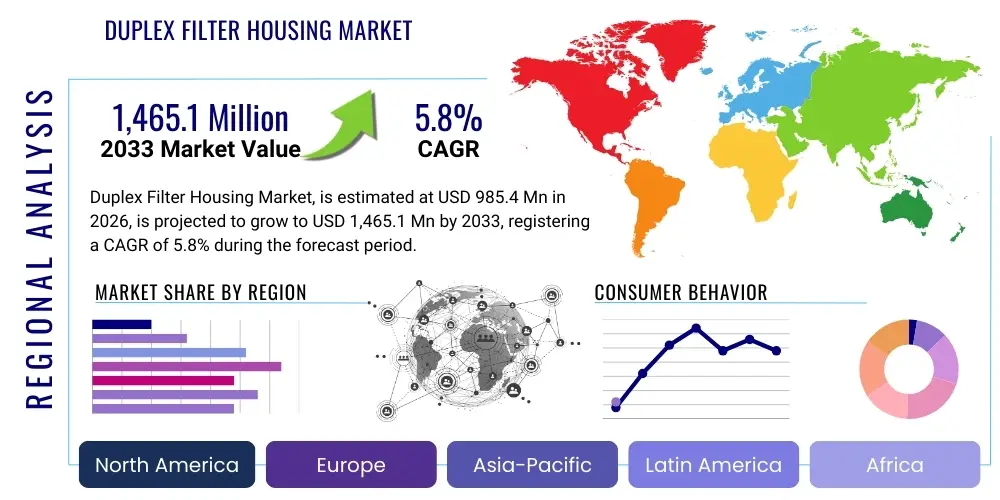

Duplex Filter Housing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436800 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Duplex Filter Housing Market Size

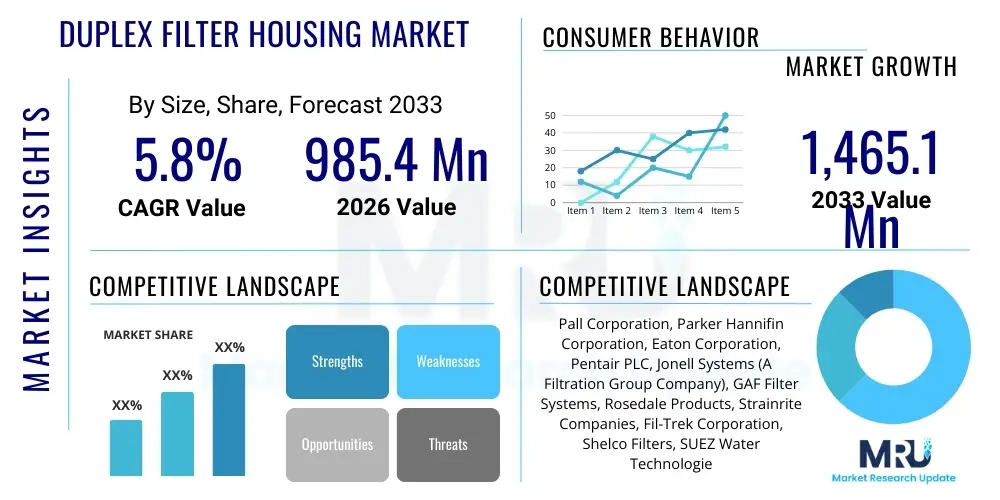

The Duplex Filter Housing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 985.4 Million in 2026 and is projected to reach USD 1,465.1 Million by the end of the forecast period in 2033.

Duplex Filter Housing Market introduction

The Duplex Filter Housing Market encompasses specialized industrial equipment designed to provide continuous filtration for critical processes where system shutdown is unacceptable. A duplex system consists of two identical filter housings connected by diverter valves, allowing the system operator to switch the flow from one housing (in use) to the other (standby) without interrupting the process stream. This inherent redundancy ensures operational continuity, making these housings indispensable in sectors such as oil and gas, petrochemicals, pharmaceuticals, power generation, and water treatment. The primary function is to protect sensitive downstream equipment, such as pumps, nozzles, heat exchangers, and instrumentation, from particulate contamination, thereby extending equipment lifespan and minimizing maintenance costs. The design adherence to stringent industrial standards, including ASME, PED, and various environmental regulations, drives the adoption across highly regulated environments globally.

Duplex filter housings are characterized by robust construction, typically utilizing materials like carbon steel, stainless steel (304L, 316L), and high-performance alloys, depending on the corrosive nature, temperature, and pressure requirements of the fluid being filtered. The versatility of these housings allows them to accommodate various filter elements, including baskets, cartridges, and bag filters, catering to diverse micron rating requirements and contaminant loads. Key benefits driving market expansion include enhanced operational uptime, improved product quality through finer filtration, reduced fluid loss during changeover procedures, and superior safety features designed for high-pressure industrial applications. As industrial automation and the demand for zero-downtime manufacturing processes accelerate globally, the reliance on reliable, redundant filtration systems, specifically duplex housings, intensifies, reinforcing their market position as essential process components.

Major applications span hydrocarbon processing, where they safeguard catalysts and burners; municipal water treatment, providing pre-filtration for reverse osmosis units; and the pharmaceutical industry, where sterile environments demand absolute continuity in liquid purification. Driving factors include the increasing global investment in new petrochemical refineries and pipeline infrastructure, stringent government regulations concerning wastewater discharge and emissions, and the growing complexity of manufacturing processes that necessitate ultra-pure input streams. Furthermore, the rising adoption of advanced filtration technologies, such as automatic backwash systems integrated into duplex configurations, further enhances efficiency and reduces manual intervention, sustaining the growth trajectory of this specialized housing market segment.

Duplex Filter Housing Market Executive Summary

The global Duplex Filter Housing Market is witnessing robust growth, propelled primarily by significant capital expenditures in the energy and water infrastructure sectors, where continuous flow filtration is a non-negotiable prerequisite. Business trends indicate a strong move toward customization, with end-users demanding housings tailored for extreme conditions, particularly high pressure and high temperature, necessitating the use of specialized materials and adherence to strict international pressure vessel codes. Strategic partnerships focusing on providing comprehensive filtration solutions, integrating sensors and monitoring capabilities (Industry 4.0 readiness) into traditional housing designs, are dominating competitive strategies. Furthermore, sustainability initiatives are driving demand for filter housings compatible with recyclable or long-life filter elements, reducing environmental waste associated with industrial processes.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, driven by rapid industrialization, massive investments in water management projects, and the expansion of the chemical and power generation industries, particularly in China and India. North America and Europe maintain significant market shares, characterized by high adoption rates of advanced, highly automated duplex systems, fueled by strict process safety regulations and a focus on maximizing operational efficiency in mature industrial bases. Geopolitical stability and energy transition policies are influencing investment cycles, indirectly boosting demand for duplex filtration systems utilized in green energy technologies, such as biofuel production and carbon capture processes, ensuring sustained revenue streams from diversified industrial sources.

Segment trends reveal that the basket filter housing segment continues to dominate based on volume due to its ease of cleaning and suitability for high flow rate applications with coarse filtration requirements. However, the cartridge filter housing segment is exhibiting faster growth, reflecting the increasing need for high-efficiency filtration (sub-micron levels) in critical applications like fine chemical synthesis and pharmaceutical manufacturing. Material-wise, stainless steel remains the preferred choice due to its chemical resistance and longevity. The critical drivers influencing segment penetration are the increasing adoption of automated switchover mechanisms, which minimize human error, and the standardized implementation of predictive maintenance protocols enabled by advanced instrumentation integrated within the duplex housing infrastructure.

AI Impact Analysis on Duplex Filter Housing Market

User queries regarding AI's impact on the Duplex Filter Housing Market commonly revolve around themes such as predictive maintenance integration, optimization of filter change schedules, potential for autonomous flow switching, and the role of machine learning in diagnosing system anomalies. Users are keenly interested in whether AI can transition duplex systems from reactive (manual switchover upon high differential pressure) to proactive management systems. The central concern is the operational viability and ROI of integrating complex, expensive AI-driven diagnostics into traditionally mechanical, passive components like filter housings. There is a clear expectation that AI will primarily enhance asset reliability management rather than fundamentally altering the physical housing structure, focusing on optimizing efficiency and reducing the total cost of ownership (TCO) over the long term.

The impact of Artificial Intelligence and Machine Learning (ML) on the Duplex Filter Housing Market is centered on enhancing operational efficiency and predictive maintenance capabilities rather than redesigning the basic housing structure. AI algorithms analyze real-time data collected from differential pressure sensors, flow meters, temperature gauges, and vibration sensors mounted on or near the housing unit. By continuously monitoring operational parameters and historical performance data, AI models can accurately predict the remaining useful life (RUL) of the filter element in the active housing. This allows plant managers to schedule the changeover and maintenance of the standby unit precisely during planned downtime or at the optimal point before system clogging affects process efficiency, minimizing unscheduled interruptions and maximizing element utilization.

Furthermore, AI-driven diagnostics contribute significantly to optimizing the entire filtration process. ML algorithms can correlate process fluid characteristics, upstream operational fluctuations, and filter performance metrics to recommend the ideal filter element type and material for specific applications, especially when dealing with complex or varying fluid compositions. This level of optimization ensures that the redundancy offered by the duplex system is utilized most effectively, preventing premature element failures and unnecessary energy expenditure associated with increased pump pressure required to overcome differential pressure buildup. The integration of AI thus elevates the duplex housing from a simple mechanical safeguard to a smart, predictive asset management tool crucial for modern, data-driven industrial environments.

- AI enables predictive maintenance by analyzing differential pressure trends, forecasting filter element failure, and optimizing replacement schedules.

- Machine Learning algorithms refine flow switching strategies, ensuring automatic transfer to the standby unit occurs precisely at the point of maximum efficiency, rather than solely relying on fixed pressure limits.

- Integration of smart sensors and IoT gateways facilitates data collection, feeding operational metrics into centralized AI platforms for real-time performance monitoring and anomaly detection.

- AI systems can correlate fluid contamination levels with filter performance, offering recommendations for optimizing filtration media selection and housing material based on process variation.

- Reduced reliance on manual inspection and reactive maintenance, lowering labor costs and minimizing human error during critical switchover procedures.

- Enhanced energy efficiency through optimized pump operations based on AI predictions of pressure drop across the active filter housing.

DRO & Impact Forces Of Duplex Filter Housing Market

The Duplex Filter Housing Market is shaped by a confluence of powerful drivers (D) related to industrial growth and regulatory compliance, stringent restraints (R) associated with high initial capital outlay and competitive alternatives, and significant opportunities (O) stemming from technological integration and emerging market industrialization. The primary driver is the absolute necessity for zero-downtime processes across critical infrastructure sectors, forcing mandatory adoption of redundant systems like duplex filters. Conversely, the high cost of specialized alloy construction required for corrosive environments acts as a significant restraint. Key opportunities lie in integrating IIoT, sensor technology, and automation for smart filtration management. These factors interact dynamically, creating powerful impact forces that determine market penetration and technological evolution within the industrial filtration landscape.

Drivers include accelerating global investments in oil and gas midstream and downstream operations, particularly in developing regions, which require extensive pipeline and refinery filtration infrastructure. Additionally, the proliferation of stringent environmental protection mandates and stricter quality control standards across the food & beverage and pharmaceutical sectors necessitates higher efficiency and continuous process purity, thereby increasing the demand for robust duplex systems. Technological advancements, such as quicker-opening closures and lighter, yet equally durable, housing materials, also improve maintenance efficiency and operational convenience, acting as a secondary growth driver. The shift towards manufacturing higher-value specialty chemicals also drives demand for cleaner input streams and reliable process continuity.

Restraints primarily involve the substantial initial capital investment required for high-specification duplex housings, especially those built to ASME Section VIII Div. 1 standards using specialized materials like Hastelloy or Duplex Stainless Steel, which can deter smaller enterprises. Furthermore, competition from alternative filtration technologies, such as advanced automatic self-cleaning filters and highly efficient simplex systems utilized in batch processes, slightly limits the market share for traditional duplex systems. Opportunities, however, abound in developing smart, connected filtration solutions. Integrating wireless communication capabilities and advanced automation into the valve switching mechanisms presents a substantial opportunity for vendors to offer high-value, digitally enabled products. Moreover, the expanding market for industrial wastewater recycling and treatment provides a significant long-term growth avenue for large-volume duplex filter systems.

Segmentation Analysis

The Duplex Filter Housing Market is comprehensively segmented based on filter element type, material of construction, operating pressure range, and end-use application, allowing for a detailed analysis of specific market niches and demand trends. This segmentation helps manufacturers align their product development efforts with the evolving requirements of different industrial sectors. The classification by filter element type, covering basket, bag, and cartridge filters, directly reflects the required filtration efficiency and contamination load handling capacity, where basket filters prioritize high flow rates and easy debris removal, while cartridge filters address fine filtration needs. Analyzing these segments provides strategic insights into areas experiencing the most rapid technological advancement and market adoption.

Segmentation by material is crucial, as the chemical compatibility and operational limits (temperature and pressure) of the housing are determined by the fluid media and process conditions. Stainless steel (SS 304L/316L) dominates due to its excellent corrosion resistance and hygiene characteristics, crucial for the chemical and food industries. Carbon steel, while more economical, serves less demanding, non-corrosive industrial applications. High-performance alloys are reserved for extreme temperature or highly aggressive chemical services. Furthermore, segmenting by end-use application highlights the critical role duplex filters play across diverse global infrastructure, confirming the market’s reliance on the stability and growth of key industrial consumers like Oil & Gas, Water Treatment, and Pharmaceuticals, each presenting unique demands regarding compliance and performance standards.

The market landscape is also defined by the operating pressure segment, differentiating standard industrial housings from high-pressure vessels designed for critical applications such as deep-sea pipelines or high-pressure gas processing plants. This pressure-based segmentation impacts manufacturing complexity, material thickness, and required certification (e.g., API 6A). Strategic focus areas for market players include developing modular duplex systems that offer flexibility across various pressure ranges and standardizing components to reduce manufacturing lead times, catering to the immediate replacement and installation needs of industrial operators worldwide seeking reliable, certified continuous filtration solutions.

- By Filter Element Type:

- Basket Filter Housing

- Bag Filter Housing

- Cartridge Filter Housing

- By Material of Construction:

- Stainless Steel (SS 304L, 316L)

- Carbon Steel

- High-Performance Alloys (e.g., Hastelloy, Duplex Steel)

- Non-Metallic/Polymer

- By Operating Pressure:

- Low Pressure (Up to 150 PSI)

- Medium Pressure (150 PSI to 600 PSI)

- High Pressure (Above 600 PSI)

- By End-Use Application:

- Oil & Gas (Upstream, Midstream, Downstream)

- Water and Wastewater Treatment

- Chemical and Petrochemicals

- Pharmaceuticals and Biotechnology

- Power Generation (Nuclear, Fossil Fuel)

- Food & Beverage

Value Chain Analysis For Duplex Filter Housing Market

The value chain for the Duplex Filter Housing Market begins with the sourcing of specialized raw materials, primarily high-grade stainless steel, carbon steel plates, and various alloys. Upstream analysis focuses heavily on the procurement strategy, where supply stability and fluctuating prices of metals like nickel and chromium significantly impact manufacturing costs. Suppliers must adhere to strict material certifications (e.g., ASME, ASTM) to meet pressure vessel standards. The subsequent stage involves precision manufacturing, including forming, welding, non-destructive testing (NDT), surface treatment, and assembly, which are highly specialized processes requiring certified welders and adherence to rigorous quality control standards, ensuring the structural integrity of the high-pressure housings.

The midstream component is dominated by specialized manufacturers who integrate proprietary closure mechanisms, valve assemblies, and internal baffling systems specific to duplex configurations. This stage focuses on efficiency of production and maintaining compliance with regional codes (e.g., PED in Europe, ASME in North America). Distribution channels play a critical role; direct channels are favored for large, complex, highly customized projects (e.g., greenfield refinery construction), allowing for close collaboration between the manufacturer and the engineering, procurement, and construction (EPC) firm. This direct model ensures precise specification matching and streamlined commissioning.

Conversely, indirect channels, involving established industrial distributors, filtration specialists, and value-added resellers (VARs), efficiently handle the sale of standardized, off-the-shelf duplex units and aftermarket spares (gaskets, seals, replacement elements). These indirect partners provide essential local stock, installation services, and rapid response maintenance support, particularly for the maintenance, repair, and overhaul (MRO) segment. Downstream analysis reveals that end-users prioritize total cost of ownership (TCO), reliability, and availability of certified spare parts. The efficiency of the distribution network directly influences downtime, making robust local support a competitive necessity in the aftermarket sector.

Duplex Filter Housing Market Potential Customers

Potential customers for Duplex Filter Housings are predominantly large-scale industrial operators and utility providers whose operations demand uninterrupted fluid processing and require regulatory compliance for product purity or environmental discharge. The primary buyers include multinational oil and gas companies, both national oil companies (NOCs) and international oil companies (IOCs), operating refineries, petrochemical complexes, and cross-country pipelines where continuous flow protection is essential to prevent costly equipment damage and massive environmental liabilities. These entities procure high-pressure, specialty-alloy duplex systems designed for highly corrosive and demanding hydrocarbon services.

A significant customer base resides within the municipal and industrial water treatment sectors. Municipal water utilities utilize large-scale duplex systems for continuous pre-treatment of source water before advanced processes like reverse osmosis (RO) or ultrafiltration (UF), ensuring uninterrupted supply to consumers. Industrial wastewater treatment facilities, particularly those associated with mining, textiles, and heavy manufacturing, rely on duplex filters to meet strict discharge regulations and facilitate water reuse programs, prioritizing flow consistency and effective particle removal to protect pumps and membranes from fouling and scaling.

Furthermore, the pharmaceutical and biotechnology industries represent high-value customers, requiring stainless steel, sanitary-design duplex housings for critical processes such as sterile fluid purification, fermentation media preparation, and solvent recycling. In these highly regulated environments, the zero-bypass feature and ease of sterilization of duplex systems are non-negotiable requirements, making reliable, certified filtration equipment procurement a core operational expenditure. EPC firms also act as crucial intermediate customers, purchasing duplex housings as integral components of major capital projects they design and construct for various industrial end-users globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 985.4 Million |

| Market Forecast in 2033 | USD 1,465.1 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pall Corporation, Parker Hannifin Corporation, Eaton Corporation, Pentair PLC, Jonell Systems (A Filtration Group Company), GAF Filter Systems, Rosedale Products, Strainrite Companies, Fil-Trek Corporation, Shelco Filters, SUEZ Water Technologies & Solutions, CLARCOR Industrial Air (Parker), Filter Specialists Inc. (FSI), Inline Filters, HILCO Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Duplex Filter Housing Market Key Technology Landscape

The technological landscape of the Duplex Filter Housing Market is driven by advancements aimed at maximizing reliability, simplifying maintenance, and improving integration with modern process control systems. A pivotal technological focus is on the design and automation of the diverter valve mechanism. While traditional systems utilize manual three-way ball or plug valves, the market is increasingly shifting towards automated, high-integrity butterfly or specially designed proprietary switch valves powered by pneumatic or electric actuators. This shift minimizes manual intervention, ensures seamless flow transfer, and reduces the risk of human error or pressure surges during switchover, which is critical in high-pressure or hazardous fluid applications. Furthermore, optimizing the internal geometry of the housing through Computational Fluid Dynamics (CFD) analysis is a critical technology employed to reduce pressure drop across the housing, minimizing energy consumption and enhancing flow stability without compromising filtration efficiency.

Material science innovation constitutes another core technological area. Manufacturers are continuously exploring advanced material coatings and surface treatments, such as specialized passivation techniques or ceramic coatings, to enhance the corrosion resistance and extend the lifespan of carbon steel or standard stainless steel housings operating in mildly aggressive environments, thus offering a cost-effective alternative to expensive nickel alloys. Simultaneously, the focus on quick-opening closure systems, such as swing bolts, clamp designs, and specialized ring closures, has significantly reduced the time required for filter element replacement. These ergonomic and safety-certified closure technologies meet increasingly strict industrial safety standards and improve operator efficiency during routine maintenance, directly contributing to overall operational uptime, a key metric for end-users.

The most significant emerging technology is the integration of Industrial Internet of Things (IIoT) capabilities. Modern duplex systems are equipped with smart sensors that monitor differential pressure, temperature, and even vibration, feeding data wirelessly to plant control systems (DCS or SCADA). This enables real-time performance tracking and facilitates the implementation of predictive maintenance strategies, as previously discussed in the AI analysis. Advanced systems are incorporating diagnostic software that can analyze complex operational variables, moving beyond simple high-pressure alarms to diagnose the root cause of pressure fluctuations or premature clogging. This digital transformation of the housing system elevates it from a purely mechanical device to an interconnected, data-generating asset essential for modern industrial process optimization.

Regional Highlights

- Asia Pacific (APAC): The APAC region is the primary engine of market growth, driven by massive infrastructure expansion in countries like China, India, and Southeast Asia. Robust growth in power generation projects, especially coal and gas-fired plants requiring continuous lubrication and cooling water filtration, coupled with soaring demand for reliable municipal water supply systems, solidifies its dominance. High industrial pollution levels also necessitate stringent wastewater treatment, boosting demand for large-scale duplex filter systems in countries undergoing rapid urbanization and industrial capacity expansion.

- North America: North America represents a mature yet high-value market, characterized by stringent regulatory environments (e.g., EPA, ASME) and a strong focus on automation and safety. Demand is consistently high in the highly specialized oil and gas sector (shale operations, high-pressure pipeline systems) and the chemical processing industry. Market growth here is largely fueled by replacement and retrofit cycles, alongside the adoption of technologically advanced, sensor-equipped duplex housings suitable for digital integration and Industry 4.0 standards.

- Europe: Europe exhibits stable demand, primarily driven by the pharmaceutical, food and beverage, and fine chemical industries, which require ultra-high purity and sanitary filtration standards. European regulations, particularly the Pressure Equipment Directive (PED), mandate the highest levels of material traceability and manufacturing quality, favoring manufacturers capable of delivering premium, certified stainless steel duplex systems. The region is also a key adopter of systems related to hydrogen production and carbon capture technologies.

- Middle East and Africa (MEA): This region is heavily influenced by large-scale oil and gas investments and critical desalination projects. The demand for duplex filters is intense in upstream and midstream crude oil processing, where reliable continuous filtration is necessary to manage high volumes of produced water and maintain pipeline integrity in harsh environmental conditions. Capital expenditures on new refineries and strategic oil reserve facilities are the main demand drivers in this region.

- Latin America: Market growth in Latin America is uneven but shows significant potential, particularly in countries with strong mining operations (water management) and growing petrochemical sectors (Brazil, Mexico). Economic fluctuations can influence capital expenditure, but essential infrastructure projects and continuous operational requirements in the established oil and gas extraction industries ensure a baseline level of demand for robust, reliable duplex filtration equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Duplex Filter Housing Market.- Pall Corporation (A Danaher Company)

- Parker Hannifin Corporation

- Eaton Corporation

- Pentair PLC

- Jonell Systems (A Filtration Group Company)

- Rosedale Products, Inc.

- Strainrite Companies

- Fil-Trek Corporation

- Shelco Filters

- Filter Specialists Inc. (FSI)

- SUEZ Water Technologies & Solutions

- Donaldson Company, Inc.

- Vee Bee Filtration Ltd.

- Plenty Filtration (part of the ClydeUnion Pumps/SPX FLOW group)

- Dover Corporation (through relevant subsidiaries)

- CLARCOR Industrial Air (A Parker Company)

- HILCO Corporation

- Inline Filters

- Lenz Hydraulic Accessories, Inc.

- Sure Flow Equipment Inc.

Frequently Asked Questions

Analyze common user questions about the Duplex Filter Housing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary operational benefits of using a duplex filter housing compared to a standard simplex system?

The primary benefit of a duplex filter housing is the ability to maintain continuous fluid flow without interruption during filter element maintenance or replacement. This redundancy ensures zero-downtime operations, which is critical for continuous processes in industries like petrochemicals, power generation, and specialized manufacturing, thereby protecting expensive downstream equipment and maximizing operational efficiency.

Which materials of construction are most commonly used for duplex filter housings in industrial applications?

The most common materials are Stainless Steel (304L and 316L) due to their superior corrosion resistance and hygienic properties, favored heavily in chemical and pharmaceutical sectors. Carbon steel is widely used for non-corrosive, high-volume applications like lubricating oil or general utility water. High-performance alloys are reserved for extremely aggressive chemicals or high-temperature/high-pressure services.

What is the Compound Annual Growth Rate (CAGR) projected for the Duplex Filter Housing Market?

The Duplex Filter Housing Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 5.8% between the forecast years of 2026 and 2033, driven by increasing regulatory requirements for continuous process safety and expanding industrial infrastructure globally, particularly in the Asia Pacific region.

How does the integration of IIoT (Industrial Internet of Things) affect the performance of duplex filter systems?

IIoT integration, facilitated by smart sensors monitoring differential pressure and flow, allows duplex systems to transition to predictive maintenance models. This technology enables real-time performance analysis and optimizes the filter change schedule, minimizing unnecessary manual checks, reducing energy consumption, and ensuring the switchover occurs precisely when required to prevent system pressure drops.

What key factors should buyers consider when selecting a duplex filter housing for a critical application?

Buyers must consider five critical factors: material compatibility (based on fluid corrosivity and temperature), required operating pressure rating (adherence to ASME/PED standards), type of filter element (bag, basket, or cartridge) needed for the micron rating, ease of maintenance (quick-opening closures), and the required flow rate capacity to prevent excessive pressure drop across the system.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager