cutting-edge industries, robust investments in semiconductor fabrication plants globally, and the continuous growth in scientific research and development activities. Furthermore, increasing regulatory pressures for environmental sustainability and the need for energy-efficient vacuum solutions are propelling the adoption of dry scroll technology, as these pumps offer a cleaner, more economical alternative to traditional oil-sealed pumps.

Dry Scroll Vacuum Pumps Market Executive Summary

The Dry Scroll Vacuum Pumps market is experiencing robust growth driven by advancements in high-tech manufacturing and stringent demands for clean processing environments. Key business trends indicate a strong focus on enhancing pump efficiency, integrating smart monitoring systems for predictive maintenance, and developing application-specific solutions. Manufacturers are increasingly investing in research and development to improve scroll geometries, material durability, and noise reduction, alongside strategic partnerships to expand market reach and product portfolios. The emphasis on sustainability is also pushing innovation towards more energy-efficient and environmentally friendly designs, reducing operational costs and meeting evolving regulatory standards.

Regionally, the Asia Pacific continues to dominate the market, propelled by its expanding semiconductor, electronics, and solar manufacturing industries, particularly in countries like China, South Korea, Taiwan, and Japan. This region benefits from significant government investments in advanced manufacturing infrastructure and a burgeoning R&D landscape. North America and Europe also maintain substantial market shares, primarily due to established pharmaceutical and biotechnology sectors, sophisticated research institutions, and aerospace applications, coupled with a strong emphasis on technological innovation and stringent quality standards. Emerging economies in Latin America and the Middle East & Africa are showing promising growth, albeit from a smaller base, as industrialization and technological adoption accelerate.

Segment-wise, the semiconductor manufacturing application segment holds the largest share, reflecting the critical role of dry scroll pumps in highly sensitive processes like thin-film deposition and etching. The analytical and R&D segment also demonstrates consistent growth, fueled by continuous innovation in scientific instrumentation and academic research. In terms of technology, variable speed drive (VSD) dry scroll pumps are gaining traction due to their energy-saving capabilities and ability to optimize performance for varying vacuum demands, offering enhanced flexibility and reduced operational expenditures compared to fixed-speed alternatives. This dynamic interplay of technological advancement, regional growth, and application-specific demand is shaping the competitive landscape and driving market evolution.

AI Impact Analysis on Dry Scroll Vacuum Pumps Market

Users frequently inquire about how artificial intelligence (AI) can transform the operation, maintenance, and manufacturing of dry scroll vacuum pumps, seeking improvements in efficiency, reliability, and cost reduction. There is significant interest in AI's capacity for predictive analytics to prevent failures, optimize energy consumption, and automate diagnostic processes, ultimately enhancing the longevity and performance of these critical industrial components. Concerns often revolve around the integration complexity of AI systems with existing vacuum infrastructure and the data security implications of connected devices.

The primary themes emerging from user questions highlight expectations for AI to deliver smarter, more autonomous vacuum solutions. Users envision pumps that can self-diagnose issues, automatically adjust operating parameters for peak efficiency, and integrate seamlessly into broader Industry 4.0 ecosystems. This includes a desire for AI-driven insights that can inform operational decisions, streamline maintenance schedules, and reduce downtime, thereby maximizing productivity in sensitive manufacturing and research environments. The demand for intelligent, self-optimizing vacuum systems underscores a forward-looking perspective on leveraging AI for competitive advantage.

- Predictive maintenance through AI-driven anomaly detection, reducing unscheduled downtime.

- Optimized energy consumption by dynamically adjusting pump speed based on real-time process demands.

- Enhanced remote monitoring and diagnostics, allowing for quicker troubleshooting and maintenance scheduling.

- Improved manufacturing processes for dry scroll pumps through AI-driven quality control and process optimization.

- Development of 'smart' vacuum systems that integrate seamlessly with broader industrial IoT networks.

- Automated performance tuning for varying applications and environmental conditions.

- Supply chain optimization for components and spare parts, anticipating needs based on usage patterns.

DRO & Impact Forces Of Dry Scroll Vacuum Pumps Market

The Dry Scroll Vacuum Pumps market is significantly influenced by a confluence of driving factors, restraints, opportunities, and broader impact forces. A primary driver is the accelerating expansion of the semiconductor industry, which relies heavily on contamination-free vacuum environments for intricate manufacturing processes like etching, deposition, and ion implantation. Furthermore, continuous advancements in scientific research and development across various disciplines, including life sciences, material science, and physics, fuel the demand for high-performance, clean vacuum solutions. The inherent energy efficiency and reduced environmental footprint of dry scroll pumps also align with global sustainability trends and stricter environmental regulations, promoting their adoption over traditional oil-sealed alternatives. The compact design and quiet operation of these pumps make them ideal for integration into sensitive laboratory and medical equipment.

However, the market faces several restraints that could impede its growth. The relatively high initial capital cost of dry scroll vacuum pumps compared to some conventional vacuum technologies can be a barrier for smaller enterprises or those with budget constraints. Competition from other advanced vacuum technologies, such as turbomolecular pumps and cryopumps, which offer superior ultimate vacuum levels for specific ultra-high vacuum applications, also presents a challenge. Additionally, the sensitivity of dry scroll pumps to certain harsh chemical environments or particulate-heavy processes can limit their applicability in some industrial settings, requiring careful material selection and design modifications to ensure longevity and performance.

Despite these challenges, numerous opportunities exist for market expansion. The growing adoption of dry scroll vacuum pumps in emerging economies, driven by rapid industrialization and technological upgrades, offers significant untapped market potential. Customization of pump designs for specific niche applications, such as specialized medical devices or advanced battery manufacturing, presents avenues for product differentiation and value creation. The ongoing integration of IoT and Industry 4.0 technologies allows for the development of smart, connected pumps offering predictive maintenance and remote diagnostics, enhancing operational efficiency and customer value. Furthermore, the expansion of renewable energy sectors, particularly solar panel manufacturing, creates new demand segments for clean vacuum solutions. These opportunities, combined with the underlying technological impact forces of innovation and economic growth, will continue to shape the market landscape.

Segmentation Analysis

The Dry Scroll Vacuum Pumps market is comprehensively segmented to provide a granular view of its dynamics, categorized primarily by pump type, application, and end-user industry. This segmentation allows for a detailed understanding of demand drivers and competitive landscapes within specific niches. The types of pumps typically include fixed speed and variable speed models, each offering distinct advantages in terms of operational flexibility and energy efficiency. Variable speed drives (VSD) are gaining prominence due to their ability to optimize performance based on real-time vacuum requirements, leading to significant energy savings and reduced wear.

Applications are diverse and critical, ranging from the demanding purity requirements of semiconductor manufacturing and the precision needs of analytical and R&D laboratories to the sterile environments of pharmaceutical and biotechnology processes. Other significant applications include industrial and chemical processes, solar cell production, and food processing and packaging, where contamination-free vacuum is essential. The end-user segment distinguishes between original equipment manufacturers (OEMs) who integrate these pumps into their larger systems, and direct end-users such as hospitals, research institutions, and industrial facilities, reflecting varied purchasing patterns and technical specifications.

- By Type:

- Fixed Speed Dry Scroll Vacuum Pumps

- Variable Speed Dry Scroll Vacuum Pumps

- By Application:

- Semiconductor Manufacturing

- Analytical & R&D

- Pharmaceutical & Biotechnology

- Industrial & Chemical

- Solar

- Food Processing & Packaging

- Others (e.g., HVAC, Aerospace)

- By End-User:

- OEM (Original Equipment Manufacturers)

- End-User Industries (e.g., Hospitals, Research Institutes, Industrial Facilities)

- By Pumping Speed:

- Small (below 100 L/min)

- Medium (100-500 L/min)

- Large (above 500 L/min)

Value Chain Analysis For Dry Scroll Vacuum Pumps Market

The value chain for the Dry Scroll Vacuum Pumps market begins with upstream analysis, focusing on the sourcing and supply of critical raw materials and components. This segment involves suppliers of high-grade metals like aluminum and stainless steel for pump bodies, specialized ceramics and polymers for scroll tips and seals, and precision components such as motors, bearings, and electronic controls. The quality and availability of these materials directly impact the performance, durability, and cost-effectiveness of the final product. Strong relationships with reliable suppliers are crucial for maintaining consistent production quality and managing costs effectively within this complex supply chain.

Moving downstream, the value chain encompasses the manufacturing, assembly, and testing of the dry scroll vacuum pumps. This stage involves sophisticated engineering processes, precision machining, and rigorous quality control to ensure the pumps meet stringent performance and reliability standards. Post-manufacturing, the products enter the distribution channels, which are vital for reaching the diverse global customer base. These channels can be broadly categorized into direct and indirect methods. Direct distribution typically involves manufacturers selling directly to large industrial clients, major OEMs, or government research institutions, allowing for close customer relationships and tailored solutions.

Indirect distribution relies on a network of distributors, resellers, and system integrators who facilitate market penetration, especially into smaller businesses, regional markets, and specific niche applications. These partners often provide additional value-added services such as local technical support, installation, and maintenance, extending the manufacturer's reach and expertise. The effectiveness of the distribution network, whether direct or indirect, is paramount for market coverage, customer service, and overall market share in the highly competitive dry scroll vacuum pumps industry. Efficient logistics and robust after-sales support further strengthen this downstream segment.

Dry Scroll Vacuum Pumps Market Potential Customers

The potential customers for dry scroll vacuum pumps are diverse and span across various high-technology and industrial sectors, all united by a critical need for clean, reliable, and efficient vacuum generation. A primary segment includes semiconductor fabrication plants, where these pumps are indispensable for numerous processes such as atomic layer deposition (ALD), chemical vapor deposition (CVD), etching, and ion implantation. The demand for ultra-clean vacuum in chip manufacturing ensures a continuous and growing customer base in this sector, particularly with the global expansion of semiconductor production capabilities and the increasing complexity of chip designs requiring even finer process control.

Another significant customer base lies within the scientific research and development community, encompassing university laboratories, national research institutions, and corporate R&D centers. These entities utilize dry scroll pumps for analytical instruments like mass spectrometers, electron microscopes, and surface analysis equipment, as well as for general laboratory vacuum applications. The pharmaceutical and biotechnology industries also represent key end-users, where the pumps are critical for lyophilization (freeze-drying), sterile packaging, and various bioprocessing applications, ensuring product purity and preventing contamination in sensitive drug manufacturing and research environments.

Beyond these core sectors, potential customers include manufacturers in the solar panel industry for thin-film deposition, medical device manufacturers requiring sterile environments for production and packaging, and companies in the food processing and packaging sector for modified atmosphere packaging (MAP) and dehydration. The industrial and chemical processing sectors also deploy these pumps for applications where oil-free vacuum is preferred to prevent contamination or comply with environmental regulations. Ultimately, any industry prioritizing cleanliness, reliability, energy efficiency, and low maintenance in its vacuum processes stands as a potential buyer for dry scroll vacuum pumps.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.38 Billion |

| Market Forecast in 2033 | USD 2.36 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Edwards Vacuum (Atlas Copco), Agilent Technologies, Pfeiffer Vacuum, Busch Vacuum Solutions, ULVAC, Leybold (Atlas Copco), Osaka Vacuum, Ebara Corporation, Shimadzu Corporation, Kashiyama Industries, Gardner Denver (Ingersoll Rand), Anest Iwata, CPI (Compressor Products International), Shanghai Vacuum Pump Mfg. Co., Ltd., Vacuum Technology Inc., Hitachi High-Tech, Terra Universal, Beijing Beiyizhen Vacuum Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dry Scroll Vacuum Pumps Market Key Technology Landscape

The technological landscape of the Dry Scroll Vacuum Pumps market is continuously evolving, driven by the demand for enhanced performance, greater efficiency, and extended operational lifespans. Central to this evolution are advancements in scroll geometry and material science. Manufacturers are investing significantly in optimizing scroll profiles to improve pumping speed, ultimate vacuum levels, and volumetric efficiency, while simultaneously reducing noise and vibration. The development of new, highly durable materials for scroll tips and seals, such as advanced composites and ceramics, is crucial for improving resistance to wear, chemical attack, and temperature variations, thereby extending maintenance intervals and operating reliability in demanding applications.

Another pivotal technological trend is the widespread adoption of variable speed drive (VSD) technology. VSD-equipped dry scroll pumps can precisely match their pumping speed to the specific process requirements, leading to substantial energy savings compared to fixed-speed pumps. This not only reduces operational costs but also minimizes wear on internal components, contributing to a longer service life. Furthermore, VSD technology enables quieter operation and greater flexibility in handling varying gas loads, making these pumps highly adaptable to dynamic industrial and research environments. The integration of intelligent control systems with VSDs allows for automated optimization and remote monitoring capabilities, enhancing their appeal.

The rise of Industry 4.0 and the Internet of Things (IoT) is also profoundly shaping the technology landscape. Modern dry scroll vacuum pumps are increasingly incorporating integrated sensor technology for real-time monitoring of critical parameters such as temperature, pressure, current, and vibration. This data is often transmitted wirelessly to central control systems or cloud platforms, enabling predictive maintenance, remote diagnostics, and performance analytics. Such connectivity allows operators to anticipate potential failures, schedule maintenance proactively, and optimize pump operation for peak efficiency, ultimately reducing downtime and enhancing overall system reliability. Noise reduction technologies, improved bearing designs, and advanced motor controls are also key areas of ongoing innovation, aiming to deliver quieter, more compact, and even more efficient pump solutions.

Regional Highlights

- North America: A mature market characterized by robust R&D activities, strong demand from the pharmaceutical, biotechnology, aerospace, and advanced manufacturing sectors. The U.S. and Canada lead in adopting cutting-edge vacuum technologies, driven by stringent quality standards and substantial investment in scientific research.

- Europe: A significant market with a strong presence in pharmaceuticals, automotive R&D, and environmental applications. Germany, France, and the UK are key contributors, focusing on energy efficiency, precision engineering, and adherence to strict environmental regulations, fostering innovation in pump design and integration.

- Asia Pacific (APAC): The largest and fastest-growing market, primarily fueled by the booming semiconductor, electronics, and solar industries in countries like China, Taiwan, South Korea, and Japan. Massive investments in new fabrication facilities and continuous industrial expansion are driving unprecedented demand for dry scroll vacuum pumps.

- Latin America: An emerging market experiencing gradual industrialization and increasing investment in research and healthcare infrastructure. Brazil and Mexico are key markets, showing growing adoption of dry scroll pumps in pharmaceuticals, food processing, and general industrial applications.

- Middle East and Africa (MEA): A nascent but growing market, particularly in sectors such as oil and gas research, petrochemicals, and nascent manufacturing industries. Expanding industrialization efforts and diversification away from oil economies are slowly driving the demand for advanced vacuum solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dry Scroll Vacuum Pumps Market.- Edwards Vacuum (Atlas Copco)

- Agilent Technologies

- Pfeiffer Vacuum

- Busch Vacuum Solutions

- ULVAC

- Leybold (Atlas Copco)

- Osaka Vacuum

- Ebara Corporation

- Shimadzu Corporation

- Kashiyama Industries

- Gardner Denver (Ingersoll Rand)

- Anest Iwata

- CPI (Compressor Products International)

- Shanghai Vacuum Pump Mfg. Co., Ltd.

- Vacuum Technology Inc.

- Hitachi High-Tech

- Terra Universal

- Beijing Beiyizhen Vacuum Technology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Dry Scroll Vacuum Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of dry scroll vacuum pumps?

Dry scroll vacuum pumps offer numerous benefits, including oil-free operation, ensuring a contamination-free vacuum environment crucial for sensitive processes. They are also known for their quiet operation, low vibration, energy efficiency, and minimal maintenance requirements, leading to reduced operational costs and a smaller environmental footprint compared to traditional oil-sealed pumps.

Which industries are the largest consumers of dry scroll vacuum pumps?

The semiconductor manufacturing industry is the largest consumer due to its critical need for ultra-clean vacuum processes in chip production. Other significant consumers include analytical and R&D laboratories, pharmaceutical and biotechnology companies for sterile applications, and industries involved in solar panel manufacturing, medical devices, and food packaging.

How do dry scroll pumps compare to other vacuum pump technologies?

Dry scroll pumps excel in applications requiring clean, oil-free vacuum, often providing a cost-effective and energy-efficient alternative to oil-sealed rotary vane pumps without the risk of oil backstreaming. While they typically don't achieve the ultra-high vacuum levels of turbomolecular or cryopumps, they are highly suitable for rough to medium vacuum applications, offering a balance of performance, cleanliness, and operational simplicity.

What role does energy efficiency play in the dry scroll vacuum pump market?

Energy efficiency is a major driving factor. Modern dry scroll pumps, especially those with variable speed drive (VSD) technology, can significantly reduce energy consumption by adjusting pumping speed to meet demand. This not only lowers operating costs for end-users but also aligns with global sustainability goals and environmental regulations, making them an attractive choice for industries seeking to minimize their carbon footprint.

What maintenance is typically required for dry scroll vacuum pumps?

Dry scroll vacuum pumps are celebrated for their low maintenance needs due to their oil-free design. Routine maintenance primarily involves periodic replacement of tip seals, typically after several thousand hours of operation, depending on the application and operating conditions. Advanced models often feature predictive maintenance capabilities through integrated sensors, signaling when service is due, further simplifying upkeep.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager