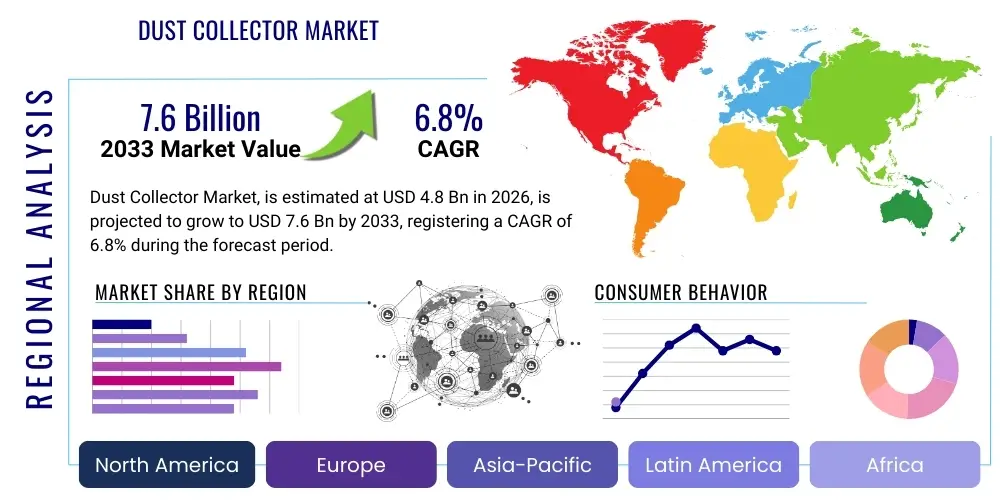

Dust Collector Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435882 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Dust Collector Market Size

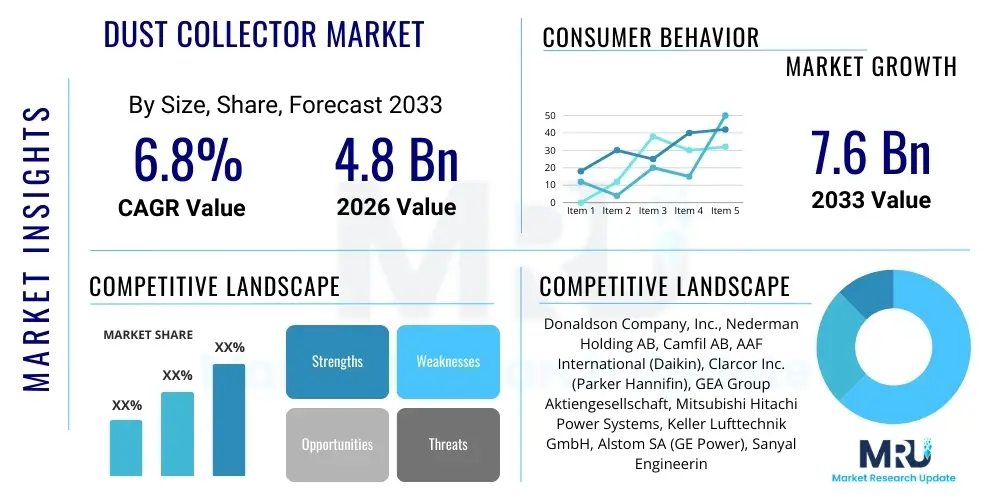

The Dust Collector Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.6 Billion by the end of the forecast period in 2033.

Dust Collector Market introduction

The Dust Collector Market encompasses the sale and deployment of industrial air pollution control equipment designed to enhance air quality by capturing and removing particulate matter from the air or gas stream. These systems are critical components in manufacturing environments where processes like grinding, welding, sanding, and chemical processing generate hazardous dust and fumes. The fundamental purpose of a dust collector is twofold: ensuring compliance with stringent environmental regulations set forth by agencies like OSHA and EPA, and safeguarding employee health by mitigating risks associated with respiratory exposure to harmful airborne substances. The market offers a variety of technologies, including cyclone collectors, fabric filters (baghouses), wet scrubbers, and unit collectors, tailored to different industrial dust loading and particle size requirements, driving specialization across end-user sectors.

Major applications of dust collectors span a vast array of industries, including pharmaceuticals, food and beverage processing, cement production, metals fabrication, woodworking, and power generation. In sectors like pharmaceuticals and food processing, dust control is paramount not only for environmental compliance but also for preventing cross-contamination, ensuring product purity, and minimizing explosion hazards (combustible dust). The benefits derived from implementing effective dust collection systems include reduced operational downtime due to equipment fouling, enhanced safety protocols, lower maintenance costs on surrounding machinery, and potential recovery of valuable process material, making them an essential capital investment for modern industrial operations.

Driving factors propelling the expansion of this market include the global intensification of manufacturing activities, particularly in emerging economies of Asia Pacific, coupled with the rising global consciousness regarding air pollution and occupational safety. Furthermore, technological advancements in filtration media, leading to higher efficiency in capturing ultrafine particulates (PM2.5), and the integration of smart monitoring capabilities (IoT sensors) for predictive maintenance and energy efficiency are significantly contributing to market growth. The ongoing shift toward automated and high-throughput manufacturing processes necessitates more robust and reliable dust mitigation solutions, securing the market's trajectory through the forecast period.

Dust Collector Market Executive Summary

The Dust Collector Market is characterized by robust expansion driven by global regulatory tightening concerning industrial emissions and occupational health standards. Business trends indicate a strong move toward advanced filtration technologies, such as cartridge collectors offering higher efficiency and smaller footprints, replacing traditional shaker-style baghouses in many new installations. Key players are focusing on modular system designs and implementing IoT technologies to offer integrated solutions that provide real-time performance monitoring, energy consumption optimization, and automated filter cleaning cycles, thereby catering to the increasing demand for high operational efficiency and lower total cost of ownership (TCO). Strategic mergers and acquisitions are common as large corporations seek to consolidate specialized filtration expertise and expand geographical reach, particularly into rapidly industrializing regions.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, primarily fueled by massive infrastructure development, exponential growth in the cement, metals, and electronics manufacturing sectors in countries like China and India, and the subsequent implementation of stricter local environmental protection laws. North America and Europe, while being mature markets, exhibit consistent growth driven by replacement demand, modernization of existing infrastructure, and high adoption rates of premium, energy-efficient pulse jet collectors. Furthermore, the emphasis on controlling fugitive emissions in complex sectors like chemicals and petrochemicals across these developed regions ensures sustained market investment and technological innovation.

Segment trends reveal that the fabric filter segment (baghouses) continues to dominate the market share by value, particularly in high-volume, heavy-dust loading applications such as cement and power generation, owing to their proven durability and scalability. However, the cartridge collector segment is projected to witness the highest CAGR, propelled by their compact design, superior filtration efficiency, and ease of maintenance, making them ideal for fine dust applications in pharmaceuticals and electronics manufacturing. By end-user, the cement and mining industry remains a foundational consumer, but the pharmaceutical and food and beverage sectors are demonstrating accelerated growth due to non-negotiable hygiene and cross-contamination prevention requirements, demanding specialized stainless steel and explosion-proof dust collectors.

AI Impact Analysis on Dust Collector Market

Common user questions regarding AI’s impact on the Dust Collector Market frequently revolve around how artificial intelligence and machine learning can enhance system efficiency, reduce maintenance costs, and predict operational failures. Users are concerned about implementing complex sensor arrays and the ROI of integrating these sophisticated tools into established mechanical equipment. Analysis reveals that user interest centers on leveraging AI for predictive maintenance—determining the optimal time to clean or replace filters based on differential pressure trends and ambient air quality data, rather than relying on fixed schedules or reacting to failures. Furthermore, AI is expected to revolutionize energy consumption by dynamically adjusting fan speeds and pulse jet cleaning intensity based on real-time dust loading and production schedules, optimizing performance while minimizing unnecessary energy use, thereby transforming dust collection from a reactive necessity into a proactively managed utility.

- AI-driven Predictive Maintenance (PdM): Algorithms analyze sensor data (pressure, temperature, flow) to forecast filter life and potential mechanical failures, significantly reducing unplanned downtime.

- Optimized Energy Management: AI systems dynamically adjust blower and fan speeds according to actual dust burden, minimizing energy consumption and operational costs.

- Filter Cleaning Optimization: Machine learning models determine the precise timing and intensity for pulse jet cleaning, maximizing filter lifespan and maintaining consistent pressure drop efficiency.

- Enhanced Regulatory Compliance Reporting: Automated AI systems generate detailed, auditable reports on emission levels and performance metrics, simplifying environmental compliance documentation.

- Smart Process Integration: AI facilitates seamless integration with overall manufacturing execution systems (MES), ensuring dust collection scales proportionally with production output fluctuations.

- Combustible Dust Risk Mitigation: Advanced algorithms analyze particle size distribution and temperature profiles in real-time to alert operators instantly to conditions nearing explosive limits (e.g., Kst values), enhancing safety protocols.

DRO & Impact Forces Of Dust Collector Market

The Dust Collector Market is fundamentally shaped by a powerful confluence of regulatory mandates and technological necessity, defining its inherent Drivers, Restraints, and Opportunities. The primary driver is the non-negotiable enforcement of industrial safety standards globally, pushing industries to invest heavily in reliable dust mitigation technologies. Opportunities are vast, primarily centered on implementing smart, IoT-enabled solutions that promise high energy efficiency and predictive maintenance capabilities, appealing directly to industry pain points regarding operational expenditure. Conversely, market restraints largely stem from the high initial capital investment required for advanced systems and the fragmented nature of end-user requirements, which demand highly customized, rather than standardized, solutions.

Drivers: Intensifying industrialization, particularly in APAC and Latin America, inherently increases the volume of airborne particulate matter requiring capture. Concurrently, strict enforcement of occupational safety regulations (e.g., OSHA's standards on crystalline silica exposure) mandates compliance measures that only advanced dust collection systems can reliably meet. Furthermore, the increasing awareness among manufacturers regarding the economic benefits of material recovery (e.g., precious metals or pharmaceutical compounds) captured by high-efficiency dust collectors incentivizes new purchases and upgrades.

Restraints: The most significant restraint is the substantial initial investment cost associated with purchasing and installing sophisticated dust collection systems, which can deter smaller enterprises despite regulatory pressure. Another challenge is the lack of standardized regulatory frameworks across developing regions, creating ambiguity and hindering consistent market adoption. The complexity involved in designing systems for highly specific dust types, characterized by varying abrasiveness, stickiness, and explosivity indices (Kst values), requires specialized engineering, adding to complexity and expense.

Opportunity: The market presents significant opportunities through the adoption of integrated digitalization and smart manufacturing paradigms. Developing energy-efficient dust collectors that incorporate variable frequency drives (VFDs) and real-time monitoring sensors caters directly to the global push for sustainability and reduced carbon footprint. Furthermore, the specialized handling of combustible dust (e.g., metal powders, sugar, wood flour) offers niche high-growth opportunities for vendors specializing in NFPA and ATEX compliant explosion-proof and mitigation systems, such as isolation valves and chemical suppression.

Impact Forces: The overall impact forces are predominantly positive, driven by external governmental pressure (regulation) and internal industrial demand (efficiency and safety). While capital expenditure acts as a dampening restraint, the accelerating need for cleaner production processes, improved worker health outcomes, and the promise of lower long-term operational costs dueled by smart technology integration strongly outweigh the restraints, ensuring sustained market momentum throughout the forecast period. The combined force of regulatory mandates and technological innovation dictates continued robust growth.

Segmentation Analysis

The Dust Collector Market is comprehensively segmented based on type, operation, end-user industry, and capacity, reflecting the diverse and specialized requirements of industrial air quality control. The segmentation by type—including fabric filters (baghouses), cartridge collectors, cyclone collectors, and wet scrubbers—is crucial as it distinguishes between technologies optimized for high-volume, coarse dust loads versus those designed for capturing fine, toxic particulates. Understanding these segments allows manufacturers to target specific industrial applications, ranging from heavy mining operations requiring robust baghouses to sensitive pharmaceutical environments demanding high-efficiency cartridge systems and validated compliance.

- By Type:

- Fabric Filters (Baghouse Collectors)

- Cartridge Collectors

- Cyclone Collectors

- Wet Scrubbers

- Electrostatic Precipitators (ESPs)

- Unit Collectors (Dust Booths, Portable Collectors)

- By Operation:

- Pulse Jet

- Shaker

- Reverse Air

- By End-User Industry:

- Cement, Mining, and Construction

- Pharmaceutical and Chemical

- Food and Beverage

- Metal Fabrication and Machining

- Woodworking and Paper

- Power Generation (Coal Fired Plants)

- Electronics and Semiconductor

- By Capacity/Size:

- Small (Below 10,000 CFM)

- Medium (10,000 to 40,000 CFM)

- Large (Above 40,000 CFM)

- By Application:

- Particulate Collection

- Fume and Smoke Collection

- Mist Collection

Value Chain Analysis For Dust Collector Market

The value chain for the Dust Collector Market begins with upstream activities involving raw material procurement, primarily steel, specialized filtration media (e.g., polyester, PTFE, fiberglass), and electronic components such as sensors and controllers. Suppliers of highly durable and chemically resistant filter bags and cartridges hold significant leverage, as filter media quality directly dictates the efficiency and longevity of the final system. Upstream innovation focuses heavily on developing filtration materials capable of handling high temperatures, abrasive particles, and corrosive gases, while also offering enhanced dust release properties for more efficient cleaning cycles, thus reducing operational complexity for downstream users.

The core midstream phase involves the design, manufacturing, and assembly of the collection units. This stage includes specialized engineering services to customize systems based on the specific industrial process, volumetric airflow requirements (CFM), and regulatory mandates (e.g., ATEX certification for explosive dust). Manufacturers often differentiate themselves through proprietary design elements, such as optimized baffle plates, venturi nozzles, and advanced sealing mechanisms, ensuring minimal dust leakage and maximizing energy efficiency. Direct and indirect distribution channels play a pivotal role, with direct sales models typically utilized for large, custom-engineered projects, involving direct consultation between the manufacturer's engineers and the end-user's facility managers.

Downstream activities center on installation, commissioning, aftermarket services, and regular maintenance. Indirect distribution channels, often involving specialized industrial distributors and system integrators, handle standard unit collectors and provide essential local support. Aftermarket services, including the consistent supply of replacement filters, spares, and upgrade kits, represent a substantial and highly profitable component of the value chain. As dust collectors are long-term assets requiring continuous consumable replacement, companies that establish strong service networks and offer comprehensive maintenance contracts secure long-term revenue streams and maintain deep engagement with the end-user base, enhancing brand loyalty and ensuring operational uptime.

Dust Collector Market Potential Customers

Potential customers for dust collector systems encompass a wide spectrum of industrial entities where particulate matter generation is inherent to the manufacturing process or materials handling. The primary buyers are large-scale industrial complexes and heavy processing facilities, particularly within the cement manufacturing, mining, and metal fabrication sectors. These end-users typically require large, centralized fabric filters or hybrid systems (e.g., cyclone pre-collectors followed by baghouses) capable of handling immense volumes of abrasive dust and maintaining continuous operation under severe environmental conditions, prioritizing durability and scalability above all else.

Another rapidly expanding customer base includes the high-specification industries, specifically pharmaceutical manufacturing, biotechnology, and food processing. These sectors are critical buyers of cartridge collectors and highly specialized unit collectors due to stringent governmental regulations regarding product purity, cross-contamination prevention, and sanitation (e.g., FDA and cGMP standards). For these customers, the primary purchasing drivers are filtration efficiency (HEPA/ULPA standards), validated system performance, ease of cleaning (WIP/CIP compatibility), and specialized construction materials (e.g., 316L stainless steel) to prevent microbial growth.

Furthermore, small to medium enterprises (SMEs) engaged in woodworking, specialized coatings, additive manufacturing (3D printing with metal powders), and localized welding operations represent a significant segment for unit collectors and portable dust extraction systems. While their individual purchasing volume is lower, their sheer numbers and increasing adherence to localized workplace safety regulations (e.g., requirements for source capture ventilation) drive consistent demand for smaller, modular, and affordable dust collector solutions. System integrators and engineering procurement construction (EPC) firms, acting as intermediaries, are also crucial customers, purchasing systems for integration into new plant build-outs and modernization projects across all end-user categories.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Donaldson Company, Inc., Nederman Holding AB, Camfil AB, AAF International (Daikin), Clarcor Inc. (Parker Hannifin), GEA Group Aktiengesellschaft, Mitsubishi Hitachi Power Systems, Keller Lufttechnik GmbH, Alstom SA (GE Power), Sanyal Engineering, Thermax Limited, Sumitomo Heavy Industries, Fuji Electric Co., Ltd., CECO Environmental, Absolent Group AB, MikroPul, Scientific Dust Collectors, IVETRY International, Filtermist International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dust Collector Market Key Technology Landscape

The technology landscape of the Dust Collector Market is rapidly evolving, moving beyond simple mechanical separation toward sophisticated, integrated filtration and monitoring solutions. A significant trend involves advancements in filtration media, specifically the development and wider adoption of Nanofiber technology coatings and PTFE membranes. These materials offer significantly higher filtration efficiency (up to MERV 16 and higher) for ultrafine particulate matter (PM2.5 and below) compared to traditional cellulose or standard polyester media, while simultaneously exhibiting superior dust cake release, leading to reduced pressure drop and lower energy consumption over the operational lifetime. Furthermore, proprietary filter pleating and sealing techniques are continually refined to maximize filter area within a smaller physical footprint, driving the dominance of compact cartridge collectors in many high-value manufacturing settings.

The convergence of industrial equipment with Information Technology (IT), commonly termed Industry 4.0, is profoundly impacting system operation. Modern dust collectors are increasingly equipped with integrated IoT sensors that monitor critical performance indicators such as differential pressure, airflow velocity, temperature, and fan vibration in real-time. This connectivity enables remote monitoring and control, allowing facility managers to access performance data via cloud platforms. This technological capability shifts maintenance practices from reactive or time-based schedules to proactive, condition-based monitoring, optimizing the timing of pulse jet cleaning cycles and filter replacements, directly translating into tangible reductions in energy usage and maximizing filter element service life.

Another crucial area of technological innovation centers on safety and hazard mitigation, especially concerning combustible dust. Manufacturers are embedding technology compliant with stringent standards like NFPA 652 and ATEX directives. This includes the development of robust explosion venting systems, chemical suppression systems, and fast-acting isolation valves (passive and active) designed to prevent deflagration propagation into upstream piping or downstream hoppers. Finally, the growing market for specialized wet scrubbers and mist collectors, utilizing advanced impingement plate technology and high-velocity venturis, addresses the critical need to control dangerous oil mists and sticky dusts that are incompatible with dry media filtration, broadening the applicability of dust collection technologies across diverse processing environments.

Regional Highlights

- Asia Pacific (APAC): Dominates the market growth trajectory and is expected to exhibit the highest CAGR due to massive industrial expansion across China, India, and Southeast Asian nations. Regulatory pressure, especially concerning air quality standards in large urban industrial clusters, compels industries like cement, textiles, steel, and electronics manufacturing to adopt modern, high-capacity dust collection systems. The region is characterized by high demand for both affordable and high-efficiency solutions.

- North America: A mature market characterized by stringent EPA and OSHA regulations, driving consistent demand for replacement units and technology upgrades focused on superior efficiency and regulatory compliance (especially for crystalline silica). Growth is driven primarily by the high adoption rate of IoT-enabled smart dust collectors and robust investment in the pharmaceutical, food processing, and advanced manufacturing sectors.

- Europe: Exhibits steady growth driven by the EU’s Industrial Emissions Directive (IED) and strong emphasis on sustainability and energy efficiency (Ecodesign requirements). Key countries like Germany and Italy, with strong manufacturing bases, demand premium, technologically advanced systems (e.g., highly energy-efficient pulse jet collectors) that minimize operational footprint and meet rigorous ATEX explosion protection standards.

- Latin America (LATAM): Showing accelerated growth, particularly in countries like Brazil and Mexico, fueled by increasing mining, construction, and basic materials processing activities. While regulatory enforcement is varied, market potential is realized through multinational corporations establishing operations that adhere to global safety standards, driving demand for industrial filtration systems.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) countries due to massive infrastructure projects, cement production, and petrochemical processing. High desert environments create a specific need for robust systems capable of handling extremely fine and high-volume dust loads, favoring durable baghouses and specialized filtration solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dust Collector Market.- Donaldson Company, Inc.

- Nederman Holding AB

- Camfil AB

- AAF International (Daikin Industries)

- Clarcor Inc. (Parker Hannifin Corporation)

- GEA Group Aktiengesellschaft

- Mitsubishi Hitachi Power Systems (MHPS)

- Keller Lufttechnik GmbH

- Alstom SA (GE Power)

- Sanyal Engineering

- Thermax Limited

- Sumitomo Heavy Industries, Ltd.

- Fuji Electric Co., Ltd.

- CECO Environmental

- Absolent Group AB

- MikroPul (Nederman Group)

- Scientific Dust Collectors

- IVETRY International

- Filtermist International (Absolent Group)

- Met-Pro Environmental Solutions

Frequently Asked Questions

Analyze common user questions about the Dust Collector market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current demand for industrial dust collectors?

The primary driver is the global escalation of stringent occupational safety and environmental regulations (e.g., OSHA, EPA, EU IED) concerning worker exposure to particulate matter and limits on stack emissions, compelling industries to invest in high-efficiency air pollution control equipment for compliance.

Which type of dust collector is most effective for handling fine, explosive dusts in pharmaceutical environments?

Cartridge collectors equipped with high-efficiency PTFE membrane filters are generally preferred for pharmaceutical applications due to their superior filtration performance for fine dust (often requiring HEPA final stages) and their compact design, often integrated with NFPA/ATEX-compliant explosion isolation and venting features.

How is Industry 4.0 influencing the design and maintenance of modern dust collector systems?

Industry 4.0 integration, specifically through IoT sensors and AI analytics, enables predictive maintenance (PdM). Systems can monitor differential pressure and energy use in real-time, optimizing filter cleaning cycles and fan speed dynamically, which reduces energy costs and significantly extends the operational life of the filtration media.

What is the expected CAGR of the Dust Collector Market during the forecast period 2026–2033?

The Dust Collector Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by continuous industrial expansion in APAC and ongoing modernization efforts in developed economies to meet safety and environmental mandates.

What is the main challenge restraining the adoption of advanced dust collection systems globally?

The chief restraint is the high initial capital expenditure (CapEx) required for sophisticated, large-scale dust collection systems and associated compliance infrastructure, which can present a financial barrier for smaller industrial manufacturers and facilities operating on limited equipment budgets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Electrostatic Dust Collector Market Statistics 2025 Analysis By Application (Pharmaceutical Factory, Metallurgy Factory, Coal Plants, Electronics Factory), By Type (Dry Electrostatic Dust Collector, Wet Electrostatic Dust Collector), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Mechanical Dust Collector Market Statistics 2025 Analysis By Application (Industrial Dedusting, Chemical Machining, Mining Industry, Food Processing), By Type (Inertial Dust Collector, Centrifugal Force Dust Collector), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager