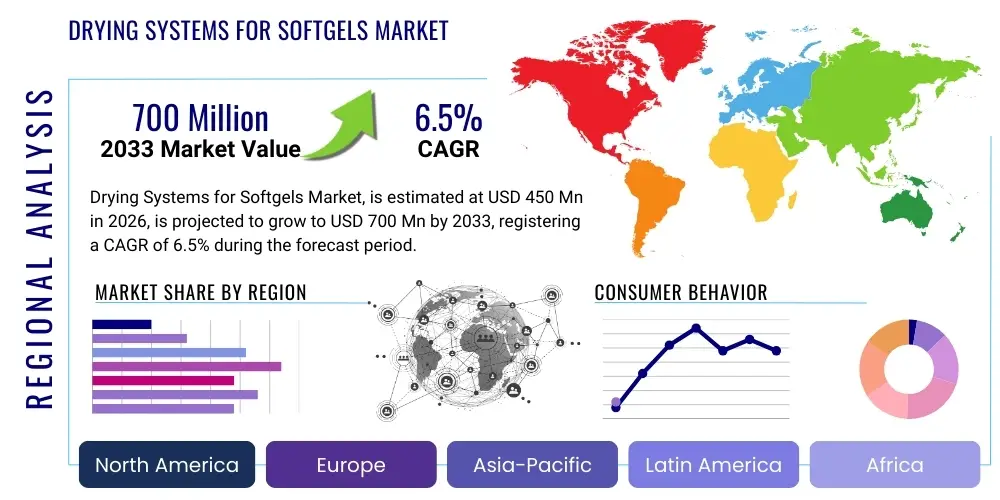

Drying Systems for Softgels Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432159 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Drying Systems for Softgels Market Size

The Drying Systems for Softgels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033. This growth trajectory is significantly influenced by the escalating demand for softgel capsules across the pharmaceutical and nutraceutical sectors, coupled with stringent regulatory requirements that necessitate precise, controlled, and validated drying processes to ensure product stability and efficacy. The inherent need for rapid and consistent moisture reduction in softgel shells (composed primarily of gelatin) drives the adoption of advanced drying technologies such as automated tumble drying systems and sophisticated dehumidification units, which are crucial for achieving optimal hardness and disintegration profiles.

The market valuation reflects the high capital expenditure required for installing technologically advanced drying infrastructure. Key factors contributing to the financial scope include the integration of high-efficiency particulate air (HEPA) filtration systems, sophisticated humidity and temperature sensors, and programmable logic controllers (PLCs) for process automation. Furthermore, the expansion of manufacturing capabilities in emerging economies, particularly in Asia Pacific, where softgel production is scaling rapidly to cater to growing local healthcare and supplement consumption, substantially impacts the market size. Manufacturers are prioritizing energy-efficient and faster drying solutions to reduce operational costs and increase throughput, thereby investing in modern systems that justify the increasing market value.

Drying Systems for Softgels Market introduction

The Drying Systems for Softgels Market encompasses specialized equipment and integrated solutions designed to remove excess moisture from the gelatin shells of newly encapsulated softgel capsules. This crucial post-encapsulation stage is vital for achieving the desired firmness, stability, and shelf life of the final product, preventing phenomena such as stickiness, leakage, or microbial growth. These systems employ controlled environment technologies, including specific combinations of temperature, relative humidity, and airflow, tailored to the formulation's characteristics. Major applications span the production of prescription drugs, over-the-counter medications, dietary supplements (vitamins, minerals, omega-3 fatty acids), and specialized cosmetic formulations, positioning these systems as indispensable components in modern drug and nutraceutical manufacturing lines.

The primary benefit derived from advanced drying systems is enhanced product quality assurance and process efficiency. By ensuring precise moisture content control, manufacturers minimize batch rejection rates and comply strictly with Good Manufacturing Practices (GMP). Driving factors include the overall expansion of the global nutraceutical industry, increasing consumer preference for easy-to-swallow softgel dosages over traditional tablets, and the continuous innovation in pharmaceutical formulation, demanding more complex and sensitive drying parameters. The shift towards continuous manufacturing processes also mandates the integration of highly responsive and automated drying technologies, pushing market players toward developing in-line solutions that reduce manual handling and processing time.

Drying Systems for Softgels Market Executive Summary

The Drying Systems for Softgels Market is characterized by robust growth driven by high demand from the rapidly expanding nutraceutical sector and continuous technological advancements aimed at improving process efficiency and compliance. Business trends emphasize automation and the adoption of energy-efficient dehumidifying technologies, moving away from conventional drying room setups toward integrated, controlled environments. Leading vendors are focusing on developing modular systems that offer scalability and flexibility, allowing producers to handle diverse batch sizes and product types with minimal changeover time. Strategic partnerships between equipment manufacturers and contract manufacturing organizations (CMOs) are becoming prevalent, facilitating the implementation of cutting-edge drying solutions globally and driving significant investment in smart monitoring and validation capabilities.

Regionally, North America and Europe hold substantial market shares due to stringent quality standards and the presence of major pharmaceutical and dietary supplement producers, fostering early adoption of high-end, validated drying machinery. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth, propelled by rapidly increasing healthcare expenditure, rising awareness regarding preventive supplements, and significant investments in local pharmaceutical manufacturing infrastructure, particularly in countries like China and India. Segment trends indicate a strong preference for automated tumble dryers integrated with sophisticated dehumidification units, as these systems offer the best balance between high throughput and precise environmental control, crucial for maintaining the integrity of sensitive active pharmaceutical ingredients (APIs) and nutritional compounds encapsulated in the softgel matrix.

AI Impact Analysis on Drying Systems for Softgels Market

User queries regarding AI's influence in the softgel drying domain primarily center on predictive maintenance, real-time quality control, and process optimization. Users frequently ask if AI can reduce drying cycle times without compromising product stability, whether machine learning models can accurately predict end-point moisture content based on initial encapsulation parameters, and how AI integration affects GMP validation processes. The prevailing themes indicate high expectations for AI to solve historical pain points associated with variability in drying times due to ambient conditions and batch inconsistencies. There is also significant interest in using deep learning models to correlate environmental data (temperature, humidity, airflow) with product parameters (shell hardness, moisture content, disintegration time) to achieve self-adjusting drying cycles, thereby minimizing energy consumption and maximizing throughput predictability, ensuring the systems operate within optimal efficiency envelopes and reducing human intervention.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast equipment failures and schedule preventive maintenance, minimizing unexpected downtime and maximizing operational uptime.

- Real-time Quality Control (RTQC): Implementing machine vision and deep learning algorithms to monitor softgel appearance and movement within the drying system, instantly detecting defects or inconsistencies related to moisture distribution.

- Optimized Process Parameters: Employing machine learning models to dynamically adjust temperature, humidity, and airflow settings based on current batch metrics and environmental conditions, leading to faster, more consistent drying cycles.

- Energy Consumption Reduction: AI algorithms analyze historical energy use patterns and process efficiency to recommend or implement settings that minimize power usage during off-peak demand periods or when moisture extraction requirements are low.

- Enhanced Regulatory Compliance: AI-powered data logging and anomaly detection systems provide highly granular, immutable records of all environmental and process variables, streamlining audit trails and validation documentation for regulatory submissions.

- Digital Twin Simulation: Creating virtual models of the drying system to simulate various operational scenarios and test new product formulations or batch sizes without disrupting physical production lines.

DRO & Impact Forces Of Drying Systems for Softgels Market

The market dynamics are governed by critical Drivers, Restraints, and Opportunities (DRO) that shape investment and technological evolution. Key Drivers include the robust expansion of the nutraceutical sector globally, coupled with increasing consumer preference for softgel dosage forms due to superior bioavailability and ease of ingestion. Restraints primarily revolve around the high initial capital investment required for automated, GMP-compliant drying machinery and the significant energy consumption associated with maintaining tightly controlled dehumidified environments. Opportunities lie in the development of highly sustainable and energy-efficient drying technologies, such as advanced heat pump dehumidifiers and vacuum drying methods, and the expanding market reach into emerging economies, providing fertile ground for new installations and upgrades.

The Impact Forces, categorized by Porter's Five Forces, indicate a moderate to high intensity of competitive rivalry due to the presence of both large multinational equipment manufacturers and specialized niche players, all vying for technological supremacy and market share. Supplier bargaining power is moderate, as the components (sensors, dehumidifiers, PLCs) are sourced from a diverse industrial base, though specialized softgel handling components are proprietary. Buyer bargaining power is significant, particularly from large CMOs and pharmaceutical giants who demand high performance, validation capabilities, and favorable long-term service contracts. The threat of substitutes is low, as specific softgel drying requirements cannot be met by generic industrial dryers, while the threat of new entrants is moderate, requiring substantial R&D investment and regulatory expertise.

Segmentation Analysis

The Drying Systems for Softgels Market is comprehensively segmented based on the type of technology used, the specific application industry, the capacity of the system, and the stage of the drying process. Technology segmentation highlights the prevalence of automated tumble drying systems, favored for their high throughput in initial drying phases, alongside sophisticated dehumidifying drying systems that ensure precise moisture removal in the final stages. Application segmentation showcases the pharmaceutical industry as the dominant consumer, driven by stringent quality requirements, closely followed by the high-volume nutraceutical sector. Understanding these segments is crucial for manufacturers to tailor their product offerings and marketing strategies to meet the specific throughput, validation, and footprint requirements of various end-users across the global landscape.

- By Type:

- Tumble Dryers (Automated Baskets)

- Tray Dryers (Static Racks)

- Dehumidifying Dryers (Controlled Climate Rooms/Tunnels)

- Fluidized Bed Dryers (Niche/Advanced Applications)

- Vacuum Drying Systems (Specialized)

- By Application:

- Pharmaceutical Industry (Prescription Drugs, OTC)

- Nutraceutical Industry (Vitamins, Supplements, Herbals)

- Cosmetic Industry (Specialty Oils, Bath Products)

- Food Processing Industry (Limited Applications)

- By Capacity:

- Low Capacity Systems (R&D, Small Batch Production)

- Medium Capacity Systems (Mid-Sized CMOs)

- High Capacity Systems (Large Pharma and Nutraceutical Manufacturers)

- By Process Stage:

- Pre-Drying (Initial moisture reduction, often using tumble dryers)

- Final Drying/Curing (Achieving required hardness and stability, often using dehumidifying tunnels)

Value Chain Analysis For Drying Systems for Softgels Market

The Value Chain for the Drying Systems for Softgels Market begins with upstream analysis, focusing on the sourcing of key components and raw materials such as specialized stainless steel alloys (for hygienic construction), advanced sensors (humidity, temperature), high-efficiency compressors, and programmable logic controllers (PLCs). Key suppliers include specialized HVAC manufacturers, electronics firms, and automation software developers. Midstream activities involve the design, manufacturing, assembly, and rigorous testing of the complex drying machinery, often requiring specialized engineering expertise in thermodynamics and controlled environment technology. This stage is dominated by established equipment manufacturers who ensure compliance with GMP and other international quality standards, focusing heavily on modular design and system validation capabilities.

Downstream analysis involves the distribution channels, installation, commissioning, and post-sales service. Direct distribution channels are prevalent for large, customized, and complex systems, where equipment manufacturers engage directly with major pharmaceutical and nutraceutical clients to provide bespoke solutions, validation protocols (IQ, OQ, PQ), and operator training. Indirect distribution involves leveraging regional distributors or agents, particularly in smaller or emerging markets, who handle sales, logistics, and localized support. Post-sales service, including calibration, maintenance, and software updates, constitutes a significant ongoing revenue stream and competitive differentiator, ensuring the long-term reliability and performance of these critical systems within the end-user's highly controlled manufacturing environment.

Drying Systems for Softgels Market Potential Customers

Potential customers for Drying Systems for Softgels are primarily entities engaged in the large-scale production, formulation, and packaging of softgel dosage forms. The most significant segment comprises integrated pharmaceutical companies that manufacture both branded and generic prescription drugs requiring precise moisture control for API stability. Contract Manufacturing Organizations (CMOs) represent another pivotal customer group; these organizations often require versatile drying systems capable of handling multiple client formulations and batch sizes, necessitating flexibility and rapid changeover capabilities. Furthermore, major nutraceutical corporations, responsible for the vast output of vitamins, dietary supplements, and health oils, are consistently upgrading their drying infrastructure to manage increased production volumes and maintain competitive cost structures, ensuring their final products meet consumer expectations for quality and dissolution properties.

Additional high-potential customer bases include specialized veterinary medicine producers, who use softgels for animal health products, and advanced cosmetic and wellness companies that encapsulate high-value ingredients like specialized botanical extracts or essential oils. These buyers prioritize systems offering highly inert environments to prevent degradation of sensitive materials. Investment decisions are heavily influenced by the total cost of ownership (TCO), including energy efficiency and regulatory compliance features. Customers frequently seek systems that offer seamless integration with existing encapsulation machines and automated handling systems, minimizing manual intervention and maximizing hygienic operation throughout the entire manufacturing flow, thereby making highly automated solutions particularly attractive.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Catalent, Capsugel (Lonza), Aenova Group, Thermo Fisher Scientific, Freund-Vector, Shionogi Qualicaps, Technophar Equipment, Changsung Corp, SKAN AG, GEA Group, Glatt GmbH, Bosch Packaging Technology, Zhejiang Guangda Capsule, ACG Worldwide, MG America |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Drying Systems for Softgels Market Key Technology Landscape

The technology landscape of the Drying Systems for Softgels market is marked by a strong emphasis on controlled environmental parameters and automation to ensure product consistency and stability. Traditional tray drying methods, while low-cost, are increasingly being replaced by sophisticated automated tumble drying systems. These modern systems feature perforated stainless steel drums that rotate gently, exposing the softgels uniformly to conditioned air flow during the initial moisture reduction phase (pre-drying). Key technological advancements include the integration of in-line softgel transfer and conveying systems, minimizing manual handling and reducing the risk of cross-contamination or damage to the delicate, wet capsules immediately post-encapsulation. The primary challenge remains achieving rapid moisture removal without inducing heat damage or affecting the physical integrity of the gelatin shell, requiring highly precise control over air temperature and humidity levels.

Dehumidification technology forms the backbone of the final drying or curing stage. The most critical component is the industrial dehumidifier, often employing desiccant wheel technology or advanced refrigeration coils, which effectively lowers the relative humidity of the circulating air to levels sometimes below 20% RH. This ultra-low humidity environment accelerates the drying process significantly and ensures the gelatin shell achieves the required hardness and residual moisture content (typically 6-9%). Innovations focus on developing energy-efficient dehumidification units utilizing heat recovery and variable frequency drives (VFDs) to modulate compressor speed and airflow based on real-time feedback from humidity sensors, thereby optimizing electricity consumption while maintaining tight control. Furthermore, sophisticated monitoring software based on SCADA (Supervisory Control and Data Acquisition) systems provides comprehensive data logging and remote diagnostics capabilities, essential for GMP compliance and efficient troubleshooting in highly regulated environments.

A growing niche is the application of vacuum drying techniques, specifically designed for highly temperature-sensitive or volatile liquid fills. Vacuum drying allows moisture to be removed at significantly lower temperatures by reducing the ambient pressure, thus protecting the active ingredients from thermal degradation. Although carrying a higher capital cost, these systems are gaining traction in specialized markets such as biologics and certain nutritional supplements where high potency ingredients require delicate processing. The future of the technology landscape is geared towards seamless integration: connecting encapsulation machines, washing units, and drying systems into a unified, digitally controlled line, minimizing product exposure, maximizing throughput, and facilitating continuous processing paradigms currently being adopted across the pharmaceutical manufacturing landscape worldwide.

Regional Highlights

- North America: This region dominates the market due to the robust presence of leading pharmaceutical and nutraceutical corporations, particularly in the United States. High regulatory standards imposed by bodies like the FDA necessitate the use of validated, high-precision drying equipment, driving investment in technologically advanced, automated systems. The region is a pioneer in the adoption of AI-enabled predictive maintenance and smart manufacturing practices for softgel production lines.

- Europe: Europe represents a mature market characterized by stringent GMP requirements and strong demand from generics and specialized supplement manufacturers, especially in Germany, Switzerland, and the UK. Focus is placed on sustainability and energy efficiency, spurring the demand for advanced heat pump-based dehumidification systems and low-energy consumption drying tunnels.

- Asia Pacific (APAC): Expected to register the highest CAGR, APAC growth is fueled by massive capacity expansion in key manufacturing hubs like China, India, and South Korea, aiming to satisfy rapidly growing domestic demand for cost-effective supplements and pharmaceuticals. Investment is concentrated on scalable, medium-to-high capacity automated drying solutions, often purchased by large Contract Manufacturing Organizations (CMOs) that serve both local and international markets.

- Latin America (LATAM): Growth in LATAM is steady, driven primarily by localized pharmaceutical production expansion and increasing investment in establishing modern manufacturing facilities compliant with international standards, particularly in Brazil and Mexico. The market often seeks solutions that balance cost-effectiveness with foundational automation features.

- Middle East and Africa (MEA): This region is emerging, with growth linked to government initiatives aimed at boosting local drug manufacturing capabilities and reducing reliance on imports. Investment is targeted towards establishing basic to moderately automated softgel manufacturing lines, prioritizing reliability and ease of maintenance in challenging climatic conditions that often require robust dehumidification capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Drying Systems for Softgels Market.- Catalent Inc. (A major softgel manufacturer and technology provider)

- Capsugel (Lonza) (Global leader known for integrated drug delivery solutions)

- Aenova Group (Leading CMO utilizing extensive drying infrastructure)

- Thermo Fisher Scientific (Provides comprehensive laboratory and production equipment)

- Freund-Vector Corporation (Specializes in fluid bed and coating technologies applicable to drying)

- Shionogi Qualicaps (Focused on capsule and equipment solutions)

- Technophar Equipment & Services Ltd. (Specialized in softgel encapsulation and auxiliary equipment)

- Changsung Corp. (Prominent Asian supplier of softgel manufacturing equipment)

- SKAN AG (Expert in cleanroom and process isolator technologies, relevant for controlled drying environments)

- GEA Group (Offers wide range of pharmaceutical processing technology)

- Glatt GmbH (Key player in pharmaceutical process technology, including drying and granulation)

- Bosch Packaging Technology (Provides automated packaging and process solutions)

- Zhejiang Guangda Capsule Co., Ltd. (Supplier of encapsulation and complementary machinery)

- ACG Worldwide (Integrated solutions provider for pharmaceutical manufacturing)

- MG America (Offers packaging and processing equipment for the pharmaceutical industry)

- Klimaoprema d.d. (Specialist in cleanroom and environmental control systems)

- PneumaticScaleAngelus (Focuses on filling and packaging solutions often integrated with drying)

- Fette Compacting GmbH (Though known for tablet presses, related drying technology expertise is applicable)

- Sartorius AG (Focuses on bioprocess solutions including monitoring technologies)

- Telstar (Provides high-technology solutions for controlled atmosphere environments)

Frequently Asked Questions

Analyze common user questions about the Drying Systems for Softgels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of drying systems in softgel manufacturing?

The primary function is to remove excess moisture from the gelatin shell immediately after encapsulation. This process, known as curing or drying, is critical for achieving the requisite shell hardness, ensuring capsule stability, preventing leakage or sticking, and optimizing the product’s shelf life and disintegration profile according to regulatory standards.

Which drying technology offers the best throughput for high-volume softgel production?

Automated tumble drying systems, often utilized for the initial, high-volume moisture removal (pre-drying), combined with large, continuous dehumidifying drying tunnels or rooms for the final curing stage, provide the highest throughput and efficiency for modern, high-capacity softgel manufacturing lines.

How do regulatory standards influence the selection of softgel drying equipment?

Regulatory bodies like the FDA and EMA mandate strict adherence to Good Manufacturing Practices (GMP). This requires drying equipment to offer precise, validated control over temperature, humidity, and airflow, along with comprehensive data logging capabilities for batch consistency and audit trail generation (IQ, OQ, PQ documentation).

What role does dehumidification play in the softgel drying process?

Dehumidification is essential for creating the ultra-low relative humidity environment necessary for efficient and complete moisture removal from the gelatin shell. Maintaining RH levels typically between 20% and 30% prevents mold growth and ensures the softgel achieves the required final moisture content (6-9%) for optimal stability and integrity.

What is the future trend concerning automation and sustainability in softgel drying?

Future trends focus on integrating AI and machine learning for predictive optimization of drying cycles, minimizing energy consumption, and reducing variability. Furthermore, there is a strong shift towards highly energy-efficient technologies, such as advanced desiccant dehumidifiers and vacuum drying, to reduce the operational environmental footprint and lower utility costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager