EAA and EMAA Copolymer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440512 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

EAA and EMAA Copolymer Market Size

The EAA and EMAA Copolymer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033.

EAA and EMAA Copolymer Market introduction

The EAA (Ethylene Acrylic Acid) and EMAA (Ethylene Methacrylic Acid) copolymer market encompasses specialty thermoplastic resins known for their excellent adhesion, toughness, and barrier properties. These copolymers are primarily derived from ethylene and acrylic or methacrylic acid, offering a unique combination of characteristics that make them indispensable in various industrial applications. Their robust performance across a spectrum of temperatures and environmental conditions contributes significantly to their widespread adoption. The ability of these materials to bond effectively to diverse substrates, coupled with their inherent flexibility and resistance to chemicals, positions them as critical components in advanced material solutions.

Major applications for EAA and EMAA copolymers include diverse packaging solutions, particularly for food and medical products where barrier properties and seal integrity are paramount. They are also extensively utilized in adhesives, providing strong bonds in laminates and multi-layer structures, and in powder coatings, offering improved adhesion and corrosion resistance. Furthermore, their utility extends to ink and toner formulations, cable jacketing, and specialized barrier layers in demanding industrial settings. The primary benefits these copolymers offer include enhanced adhesion to polar substrates, excellent hot tack strength, superior toughness and impact resistance, and improved environmental stress crack resistance, making them ideal for high-performance applications.

Driving factors for the EAA and EMAA copolymer market include the escalating demand for high-performance and sustainable packaging materials, particularly in the food and beverage industry, where extended shelf life and product safety are crucial. The automotive sector's increasing focus on lightweighting and enhanced material performance also contributes significantly, with these copolymers finding applications in composite materials and specialized adhesives. Growth in the construction sector, coupled with advancements in powder coating technologies requiring superior adhesion and durability, further propels market expansion. Additionally, the continuous innovation in adhesive formulations and the broadening scope of their application across various consumer goods underscore their market trajectory.

EAA and EMAA Copolymer Market Executive Summary

The EAA and EMAA Copolymer Market is experiencing robust growth, driven by an accelerating shift towards high-performance and sustainable material solutions across multiple industries. Key business trends indicate a strong focus on product differentiation through enhanced barrier properties, improved processability, and the development of bio-based or recycled content copolymers to meet evolving regulatory landscapes and consumer preferences for eco-friendly products. Strategic collaborations between raw material suppliers and end-product manufacturers are becoming more prevalent, aimed at optimizing supply chains and accelerating the introduction of innovative applications. Furthermore, market players are investing heavily in research and development to expand the functional scope of these copolymers, exploring new blends and composites that offer superior properties and address niche market demands.

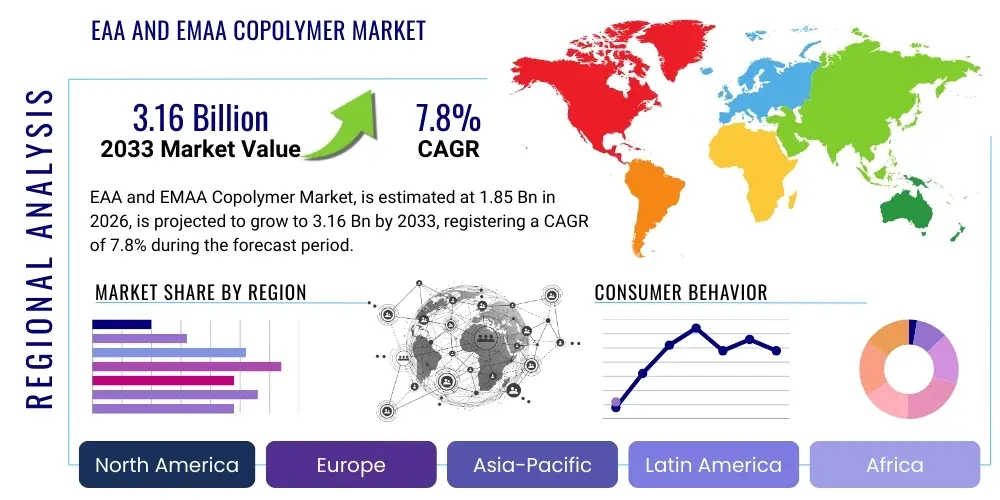

Regionally, Asia Pacific continues to dominate the market, largely due to rapid industrialization, burgeoning population growth, and increasing investments in manufacturing sectors, particularly in packaging, automotive, and construction industries within countries like China, India, and Southeast Asian nations. North America and Europe also represent significant markets, characterized by stringent environmental regulations driving demand for sustainable solutions and advanced material performance requirements in established industries. The Middle East and Africa, along with Latin America, are emerging as high-potential regions, fueled by infrastructure development, expanding consumer markets, and diversification of industrial bases, leading to increased adoption of EAA and EMAA copolymers in various applications.

Segment-wise, the packaging sector remains the largest end-use application for EAA and EMAA copolymers, driven by the critical need for reliable sealing, barrier protection, and adhesion in food, medical, and industrial packaging. The adhesives segment is also witnessing substantial growth, propelled by the demand for strong, durable, and versatile bonding solutions in automotive, construction, and consumer goods manufacturing. Innovation within the powder coatings and ink & toner segments, focusing on enhanced adhesion, flexibility, and environmental compliance, further contributes to market expansion. The increasing sophistication of specialized applications, such as hot-melt adhesives, tie layers in multi-layer films, and components in footwear, underscores the versatility and growing market penetration of these advanced copolymer solutions.

AI Impact Analysis on EAA and EMAA Copolymer Market

The EAA and EMAA Copolymer market is poised to experience transformative impacts from the integration of Artificial Intelligence (AI) technologies, addressing critical aspects from material discovery to market dynamics. Users frequently inquire about how AI can enhance the efficiency of polymer synthesis, optimize material properties for specific applications, and streamline supply chain operations to mitigate raw material price volatility. Concerns often revolve around the initial investment required for AI implementation, the need for skilled personnel to manage AI-driven systems, and data privacy issues. Expectations include AI's role in predictive analytics for market trends, personalized product development, and accelerating the transition towards more sustainable manufacturing practices, ultimately leading to higher efficiency, cost reduction, and superior product performance.

- AI-driven optimization of polymer synthesis processes, reducing waste and energy consumption.

- Predictive modeling for material properties, enabling faster development of customized EAA/EMAA copolymer formulations.

- Enhanced supply chain management through AI-powered forecasting and logistics optimization, mitigating raw material price fluctuations.

- Automated quality control and inspection systems improving product consistency and reducing defects in copolymer production.

- Accelerated discovery of novel bio-based or recycled EAA/EMAA copolymer alternatives through AI-guided material design.

- Predictive maintenance for manufacturing equipment, minimizing downtime and increasing operational efficiency.

- Market trend analysis and demand forecasting using AI algorithms, informing strategic production and inventory decisions.

- Personalized product development and customization for specific end-user applications based on AI-driven insights into performance requirements.

- Robotics and automation, often AI-driven, in handling, mixing, and packaging of EAA/EMAA copolymers, improving safety and throughput.

- Development of smart packaging solutions integrating EAA/EMAA copolymers with AI-enabled sensors for real-time monitoring of product condition.

DRO & Impact Forces Of EAA and EMAA Copolymer Market

The EAA and EMAA Copolymer Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, alongside broader impact forces shaping its trajectory. Key drivers include the escalating demand for high-performance packaging, particularly in food and medical sectors, where barrier properties and seal integrity are paramount. The automotive industry's continuous pursuit of lightweighting solutions and enhanced safety features also fuels demand for these versatile copolymers. Furthermore, the growth of the global construction industry and the increasing adoption of powder coatings requiring superior adhesion and durability contribute substantially to market expansion. Consumer preference for sustainable and recyclable materials is also pushing innovation in copolymer formulations, aligning with environmental objectives and fostering new market avenues. These factors collectively create a robust growth environment, encouraging manufacturers to innovate and expand their production capacities to meet the rising global demand.

However, the market faces notable restraints that could temper its growth. Volatility in the prices of key raw materials, such as ethylene, acrylic acid, and methacrylic acid, directly impacts production costs and profit margins for manufacturers. This fluctuation is often linked to global oil prices and supply chain disruptions, posing a persistent challenge. Stringent environmental regulations concerning plastic waste and the lifecycle assessment of polymer products, particularly in developed economies, can also restrict certain applications or necessitate costly R&D efforts for compliance. Competition from alternative materials, including other specialty polymers and bio-plastics, presents a formidable challenge, requiring EAA and EMAA copolymer manufacturers to continuously innovate and demonstrate superior performance-to-cost ratios to maintain market share. These restraints demand strategic planning and adaptable business models to ensure sustainable growth.

Opportunities within the EAA and EMAA copolymer market are abundant, particularly in emerging economies characterized by rapid industrialization, urbanization, and growing middle-class populations with increasing purchasing power. These regions present untapped potential for packaging, automotive, and construction applications. Significant opportunities also lie in extensive research and development efforts focused on creating bio-based EAA and EMAA copolymers, which could address environmental concerns and appeal to a broader, eco-conscious market segment. Advancements in adhesion technology and the exploration of novel, specialized applications, such as in renewable energy components, advanced composites, and smart materials, further broaden the market's scope. The continuous evolution of manufacturing processes to enhance efficiency and reduce environmental footprints also presents avenues for innovation and competitive advantage. The interplay of these opportunities with strategic investment in R&D is critical for long-term market leadership and sustained profitability.

Segmentation Analysis

The EAA and EMAA Copolymer market is meticulously segmented to provide a granular understanding of its diverse applications, material types, and end-use industries, enabling targeted strategic planning and market analysis. This segmentation helps stakeholders identify specific growth areas, competitive landscapes, and evolving consumer demands. The market's structure reflects the specialized performance attributes of these copolymers, which are tailored to meet rigorous industry standards and application-specific requirements. Understanding these segments is crucial for manufacturers to optimize their product portfolios, for distributors to manage their supply chains effectively, and for investors to gauge market potential and risks.

- By Type

- EAA Copolymer

- EMAA Copolymer

- By Application

- Packaging

- Food Packaging

- Industrial Packaging

- Medical Packaging

- Adhesives

- Hot Melt Adhesives

- Laminating Adhesives

- Pressure Sensitive Adhesives

- Powder Coatings

- Ink & Toners

- Barrier Layers

- Cable Jacketing

- Others (e.g., footwear components, tie layers in multi-layer films)

- Packaging

- By End-Use Industry

- Food & Beverage

- Automotive

- Pharmaceutical & Medical

- Building & Construction

- Consumer Goods

- Electrical & Electronics

- Others (e.g., Textiles, Agriculture)

Value Chain Analysis For EAA and EMAA Copolymer Market

The value chain for the EAA and EMAA Copolymer market is a multi-stage process involving raw material sourcing, manufacturing, distribution, and end-use application, each contributing significantly to the final product's value. The upstream segment primarily involves the procurement of key monomers such as ethylene, acrylic acid, and methacrylic acid, which are typically derived from petrochemical sources. Major chemical companies specializing in basic chemicals and petrochemicals play a critical role at this stage, providing the foundational building blocks for copolymer production. The stability and cost-effectiveness of these raw material supplies directly impact the overall profitability and competitiveness of the downstream manufacturers. Managing relationships with these upstream suppliers is crucial for ensuring a consistent and reliable flow of essential inputs, which often involves long-term contracts and strategic partnerships to mitigate price volatility and supply chain disruptions.

The midstream of the value chain is dominated by EAA and EMAA copolymer manufacturers who convert the raw monomers into specialized polymer resins through polymerization processes. These manufacturers invest heavily in advanced R&D to develop a diverse portfolio of copolymers with varying properties, molecular weights, and melt flow rates, catering to specific application requirements. This stage involves complex chemical engineering, quality control, and process optimization to ensure high-performance and consistent product quality. Innovation in manufacturing techniques, such as continuous polymerization and reactor design, is crucial for efficiency and cost-effectiveness. Post-production, these resins are often processed into pellets, powders, or dispersions, ready for further conversion or direct use by downstream industries, which is often facilitated by a sophisticated network of distribution channels.

Downstream, the value chain encompasses various converters and product manufacturers who utilize EAA and EMAA copolymers in their end products. This includes packaging companies that extrude films, laminates, and coatings; adhesive manufacturers that formulate hot-melt, pressure-sensitive, and laminating adhesives; and powder coating producers. Distribution channels can be both direct and indirect. Direct distribution involves manufacturers selling directly to large industrial customers or key strategic partners, enabling closer collaboration and customized solutions. Indirect channels involve a network of distributors, agents, and specialized resellers who facilitate market penetration, especially in fragmented markets or for smaller customers. These intermediaries often provide technical support, inventory management, and logistical services, playing a vital role in connecting manufacturers with a broad base of end-users across diverse geographic regions and industry sectors. The efficiency of these distribution networks is paramount for market reach and customer satisfaction.

EAA and EMAA Copolymer Market Potential Customers

The EAA and EMAA Copolymer market serves a wide array of potential customers across various industries, driven by the unique performance characteristics of these materials, including superior adhesion, toughness, and barrier properties. Primarily, the food and beverage packaging industry represents a significant customer base. Companies involved in manufacturing flexible packaging, aseptic cartons, and barrier films for perishable goods are key buyers, leveraging these copolymers for enhanced seal integrity, moisture resistance, and extended shelf life of products. The demand from this sector is consistently high due to global population growth, evolving consumer dietary habits, and the increasing need for safe and durable food preservation solutions, which directly translates to a continuous need for advanced packaging materials.

Another major segment of potential customers includes manufacturers within the automotive industry. These companies utilize EAA and EMAA copolymers in applications such as automotive composites, protective coatings, and specialized adhesives for interior and exterior components. The push for lightweighting vehicles to improve fuel efficiency and reduce emissions, coupled with the need for high-performance bonding solutions, makes these copolymers indispensable. Furthermore, the pharmaceutical and medical packaging sectors constitute a critical customer base, demanding materials that offer excellent barrier properties, chemical inertness, and sterilization compatibility for drug delivery systems, medical devices, and sterile packaging, where product safety and integrity are non-negotiable standards.

Beyond these core industries, the building and construction sector is a growing customer, using these copolymers in specialized adhesives for flooring, roofing membranes, and protective coatings for structural elements. The consumer goods industry, encompassing footwear, sports equipment, and various household items, also presents a substantial market, leveraging the flexibility, adhesion, and durability of EAA and EMAA copolymers. Moreover, the electrical and electronics sector relies on these materials for cable jacketing and protective layers, offering insulation and mechanical protection. These diverse end-users are continually seeking innovative material solutions to enhance product performance, durability, and sustainability, solidifying the market for EAA and EMAA copolymers across a broad spectrum of industrial and consumer applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dow Chemical, DuPont, LyondellBasell, ExxonMobil, Arkema, SK Global Chemical, Westlake Chemical, Nippon Gohsei, Mitsubishi Chemical, Mitsui Chemicals, Hanwha Total Petrochemical, Tosoh Corporation, Celanese, Kuraray, Sipchem (Saudi International Petrochemical Company), Eastman Chemical, LG Chem, Braskem, Formosa Plastics, BASF SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

EAA and EMAA Copolymer Market Key Technology Landscape

The EAA and EMAA Copolymer market's technological landscape is characterized by continuous innovation aimed at enhancing material performance, improving production efficiency, and addressing sustainability goals. Core technologies revolve around advanced polymerization techniques, primarily high-pressure free radical polymerization, which allows for precise control over molecular weight distribution, comonomer content, and degree of branching, thereby tailoring the final copolymer properties for specific applications. Recent advancements include solution polymerization and emulsion polymerization methods that offer greater versatility in producing different forms of copolymers, such as dispersions and emulsions, which are critical for applications like coatings and adhesives. The focus is increasingly on developing process technologies that minimize energy consumption and reduce waste generation, aligning with environmental responsibility.

Another crucial aspect of the technology landscape involves post-processing and modification techniques. This includes compounding technologies that integrate various additives, fillers, and other polymers to create specialized blends with enhanced properties like UV resistance, flame retardancy, or improved processability. Surface modification technologies, such as plasma treatment or chemical grafting, are also gaining traction to further optimize adhesion characteristics to difficult substrates. Furthermore, the development of multi-layer co-extrusion and lamination technologies is vital, enabling the creation of complex film structures where EAA and EMAA copolymers act as indispensable tie layers or sealant layers, providing superior barrier properties and structural integrity in packaging applications.

The future of the EAA and EMAA Copolymer technology landscape is largely driven by sustainable chemistry and digitalization. There is a strong technological push towards the development of bio-based monomers for EAA and EMAA production, utilizing renewable resources to reduce reliance on petrochemicals and improve the environmental footprint of the copolymers. Additionally, the integration of advanced analytics, computational chemistry, and AI/ML (Artificial Intelligence/Machine Learning) in material design and process optimization is rapidly transforming the R&D cycle. These digital technologies enable faster screening of new formulations, predictive modeling of material performance, and optimization of manufacturing parameters, leading to accelerated product innovation and more efficient, cost-effective production of next-generation EAA and EMAA copolymers.

Regional Highlights

- Asia Pacific: Dominates the market due to rapid industrialization, burgeoning population, and significant investments in packaging, automotive, and construction sectors, particularly in China, India, and Southeast Asian countries.

- North America: A mature market characterized by stringent environmental regulations, driving demand for sustainable packaging solutions and high-performance adhesives in automotive and pharmaceutical industries.

- Europe: Exhibits robust growth driven by stringent regulatory frameworks promoting eco-friendly materials, coupled with strong demand from the automotive, construction, and advanced packaging sectors.

- Latin America: Emerging as a growth region, fueled by increasing industrialization, infrastructure development, and expanding consumer markets, particularly in Brazil and Mexico.

- Middle East & Africa (MEA): Shows high potential due to diversification of economies, growing manufacturing base, and increasing demand for specialized packaging and construction materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the EAA and EMAA Copolymer Market.- Dow Chemical

- DuPont

- LyondellBasell

- ExxonMobil

- Arkema

- SK Global Chemical

- Westlake Chemical

- Nippon Gohsei

- Mitsubishi Chemical

- Mitsui Chemicals

- Hanwha Total Petrochemical

- Tosoh Corporation

- Celanese

- Kuraray

- Sipchem (Saudi International Petrochemical Company)

- Eastman Chemical

- LG Chem

- Braskem

- Formosa Plastics

- BASF SE

Frequently Asked Questions

What are the primary applications of EAA and EMAA copolymers?

EAA and EMAA copolymers are primarily used in high-performance packaging (food, medical, industrial), adhesives (hot melt, laminating), powder coatings, ink and toner formulations, barrier layers, and cable jacketing due to their excellent adhesion, toughness, and barrier properties.

How do EAA and EMAA copolymers contribute to sustainable packaging?

These copolymers enhance packaging durability and seal integrity, which reduces food waste. They also facilitate the creation of mono-material or recyclable multi-layer structures, and ongoing research focuses on developing bio-based or recycled content versions, supporting sustainability goals.

What are the key market drivers for EAA and EMAA copolymers?

Key drivers include the growing demand for high-performance and sustainable packaging, increasing adoption in automotive lightweighting, expansion of the food and beverage industry, and rising use in advanced powder coatings and adhesive formulations.

What role does innovation play in the EAA and EMAA copolymer market?

Innovation is crucial for developing bio-based copolymers, enhancing specific properties like adhesion and barrier performance, improving processing efficiency, and creating new applications, ensuring market competitiveness and addressing evolving industry needs.

Which regions are currently leading the EAA and EMAA copolymer market?

The Asia Pacific region currently leads the EAA and EMAA copolymer market due to rapid industrialization and significant growth in manufacturing sectors. North America and Europe also hold substantial market shares driven by advanced industrial applications and sustainability initiatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager