Eddy Current Separator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435308 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Eddy Current Separator Market Size

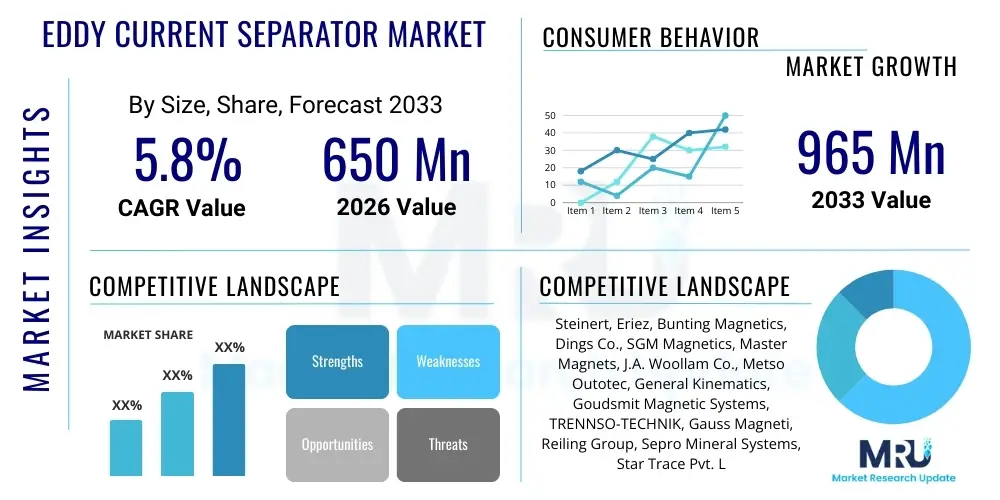

The Eddy Current Separator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 965 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by stringent global environmental regulations mandating higher recycling rates for municipal solid waste (MSW) and industrial scrap. The inherent efficiency of Eddy Current Separators (ECS) in recovering high-purity non-ferrous metals, such as aluminum and copper, positions them as indispensable assets in modern material recovery facilities (MRFs) and recycling operations worldwide. Investment in infrastructure upgrades and the expansion of e-waste processing capabilities further bolster this optimistic market forecast.

Eddy Current Separator Market introduction

The Eddy Current Separator Market encompasses the manufacturing, distribution, and utilization of advanced machinery designed to separate non-ferrous metals from bulk waste streams, relying on electromagnetic principles. ECS machines utilize a high-speed magnetic rotor spinning inside a non-metallic drum shell, generating powerful, rapidly alternating magnetic fields. As conductive non-ferrous materials pass over the drum, these fields induce eddy currents within the metal particles. These induced currents create temporary magnetic fields that oppose the primary magnetic field, resulting in a repulsive force that flings the metal away from the bulk material stream, thereby achieving efficient separation.

Major applications of ECS technology span across diverse industrial sectors, predominantly including municipal solid waste recycling, construction and demolition (C&D) waste processing, end-of-life vehicle (ELV) shredding residue recovery, and specialized e-waste recycling. The primary benefit derived from deploying ECS units is the enhanced purity of recovered materials, which significantly increases their market value. Furthermore, these systems contribute directly to landfill diversion goals and resource conservation, meeting growing demands for circular economy practices. Key driving factors propelling market expansion include rising global metal commodity prices, government incentives for sustainable waste management, and continuous technological advancements in rotor design and magnetic strength, which improve separation yield even for finer particulate sizes.

The product portfolio within the market ranges from large, heavy-duty separators used in scrap yards processing thousands of tons daily, to smaller, highly specialized units tailored for specific high-value applications like electronics recycling. The increasing complexity of mixed waste streams necessitates highly flexible and precise separation technologies. ECS systems offer a robust solution for extracting valuable non-ferrous components, which are often difficult or impossible to separate using traditional mechanical or gravity-based methods. This essential functionality solidifies the ECS as a core technology in maximizing material recovery rates across the globe.

Eddy Current Separator Market Executive Summary

The Eddy Current Separator market is undergoing robust expansion driven by stringent environmental compliance and high demand for secondary non-ferrous metals. Business trends indicate a strong move toward integrated solutions, where ECS units are bundled with sensor-based sorting (SBS) and artificial intelligence (AI) systems to optimize throughput and material purity. Key manufacturers are focusing on developing eccentric pole systems for enhanced separation efficiency and offering modular, scalable units that can be easily integrated into existing recycling infrastructure. Furthermore, there is a distinct trend towards the leasing and service-oriented business models, reducing the initial capital expenditure burden for smaller Material Recovery Facilities (MRFs), thus accelerating technology adoption across emerging markets.

Regionally, North America and Europe currently dominate the market due to established recycling infrastructures, supportive regulatory frameworks such as the European Union’s Waste Framework Directive, and high public awareness regarding sustainable resource management. However, the Asia Pacific (APAC) region is projected to register the highest growth rate during the forecast period. This accelerated growth in APAC is attributed to massive infrastructure development, escalating industrial waste generation, and governmental initiatives, particularly in China and India, aimed at phasing out uncontrolled waste dumping in favor of formalized, high-efficiency recycling processes. The Middle East and Africa (MEA) are also showing promising potential, driven by significant investments in the oil and gas sector decommissioning and municipal waste treatment plants.

Segment trends reveal that the eccentric rotor type segment maintains a leading market share due to its superior capability in handling varying particle sizes and achieving higher non-ferrous metal purity compared to concentric models. Application-wise, the waste recycling segment, encompassing MSW and C&D waste, remains the largest revenue generator. However, the specialized e-waste and automotive recycling segments are expected to exhibit the fastest growth, primarily because of the increasing volume and complexity of electronic and end-of-life vehicle materials, which contain high concentrations of valuable non-ferrous metals requiring highly efficient separation techniques like ECS.

AI Impact Analysis on Eddy Current Separator Market

Common user questions regarding AI's impact on the Eddy Current Separator Market frequently revolve around quantifying improvements in sorting precision, the potential for autonomous optimization of machine settings, and the integration costs associated with deploying machine learning algorithms on existing equipment. Users are keen to understand how AI can help differentiate between complex, layered materials that traditionally challenge standard electromagnetic separation, and whether AI integration facilitates proactive predictive maintenance to minimize costly downtime. Analysis reveals that the key themes are focused on leveraging AI for real-time adjustments of rotor speed and belt trajectories based on feed composition variability, thereby maximizing recovery rates and purity levels previously unattainable by fixed-setting ECS systems alone. User expectations are high regarding AI’s ability to turn raw ECS data into actionable operational insights.

- AI-powered sensor fusion (combining ECS output with vision systems) dramatically enhances the differentiation of non-ferrous metal types (e.g., distinguishing copper from aluminum).

- Machine learning algorithms enable real-time, dynamic adjustments of rotor speed and magnetic field intensity based on input material density and flow rate, optimizing separation efficiency.

- Predictive maintenance analytics, driven by AI monitoring of rotor vibrations and bearing temperature, significantly reduces unplanned operational downtime.

- AI facilitates automatic quality control by continuously analyzing the purity of the separated stream and flagging inconsistencies, minimizing human error.

- Optimization of energy consumption by adjusting machine operations based on actual load and required separation purity, contributing to lower operational expenditure.

DRO & Impact Forces Of Eddy Current Separator Market

The Eddy Current Separator Market is dynamically shaped by a strong interplay of drivers, regulatory constraints, and technological opportunities, summarized in the DRO framework. A primary driver is the global imposition of stringent waste management regulations, particularly those focusing on achieving high material recycling targets and minimizing landfill use. This regulatory push forces industries, including construction, automotive dismantling, and consumer electronics recycling, to invest in high-efficiency separation technologies like ECS. Furthermore, the increasing volatility and value of secondary raw materials, especially aluminum and copper, provide significant financial incentives for maximizing recovery purity, driving capital investment into advanced ECS systems that offer superior separation precision.

Restraints primarily revolve around the high initial capital investment required for purchasing and installing sophisticated ECS units, which can pose a barrier to entry for smaller or regional recycling facilities. Operational challenges also exist, including the difficulty of efficiently separating very fine non-ferrous particulates (typically below 5mm) and managing maintenance costs associated with high-speed rotors and powerful magnetic assemblies. The market also faces technical restraints related to the sensitivity of ECS performance to fluctuations in feed material homogeneity and moisture content, necessitating expensive pre-processing steps.

Conversely, significant opportunities are emerging from the burgeoning sectors of e-waste and battery recycling. The high concentration of valuable non-ferrous metals in these waste streams, coupled with their complex structure, demands specialized and highly precise separation solutions. Additionally, the development of customized ECS systems tailored for specific industrial applications, such as separating high-purity aluminum alloys in automotive shredding residue, presents lucrative market avenues. Technological innovations focusing on enhanced magnetic field strength using superconducting magnets and improved sensor integration represent pivotal impact forces that are driving market acceptance and operational efficacy, continuously pushing the boundaries of material recovery potential.

Segmentation Analysis

The Eddy Current Separator Market is extensively segmented based on key operational and application criteria, providing a granular view of market dynamics. Segmentation is critical for understanding specific end-user needs, allowing manufacturers to tailor products for maximum efficiency, whether focusing on high-volume processing in scrap yards or high-purity recovery in specialized waste streams like electronics. The primary segmentation criteria involve the type of magnetic rotor employed, the size of the unit for handling capacity, and the specific application industry, which dictates the required separation precision and robustness of the equipment.

- By Rotor Type:

- Concentric Rotor ECS: Offers a consistent magnetic field across the width of the drum; suitable for smaller particle sizes and lower capacity requirements.

- Eccentric Rotor ECS: Provides a higher concentration of magnetic force over a specific discharge area, resulting in superior separation efficiency and better handling of larger, dense materials; currently the dominant segment.

- By Application:

- Waste Recycling (MSW, C&D Waste, Ash Recycling)

- Mining and Mineral Processing

- Automotive Shredding Residue (ASR)

- E-Waste Recycling

- Plastics and Glass Processing

- By End-User Industry:

- Material Recovery Facilities (MRFs)

- Smelters and Refineries

- Industrial Shredders

- Plastics Recyclers

- By Capacity:

- Low Capacity (Under 5 TPH)

- Medium Capacity (5–20 TPH)

- High Capacity (Above 20 TPH)

Value Chain Analysis For Eddy Current Separator Market

The value chain for the Eddy Current Separator market starts with upstream suppliers providing critical raw materials and components. This stage involves specialized manufacturers of rare-earth magnets (such as Neodymium-Iron-Boron magnets), high-speed bearings, electrical motors, and sophisticated control systems. The quality and magnetic strength of the rare-earth magnets are paramount, directly influencing the performance and cost of the final ECS unit. Manufacturers often secure long-term contracts with these specialized suppliers to ensure a consistent supply of high-grade magnetic components, which represent a significant proportion of the unit's production cost. Fluctuations in rare-earth element markets directly impact the profitability of ECS manufacturers.

The next critical stage is the manufacturing and assembly process, where core competencies in precision engineering and electromagnetic physics are essential. Manufacturers focus on optimizing rotor design—ensuring precise balancing and high-speed stability—and integrating advanced features such as variable frequency drives (VFDs) and real-time monitoring systems. Distribution channels are varied: direct sales are common for large, customized, high-capacity industrial units sold directly to major MRFs or scrap metal processors. Conversely, indirect distribution utilizes specialized distributors and local engineering firms, particularly in geographically dispersed or smaller emerging markets, to handle sales, installation, and after-sales service. These distributors play a crucial role in providing local support and training.

Downstream analysis focuses on the end-users, primarily recycling facilities and industrial operations that integrate the ECS into complex processing lines. The value extracted at this stage is the pure, separated non-ferrous material, which is then sold to smelters and metal refineries. After-sales service, including maintenance contracts, spare parts supply for high-wear components (like conveyor belts and rotor bearings), and operational training, constitutes a significant part of the value chain, ensuring system longevity and sustained high performance. Effective service networks are crucial for maintaining customer satisfaction and minimizing operational downtime, which is highly sensitive in 24/7 recycling operations.

Eddy Current Separator Market Potential Customers

Potential customers for Eddy Current Separators primarily constitute entities involved in large-scale material processing and waste reduction, where the recovery of valuable non-ferrous metals is a critical economic and environmental requirement. The largest segment of buyers consists of Material Recovery Facilities (MRFs) that handle municipal solid waste, seeking to extract aluminum cans and other conductive packaging materials efficiently. These customers prioritize high throughput capacity and low operational complexity, requiring robust, continuous-duty machines capable of handling heterogeneous feed streams.

A rapidly growing customer base includes automotive shredding operators and electronics recyclers. Automotive dismantlers utilize ECS systems to process Automobile Shredder Residue (ASR), recovering valuable copper, brass, and aluminum from the non-metallic mix remaining after ferrous extraction. Similarly, e-waste processors require high-precision ECS units, often integrated with optical sorters, to separate small but highly valuable non-ferrous components from circuit boards and electronic casings. These specialized sectors often demand smaller, higher-precision eccentric rotor systems to maximize recovery yield from complex composite materials.

Other key buyers include construction and demolition (C&D) waste processors, glass recyclers seeking to remove ceramic and metal contaminants, and specialized industrial facilities that produce non-ferrous metal slags or ash requiring processing for resource recovery. For these end-users, the ECS acts as a crucial purification step, ensuring that downstream products meet stringent quality specifications. Geographically, potential customers are concentrated in regions with strict Extended Producer Responsibility (EPR) schemes and high costs for virgin material acquisition, making secondary material recovery economically compelling.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 965 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Steinert, Eriez, Bunting Magnetics, Dings Co., SGM Magnetics, Master Magnets, J.A. Woollam Co., Metso Outotec, General Kinematics, Goudsmit Magnetic Systems, TRENNSO-TECHNIK, Gauss Magneti, Reiling Group, Sepro Mineral Systems, Star Trace Pvt. Ltd., Magnetic Separation Systems (MSS), Wendt Corporation, TOMRA Sorting, Boxmag Rapid, Foshan JCT Machinery. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Eddy Current Separator Market Key Technology Landscape

The core technology landscape of the Eddy Current Separator market is characterized by continual innovation focused on increasing magnetic field strength, enhancing rotor speed stability, and improving material handling efficiency. The transition from older, less efficient permanent magnet materials to high-grade rare-earth magnets, predominantly Neodymium-Iron-Boron (NdFeB), has been pivotal, allowing for stronger magnetic repulsion forces capable of ejecting smaller, denser, and weaker-conducting non-ferrous materials. Furthermore, there is a distinct technological advancement in rotor design, particularly the shift towards optimized eccentric pole configurations, which allows for a more focused and powerful magnetic pulse at the point of discharge, maximizing the separation trajectory and purity of the recovered stream.

Beyond the fundamental magnetic mechanics, modern ECS systems heavily rely on integrated control and monitoring technologies. High-precision sensor systems, often including proximity sensors and load cells, are employed to monitor feed rates and material distribution across the conveyor belt, ensuring optimal machine performance. Variable Frequency Drives (VFDs) are essential components, allowing operators to precisely tune the speed of both the conveyor belt and the magnetic rotor independently. This variable control is crucial for adapting the separation force and throw trajectory to changes in the composition and particle size of the incoming material stream, thereby maximizing overall system efficiency and reducing energy waste associated with fixed-speed operation.

The latest technological evolution integrates ECS units with upstream and downstream processing equipment through advanced digital interfaces and data analytics platforms. This includes the implementation of sensor-based sorting (SBS) technology, such as near-infrared (NIR) or X-ray sensors, positioned before the ECS to precondition the material stream or after the ECS to verify purity. The convergence of these separation mechanisms, often governed by sophisticated AI and machine learning algorithms, allows for the creation of truly automated, closed-loop recycling systems. These technological synergies are defining the competitive edge for leading manufacturers by offering unparalleled purity levels and operational flexibility in handling complex waste matrices like shredded aluminum scrap contaminated with stainless steel or plastics.

Regional Highlights

- North America: This region is characterized by a mature recycling infrastructure and large processing volumes, particularly in the scrap metal and automotive shredding sectors. The market growth is driven by significant investments in upgrading existing Material Recovery Facilities (MRFs) to comply with stricter purity standards imposed by international commodity buyers. The US, with its extensive network of industrial shredders, remains a primary consumer of high-capacity eccentric rotor ECS units.

- Europe: Europe represents a highly regulated market, driven by ambitious circular economy policies and high landfill taxes, making metal recovery economically imperative. Countries such as Germany, the UK, and the Netherlands lead in adopting advanced sorting technologies, often integrating ECS with optical sorters for ultra-high purity recovery from municipal and packaging waste streams. The focus here is on achieving mandated high recycling rates across various complex waste categories.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid urbanization, massive industrial output, and emerging regulatory enforcement across key economies like China, India, and Southeast Asia. The region is seeing substantial governmental investment in new waste processing infrastructure to manage vast quantities of municipal and industrial waste. Demand is strong for both high-volume ECS units for scrap metal and precision units for the massive e-waste processing sector.

- Latin America (LATAM): Growth in LATAM is gradual but accelerating, primarily concentrated in Brazil and Mexico, driven by increasing foreign direct investment in recycling infrastructure and rising awareness of environmental stewardship. The market often favors medium-capacity, robust ECS systems that can handle less pre-sorted waste streams typical of developing infrastructure.

- Middle East and Africa (MEA): This region presents nascent opportunities, particularly in Saudi Arabia and the UAE, where large-scale infrastructure projects and diversification initiatives are leading to the development of modern waste management facilities. The decommissioning of large industrial projects, particularly in the energy sector, also necessitates specialized metal recovery solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Eddy Current Separator Market.- Steinert

- Eriez

- Bunting Magnetics

- Dings Co.

- SGM Magnetics

- Master Magnets

- J.A. Woollam Co.

- Metso Outotec

- General Kinematics

- Goudsmit Magnetic Systems

- TRENNSO-TECHNIK

- Gauss Magneti

- Reiling Group

- Sepro Mineral Systems

- Star Trace Pvt. Ltd.

- Magnetic Separation Systems (MSS)

- Wendt Corporation

- TOMRA Sorting

- Boxmag Rapid

- Foshan JCT Machinery

Frequently Asked Questions

Analyze common user questions about the Eddy Current Separator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary operational difference between concentric and eccentric Eddy Current Separator rotors?

The concentric rotor provides a continuous, consistent magnetic field across the full width of the drum, typically used for smaller or lower-capacity applications. The eccentric rotor (the market leader) shifts the magnetic field concentration towards the end of the drum, creating a stronger, more focused separation force, leading to higher purity recovery and superior performance when handling larger or varied particle sizes.

Which factors most heavily influence the cost-effectiveness of deploying an ECS unit?

The primary factors influencing cost-effectiveness are the initial capital expenditure, the sustained purity percentage of recovered non-ferrous metals (which dictates market value), and the operational downtime. High-purity output significantly increases revenue, quickly offsetting the high initial cost, especially when processing high-value streams like e-waste.

Are Eddy Current Separators capable of separating all types of non-ferrous metals?

ECS systems are highly effective at separating conductive non-ferrous metals such as aluminum, copper, and brass. However, separation efficiency is dependent on the conductivity-to-mass ratio. Weakly conductive or very fine metals may require integrating the ECS with secondary sorting technologies like sensor-based sorters (e.g., XRT or NIR) for optimal recovery.

How is the market addressing the separation challenge presented by small-sized particulate matter?

The market is addressing fine particulate separation through the development of ECS units with smaller diameter, high-speed eccentric rotors and highly focused magnetic fields. Furthermore, integrating pre-screening processes and combining ECS technology with advanced sensor sorting systems ensures that even non-ferrous particles below 5mm are efficiently recovered at high purity levels.

What role do global environmental regulations play in the adoption of ECS technology?

Global environmental regulations, particularly those enforcing strict recycling targets (like the EU's Waste Framework Directive) and imposing high landfill taxes, are the main market drivers. These regulations necessitate highly efficient recovery technologies, making the Eddy Current Separator an essential investment for industries aiming to comply with material recovery mandates and improve resource stewardship.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager