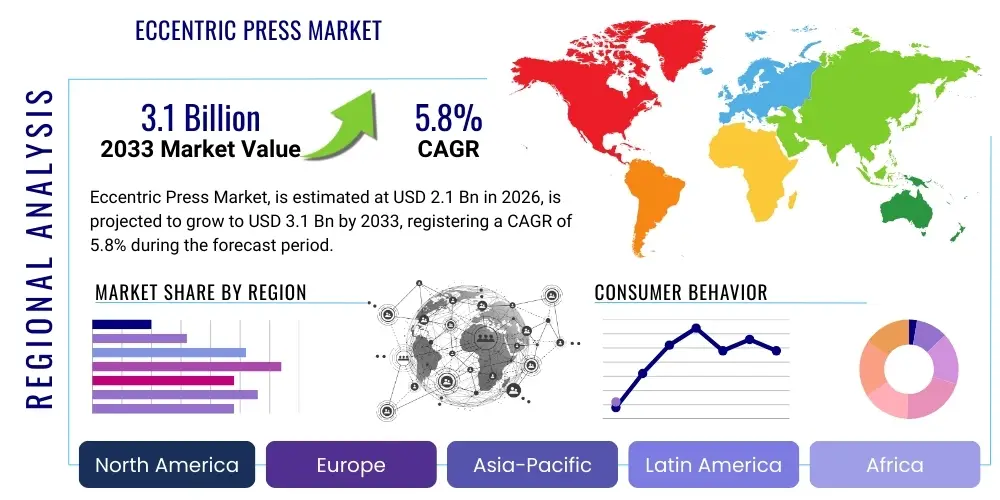

Eccentric Press Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438795 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Eccentric Press Market Size

The Eccentric Press Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $2.1 Billion in 2026 and is projected to reach $3.1 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by the increasing demand for high-speed stamping and precision metal forming across key industrial sectors, particularly automotive and electronics manufacturing. The inherent mechanical robustness and speed advantages of eccentric presses over hydraulic alternatives in specific high-volume applications solidify their market position. Investment in modernization and automation within mature industrial economies further fuels this expansion.

Eccentric Press Market introduction

The Eccentric Press Market encompasses machinery critical for metal forming operations such as stamping, punching, blanking, and deep drawing. Eccentric presses, often referred to as mechanical power presses, utilize a crankshaft mechanism—driven by an eccentric wheel—to convert rotary motion into high-force linear motion, providing rapid, consistent force delivery at a precise point in the stroke. This design makes them indispensable for high-volume, repetitive production lines where speed and reproducibility are paramount. These machines range from small bench-top models used for precision electronics components to large-tonnage presses employed in automotive frame production.

Major applications of eccentric presses span diverse manufacturing verticals. In the automotive industry, they are essential for producing body panels, internal engine components, and structural parts. The electrical and electronics sectors rely heavily on them for forming connectors, heat sinks, and enclosure parts, necessitating extreme precision and minimal tolerance deviation. Furthermore, the construction and appliance industries utilize these presses for manufacturing brackets, fasteners, and housing components. The primary benefit these machines offer is high production speed, coupled with operational efficiency and lower long-term maintenance costs compared to complex hydraulic systems, especially in applications requiring impact force rather than sustained pressure.

The market is primarily driven by rapid industrialization in emerging economies and the global push toward automated manufacturing processes (Industry 4.0). Key driving factors include the lightweighting trend in automotive manufacturing, increasing global demand for sophisticated electronic devices, and the continuous need for complex, high-precision stamped parts. Ongoing technological innovations, such as the integration of servo-driven mechanisms and advanced safety features, are making eccentric presses more versatile and appealing to manufacturers looking to upgrade aging equipment and enhance operational safety compliance across their production lines.

Eccentric Press Market Executive Summary

The Eccentric Press Market exhibits robust growth, underpinned by fundamental business trends centered on automation and energy efficiency. Manufacturers are increasingly integrating eccentric presses with auxiliary equipment, such as coil feeding systems and robotic arms, to achieve fully automated stamping lines, thereby reducing labor costs and enhancing throughput. A significant trend involves the migration from traditional fixed-stroke mechanical presses to advanced servo-mechanical presses, which offer programmable stroke customization, optimizing energy usage and material flow for complex materials like high-strength steel (HSS) and aluminum alloys. Supply chain resilience, following recent global disruptions, is pushing manufacturers to invest domestically, stimulating localized market growth and equipment procurement.

Regionally, the Asia Pacific (APAC) dominates the market, largely driven by the colossal manufacturing bases in China, India, and Southeast Asian nations, particularly within the electronics and electric vehicle (EV) automotive sectors. North America and Europe demonstrate growth fueled by the need for equipment modernization and strict regulatory requirements mandating advanced safety features (e.g., safety light curtains and dual-channel monitoring systems) in existing press installations. European markets emphasize precision and sustainability, prompting investment in high-efficiency, low-noise eccentric press models that comply with stringent environmental standards. The focus in these mature markets is often on technological upgrades rather than sheer volume expansion.

Segment trends reveal a pronounced shift toward higher tonnage capacity presses (above 200 tons) due to the increasing size and complexity of components required in heavy industry and large-format automotive stamping. The C-frame press segment maintains a leading market share due to its flexibility and lower initial cost, making it popular among small and medium enterprises (SMEs). However, the H-frame (or straight-side) press segment is growing faster, driven by large manufacturers requiring maximum rigidity, minimized deflection, and greater precision for long, progressive die setups. Furthermore, the adoption rate of automatic eccentric presses is accelerating significantly across all regions as manufacturers strive for lights-out manufacturing capabilities.

AI Impact Analysis on Eccentric Press Market

User queries regarding AI's influence on the Eccentric Press Market frequently revolve around how AI can enhance uptime, predict failures, and optimize complex stamping parameters for new, lightweight materials. Key concerns include the feasibility of integrating expensive AI solutions into legacy equipment and the required data infrastructure. Users seek practical applications of machine learning in reducing material waste, automating quality inspection through vision systems, and dynamically adjusting press settings (like speed profiles or shut height) in real-time based on material elasticity and thermal conditions. The underlying expectation is that AI will transform eccentric presses from mechanical workhorses into intelligent, self-optimizing manufacturing centers.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is set to revolutionize the operational lifespan and efficiency of eccentric presses. AI primarily enables predictive maintenance by analyzing vibration, temperature, and lubrication data streams gathered via Industrial IoT (IIoT) sensors. This allows manufacturers to schedule maintenance precisely before component failure, maximizing uptime and reducing unexpected catastrophic breakdowns that are extremely costly in high-volume production lines. Furthermore, AI-powered vision systems are being deployed for 100% inline quality inspection, immediately identifying minor defects in stamped parts (such as micro-cracks or burrs) that human inspectors might miss, ensuring superior output quality.

Beyond maintenance and quality control, AI is crucial for optimizing the complex stamping process itself. Digital twin technology, driven by ML models, simulates the deformation process under varying operational parameters, helping engineers determine the ideal eccentric profile and speed curve for specific materials and die geometry. This simulation drastically reduces the time and material wasted during physical die tryouts. The application of AI ensures faster setup times for complex dies, improved energy management by optimizing motor cycling, and higher material utilization rates, directly impacting the manufacturer’s bottom line and promoting sustainable manufacturing practices.

- Predictive Maintenance: AI analyzes sensor data (vibration, temperature, current load) to forecast component failure, maximizing operational uptime.

- Quality Control Automation: Machine vision and AI classification algorithms enable high-speed, 100% automated inspection of stamped parts for defects.

- Parameter Optimization: Machine Learning models optimize stroke rates, shut heights, and feed mechanisms for high-strength or complex materials.

- Energy Efficiency: AI dynamic control systems adjust motor speeds and clutch engagement profiles to minimize energy consumption per part.

- Digital Twin Simulation: Creation of virtual models to predict material behavior and tooling stress, reducing physical prototyping and tryout costs.

DRO & Impact Forces Of Eccentric Press Market

The Eccentric Press Market dynamic is shaped by strong growth drivers stemming from industrial expansion and technological necessity, balanced by significant operational and financial restraints, while sustained opportunities emerge from automation and emerging material science. The dominant drivers include the relentless global expansion of automotive and electronics production, which necessitates high-speed, repeatable stamping processes. Restraints often center on high initial capital investment required for large-tonnage presses and the increasing operational complexity linked to integrating these machines into modern, networked factories. The greatest opportunities lie in the modernization of legacy equipment fleets, particularly through retrofitting with IIoT sensors and servo controls, and the development of tailored presses capable of handling new, lightweight, and complex alloys (e.g., advanced high-strength steel or carbon fiber composites), which require precise force application and control.

Drivers: The paramount driver is the rising demand for high-precision, deep-drawn, and stamped metal components driven by global vehicle lightweighting trends. Manufacturers require presses capable of high repeatability and consistent tonnage application at high speeds to meet strict mass production quotas. The continuous growth of consumer electronics, necessitating billions of small, highly accurate stamped components like battery contacts and shielding components, further accelerates demand. Additionally, labor cost optimization pressures compel companies, particularly in mature markets, to invest in fully automated press lines to reduce human intervention and increase operational safety, creating a demand cycle for technologically advanced eccentric presses with integrated automation features.

Restraints: Significant restraints include the substantial initial capital expenditure required to procure and install heavy-duty eccentric presses, which can deter smaller manufacturers or those operating in volatile economies. Furthermore, the implementation of stringent safety standards (such as OSHA and CE directives) demands continuous investment in safety features like integrated light curtains, interlocking guards, and ergonomic material handling solutions, increasing the total cost of ownership. The technical skills gap—a shortage of technicians capable of maintaining and programming complex, digitally integrated servo-mechanical eccentric presses—also acts as a crucial bottleneck in adoption, particularly in regions lacking specialized industrial training infrastructure.

Opportunities: Major opportunities reside in the advancement of servo press technology, which allows for unparalleled control over the ram motion profile, enabling complex stamping operations previously limited to hydraulic or specialized fine-blanking presses. The aftermarket services sector presents a strong opportunity, focusing on retrofitting older mechanical presses with modern controls, sensors, and safety features, extending their useful life. Lastly, the growth of localized, high-value manufacturing in countries seeking supply chain independence offers opportunities for press manufacturers to establish regional service and manufacturing hubs, catering directly to specific local material handling and regulatory requirements, such as those related to noise and energy consumption.

Segmentation Analysis

The Eccentric Press Market is extensively segmented based on key structural, operational, and performance characteristics, allowing manufacturers to precisely match equipment capabilities to application requirements. Key segmentation criteria include the frame type (H-frame vs. C-frame), which defines rigidity and accessibility; the mechanism (Standard Mechanical vs. Servo Mechanical), influencing speed and control; and the tonnage capacity, determining the press's maximum force application. Understanding these segments is crucial as industrial requirements shift, particularly with the growth of complex automotive components necessitating high-tonnage, high-precision H-frame servo presses, while smaller fabrication shops still rely heavily on the accessible C-frame design for general-purpose stamping and punching tasks.

The segmentation by automation level (manual, semi-automatic, automatic) strongly reflects investment trends, with the automatic segment experiencing the fastest growth globally due to the push for efficiency and reduced labor costs. End-user industry segmentation highlights the dominance of the automotive sector, followed closely by electrical and general metalworking. Each segment demands tailored press features; for example, automotive requires large beds and rapid die change systems, whereas the electronics segment needs high-speed, precise mechanisms suitable for miniature components. This diverse demand structure necessitates a customized approach by press manufacturers, offering solutions optimized for material handling, speed, and overall structural integrity tailored to specific industrial needs.

- By Tonnage Capacity:

- Up to 100 Tons

- 100 Tons to 200 Tons

- 200 Tons to 500 Tons

- Above 500 Tons

- By Frame Type:

- C-Frame (Open Back Inclinable)

- H-Frame (Straight Side)

- By Operation Mode:

- Manual

- Semi-Automatic

- Automatic (Fully Automated Lines)

- By Technology:

- Standard Mechanical Press (Flywheel)

- Servo Mechanical Press (Direct Drive)

- By End-Use Industry:

- Automotive

- Electrical & Electronics

- Aerospace & Defense

- General Metalworking & Fabrication

- Appliances & Consumer Goods

Value Chain Analysis For Eccentric Press Market

The value chain for the Eccentric Press Market begins with the highly specialized procurement of raw materials, primarily high-grade steel and iron castings, which form the structural components of the press frame, crankshaft, and critical mechanical systems. Upstream activities involve precision machining of these large components to exacting tolerances, ensuring the rigidity and longevity required for high-force operations. Suppliers of specialized components, such as high-torque motors, clutch and brake systems (often pneumatic or hydraulic), and electronic control units (PLCs and HMI interfaces), play a critical role, contributing significantly to the final performance and cost of the machine. The integration of advanced servo drives and safety systems has intensified the reliance on specialized technology suppliers in the upstream segment, making supplier relationship management crucial for press manufacturers.

The core manufacturing stage involves the complex assembly of the press structure, the installation of the eccentric drive mechanism, and the integration of control software and auxiliary features. This phase is highly capital-intensive and requires skilled labor for calibration and alignment. Downstream activities focus heavily on distribution and post-sales support. Distribution channels are typically a mix of direct sales teams for large, complex installations (especially to Tier 1 automotive suppliers) and indirect distribution through specialized industrial machinery dealers and agents for smaller presses aimed at general fabrication workshops. These distributors often provide localized installation and training services.

Post-sales service represents a significant value addition. Direct and indirect channels are both essential here, offering maintenance, spare parts, tooling design consultation, and system retrofitting services. Given the long operational lifespan of eccentric presses, recurring revenue from maintenance and parts replacement is substantial. Furthermore, the current trend toward IIoT integration means press manufacturers are increasingly offering remote diagnostics and software update packages, further deepening the direct relationship between the manufacturer and the end-user, enhancing value capture throughout the machine's entire life cycle.

Eccentric Press Market Potential Customers

Potential customers for eccentric presses are predominantly large-scale manufacturing enterprises and specialized job shops that require high-speed, repetitive stamping and forming operations. The largest segment of end-users is the automotive industry, encompassing original equipment manufacturers (OEMs) and their extensive network of Tier 1 and Tier 2 suppliers who utilize presses for everything from structural body components (doors, hoods, chassis parts) to specialized internal components (clutch plates, brackets). These customers demand high tonnage, automation integration, and precise control capabilities to handle modern, high-strength materials while meeting strict quality and throughput targets.

Beyond automotive, the electrical and electronics industry constitutes a growing customer base, focused on precision and speed for small component manufacturing. This includes companies producing semiconductors, consumer appliance casings, electrical switchgear, and complex wiring connectors. These users typically favor smaller, high-speed eccentric presses with exceptional accuracy to ensure minimal material waste and tight dimensional control. General metalworking and fabrication shops form a third major customer group, using versatile C-frame presses for general punching, blanking, and forming tasks across diverse industries, including HVAC, agricultural equipment, and construction hardware, emphasizing reliability and adaptability across various job specifications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.1 Billion |

| Market Forecast in 2033 | $3.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schuler AG, AIDA Engineering Ltd., Stamtec Inc., Komatsu Industries Corp., AMADA Co., Ltd., Chin Fong Machine Industrial Co., Ltd., JFY International, Providence Machine, Hitachi Zosen Corporation, Seyi Presses (Shieh Yih), SMS Group GmbH, Danly, Mueller Weingarten, Nidec Shimpo, Santec Group, Dalian Machine Tool Group (DMTG), Samho Press, Yangli Group, Qiaosen Press, Mecanismos Auxiliares Industriales S.A. (MAI) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Eccentric Press Market Key Technology Landscape

The technology landscape of the Eccentric Press Market is rapidly evolving, moving away from purely mechanical systems toward digitally controlled, integrated electro-mechanical solutions. The single most transformative technology is the incorporation of servo motors and direct-drive mechanisms, resulting in the "Servo Mechanical Press." Unlike traditional presses relying on a fixed-stroke flywheel design, servo presses allow the ram speed and position to be precisely controlled throughout the entire stroke. This programmability enables complex stamping sequences, such as pendulum motion for efficiency or slow, high-force application for deep drawing, significantly expanding the material and process capabilities of the eccentric press.

Another crucial technological development involves advanced control and safety systems. Modern eccentric presses utilize sophisticated Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) that integrate fully with feeding equipment, robotics, and safety features like non-contact guarding and dual-channel safety circuits, meeting stringent global safety standards. Furthermore, the integration of quick die change (QDC) systems, including hydraulic clamping, rolling bolsters, and automated die storage, drastically reduces downtime between production runs, enhancing overall equipment effectiveness (OEE), a key performance metric for high-volume manufacturers. These QDC systems are essential for industries with diversified product portfolios.

The penetration of Industry 4.0 concepts is driving the integration of IIoT sensors into every critical press component, monitoring lubrication flow, bearing temperatures, motor load, and vibration signatures. This connectivity forms the foundation for AI-driven predictive maintenance, moving maintenance from a reactive to a proactive function. Enhanced digital monitoring not only improves reliability but also facilitates process optimization. Additionally, new tooling materials and designs, coupled with dynamic cushion systems (hydraulic or pneumatic) integrated into the press bed, ensure better control over blank holding force, minimizing wrinkling and tearing when working with demanding, thin-gauge high-strength materials, critical for the automotive sector's lightweighting strategy.

Regional Highlights

The global Eccentric Press Market exhibits distinct regional characteristics driven by localized industrial policies, labor costs, and technological maturity.

- Asia Pacific (APAC): Dominates the market share due to its status as the world's leading manufacturing hub for automotive components (especially electric vehicles) and consumer electronics. Countries like China, India, and South Korea are experiencing massive infrastructure investment, leading to high-volume installations of both traditional C-frame presses for general metalworking and high-tonnage H-frame presses for automotive Tier 1 suppliers. High growth rates are sustained by aggressive industrial automation adoption, although competition is intense among local and international press manufacturers.

- North America: Characterized by a strong emphasis on modernization and high-end servo press technology. Growth here is focused on replacing aging equipment fleets and adhering to rigorous safety regulations, driving demand for technologically advanced, often custom-built, high-precision presses. The automotive and aerospace sectors are the primary demand generators, demanding superior material handling capabilities for specialized alloys used in lightweight structures.

- Europe: Exhibits steady growth, focusing heavily on precision engineering, energy efficiency, and compliance with strict environmental and safety standards (CE marking). European manufacturers prioritize the adoption of servo-mechanical presses for their control, flexibility, and reduced energy footprint. Germany, Italy, and Eastern European countries, with their strong automotive and machinery sectors, are key contributors, favoring integration with sophisticated automation and robotic cells.

- Latin America (LATAM): This region shows moderate growth, primarily centered in Mexico and Brazil, driven by their respective automotive assembly and manufacturing bases. Investment tends to be constrained by economic volatility, leading to a higher demand for cost-effective, reliable standard mechanical presses and used machinery, though there is a gradual shift toward integrating more modern, safer equipment.

- Middle East and Africa (MEA): Represents the smallest but fastest-growing market, largely fueled by diversification efforts beyond oil and gas, focusing on localized general manufacturing, infrastructure development, and defense manufacturing. Demand is project-based and often requires robust, easy-to-maintain equipment suitable for diverse operational environments, with Turkey and Saudi Arabia being key investment hubs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Eccentric Press Market.- Schuler AG

- AIDA Engineering Ltd.

- Stamtec Inc.

- Komatsu Industries Corp.

- AMADA Co., Ltd.

- Chin Fong Machine Industrial Co., Ltd.

- JFY International

- Providence Machine

- Hitachi Zosen Corporation

- Seyi Presses (Shieh Yih)

- SMS Group GmbH

- Danly

- Mueller Weingarten

- Nidec Shimpo

- Santec Group

- Dalian Machine Tool Group (DMTG)

- Samho Press

- Yangli Group

- Qiaosen Press

- Mecanismos Auxiliares Industriales S.A. (MAI)

Frequently Asked Questions

Analyze common user questions about the Eccentric Press market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a servo eccentric press over a traditional mechanical press?

The primary advantage of a servo eccentric press is the programmability of the ram motion profile. This allows manufacturers to control the speed and force throughout the stroke, enabling complex stamping operations, better material handling (especially for AHSS), and enhanced energy efficiency compared to the fixed stroke cycle of traditional mechanical presses.

How is Industry 4.0 influencing the Eccentric Press Market?

Industry 4.0 is influencing the market through the integration of IIoT sensors and cloud connectivity, facilitating real-time monitoring, remote diagnostics, and AI-driven predictive maintenance, which significantly boosts Overall Equipment Effectiveness (OEE) and reduces unexpected downtime in stamping operations.

Which industry segment drives the highest demand for high-tonnage eccentric presses?

The automotive industry drives the highest demand for high-tonnage eccentric presses (typically above 200 tons). These presses are essential for stamping large, complex components such as body panels, structural frame elements, and specialized deep-drawn parts required for modern vehicle manufacturing.

What are the key safety features required for modern eccentric presses?

Key safety features include integrated safety light curtains or laser scanners, dual-channel electronic safety circuits, interlocking guards, centralized lubrication systems monitored for pressure, and advanced control systems that ensure rapid stopping mechanisms (clutch/brake) are functional to comply with standards like OSHA and CE directives.

Is the C-Frame or H-Frame eccentric press design more suitable for progressive die applications?

The H-Frame (Straight Side) design is significantly more suitable for progressive die applications, especially those requiring high tonnage. Its four-post structure provides superior rigidity, minimizes frame deflection under load, and offers better parallelism necessary for maintaining the integrity and precision of long, multi-stage progressive dies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager