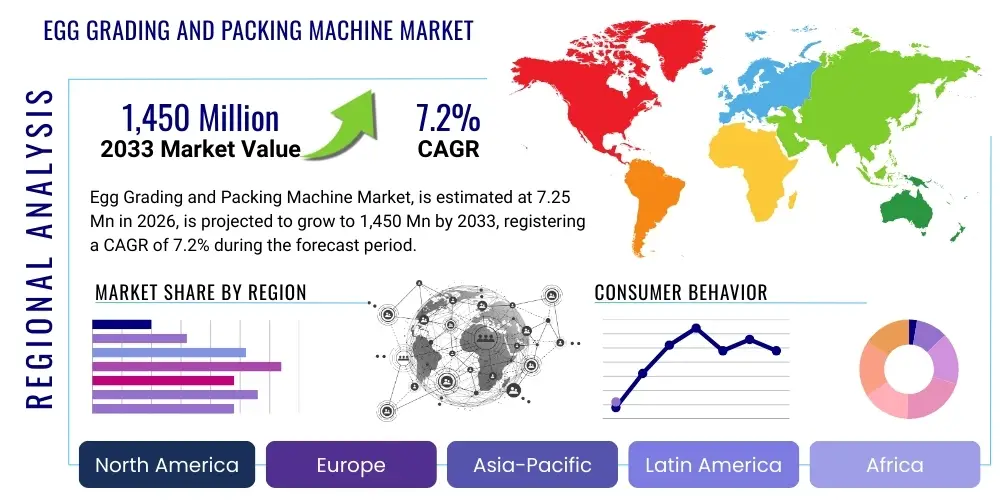

Egg Grading and Packing Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440011 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Egg Grading and Packing Machine Market Size

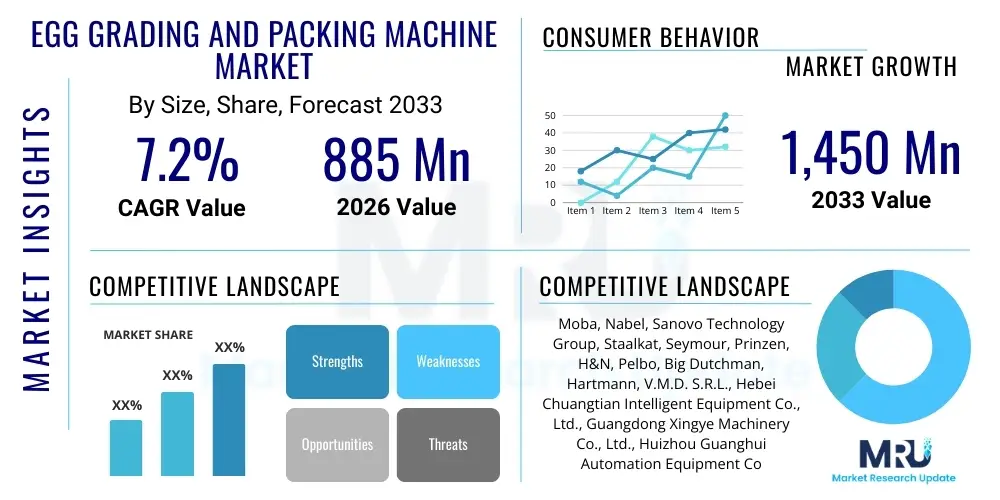

The Egg Grading and Packing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 885 Million in 2026 and is projected to reach USD 1,450 Million by the end of the forecast period in 2033.

Egg Grading and Packing Machine Market introduction

The Egg Grading and Packing Machine Market encompasses the global industry for automated and semi-automated systems designed to sort eggs by size, weight, quality, and then package them efficiently. These machines are crucial for maintaining egg quality, ensuring food safety, and optimizing operational workflows in the poultry industry. The primary product includes advanced machinery equipped with vision systems, precise weighing mechanisms, and gentle handling capabilities, catering to various scales of production from small farms to large commercial egg processing plants. The technological sophistication ranges from basic mechanical sorting to highly integrated systems featuring complex software for data analytics and process optimization. The continuous evolution of these machines focuses on enhancing accuracy, speed, and minimizing egg breakage, which are vital for profitability in a highly competitive market.

Major applications for egg grading and packing machines span across commercial egg production facilities, large poultry farms, and egg processing centers that supply to retail, food service, and industrial ingredient markets. These machines play an indispensable role in preparing eggs for market by ensuring uniformity and compliance with stringent quality standards. They are instrumental in reducing manual labor, thereby mitigating operational costs and increasing throughput significantly. The benefits extend to improved hygiene, consistency in product delivery, and enhanced shelf life through gentler handling and rapid processing. By automating these critical steps, producers can focus on other aspects of farm management and product innovation, contributing to a more streamlined and efficient supply chain.

Driving factors for the market's expansion include the escalating global demand for protein-rich diets, leading to a surge in egg production worldwide. Increased consumer awareness regarding food safety and quality standards further propels the adoption of advanced grading technologies. The rising cost of manual labor, coupled with the need for greater efficiency and automation in agricultural practices, particularly in developing economies, is another significant impetus. Furthermore, stringent government regulations concerning egg classification, sanitation, and packaging across various regions mandate the use of automated systems, pushing producers to invest in modern machinery to ensure compliance and market access. Technological advancements, such as the integration of artificial intelligence and robotics, are also enhancing the capabilities and appeal of these machines, driving their adoption.

Egg Grading and Packing Machine Market Executive Summary

The Egg Grading and Packing Machine Market is experiencing robust growth driven by a confluence of factors including increasing global egg consumption, heightened focus on food safety, and the imperative for operational efficiency in the poultry industry. Business trends indicate a strong move towards full automation and integration, with manufacturers developing systems that offer higher capacities, greater precision in grading, and reduced downtime. This shift is particularly evident in large-scale commercial farms and processing centers looking to optimize their supply chain and meet burgeoning consumer demand. There is also a growing demand for modular and customizable solutions that can adapt to varying production scales and specific regional regulations. Investment in research and development is focused on improving machine vision systems for defect detection, enhancing gentle handling mechanisms to minimize breakage, and integrating data analytics for predictive maintenance and operational insights.

Regional trends reveal significant market expansion in Asia Pacific, particularly in countries like China and India, where growing populations and increasing disposable incomes are fueling demand for eggs. This region is witnessing substantial investments in modernizing poultry infrastructure. North America and Europe, while mature markets, continue to innovate, with a strong emphasis on smart factory concepts, IoT integration, and sustainable practices that reduce energy consumption and waste. Latin America and the Middle East & Africa are emerging as high-growth markets, driven by economic development, urbanization, and a rising per capita consumption of eggs, prompting local producers to adopt automated solutions to scale their operations and meet international quality standards. The competitive landscape varies regionally, with global players dominating the high-capacity, advanced technology segments, while local manufacturers often cater to small to medium-sized operations with cost-effective solutions.

Segmentation trends highlight the dominance of automatic egg grading and packing machines due to their unparalleled efficiency, accuracy, and labor-saving benefits, especially for large-volume producers. The capacity segment is seeing significant growth in machines capable of handling over 30,000 eggs per hour, reflecting the industrialization of egg production. Application-wise, commercial farms and dedicated egg processing centers remain the largest end-users, continuously upgrading their machinery to cope with increasing demand and regulatory pressures. Furthermore, advancements in specific components, such as sophisticated washing and sanitizing systems, are gaining traction as food safety becomes a paramount concern. The market is also witnessing a demand for integrated solutions that combine grading, packing, washing, and even palletizing into a single, seamless operation, providing end-to-end efficiency and reducing the need for multiple vendors and complex system integrations.

AI Impact Analysis on Egg Grading and Packing Machine Market

The integration of Artificial Intelligence (AI) is fundamentally transforming the Egg Grading and Packing Machine Market, addressing common user questions about enhanced accuracy, reduced labor dependency, and predictive maintenance. Users are increasingly seeking solutions that move beyond traditional mechanization to intelligent automation, querying how AI can improve defect detection, optimize sorting logic, and provide actionable insights from production data. There's a strong expectation that AI will lead to machines capable of learning and adapting to varying egg characteristics, minimizing human intervention, and ensuring consistent output quality. Concerns often revolve around the initial investment costs, the complexity of integrating AI systems into existing infrastructure, and the need for specialized technical expertise for operation and maintenance. However, the overarching theme is a strong desire for AI-driven systems to unlock new levels of efficiency, reduce operational expenditures in the long term, and contribute to higher profit margins by minimizing waste and maximizing product yield.

Key themes emerging from user inquiries also include the role of AI in improving food safety and traceability. Producers are asking how AI-powered vision systems can identify not just obvious cracks or dirt, but also subtle imperfections, internal defects, or disease indicators that might be missed by conventional methods. The potential for AI to integrate with blockchain technology for enhanced supply chain transparency, tracking eggs from farm to table, is also a significant area of interest. Expectations are high for AI to enable more precise quality control, leading to fewer recalls and stronger brand reputation. Furthermore, users anticipate that AI will empower machines with better decision-making capabilities, allowing for dynamic adjustments in grading parameters based on real-time data, thus optimizing packaging processes for different market segments and seasonal variations in egg quality.

Users also anticipate that AI will play a critical role in preventative maintenance and operational foresight within egg processing plants. Questions frequently arise about how AI can predict machine failures before they occur, reducing unplanned downtime and costly repairs. The expectation is that AI algorithms, by analyzing sensor data from machine components, can identify patterns indicative of impending issues, thereby enabling scheduled maintenance and maximizing machine uptime. This not only enhances operational reliability but also extends the lifespan of expensive equipment. Additionally, the ability of AI to analyze production data to identify bottlenecks, optimize energy consumption, and suggest improvements in overall plant layout and workflow is highly valued, positioning AI as a strategic tool for comprehensive operational excellence rather than just a grading enhancement.

- Enhanced defect detection: AI-powered vision systems identify cracks, dirt, and internal defects with superior accuracy, improving quality control.

- Optimized grading precision: Algorithms learn and adapt to egg characteristics, ensuring consistent sorting by weight, size, and quality.

- Predictive maintenance: AI analyzes machine data to anticipate failures, reducing downtime and extending equipment lifespan.

- Increased throughput: AI optimizes machine settings and processes in real-time, maximizing operational speed and efficiency.

- Reduced labor costs: Automation driven by AI minimizes the need for manual inspection and handling.

- Improved yield management: AI identifies optimal packaging strategies to minimize waste and maximize product presentation.

- Data-driven insights: AI provides actionable intelligence on production patterns, quality trends, and operational bottlenecks.

- Enhanced food safety: Advanced anomaly detection contributes to stricter hygiene standards and reduced contamination risks.

- Adaptive processing: Machines can adjust to varying egg sizes, shapes, and shell qualities on the fly.

- Integration with IoT: AI leverages sensor data for a connected and intelligent processing environment.

- Energy efficiency: Optimization algorithms help reduce power consumption during operation.

- Traceability enhancement: AI can integrate with supply chain management systems for improved product tracking.

- Automated quality assurance: Real-time monitoring and autonomous adjustments ensure consistent quality output.

- Customized sorting: AI enables flexible sorting criteria to meet specific customer or market demands.

- Reduced human error: Minimizes inconsistencies associated with manual inspection and grading.

DRO & Impact Forces Of Egg Grading and Packing Machine Market

The Egg Grading and Packing Machine Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. A primary driver is the ever-increasing global demand for eggs, fueled by population growth, urbanization, and the recognition of eggs as an affordable and highly nutritious protein source. This escalating demand compels poultry producers to scale up operations and adopt automation to maintain efficiency and meet market supply. Complementing this is the rising emphasis on food safety and quality standards worldwide; consumers and regulatory bodies demand eggs that are consistently graded, hygienically processed, and accurately packaged. Automated machines fulfill these requirements by ensuring uniformity, reducing human contact, and adhering to strict health protocols, thus becoming indispensable for market access and consumer trust. Furthermore, the persistent challenge of labor shortages and rising labor costs in agricultural sectors pushes producers towards automation as a cost-effective and reliable solution, mitigating dependency on manual workers and streamlining the production line. Technological advancements, including improvements in machine vision, robotics, and artificial intelligence, are also key drivers, enhancing the capabilities, speed, and accuracy of these machines, making them more attractive investments for modern poultry farms seeking to maximize yield and minimize breakage.

Despite these powerful drivers, several significant restraints challenge the market's unbridled expansion. The most prominent restraint is the high initial capital investment required for purchasing and installing advanced egg grading and packing machines. This cost can be prohibitive for small and medium-sized poultry farms, particularly in developing regions, limiting their adoption despite the long-term benefits. The complexity of these modern machines, often involving sophisticated software and intricate mechanical components, necessitates skilled labor for operation, maintenance, and troubleshooting. A shortage of such specialized technical personnel, especially in rural agricultural areas, poses a significant hurdle to effective utilization and can increase operational costs. Additionally, the fragmented nature of the poultry industry in some regions, with a large number of small-scale producers, makes widespread adoption difficult due to varying production volumes and financial capacities. Economic downturns or price volatility in the egg market can also deter new investments in expensive machinery, as producers prioritize short-term financial stability over long-term capital expenditure. Moreover, the environmental impact of manufacturing and operating large industrial machinery, including energy consumption and waste generation, is increasingly scrutinized, pushing manufacturers to innovate towards more sustainable but potentially costlier solutions.

Opportunities for growth are abundant within the market, particularly stemming from the emergence of new technologies and expanding geographical reach. The ongoing trend of technological innovation, including the integration of IoT, big data analytics, and advanced robotics, presents significant opportunities for manufacturers to develop smarter, more efficient, and fully autonomous systems. These innovations can offer enhanced features like real-time monitoring, predictive maintenance, and precise sorting for niche markets (e.g., organic, free-range eggs), adding premium value. Furthermore, the untapped potential in developing economies, specifically in Asia Pacific, Latin America, and Africa, represents a substantial growth opportunity. As these regions experience economic development, rising incomes, and a shift towards industrialized farming practices, the demand for modern egg processing equipment is set to surge. Government initiatives promoting food security, agricultural modernization, and export growth also create a favorable environment for market penetration. The increasing focus on value-added egg products, such as liquid eggs, egg powders, and specialized egg-based ingredients for the food processing industry, necessitates highly efficient and hygienic grading and packing systems capable of handling diverse production requirements, opening new avenues for specialized machine development. Finally, strategic partnerships and collaborations between technology providers, machine manufacturers, and poultry industry stakeholders can accelerate innovation and market adoption, fostering a more integrated and robust supply chain for egg products globally.

Segmentation Analysis

The Egg Grading and Packing Machine Market is comprehensively segmented to provide a detailed understanding of its diverse landscape, catering to various operational scales, technological preferences, and end-user requirements. This segmentation allows for a precise analysis of market dynamics, identifying key growth areas and niche opportunities across different dimensions. Understanding these segments is crucial for manufacturers to tailor their product offerings, for investors to identify promising ventures, and for poultry producers to select machinery that best fits their specific needs and production volumes. The market is primarily bifurcated by factors such as the level of automation, processing capacity, specific applications in the poultry value chain, the types of components integrated into the machines, and the ultimate end-users of the graded and packed eggs. Each segment exhibits distinct growth drivers and competitive intensities, contributing uniquely to the overall market trajectory.

The segmentation by type, specifically automatic and semi-automatic machines, reflects the varying degrees of automation desired by producers. Automatic machines dominate larger commercial operations due to their high throughput, accuracy, and minimal labor requirements, leveraging advanced technologies like vision systems and robotics. Semi-automatic machines, while requiring more manual intervention, offer a cost-effective solution for smaller farms or operations with lower production volumes, providing a balance between automation and affordability. Capacity-based segmentation categorizes machines into small, medium, and large, directly correlating with the hourly egg processing volume. This allows producers to select equipment that matches their scale of operation, from family-run farms to industrial-scale processing plants. The application segment details where these machines are primarily utilized, including commercial farms focused on fresh egg sales, dedicated egg processing centers for further value addition (e.g., liquid eggs), and the burgeoning food service industry that requires consistent quality and bulk packaging. These distinct applications often necessitate machines with specialized features, such as enhanced washing capabilities or specific packing formats.

Further segmentations delve into the components that constitute these machines and the ultimate end-users of the eggs. Component segmentation includes grading systems (for weight and quality), packing systems (for various tray and carton sizes), washing systems (for hygiene), and conveyor systems (for efficient material handling), among others. This breakdown helps in understanding technological advancements and market demand for individual functionalities or integrated solutions. Finally, the end-user segmentation clearly defines the primary beneficiaries of the graded and packed eggs, ranging from poultry farms themselves (for internal use or direct sale), the expansive food and beverage industry (which utilizes eggs as raw materials), and the retail sector (supermarkets, grocery stores) where consumer-ready packaged eggs are sold. Each end-user category has specific quality, volume, and packaging requirements, driving innovation and differentiation within the egg grading and packing machine market. The interplay between these detailed segments provides a holistic view of the market's current state and its future growth potential.

- By Type

- Automatic Egg Grading and Packing Machines

- Semi-Automatic Egg Grading and Packing Machines

- By Capacity

- Small Capacity (Up to 10,000 eggs/hour)

- Medium Capacity (10,001 - 30,000 eggs/hour)

- Large Capacity (Above 30,000 eggs/hour)

- By Application

- Commercial Farms

- Egg Processing Centers

- Food Service Industry

- Wholesale & Distribution

- By End-User

- Poultry Farms

- Food & Beverage Industry

- Retail Sector

- Industrial Egg Product Manufacturers

- By Component

- Grading Systems (Weighing, Vision-based Defect Detection)

- Packing Systems (Tray Loaders, Carton Packers)

- Washing and Drying Systems

- Conveyor and Accumulation Systems

- Control Systems and Software

- Others (Sanitizing, UV Sterilization, Palletizing)

Value Chain Analysis For Egg Grading and Packing Machine Market

The value chain for the Egg Grading and Packing Machine Market is a complex and interconnected network of activities, commencing from raw material sourcing to the final distribution and after-sales support. At the upstream end, the process begins with the procurement of essential components and raw materials such as specialized steels, advanced sensors, machine vision cameras, robotic arms, programmable logic controllers (PLCs), and various electronic components. Key suppliers in this segment include metal manufacturers, precision engineering firms, and specialized electronics component providers. Research and development activities, which involve designing innovative grading and packing algorithms, improving machine efficiency, and integrating emerging technologies like AI and IoT, are also critical upstream functions. Manufacturers rely heavily on a robust supply chain to ensure the quality and availability of these high-tech components, which directly impact the performance and reliability of the final machines. Strategic relationships with upstream suppliers are crucial for cost efficiency, quality control, and timely delivery, especially given the global nature of component sourcing.

The core of the value chain involves the manufacturing and assembly of the egg grading and packing machines. This midstream segment is characterized by precision engineering, advanced fabrication techniques, and stringent quality control processes. Machine manufacturers design, develop, and assemble various modules including egg handling systems, weighing units, defect detection systems, packaging robots, and control interfaces. Customization plays a significant role here, as different poultry operations have unique requirements regarding capacity, footprint, and specific grading criteria. After manufacturing, comprehensive testing and calibration are performed to ensure the machines meet performance specifications and comply with international food safety and hygiene standards. This stage also includes the development of proprietary software for machine control, data analytics, and user interfaces, which adds significant value to the overall product offering. Strong in-house engineering capabilities and efficient production processes are key differentiators for manufacturers in this competitive space.

Downstream activities focus on the distribution, installation, and post-sales support, which are critical for customer satisfaction and market penetration. Distribution channels typically involve a mix of direct sales teams, authorized distributors, and regional partners who have deep knowledge of local market conditions and regulations. For larger, more complex installations, direct engagement with the client's engineering team is common. Installation, commissioning, and operator training are vital services provided by manufacturers or their certified partners to ensure optimal machine performance from day one. After-sales support, including maintenance services, spare parts supply, and technical assistance, forms a crucial part of the value chain, ensuring machine longevity and operational continuity for customers. The effectiveness of this downstream network directly influences brand reputation, customer loyalty, and future sales. Both direct and indirect distribution strategies are employed, with direct sales often targeting large commercial clients and indirect channels (distributors) serving smaller clients or reaching geographically diverse markets. The entire value chain is geared towards delivering high-quality, efficient, and reliable egg grading and packing solutions to the global poultry industry, ensuring that eggs reach consumers in optimal condition.

Egg Grading and Packing Machine Market Potential Customers

The primary potential customers for Egg Grading and Packing Machines are diverse entities within the expansive poultry and food processing industries, all seeking to enhance efficiency, ensure quality, and meet regulatory standards in egg handling. Large-scale commercial poultry farms represent a significant segment of end-users. These farms, often housing millions of laying hens, produce vast quantities of eggs daily and require high-capacity, fully automated systems to quickly and accurately sort, grade, and pack eggs for various market segments. Their demand is driven by the need to minimize labor costs, reduce egg breakage, and maintain consistent product quality to satisfy supermarket chains and bulk buyers. Investment in advanced machinery allows these farms to scale operations, improve hygiene, and achieve better yields, making them central to the market's growth. The imperative for automation in these settings is fueled by the sheer volume of production and the stringent standards expected by modern retail and distribution networks.

Egg processing centers constitute another critical customer base. These facilities specialize in processing raw eggs into various value-added products, such as liquid eggs (whole, yolk, or albumen), egg powders, and specialized egg ingredients for the bakery, confectionery, and food manufacturing industries. For these centers, precision grading and efficient packing are fundamental to their operations. They often require machines with specific functionalities like integrated washing and sanitizing systems to ensure maximum hygiene for further processing. The ability to handle large volumes and diverse egg characteristics, while maintaining traceability and adhering to strict food safety protocols, is paramount for these industrial-scale buyers. The increasing global demand for convenience foods and processed food products that utilize eggs as a key ingredient directly translates into a sustained and growing demand for advanced grading and packing solutions from these specialized processing centers.

Beyond large-scale operations, small to medium-sized poultry farms also represent a substantial, albeit often underserved, customer segment. While their production volumes may not justify the highest capacity automatic machines, they increasingly seek semi-automatic or modular solutions to improve efficiency and professionalize their operations. These farms might supply local markets, specialty stores, or engage in direct-to-consumer sales, where consistent quality and appealing packaging are essential for market differentiation. Furthermore, governmental and non-governmental organizations involved in agricultural development or food security initiatives in emerging markets can be potential customers, as they often support local farmers in adopting modern technologies to improve productivity and market access. Lastly, research institutions and educational facilities focused on poultry science or food technology may also acquire these machines for experimental purposes, training, and developing new processing techniques, contributing to the innovative ecosystem of the industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 885 Million |

| Market Forecast in 2033 | USD 1,450 Million |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Moba, Nabel, Sanovo Technology Group, Staalkat, Seymour, Prinzen, H&N, Pelbo, Big Dutchman, Hartmann, V.M.D. S.R.L., Hebei Chuangtian Intelligent Equipment Co., Ltd., Guangdong Xingye Machinery Co., Ltd., Huizhou Guanghui Automation Equipment Co., Ltd., Shanghai Dingyi Automation Equipment Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Egg Grading and Packing Machine Market Key Technology Landscape

The Egg Grading and Packing Machine Market is characterized by a rapidly evolving technological landscape, driven by the continuous pursuit of higher efficiency, precision, and automation in egg processing. Central to this evolution are advanced machine vision systems, which utilize high-resolution cameras and sophisticated image processing algorithms to accurately detect subtle cracks, dirt, blood spots, and other quality defects that are invisible to the human eye. These vision systems often employ spectral analysis or infrared technology to assess internal egg quality, such as yolk color or albumen integrity, without damaging the egg. Coupled with these vision capabilities are highly accurate weighing systems, which utilize precise load cells and sensors to sort eggs by weight categories with minimal tolerance, ensuring compliance with market standards and packaging requirements. The integration of these two core technologies allows for multi-parameter grading, leading to superior quality control and reduced manual intervention.

Another pivotal technological development is the incorporation of robotics and advanced automation. Robotic arms are increasingly used for delicate egg handling, from picking and placing eggs onto grading lines to precision packing into trays and cartons. These robotic systems are programmed for gentle movements, significantly reducing egg breakage rates compared to traditional mechanical systems. Furthermore, the advent of sophisticated control systems, often built on Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), provides operators with intuitive control over machine parameters, real-time performance monitoring, and fault diagnosis. These systems enable seamless integration of various modules within a single processing line, from washing and drying to grading, packing, and even palletizing, creating fully automated end-to-end solutions. The drive towards Industry 4.0 principles also means that these machines are equipped with extensive sensor networks that generate vast amounts of operational data.

The future of egg grading and packing technology is heavily influenced by the integration of Artificial Intelligence (AI) and the Internet of Things (IoT). AI algorithms are being deployed to enhance the learning capabilities of vision systems, allowing them to adapt to new defect patterns and optimize grading logic over time. AI also plays a crucial role in predictive maintenance, analyzing sensor data to forecast potential mechanical failures, thus enabling proactive servicing and minimizing costly downtime. IoT connectivity facilitates real-time data exchange between machines and centralized management systems, enabling remote monitoring, performance analysis, and optimization across multiple production lines or even different farm locations. This allows for centralized control and data-driven decision-making, improving overall operational efficiency and supply chain visibility. Additionally, technologies focused on sustainability, such as energy-efficient motors, water recycling systems for washing, and designs that minimize material waste, are gaining prominence, reflecting a broader industry commitment to environmental responsibility alongside technological advancement.

Regional Highlights

- North America: A mature market characterized by large-scale commercial poultry operations and a high adoption rate of advanced automation. Driven by stringent food safety regulations, high labor costs, and a continuous focus on optimizing supply chains. The U.S. and Canada are leading countries, investing in IoT and AI integration for efficiency and traceability.

- Europe: Exhibits a strong emphasis on animal welfare, sustainability, and high-quality standards. Countries like the Netherlands, Germany, and France are key players, investing in sophisticated, energy-efficient machines. Strict regulations on egg classification and packaging drive demand for precise grading and packing solutions, alongside increasing adoption of organic and free-range egg production technologies.

- Asia Pacific (APAC): The fastest-growing region, fueled by expanding populations, rising disposable incomes, and increasing per capita egg consumption, especially in China, India, and Southeast Asian countries. Massive investments in modernizing poultry infrastructure and shifting from traditional to industrialized farming practices are boosting demand for automated systems. Government support for food security and agricultural efficiency further propels market growth.

- Latin America: An emerging market with significant growth potential, particularly in Brazil, Mexico, and Argentina. Economic development, urbanization, and increasing demand for protein-rich diets are driving the adoption of modern egg grading and packing machines. Producers are seeking cost-effective yet efficient solutions to scale operations and meet domestic and international market demands.

- Middle East and Africa (MEA): Demonstrating nascent but steady growth, influenced by government initiatives to enhance local food production and reduce import dependency. Countries like Saudi Arabia, UAE, and South Africa are investing in modern poultry farms to achieve self-sufficiency in egg production. The need for hygienic processing and standardized products to cater to a growing consumer base and export markets is driving demand for automated equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Egg Grading and Packing Machine Market.- Moba

- Nabel Co., Ltd.

- Sanovo Technology Group

- Staalkat (part of Sanovo Technology Group)

- Seymour Inc.

- Prinzen (part of Vencomatic Group)

- H&N International (a company of EW Group)

- Pelbo S.P.A. (part of Sanovo Technology Group)

- Big Dutchman AG

- Hartmann

- V.M.D. S.R.L.

- Hebei Chuangtian Intelligent Equipment Co., Ltd.

- Guangdong Xingye Machinery Co., Ltd.

- Huizhou Guanghui Automation Equipment Co., Ltd.

- Shanghai Dingyi Automation Equipment Co., Ltd.

- Henan Kangtai Agricultural Technology Co., Ltd.

- Hebei Jiuyue Animal Husbandry Machinery Co., Ltd.

- Zhengzhou Smart Egg Packing Machine Co., Ltd.

- Foshan Huazhong Machinery Equipment Co., Ltd.

- Beijing Chia Tai Qing Chun Poultry Equipment Co., Ltd.

Frequently Asked Questions

What factors are driving the growth of the Egg Grading and Packing Machine Market?

The market's growth is primarily driven by increasing global egg consumption due to population growth and rising protein demand, coupled with a heightened focus on food safety and quality standards. Additionally, the need to mitigate rising labor costs and shortages, along with continuous technological advancements in automation and AI, significantly propel market expansion.

What are the main types of egg grading and packing machines available?

The market primarily offers two main types: automatic and semi-automatic machines. Automatic machines are highly efficient, high-capacity systems ideal for large commercial operations, often integrating advanced vision systems and robotics. Semi-automatic machines provide a more cost-effective solution for smaller to medium-sized farms, balancing automation with a degree of manual involvement.

How is AI impacting the Egg Grading and Packing Machine Market?

AI is profoundly impacting the market by enhancing defect detection accuracy through machine vision, optimizing grading precision, and enabling predictive maintenance for machines. AI-powered systems reduce labor costs, improve yield management, and provide data-driven insights for operational efficiency, contributing to superior product quality and reduced downtime.

Which regions are expected to show significant growth in this market?

The Asia Pacific region is anticipated to be the fastest-growing market, driven by expanding populations, rising incomes, and significant investments in modernizing poultry infrastructure in countries like China and India. Latin America and the Middle East & Africa are also emerging as key growth regions due to economic development and increasing demand for standardized egg products.

What challenges does the Egg Grading and Packing Machine Market face?

Key challenges include the high initial capital investment required for advanced machinery, which can be prohibitive for smaller producers. The technical complexity of modern systems necessitates skilled labor for operation and maintenance, posing a hurdle in regions with limited technical expertise. Economic volatility and market fragmentation also present significant restraints.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager