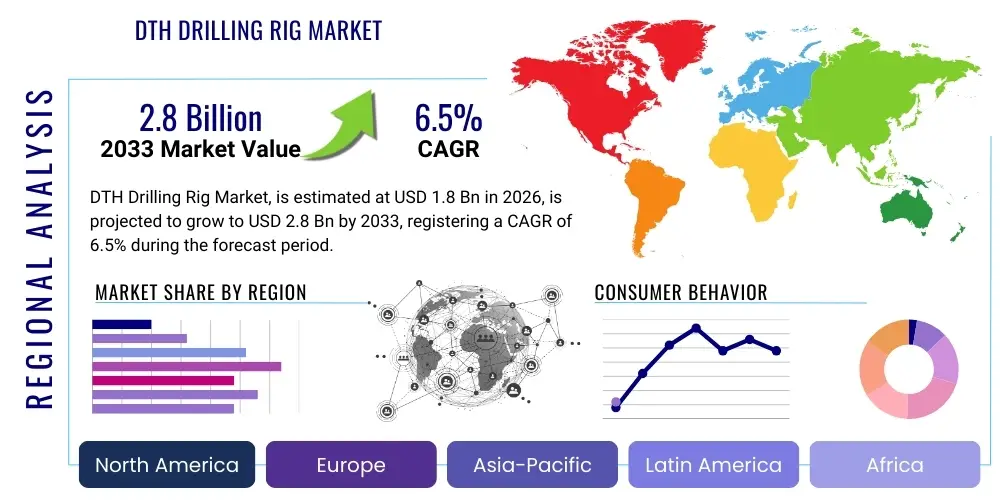

DTH Drilling Rig Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437469 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

DTH Drilling Rig Market Size

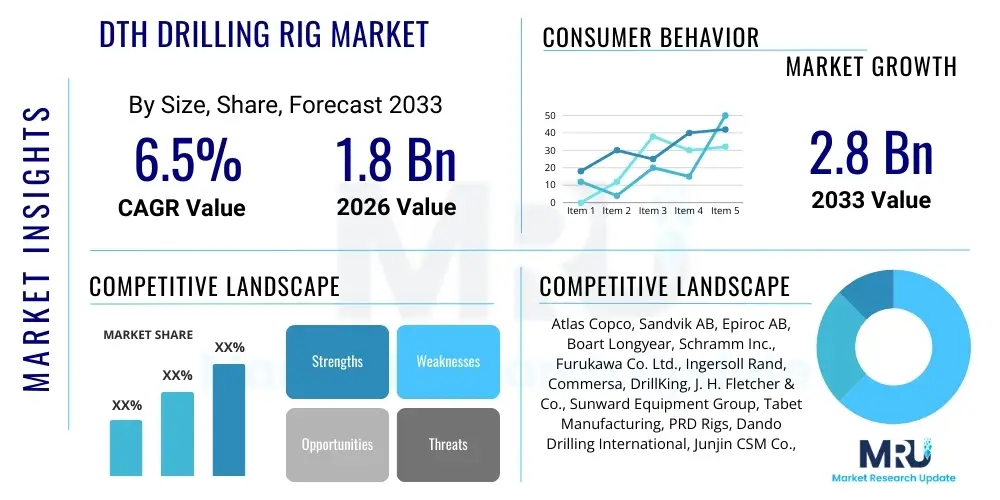

The DTH Drilling Rig Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 2.8 Billion by the end of the forecast period in 2033.

DTH Drilling Rig Market introduction

The Down-the-Hole (DTH) drilling rig market encompasses highly specialized machinery utilized for creating blast holes, exploration holes, and foundation holes across various geological formations, particularly those involving hard rock. DTH drilling technology is distinguished by the placement of the percussion mechanism directly behind the drill bit, significantly enhancing energy transfer efficiency and resulting in superior penetration rates and straightness, especially in deep holes. These rigs are crucial components in core heavy industries, including mining, quarrying, construction, and oil and gas exploration. The operational efficiency and reliability of DTH rigs are paramount for maintaining productivity schedules in large-scale infrastructure and resource extraction projects, positioning them as indispensable assets globally.

Major applications for DTH drilling rigs span infrastructure development, particularly road building, dam construction, and tunneling, where precise and rapid rock penetration is essential. In the mining sector, DTH rigs are predominantly used for production drilling to facilitate blasting operations, which is the primary step in mineral extraction. The core benefits derived from employing DTH technology include reduced energy consumption compared to conventional rotary drilling in hard rock, less deviation in boreholes, and high operational longevity of drilling components under challenging conditions. The rigs are available in various configurations, including crawler-mounted, truck-mounted, and skid-mounted versions, offering versatility tailored to specific site requirements and geological characteristics.

The market is currently being driven by several macro-economic and technological factors. Rapid urbanization and subsequent massive infrastructure investments across emerging economies, particularly in the Asia Pacific region, necessitate extensive quarrying and construction activities, directly fueling demand for high-performance DTH rigs. Furthermore, the sustained global demand for critical minerals and metals, requiring deeper and more challenging mining operations, mandates the use of highly automated and powerful drilling equipment. Technological advancements focusing on automation, telematics, and predictive maintenance are improving rig utilization rates and operational safety, further solidifying the market's trajectory towards consistent growth over the forecast period.

DTH Drilling Rig Market Executive Summary

The DTH Drilling Rig Market is experiencing robust expansion, primarily driven by accelerated global mining activity and significant governmental investment in large-scale infrastructure projects. Business trends indicate a strong shift towards the adoption of automated and semi-automated drilling systems to mitigate labor risks and enhance drilling precision, thereby reducing operational costs and improving overall site efficiency. Key manufacturers are focusing on integrating advanced sensor technologies and connectivity solutions to offer comprehensive fleet management and preventative maintenance services. This focus on digitalization is redefining competitive landscapes, favoring companies that can provide integrated, high-technology drilling solutions rather than just hardware. Furthermore, sustainability requirements are influencing design, pushing manufacturers towards developing energy-efficient rigs compliant with stringent global emission standards, particularly in the European and North American markets.

Regional trends reveal the Asia Pacific region dominating market share, fueled by unprecedented growth in construction activities in countries such as China, India, and Southeast Asian nations, coupled with massive raw material extraction demands. North America and Europe, while mature markets, emphasize replacement cycles and technological upgrades, focusing on emission reduction standards and adopting electric or hybrid drilling rigs to meet environmental mandates. Latin America and the Middle East and Africa (MEA) are also exhibiting high growth potential, driven by significant untapped mineral resources and burgeoning oil and gas exploration activities, which require robust and reliable DTH drilling solutions capable of operating in diverse and often harsh environmental conditions.

Segmentation trends highlight the crawler-mounted segment retaining the largest market share due to its superior mobility and stability on uneven terrains typical of mine sites and quarries. However, the hydraulic DTH rig segment is projected to witness the fastest growth, favored for its enhanced power-to-weight ratio and superior control mechanisms compared to pneumatic alternatives. In terms of application, the mining and quarrying sector remains the primary consumer, although civil construction and water well drilling applications are expected to accelerate significantly, especially with increasing global efforts toward sustainable resource management and addressing water scarcity issues in arid regions. Manufacturers are increasingly tailoring rigs to meet specialized application requirements, optimizing drilling parameters for specific rock types and demanding operational depths.

AI Impact Analysis on DTH Drilling Rig Market

User queries regarding the impact of Artificial Intelligence (AI) on the DTH Drilling Rig Market frequently revolve around topics such as the feasibility of fully autonomous drilling cycles, the reliability of AI-driven predictive maintenance systems, and the implications for skilled labor requirements. Common concerns include the initial cost of integrating AI systems, data security vulnerabilities associated with connected machinery, and the practical performance of machine learning algorithms in unpredictable geological environments. Users are primarily seeking clarity on how AI can translate into measurable operational benefits, specifically reduced downtime, optimized drilling paths, and improved safety standards, driving the convergence of operational technology and information technology in drilling operations. The consensus expectation is that AI will move the industry beyond semi-automation toward true intelligent drilling, significantly enhancing Return on Investment (ROI) for asset owners.

The implementation of AI and machine learning algorithms is transforming the operation of DTH drilling rigs by providing unprecedented levels of control and optimization. AI analyzes massive datasets streaming from rig sensors—including vibration, pressure, rotation speed, and penetration rate—in real-time to adjust drilling parameters dynamically, ensuring the highest possible efficiency and minimal wear on consumables. This real-time optimization capability allows rigs to adapt instantly to changes in rock density and composition, leading to significantly higher meters drilled per shift and extended tool life. Furthermore, AI models are pivotal in ensuring optimal energy usage, especially in electric or hybrid rigs, by intelligently managing power distribution based on the immediate task demands.

Beyond operational performance, AI plays a crucial role in preventative maintenance and safety protocols. Predictive maintenance systems powered by machine learning can forecast component failure with high accuracy, often days or weeks in advance, allowing for scheduled interventions that drastically reduce unplanned downtime—a major cost factor in drilling operations. Safety is enhanced through AI-driven anomaly detection, which monitors operational behaviors to identify potential risks or deviations from safe operating limits, automatically alerting operators or initiating shut-down procedures if necessary. This shift towards data-driven decision-making represents a fundamental transformation in drilling practices, moving from reactive maintenance to proactive, highly efficient asset management.

- Real-time Drilling Optimization: AI analyzes sensor data (pressure, torque, penetration rate) to adjust parameters dynamically, maximizing drilling efficiency and speed.

- Predictive Maintenance: Machine learning algorithms analyze wear patterns and operational stress data to forecast component failure, minimizing unplanned downtime.

- Autonomous Drilling Cycles: Enables partial or full autonomy in drilling sequences, reducing human error and enhancing precision, especially in routine operations.

- Geological Data Interpretation: AI aids in rapidly processing and interpreting MWD (Measurement While Drilling) data to refine blast designs and optimize hole placement.

- Enhanced Operator Safety: Monitors operator performance and rig stability, providing early warnings for dangerous conditions or structural imbalances.

- Energy Consumption Management: Optimizes power demand in electric or hybrid rigs, ensuring efficient use of energy based on current rock interaction resistance.

DRO & Impact Forces Of DTH Drilling Rig Market

The DTH Drilling Rig market is powerfully influenced by a confluence of accelerating drivers (D), persistent restraints (R), and compelling opportunities (O). A primary driver is the escalating global demand for bulk commodities, necessitating increased exploration and production drilling in mining sectors, particularly for iron ore, copper, and gold. Concurrently, massive global infrastructure initiatives, spanning highways, railways, and renewable energy projects (wind farms, hydro dams), require extensive rock excavation and foundation drilling. These drivers are amplified by technological advancements leading to more powerful, efficient, and reliable hydraulic and pneumatic DTH rigs, which offer superior performance compared to older generation equipment, thereby stimulating fleet replacement cycles and new capital expenditure.

However, the market faces significant restraints, including the high capital expenditure required for acquiring advanced DTH drilling rigs and the inherent volatility in commodity prices, which directly impacts the investment appetite of mining and construction firms. Furthermore, the specialized nature of DTH drilling requires highly skilled labor for operation and maintenance, and a global shortage of experienced technicians poses operational challenges, particularly in remote regions. Environmental regulations, especially those restricting noise pollution and requiring stringent dust suppression and emission controls, also act as a constraint, forcing manufacturers to invest heavily in compliance and potentially increasing end-user costs for meeting standards such as Tier 4 Final or Stage V.

The market opportunities are centered on the rapid digitalization and integration of telematics and IoT within drilling equipment, offering lucrative pathways for enhanced service offerings and data monetization. The transition towards electrification and automation in drilling technology presents a significant opportunity, allowing manufacturers to capture market share by providing sustainable and future-proof solutions, especially in urban or environmentally sensitive mining operations. Geographically, untapped potential in emerging economies, particularly in Africa and South America, characterized by vast mineral wealth and developing infrastructure sectors, offers robust long-term growth prospects for DTH rig deployment, provided the macroeconomic and political stability remains conducive to large foreign investments in these regions.

The impact forces driving the market are substantial. Increasing infrastructure spending in Asia Pacific and the renewed focus on domestic resource independence in North America and Europe provide foundational demand stability. The rapid rate of technological innovation, particularly in areas like remote operation and real-time monitoring, dictates that companies must continuously invest in R&D to remain competitive, pushing less innovative firms out of the specialized segments. Socio-economic forces, such as global population growth and urbanization, ensure a sustained requirement for raw materials and constructed assets, underpinning the long-term viability of the DTH drilling market across various applications.

Segmentation Analysis

The DTH Drilling Rig Market is primarily segmented based on mounting type, mechanism, application, and geographical region. Understanding these segmentations is critical for manufacturers to tailor their product offerings and for investors to gauge market dynamics effectively. The segmentation by mounting type—crawler-mounted, truck-mounted, and skid-mounted—reflects the adaptability of the equipment to different operational terrains and mobility requirements. Crawler rigs are preferred for heavy-duty, off-road applications typical of large mines, while truck-mounted rigs offer rapid setup and transportation essential for construction and utility drilling.

The mechanism segmentation, categorized into hydraulic and pneumatic systems, reflects the core operational technology. Hydraulic rigs are increasingly favored due to their efficiency, precise control, and ability to handle larger hammer sizes and deeper drilling requirements, although pneumatic rigs remain popular in specific shallow drilling and low-cost operations. The application segments—mining and quarrying, construction, water well drilling, and oil and gas exploration—highlight the diverse end-use spectrum, with mining remaining the dominant revenue generator, necessitating robust, continuous-duty rigs.

Geographical segmentation is crucial, demonstrating distinct regional demands influenced by local geological characteristics, regulatory environments, and prevailing infrastructure development cycles. Developed markets focus on replacement and high-technology adoption, whereas developing markets prioritize volume and rugged reliability. This layered approach to segmentation helps in dissecting market nuances and identifying high-growth pockets where specialized DTH rigs, particularly those incorporating automation features, can achieve rapid adoption and market penetration.

- By Mounting Type:

- Crawler-Mounted Rigs

- Truck-Mounted Rigs

- Skid-Mounted Rigs

- By Mechanism:

- Hydraulic DTH Rigs

- Pneumatic DTH Rigs

- By Application:

- Mining and Quarrying

- Construction and Infrastructure

- Water Well Drilling

- Oil and Gas Exploration (Shallow Holes)

- By End-User:

- Contract Drillers

- Mining Companies (Integrated Operations)

- Government and Utility Agencies

- By Depth Capability:

- Shallow Depth Rigs (Up to 50 meters)

- Medium Depth Rigs (50 to 200 meters)

- Deep Hole Rigs (Above 200 meters)

Value Chain Analysis For DTH Drilling Rig Market

The value chain for the DTH Drilling Rig Market begins with the upstream activities involving the sourcing and processing of core raw materials and sophisticated components. This includes high-grade steel alloys required for the drill bits, hammers, and pipes due to the extreme stress and wear encountered during operation. Upstream suppliers also provide specialized components such as advanced hydraulic pumps, robust diesel or electric engines, and complex electronic control units. The quality and cost of these input materials significantly influence the final manufacturing cost and the overall performance lifespan of the drilling rig. Manufacturers often seek strategic alliances with material providers to ensure a stable supply of high-specification components, which is critical for maintaining product quality and meeting stringent safety standards.

The midstream stage is dominated by the manufacturing and assembly process, where leading global OEMs design, fabricate, and assemble the complex drilling rigs. This stage involves significant investment in R&D, focusing on innovation in drilling mechanics, automation systems, and fuel efficiency. Once manufactured, the downstream segment involves the distribution channel, which is typically a mix of direct sales and indirect representation through established, regional dealer networks. Direct sales are usually reserved for large, integrated mining corporations purchasing multiple high-capital units, where comprehensive after-sales service contracts are bundled. Indirect channels, through specialized distributors, are essential for reaching smaller contract drillers and diverse local construction markets, leveraging the distributor's local expertise, inventory holdings, and immediate maintenance capabilities.

The effectiveness of the downstream distribution channel, including after-sales support, maintenance, and the supply of high-wear consumables (drill bits, hammers, and rods), is a critical determinant of market success. Rigs are high-cost assets, and minimizing downtime is paramount for end-users. Consequently, manufacturers that maintain efficient global logistics networks for spare parts and offer robust, localized service support gain a significant competitive advantage. The value chain concludes with the end-users—mining firms, construction contractors, and utility companies—who utilize the rigs for their specific applications. The feedback loop from these end-users back to the OEM regarding performance and required enhancements continually drives product innovation and technical specifications in subsequent rig models, ensuring the market remains responsive to operational demands.

DTH Drilling Rig Market Potential Customers

The primary purchasers and end-users of DTH drilling rigs are diversified, yet heavily concentrated within the heavy industrial and extractive sectors. Mining companies, ranging from large, multinational operators involved in iron ore and coal extraction to mid-sized firms focused on precious metals and specialty minerals, represent the largest customer base. These entities often operate their own drilling fleets (integrated mining model) and require high-capacity, durable rigs capable of continuous operation in harsh environments, demanding advanced features like automation and precise depth control to maximize blast efficiency and subsequent yield rates. Their purchasing decisions are highly influenced by operational costs per meter drilled, total cost of ownership (TCO), and after-sales service quality, necessitating long-term vendor relationships.

The second major group comprises large contract drilling service providers. These companies specialize in offering drilling services to mining, quarrying, and construction clients, operating extensive and diverse fleets of DTH rigs. Their purchasing strategy focuses on rig versatility, ease of transport between job sites, and high utilization rates, as their profitability is directly tied to the number of meters drilled across multiple contracts. Contract drillers often favor rigs that offer easy maintenance and readily available spare parts, ensuring minimal downtime when transitioning between highly varied geological and logistical challenges presented by different customer sites. They are keen adopters of telematics and fleet management systems to optimize scheduling and asset tracking.

Other substantial potential customers include civil engineering and large construction firms involved in major infrastructure projects such as dam construction, tunneling, foundation preparation for high-rise buildings, and highway creation in mountainous regions. Furthermore, government agencies or specialized contractors involved in water resource management constitute a steady demand stream, particularly in regions facing water scarcity, necessitating reliable rigs for deep water well drilling. Oil and gas exploration companies utilize DTH rigs for shallow hole drilling applications, such as setting conductors or geotechnical investigation purposes before deep conventional drilling commences. Each customer segment demands specific rig characteristics tailored to their primary operational environment and regulatory framework.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Sandvik AB, Epiroc AB, Boart Longyear, Schramm Inc., Furukawa Co. Ltd., Ingersoll Rand, Commersa, DrillKing, J. H. Fletcher & Co., Sunward Equipment Group, Tabet Manufacturing, PRD Rigs, Dando Drilling International, Junjin CSM Co., Ltd., Deep Rock Manufacturing, Sany Group, XCMG Group, ZMJ Mining, Mincon Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

DTH Drilling Rig Market Key Technology Landscape

The technology landscape of the DTH Drilling Rig Market is rapidly evolving, driven primarily by the pursuit of higher efficiency, enhanced safety, and reduced environmental impact. Central to this evolution is the increasing sophistication of hydraulic systems, which now offer highly precise control over feed force, rotation speed, and percussion frequency, enabling operators to optimize drilling parameters based on real-time feedback regarding rock hardness. Telematics and IoT integration are foundational technologies, allowing for remote monitoring of rig performance, fuel consumption, GPS location, and key maintenance indicators. This connectivity facilitates predictive maintenance scheduling and provides fleet managers with actionable data to maximize asset utilization, moving operational management from reactive repairs to proactive, data-driven strategies.

Automation technology is another major disruptor, moving DTH rigs toward increasingly autonomous operations. Modern rigs often feature auto-collaring systems, automatic rod handling, and automated drill cycle sequences, which significantly reduce the physical labor required and eliminate common human errors, thereby improving hole quality and consistency. Advanced automation systems utilize high-precision GPS (HPGPS) and inertial navigation systems (INS) for precise hole positioning and alignment, crucial for effective blasting patterns in large mining operations. Furthermore, sophisticated drilling control algorithms continuously analyze geological conditions via measurement-while-drilling (MWD) sensors to maintain optimal penetration rates, preventing equipment damage and ensuring energy efficiency across varying rock formations, a capability impossible to achieve manually.

A crucial technological shift is the development and adoption of environmentally conscious drilling solutions, including Tier 4 Final/Stage V compliant diesel engines and, increasingly, fully electric or hybrid DTH rigs. Electric rigs offer substantial benefits in terms of noise reduction and zero direct emissions, making them ideal for urban construction sites or underground mining operations where air quality is a significant concern. Parallel advancements in drilling consumables, such as specialized DTH hammers and bits, incorporating proprietary carbide grades and innovative air cycle designs, are further enhancing drilling performance and extending the service life of down-the-hole tooling. The combination of high-tech controls, predictive capabilities, and sustainable power sources defines the competitive edge in the modern DTH drilling market, necessitating continuous investment in research and development by leading manufacturers.

Regional Highlights

The Asia Pacific (APAC) region stands as the undisputed leader in the DTH Drilling Rig Market, characterized by its immense infrastructure boom and vast mining sector. Countries like China and India are undertaking massive civil engineering projects, including metropolitan expansions, road networks, and energy facilities, all of which require significant quarrying and foundation drilling work. The high demand is driven by the sheer scale of development, supported by government initiatives focusing on urbanization and industrial growth. Furthermore, the region is a major global supplier of critical raw materials, necessitating continuous investment in mining expansion and replacement of older drilling fleet assets. Manufacturers targeting APAC often focus on rugged, high-throughput rigs combined with competitive pricing strategies to capture the high-volume demand.

North America is a technologically mature market, defined less by new infrastructure volume and more by high technological adoption and stringent regulatory compliance. Demand in this region is primarily fueled by fleet replacement cycles, driven by the desire to integrate cutting-edge automation, telematics, and advanced safety features. The focus in the US and Canada is heavily on efficiency improvement (meters drilled per hour) and environmental compliance, pushing demand toward hydraulic and electric DTH rigs that meet Tier 4 Final emission standards. The mining sector, particularly for copper, gold, and aggregate, remains strong, characterized by sophisticated operators willing to invest in premium, high-capital equipment that provides superior data reporting and operational insights.

Europe demonstrates steady demand, heavily influenced by strict environmental regulations and high labor costs, making automation and low-emission equipment highly desirable. The market is fragmented, with localized demands across quarrying, construction, and specialized tunneling projects. Scandinavian countries, in particular, lead in the adoption of electric and battery-powered DTH rigs, reflecting a strong regional commitment to decarbonization in the industrial sector. Latin America and the Middle East and Africa (MEA) are emerging as high-growth regions. Latin America is rich in copper and iron ore resources, with countries like Chile and Brazil driving demand through extensive mining activities. The MEA region, particularly driven by large-scale oil and gas infrastructure projects, mineral exploration in sub-Saharan Africa, and water well drilling initiatives, is expected to exhibit the fastest growth, although market stability can be sensitive to geopolitical and commodity price fluctuations.

- Asia Pacific (APAC): Dominates the market due to massive infrastructure investments in China and India and robust demand from the regional mining and quarrying sectors. Focus on high-volume, reliable rigs.

- North America: Characterized by high technological maturity, stringent environmental standards, and emphasis on fleet replacement with automated and telematics-enabled DTH rigs for efficiency gains.

- Europe: Driven by strict emission regulations (Stage V) and high automation adoption; strong demand for hybrid and electric DTH rigs, particularly in construction and tunneling applications.

- Latin America: High growth potential fueled by extensive resource extraction (copper, iron ore) in countries like Chile, Peru, and Brazil; sensitive to global commodity prices.

- Middle East and Africa (MEA): Expected rapid growth driven by mineral exploration in Africa, massive infrastructure projects in the Gulf Cooperation Council (GCC) states, and critical water well drilling requirements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the DTH Drilling Rig Market.- Atlas Copco

- Sandvik AB

- Epiroc AB

- Boart Longyear

- Schramm Inc.

- Furukawa Co. Ltd.

- Ingersoll Rand

- Commersa

- DrillKing

- J. H. Fletcher & Co.

- Sunward Equipment Group

- Tabet Manufacturing

- PRD Rigs

- Dando Drilling International

- Junjin CSM Co., Ltd.

- Deep Rock Manufacturing

- Sany Group

- XCMG Group

- ZMJ Mining

- Mincon Group

Frequently Asked Questions

Analyze common user questions about the DTH Drilling Rig market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between hydraulic and pneumatic DTH drilling rigs?

The primary difference lies in the power source for the hammer action. Hydraulic DTH rigs use hydraulic pressure to drive the piston, offering superior control over power delivery, efficiency, and depth capability, making them preferred for hard rock and deep holes. Pneumatic DTH rigs use compressed air, which is simpler but generally less energy-efficient and limited in very deep or high-pressure applications, though they are cost-effective for shallow drilling.

How is the adoption of automation impacting labor requirements in DTH drilling?

Automation reduces the physical demand on operators and minimizes human error, shifting the labor requirement from manual operation to supervision and advanced technical maintenance. While fewer drillers may be needed per shift for operational tasks, there is a heightened demand for highly skilled technicians and engineers proficient in managing, troubleshooting, and programming the increasingly complex integrated electronic and hydraulic systems.

Which application segment drives the highest demand in the DTH Drilling Rig Market?

The Mining and Quarrying segment generates the highest demand for DTH drilling rigs. Rigs are critical for production blast hole drilling and pre-splitting in open-pit mines and quarries extracting commodities such as iron ore, copper, coal, and aggregates. The scale and continuous nature of these operations necessitate large, highly reliable, and often automated drilling fleets.

What are the main factors restraining the growth of the DTH Drilling Rig Market?

Key market restraints include the substantial initial capital investment required for purchasing modern, technologically advanced rigs, which can be prohibitive for smaller contractors. Additionally, the market is highly sensitive to the volatility of global commodity prices (metals and minerals), which directly influences the capital expenditure budgets of large mining companies and thus affects rig purchasing decisions.

What role does telematics play in modern DTH drilling operations?

Telematics plays a vital role by providing real-time data on machine performance, operational status, location, and key maintenance indicators (like engine hours and fuel consumption). This data enables advanced fleet management, optimized scheduling, remote diagnostics, and implementation of predictive maintenance programs, drastically improving rig utilization rates and overall operational transparency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager