Dual Wave Infrared Radiation Lamps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431521 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Dual Wave Infrared Radiation Lamps Market Size

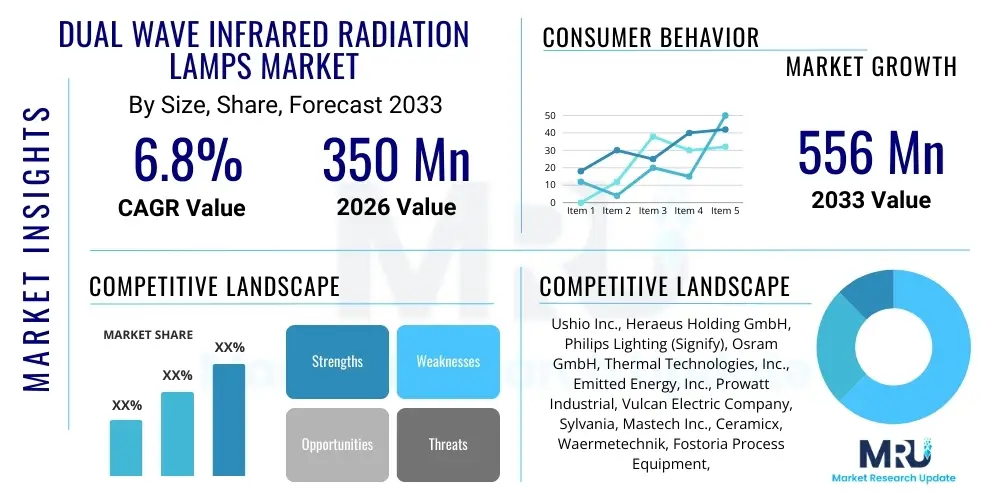

The Dual Wave Infrared Radiation Lamps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $350 million USD in 2026 and is projected to reach $556 million USD by the end of the forecast period in 2033. This substantial growth is fundamentally driven by the increasing demand for high-efficiency, precision heating solutions across industrial manufacturing sectors, notably in automotive coatings, plastics processing, and specialized semiconductor fabrication.

The market expansion is heavily correlated with the global adoption of advanced curing and drying processes that necessitate precise thermal control. Dual wave technology, which combines the benefits of both short-wave and medium-wave infrared radiation, allows for optimized energy absorption by various substrates, leading to faster processing times and superior product quality. This versatility makes dual wave lamps critical components in sophisticated production lines aiming for enhanced throughput and reduced energy consumption, thereby solidifying their position as premium heating elements.

Furthermore, regulatory pushes toward energy conservation and sustainability in manufacturing environments are accelerating the shift from conventional heating methods to highly targeted infrared systems. Dual wave lamps offer significantly better energy transfer efficiency compared to conventional convection ovens, resulting in lower operational costs and reduced carbon footprints. The continuous investment in research and development to improve emitter materials and spectral output characteristics will further underpin the robust financial outlook for this specialized market segment through 2033.

Dual Wave Infrared Radiation Lamps Market introduction

The Dual Wave Infrared Radiation Lamps Market encompasses the manufacturing, distribution, and application of specialized infrared emitters capable of generating radiation across two distinct spectral bands, typically combining short wave and medium wave infrared outputs within a single unit or system configuration. This unique capability allows manufacturers to finely tune the spectral output profile to perfectly match the absorption characteristics of specific materials (substrates), optimizing the thermal process for superior results in applications like painting, coating, curing, and thermoforming. Dual wave lamps are characterized by their high energy density, fast response times, and the ability to achieve deep penetration or surface heating as required by the application.

These sophisticated heating lamps find major applications in the automotive industry, particularly for paint drying and powder coating curing, where precise temperature ramp-up and holding times are crucial for finish quality. Other significant end-users include the printing industry for ink drying, the semiconductor sector for photoresist drying and substrate preheating, and the plastics industry for precise thermoforming and welding operations. The core benefit of employing dual wave technology lies in its efficiency and customization; by delivering the exact energy profile needed, waste is minimized, and processing speeds are maximized compared to systems relying on a single, less versatile wavelength.

The primary driving factor for market growth is the ongoing industrial shift towards lean manufacturing principles and the implementation of high-speed automation systems. Dual wave infrared lamps integrate seamlessly into automated production lines, offering instantaneous heat control necessary for rapid, repeatable cycles. Additionally, technological advancements in quartz glass durability and tungsten or carbon fiber filament design contribute to longer lamp lifecycles and improved spectral stability, making them highly attractive assets for capital-intensive industries prioritizing longevity and performance.

Dual Wave Infrared Radiation Lamps Market Executive Summary

The Dual Wave Infrared Radiation Lamps Market is poised for substantial expansion, driven by critical business trends focused on energy efficiency, automation integration, and customized material processing solutions. Key business trends include the increasing adoption of carbon fiber emitters for enhanced medium-wave output, enabling faster heat absorption by water-based coatings, and the strategic mergers and acquisitions among niche lamp manufacturers to consolidate technological expertise and expand geographic reach, particularly into emerging industrial hubs in Asia Pacific. The focus remains on developing smart heating systems where dual wave lamps are integrated with thermal sensors and AI-driven predictive maintenance platforms, ensuring optimal performance and minimizing unscheduled downtime.

Regionally, the market is spearheaded by robust industrial growth in North America and Europe, which are characterized by high levels of automation in automotive and aerospace manufacturing, demanding premium dual wave solutions for complex curing tasks. However, the Asia Pacific region, led by China and India, presents the highest growth opportunities due to rapid industrialization, burgeoning electronics manufacturing, and significant investments in modernizing infrastructure and paint shops. Regulatory environments in developed economies pushing for solvent reduction and low-VOC coatings necessitate the use of highly efficient drying technologies, favoring dual wave infrared solutions.

In terms of segment trends, the Quartz Dual Tube (QDT) segment remains dominant due to its ruggedness and high-power output capability, suitable for heavy industrial applications. The technology segment is witnessing a rapid shift towards customized spectral outputs tailored specifically for new-generation composite materials and bio-based polymers, demanding flexible dual-band tuning. Furthermore, the automotive sector continues to be the largest end-user segment, but significant growth is anticipated from the renewable energy sector, specifically for drying processes in solar panel and battery manufacturing, where precise thermal management is crucial to material integrity.

AI Impact Analysis on Dual Wave Infrared Radiation Lamps Market

Common user inquiries regarding AI in the Dual Wave Infrared Radiation Lamps Market revolve around predictive maintenance, real-time thermal optimization, and energy consumption forecasting. Users are primarily concerned with how AI can enhance the precision and efficiency of existing IR heating systems, specifically asking if AI algorithms can dynamically adjust the dual-wave output ratio in response to substrate temperature variations or environmental changes (e.g., humidity). Expectations center on AI transforming lamp operation from static, pre-programmed cycles to dynamic, responsive heating, minimizing material wastage and ensuring consistent quality across high-volume production runs. Key themes include the integration of machine learning for defect detection during curing and the use of neural networks to model optimal spectral energy absorption for complex, multi-layered coatings, ultimately leading to significant operational cost savings and prolonging lamp life through optimized usage patterns.

- AI algorithms enable predictive maintenance by analyzing current draw, temperature profiles, and cycling patterns to forecast potential lamp failure, minimizing unexpected downtime.

- Machine learning optimizes curing and drying processes by dynamically adjusting the short-wave to medium-wave radiation ratio based on real-time feedback from thermal cameras and sensors.

- Integration of AI systems reduces energy consumption by ensuring lamps operate only at the peak efficiency required for the specific substrate and stage of the manufacturing process.

- AI enhances quality control through pattern recognition, detecting subtle inconsistencies in coating dryness or curing levels that human operators might miss, improving overall yield.

- Neural networks are used in design phases to simulate the spectral absorption characteristics of new materials, accelerating the development of optimal dual wave lamp configurations.

DRO & Impact Forces Of Dual Wave Infrared Radiation Lamps Market

The Dual Wave Infrared Radiation Lamps Market is influenced by a dynamic interplay of Drivers (D), Restraints (R), and Opportunities (O), which collectively shape the competitive landscape and growth trajectory. The primary driver is the pervasive demand for high-speed, automated industrial heating processes that require instantaneous, controllable thermal energy, particularly in the automotive and electronics sectors. Coupled with this is the continuous pressure on industries to reduce energy consumption and improve environmental compliance, which favors the high efficiency and localized heating capabilities of dual wave IR systems over traditional convection heating.

However, significant restraints exist, including the high initial capital investment required for installing specialized dual wave heating systems and the associated control electronics, posing a barrier to entry for smaller manufacturers. Furthermore, the specialized nature of these lamps necessitates specific technical expertise for maintenance and spectral tuning. A major technological restraint involves the vulnerability of quartz glass envelopes to thermal shock and contamination from certain industrial environments, leading to decreased lamp lifespan if not properly managed, thus increasing operational complexity.

Opportunities abound in leveraging dual wave technology for emerging applications, notably in the production of next-generation electric vehicle (EV) batteries, where precise drying of electrode slurry is critical, and in additive manufacturing (3D printing) for post-processing and curing of complex geometries. The development of intelligent, sensor-integrated lamps that offer instantaneous remote diagnostics presents a significant opportunity for manufacturers to create value-added services, shifting the focus from product sales to comprehensive thermal solutions providers. These forces ensure that while the market faces cost sensitivity, the underlying technological advantages guarantee robust long-term demand.

Segmentation Analysis

The Dual Wave Infrared Radiation Lamps Market is systematically segmented based on construction type, heating medium, end-user industry, and geographical region to provide a comprehensive understanding of market dynamics and targeted strategic pathways. Analyzing these segments helps stakeholders understand which technology variants are driving growth and which industrial applications offer the highest returns on investment. The segmentation highlights the versatility of dual wave technology, showing its adaptation from high-power industrial coating applications to more delicate, precise operations in electronics manufacturing, ensuring the technology caters to a broad spectrum of thermal requirements globally.

Key segmentation by construction often differentiates between the materials used for the heating element and the enclosure, impacting efficiency and durability. Furthermore, application segmentation reveals that while the automotive sector remains the bedrock of demand, rapid growth in specialized industrial segments, such as aerospace composites and medical device fabrication, is diversifying the revenue streams. Geographic segmentation, focused heavily on industrialized regions, provides crucial insights into regional consumption patterns driven by distinct regulatory standards and manufacturing bases, particularly emphasizing the increasing importance of Asian manufacturing centers.

- By Construction Type:

- Quartz Dual Tube Emitters (QDT)

- Custom Hybrid Emitters

- Carbon Fiber/Tungsten Combinations

- By Heating Medium:

- Short Wave (Approx. 1.0 – 1.4 µm)

- Medium Wave (Approx. 1.8 – 3.0 µm)

- Dual Band (Simultaneous/Switched Output)

- By End-User Industry:

- Automotive (Paint Curing, Assembly)

- Plastics and Packaging (Thermoforming, Welding)

- Printing and Graphics (Ink Drying, Coating)

- Electronics and Semiconductor (Photoresist Curing, Substrate Heating)

- Food Processing and Sterilization

- Textiles and Paper

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Dual Wave Infrared Radiation Lamps Market

The value chain for the Dual Wave Infrared Radiation Lamps Market begins with the upstream procurement of highly specialized raw materials, primarily high-purity quartz glass, specialized inert gases (e.g., argon or halogen mixtures), and refractory metals like tungsten or carbon fiber for filament construction. The quality and purity of these raw inputs directly influence the lamp’s spectral efficiency, longevity, and thermal stability. Manufacturers invest heavily in proprietary coating technologies and precision winding techniques during the production phase to ensure accurate dual-band output, representing a significant source of value creation and competitive differentiation within the market.

The midstream involves the core manufacturing process, which includes precise sealing, filament installation, and quality control testing to confirm spectral specifications and power ratings. Distribution channels play a critical role; due to the technical nature of the product, both direct sales (for large OEMs and customized industrial projects) and indirect distribution through highly specialized technical distributors are utilized. Indirect channels often provide necessary installation support and after-sales service, acting as critical liaisons between the manufacturer and the diverse end-users who may lack specialized infrared heating expertise.

The downstream segment encompasses the integration of these lamps into complete thermal processing systems (ovens, tunnels, robots) by system integrators and equipment builders, followed by their deployment in end-user facilities (e.g., automotive paint shops or semiconductor fabrication plants). Aftermarket services, including replacement lamps, maintenance contracts, and periodic system recalibration, constitute a substantial revenue stream, driven by the planned obsolescence and high-usage environment typical of these products. The efficiency of the value chain is highly dependent on logistics and the ability of manufacturers to deliver precise, often custom-made, components rapidly.

Dual Wave Infrared Radiation Lamps Market Potential Customers

Potential customers for Dual Wave Infrared Radiation Lamps are primarily industrial entities requiring high-speed, non-contact heating for surface modification, drying, curing, or sterilization purposes where precise temperature profiles are non-negotiable. The largest segment of buyers comprises major automotive manufacturers (OEMs) and their Tier 1 suppliers who utilize these lamps extensively in paint booths and coating lines to accelerate the curing of modern low-VOC and waterborne paints, ensuring superior finish hardness and gloss while significantly shortening production cycle times.

Another significant customer base includes specialized electronics and semiconductor manufacturers. These buyers leverage the precise, rapid heating capabilities of dual wave lamps for essential processes such as photoresist baking, solder reflow simulation, and general substrate preheating, where contamination control and accurate thermal delivery are paramount to product yield. Furthermore, system integrators and industrial equipment builders act as crucial intermediary customers, purchasing large volumes of lamps to incorporate into custom-designed thermal processing machinery sold globally across various sectors.

Beyond traditional heavy industry, emerging buyers include specialized firms in the composites manufacturing sector (aerospace and wind energy), seeking optimal curing profiles for advanced polymer matrices, and the packaging industry, using the technology for high-speed shrink wrapping and bonding. These customers prioritize high energy transfer efficiency and repeatable performance, making the superior control offered by dual wave technology highly appealing for their technically demanding applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $350 million USD |

| Market Forecast in 2033 | $556 million USD |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ushio Inc., Heraeus Holding GmbH, Philips Lighting (Signify), Osram GmbH, Thermal Technologies, Inc., Emitted Energy, Inc., Prowatt Industrial, Vulcan Electric Company, Sylvania, Mastech Inc., Ceramicx, Waermetechnik, Fostoria Process Equipment, Advanced Radiation Corporation, Infrared Heating Technologies (IHT), Satronix, Zouping Sunshine Electric, Dr. Hönle AG, Sankyo, Alpha-Cure. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dual Wave Infrared Radiation Lamps Market Key Technology Landscape

The technological landscape of the Dual Wave Infrared Radiation Lamps Market is characterized by continuous refinement in emitter materials and encapsulation techniques aimed at maximizing spectral selectivity and power density while enhancing operational longevity. A crucial technology involves the use of specialized double-tube quartz emitters, where two tungsten filaments are housed within a fused quartz sheath. This design allows for independent or combined operation, precisely generating tailored output profiles that match the absorption peaks of the target materials, ensuring maximum energy coupling and minimal thermal waste. Recent advancements focus on incorporating reflective coatings (such as gold or ceramic) directly onto the lamp body to redirect radiation, further improving efficiency and focusing heat where needed, thereby protecting surrounding system components.

A second pivotal technology is the development and adoption of carbon fiber filaments, which offer a unique profile skewing towards medium-wave infrared radiation, contrasting with the short-wave dominance of traditional tungsten halogen lamps. Integrating carbon fiber with standard tungsten elements allows manufacturers to create true hybrid dual wave systems that can quickly switch or blend outputs to handle complex coatings, such as high-solids or waterborne paints which require different optimal absorption wavelengths during the flash-off and curing phases. This blending capability is managed by sophisticated power control units (PCUs) that utilize thyristor technology for precise modulation of input power, ensuring seamless transitions between the two spectral bands.

Furthermore, the integration of smart technology is transforming how these lamps operate. Advanced thermal sensing, including non-contact pyrometry and infrared cameras, provides instantaneous feedback on substrate temperature. This data is fed into high-speed controllers that adjust the dual wave output parameters in real-time. This level of responsiveness is vital for maintaining tight thermal tolerances in continuous manufacturing processes, enabling Industry 4.0 initiatives within thermal processing environments and significantly extending the lifespan and performance predictability of the expensive dual wave emitters.

Regional Highlights

- North America: North America represents a mature yet dynamic market, characterized by stringent quality standards in automotive and aerospace manufacturing. The demand here is primarily driven by technological upgrades to replace older convection systems with high-efficiency infrared processes. Key demand centers are the US automotive manufacturing belt and the Canadian aerospace sector. The focus is on integrating dual wave lamps into robotic curing cells for customized, high-mix, low-volume production lines. Regulatory compliance regarding energy use and low-VOC coatings fuels consistent investment in premium dual wave technology, prioritizing reliability and advanced spectral control.

- Europe: Europe holds a dominant position in the Dual Wave Infrared Radiation Lamps Market, largely due to Germany's strength in high-end machinery manufacturing and the region's early adoption of Industry 4.0 standards. European manufacturers exhibit a strong preference for durable, customized solutions that comply with strict EU environmental directives, particularly those related to energy efficiency (Ecodesign Directive). The automotive giants and specialized packaging industries drive substantial demand for customized short-wave/medium-wave combinations used in intricate bonding and coating processes, cementing Europe as a hub for high-specification lamp technology innovation and deployment.

- Asia Pacific (APAC): APAC is the fastest-growing region, driven by explosive growth in electronics manufacturing (China, Taiwan, South Korea) and massive expansion in the automotive sector (India, China). The region's rapid industrialization and increasing foreign direct investment in sophisticated production facilities necessitate rapid adoption of advanced thermal solutions like dual wave infrared lamps. While cost sensitivity exists, the critical need for speed and quality in mass production, particularly in semiconductor fabrication and large-scale textile processing, outweighs initial capital expense. This region is expected to lead global consumption growth over the forecast period.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, propelled by infrastructure development and foreign investment in local manufacturing, particularly in Brazil and Mexico's automotive assembly plants. The market is focused primarily on standard Dual Wave Quartz Tube (QDT) emitters for paint curing and basic industrial drying applications. Growth is often tied to macroeconomic stability and localized investment in modernization efforts. The preference leans toward cost-effective, proven technology that offers immediate efficiency gains over outdated systems.

- Middle East & Africa (MEA): The MEA region is an emerging market, with demand concentrated in industrialized zones like the UAE and Saudi Arabia, driven by diversification efforts away from oil dependence towards manufacturing, petrochemicals, and defense industries. The high solar irradiance in some parts of MEA makes solar panel manufacturing and associated curing processes a growing niche market for dual wave technology. Demand is sporadic but highly concentrated among large government-backed industrial projects that require robust, high-power solutions capable of operating effectively in challenging environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dual Wave Infrared Radiation Lamps Market.- Ushio Inc.

- Heraeus Holding GmbH

- Philips Lighting (Signify)

- Osram GmbH

- Thermal Technologies, Inc.

- Emitted Energy, Inc.

- Prowatt Industrial

- Vulcan Electric Company

- Sylvania

- Mastech Inc.

- Ceramicx

- Waermetechnik

- Fostoria Process Equipment

- Advanced Radiation Corporation

- Infrared Heating Technologies (IHT)

- Satronix

- Zouping Sunshine Electric

- Dr. Hönle AG

- Sankyo

- Alpha-Cure

Frequently Asked Questions

Analyze common user questions about the Dual Wave Infrared Radiation Lamps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of dual wave infrared lamps over single wave systems?

Dual wave lamps offer superior energy efficiency and process control by simultaneously or sequentially emitting radiation across two optimized spectral bands (short and medium wave). This allows for precise thermal matching to the substrate's absorption characteristics, leading to faster curing, better adhesion, and reduced energy waste compared to single, fixed-wavelength systems.

Which industrial sector is the largest end-user for dual wave infrared technology?

The automotive industry is the largest end-user, utilizing dual wave lamps extensively in paint curing and coating lines. These lamps provide the necessary precision and speed to efficiently dry modern waterborne and high-solids coatings, which require varying wavelengths throughout the curing cycle for optimal finish quality.

How does AI impact the lifespan and performance of dual wave emitters?

AI significantly enhances performance by enabling predictive maintenance and real-time output optimization. By analyzing operational data, AI prevents thermal overloading, optimizes power cycling, and adjusts the spectral mix dynamically, thereby reducing wear and tear and significantly prolonging the effective service life of the expensive emitters.

What are the main restraints hindering widespread market adoption?

The primary restraints are the high initial capital investment required for specialized dual wave systems and the need for specialized technical expertise for installation, calibration, and ongoing maintenance. Furthermore, the lamps' sensitivity to environmental contaminants in harsh industrial settings can reduce operational lifespan.

Which geographical region exhibits the highest growth rate for this market?

The Asia Pacific (APAC) region, driven by massive investments in electronics, semiconductor manufacturing, and rapid automotive expansion, is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR) for the Dual Wave Infrared Radiation Lamps Market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager