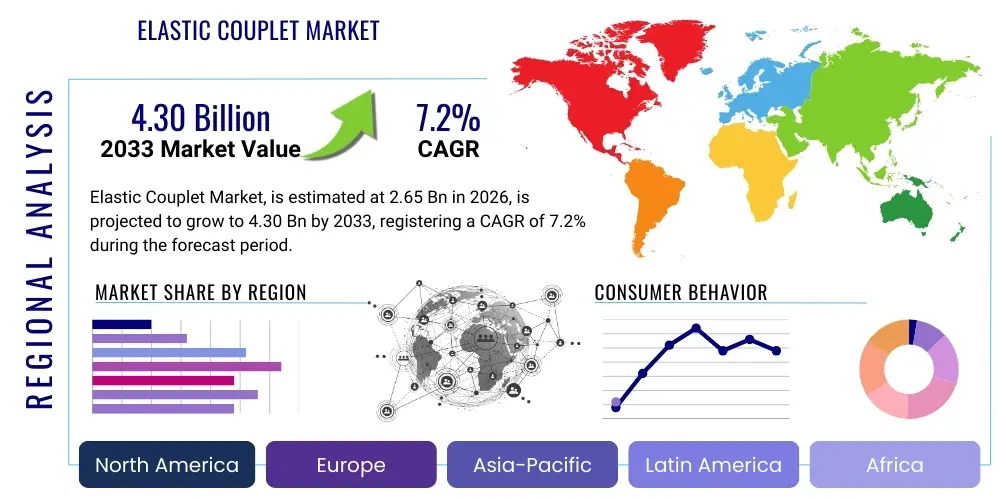

Elastic Couplet Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439904 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Elastic Couplet Market Size

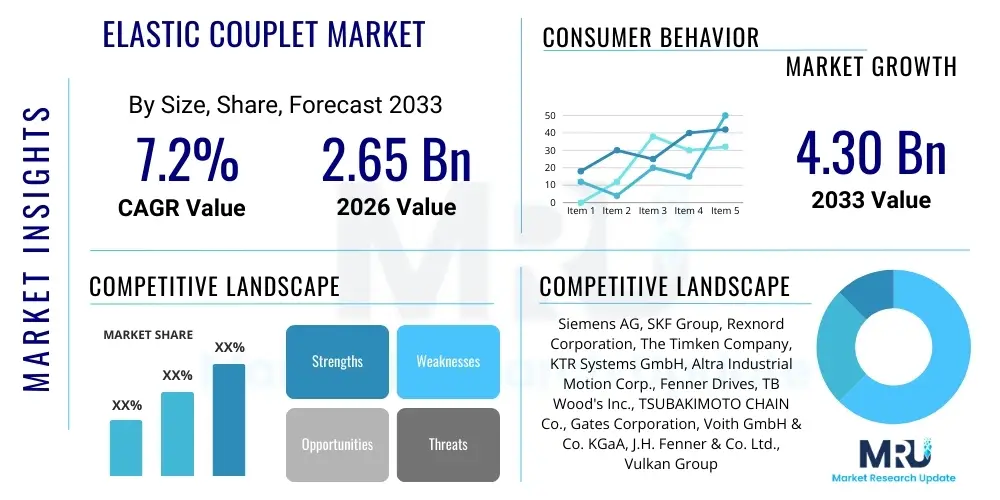

The Elastic Couplet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 2.65 Billion in 2026 and is projected to reach USD 4.30 Billion by the end of the forecast period in 2033.

Elastic Couplet Market introduction

The Elastic Couplet Market serves as a critical segment within the industrial power transmission landscape, providing essential components designed to connect two rotating shafts while accommodating misalignment, absorbing shock loads, and dampening torsional vibrations. These mechanical devices are indispensable in a vast array of industrial machinery, ensuring smooth and efficient operation, minimizing wear and tear on interconnected equipment, and extending the overall lifespan of complex systems. Their design leverages elastic elements, often made from rubber, polyurethane, or other resilient polymers, which provide the flexibility necessary for these functions. The primary goal of an elastic couplet is to transmit torque reliably while protecting adjacent components from damaging forces that can arise from imperfect alignment or fluctuating loads.

Elastic couplets are widely employed across diverse sectors due to their inherent benefits, including enhanced system reliability, reduced operational noise, and lower maintenance requirements compared to rigid coupling alternatives. Key applications span across manufacturing, oil and gas, mining, automotive, food and beverage, and power generation industries, where they are integral to the functioning of pumps, motors, compressors, conveyors, mixers, and various machine tools. The demand for these robust components is continuously driven by the global expansion of industrialization, the escalating adoption of automation technologies, and the ever-present need for efficient and reliable power transmission solutions in modern industrial settings. As industries strive for higher productivity and reduced downtime, the role of high-performance elastic couplets becomes increasingly vital, fueling innovation in material science and design methodologies to meet evolving operational challenges.

Elastic Couplet Market Executive Summary

The Elastic Couplet Market is experiencing dynamic shifts, primarily influenced by global industrial expansion and the pervasive trend towards automation and smart manufacturing. Business trends indicate a rising demand for customized and high-performance elastic couplets capable of withstanding extreme operational conditions and integrating with advanced sensor technologies for predictive maintenance. Companies are focusing on material innovations, particularly in elastomers and composite materials, to enhance durability, flexibility, and temperature resistance, thereby broadening application possibilities and extending product life cycles. Furthermore, the market is witnessing a consolidation phase, with key players acquiring smaller, specialized manufacturers to expand their product portfolios and geographical reach, leading to a more competitive landscape and an emphasis on value-added services such as technical support and bespoke engineering solutions. Sustainability initiatives are also influencing product development, with a growing focus on recyclable materials and energy-efficient designs to align with environmental regulations and corporate responsibility goals.

Regionally, the Asia Pacific (APAC) stands out as the dominant and fastest-growing market, propelled by rapid industrialization, extensive manufacturing activities, and significant infrastructure development projects in countries like China, India, and Southeast Asian nations. North America and Europe, characterized by mature industrial bases, demonstrate a steady demand driven by replacement markets, technological upgrades, and the adoption of Industry 4.0 principles, which necessitate more sophisticated and intelligent coupling solutions. Latin America, the Middle East, and Africa are showing promising growth, attributed to increasing investments in mining, oil and gas, and diversified manufacturing sectors, leading to a greater need for robust and reliable power transmission components. These regions often prioritize cost-effectiveness alongside performance, creating opportunities for manufacturers to offer competitive and durable elastic couplet solutions tailored to specific regional industrial demands. The global shift towards automation, regardless of geographical location, ensures a foundational demand for these essential mechanical components, though the nuances of application and specification vary significantly across different industrial landscapes.

Segment-wise, the market sees robust growth in jaw and tire couplings due to their versatility and shock absorption capabilities, particularly in heavy machinery and general industrial applications. Material trends are leaning towards advanced polyurethanes and specialized synthetic rubbers that offer superior chemical resistance, temperature stability, and extended fatigue life, addressing the increasing performance requirements of modern machinery. End-user segments such as automotive and robotics are driving demand for compact, high-precision elastic couplets that can operate reliably in confined spaces and high-speed applications. The oil and gas and mining sectors continue to be significant consumers, requiring heavy-duty, corrosion-resistant elastic couplets for pumps, compressors, and drilling equipment operating in harsh environments. This diverse segmentation underscores the broad utility of elastic couplets and the continuous need for innovation to cater to the unique demands of each industry, fostering a market driven by both volume and specialized technological advancement.

AI Impact Analysis on Elastic Couplet Market

The integration of Artificial Intelligence (AI) is poised to fundamentally transform the Elastic Couplet Market, addressing common user questions related to design efficiency, predictive maintenance, and operational optimization. Users are keen to understand how AI can reduce the lengthy design cycles for custom couplets, improve material selection for specific applications, and provide insights into component longevity. The primary themes revolve around enhancing product performance, reducing operational costs through intelligent fault detection, and streamlining manufacturing processes. Expectation for AI's influence extends to minimizing human error in installation and maintenance, offering real-time diagnostics, and fostering the development of "smart" components that can self-monitor and adapt to changing conditions. These advancements aim to alleviate concerns about unexpected downtime, optimize inventory management, and facilitate a proactive approach to machinery upkeep.

AI's analytical capabilities, particularly in machine learning and deep learning, offer unprecedented opportunities for data-driven design and performance prediction. By analyzing vast datasets from operational couplets, including vibration patterns, temperature fluctuations, and load histories, AI algorithms can identify subtle indicators of wear and potential failure before they become critical. This enables maintenance schedules to be optimized, shifting from reactive or time-based approaches to a more efficient, condition-based strategy. Furthermore, AI can aid in the development of next-generation elastic materials by simulating their properties under various stress conditions, accelerating the discovery of innovative compounds with superior resilience and adaptability. This not only promises enhanced durability and performance for elastic couplets but also contributes significantly to the overall reliability and efficiency of industrial systems, directly impacting user bottom lines and operational continuity. The ability of AI to process and interpret complex data sets will be crucial in designing couplets that are not only robust but also perfectly matched to the specific demands of their application environments, moving beyond conventional engineering limitations.

- Enhanced design optimization through generative AI, reducing prototype cycles and costs.

- Implementation of predictive maintenance algorithms to forecast couplet failure, minimizing downtime.

- AI-driven material selection for specific environmental and load conditions, improving durability.

- Automated quality control systems in manufacturing, detecting defects with higher precision.

- Optimized supply chain and inventory management based on AI-driven demand forecasting.

- Real-time performance monitoring and anomaly detection for in-service couplets using IoT and AI.

- Development of smart, self-adjusting elastic couplets capable of adapting to operational changes.

- Personalized product recommendations and configuration tools for industrial buyers, improving selection accuracy.

- Improved energy efficiency in power transmission systems through AI-guided component selection.

- Reduced human error in installation and maintenance through AI-powered guidance and training.

DRO & Impact Forces Of Elastic Couplet Market

The Elastic Couplet Market is shaped by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating pace of global industrialization and infrastructure development, particularly in emerging economies, which fuels the demand for new machinery and, consequently, new elastic couplets. The increasing adoption of automation and robotics across various industries further bolsters this demand, as automated systems require precise and reliable power transmission components to maintain operational continuity and efficiency. Furthermore, the inherent need for vibration damping, shock absorption, and misalignment compensation in modern machinery makes elastic couplets indispensable, driving consistent replacement demand in mature industrial sectors as well. The growing emphasis on preventative maintenance and extending equipment lifespan also contributes significantly to market expansion, as industries seek high-performance components that reduce wear and minimize unscheduled downtime.

Despite these strong drivers, the market faces several restraints. Volatility in raw material prices, particularly for specialized rubbers, polyurethanes, and metals, can impact manufacturing costs and profit margins, posing a challenge for pricing stability. Intense competition among both established global players and regional manufacturers often leads to price erosion, especially for standard products, making differentiation crucial. Additionally, a lack of standardization in certain niche applications and the inherent complexity of selecting the correct couplet for highly specialized machinery can hinder market growth and adoption rates. Economic downturns and geopolitical uncertainties also represent significant external restraints, as industrial investment often correlates directly with economic stability, leading to reduced capital expenditure on new machinery and components during periods of uncertainty. These challenges necessitate a strategic focus on innovation, cost-efficiency, and robust supply chain management to maintain market competitiveness.

Opportunities for growth are abundant within the Elastic Couplet Market. The ongoing trend towards smart factories and Industry 4.0 creates demand for couplets integrated with sensors and IoT capabilities for real-time monitoring and predictive maintenance. Developing advanced materials, such as high-performance elastomers and composite polymers, that offer superior resilience, temperature resistance, and chemical compatibility, presents a significant opportunity for product differentiation and market penetration into demanding applications. Emerging markets, with their burgeoning industrial bases, offer untapped potential for expansion, especially as their manufacturing capabilities mature and their infrastructure expands. Customization and bespoke engineering solutions, catering to specific industry needs or unique machinery designs, represent another lucrative avenue, allowing manufacturers to provide high-value offerings beyond standard product lines. The shift towards energy-efficient industrial operations also presents an opportunity for manufacturers to develop couplets that minimize energy losses during power transmission, aligning with global sustainability goals and attracting environmentally conscious buyers. External impact forces, such as evolving regulatory standards for safety and environmental performance, compel manufacturers to innovate and adhere to higher quality benchmarks, influencing product design and material choices. Technological advancements in additive manufacturing also provide opportunities for rapid prototyping and production of complex couplet geometries, potentially reducing lead times and facilitating greater customization. Geopolitical stability and trade policies can either foster or hinder international market access, while shifts in global manufacturing hubs directly impact regional demand dynamics, requiring continuous market intelligence and adaptability from industry players.

Segmentation Analysis

The Elastic Couplet Market is meticulously segmented across various parameters, providing a detailed understanding of its diverse landscape and enabling targeted market strategies. This segmentation includes analysis by type, material, application, and end-user industry, reflecting the wide range of requirements and specific operational environments where elastic couplets are deployed. Each segment offers unique characteristics and growth trajectories, influenced by technological advancements, material innovations, and evolving industrial demands. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their inventory, and for end-users to make informed purchasing decisions that align with their machinery's performance specifications and operational efficiency goals.

The segmentation by type categorizes couplets based on their design and mechanism for accommodating misalignment and absorbing shocks, while material segmentation highlights the diverse range of elastomers and polymers utilized to achieve specific performance attributes like temperature resistance, chemical compatibility, and torque capacity. Application-based segmentation provides insight into the specific machinery and systems where these components are vital, ranging from general industrial pumps to specialized process equipment. Finally, end-user industry segmentation illustrates the broad reach of elastic couplets across sectors such as manufacturing, automotive, and power generation, each presenting distinct operational challenges and component requirements. This comprehensive approach to market segmentation allows for a granular analysis of market trends, competitive positioning, and future growth opportunities, ensuring that all aspects of the elastic couplet ecosystem are thoroughly examined to provide actionable market intelligence.

- By Type:

- Jaw Couplings

- Sleeve Couplings

- Tire Couplings

- Grid Couplings

- Pin & Bush Couplings

- Disc Couplings (with elastic elements)

- Others (e.g., spider, beam, bellow)

- By Material:

- Natural Rubber (NR)

- Nitrile Butadiene Rubber (NBR)

- Ethylene Propylene Diene Monomer (EPDM)

- Polyurethane (PU)

- Nylon

- Other Elastomers & Composites

- By Application:

- Pumps

- Motors

- Compressors

- Conveyors

- Mixers

- Generators

- Printing Machinery

- Machine Tools

- Fans & Blowers

- Paper & Pulp Machinery

- Others (e.g., HVAC, Cranes)

- By End-User Industry:

- Manufacturing

- Oil & Gas

- Mining

- Automotive

- Food & Beverage

- Chemicals & Petrochemicals

- Power Generation

- Marine

- Agriculture

- Construction

- Robotics & Automation

- Textile

Value Chain Analysis For Elastic Couplet Market

The value chain for the Elastic Couplet Market encompasses a series of interconnected stages, beginning with the sourcing of raw materials and extending to the ultimate end-users. The upstream segment involves suppliers of critical raw materials such as various types of rubber (natural, synthetic), polyurethane, nylon, and metals like steel and aluminum for the hubs and other structural components. These raw material providers are crucial as the quality and cost of their offerings directly influence the final product's performance and market price. Manufacturers of elastic couplets engage in design, engineering, molding, machining, and assembly, transforming these raw materials into finished products. Specialized components like elastomers or specific metal alloys might be procured from niche suppliers, highlighting the intricate network of the upstream supply chain. Efficiency and reliability in this initial phase are paramount to ensure cost-effectiveness and consistency in the manufacturing process.

Moving downstream, the distribution channel plays a pivotal role in connecting manufacturers with end-users. This typically involves a multi-faceted approach, including direct sales to large Original Equipment Manufacturers (OEMs) who integrate couplets into their machinery during the initial build. Industrial distributors form a significant part of the indirect channel, serving as intermediaries that stock a wide range of couplet types and brands, making them accessible to a broad base of smaller OEMs, maintenance, repair, and operations (MRO) departments, and specialized system integrators. These distributors often provide value-added services such as technical support, inventory management, and regional availability, catering to diverse customer needs. The rise of e-commerce platforms and online marketplaces has also created new direct and indirect avenues, allowing for greater market reach and enabling direct-to-consumer sales for specific standard products, enhancing accessibility and potentially streamlining procurement processes for certain customer segments.

The direct distribution model is often preferred for high-volume orders or highly customized elastic couplets, where manufacturers work closely with OEMs to design and integrate solutions specific to their machinery. This close collaboration ensures precise fit and optimal performance, fostering long-term relationships and brand loyalty. Conversely, the indirect distribution through a network of industrial suppliers and MRO providers caters to the broader market, offering convenience and quick access to a diverse inventory. These channels are critical for the aftermarket, where replacement parts and routine maintenance components are frequently purchased. Both direct and indirect channels contribute significantly to market penetration and customer service, with each serving distinct customer segments and fulfilling different procurement needs within the extensive industrial ecosystem. The effectiveness of the entire value chain is dependent on seamless coordination and efficient logistics across all stages, ensuring that the right elastic couplet reaches the right application at the right time.

Elastic Couplet Market Potential Customers

The primary potential customers for the Elastic Couplet Market are diverse and span across numerous industrial sectors, essentially encompassing any enterprise that utilizes rotating machinery requiring efficient power transmission, vibration damping, or compensation for shaft misalignment. Original Equipment Manufacturers (OEMs) represent a significant customer segment. These include manufacturers of heavy machinery, automotive components, industrial automation equipment, pumps, compressors, and various types of machine tools. OEMs integrate elastic couplets into their products during the initial design and assembly phases, seeking reliable, high-performance components that enhance the functionality and durability of their end products. Their demand is typically driven by specific engineering requirements, performance specifications, and the need for components that can withstand rigorous operational environments and contribute to the overall quality and lifespan of their machinery.

Another substantial customer base comprises Maintenance, Repair, and Operations (MRO) departments within manufacturing plants, processing facilities, and industrial complexes across all sectors. These end-users purchase elastic couplets for replacement purposes during routine maintenance, repair work, or system upgrades. Industries such as oil and gas, mining, chemicals, food and beverage, power generation, and marine operations frequently require robust and specialized couplets to ensure continuous operation and minimize costly downtime. Beyond these, agricultural machinery manufacturers, construction equipment producers, and even specialized robotics and automation companies are emerging as increasingly important customers, seeking precise and durable elastic couplets that can perform reliably in dynamic and often harsh conditions. Their needs range from standard off-the-shelf components to custom-engineered solutions that meet specific torque, speed, and environmental resistance parameters, making the customer landscape highly fragmented yet rich with opportunities for specialized providers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.65 Billion |

| Market Forecast in 2033 | USD 4.30 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, SKF Group, Rexnord Corporation, The Timken Company, KTR Systems GmbH, Altra Industrial Motion Corp., Fenner Drives, TB Wood's Inc., TSUBAKIMOTO CHAIN Co., Gates Corporation, Voith GmbH & Co. KGaA, J.H. Fenner & Co. Ltd., Vulkan Group, Cross+Morse, Ringfeder Power Transmission GmbH, Renold plc, Rotex Couplings GmbH, Guardian Couplings, Flender GmbH, KOP-FLEX (Regal Beloit Corporation) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Elastic Couplet Market Key Technology Landscape

The Elastic Couplet Market is continuously evolving with significant advancements in its technology landscape, driven by the need for enhanced performance, durability, and operational efficiency. One of the most critical technological areas is advanced material science, focusing on the development of high-performance elastomers and composite materials. Innovations in polymers like advanced polyurethanes, specialized synthetic rubbers (such as HNBR, FKM), and engineering plastics are enabling couplets to withstand extreme temperatures, aggressive chemicals, and higher torque loads, thereby extending their application range into more demanding industrial environments. These materials also offer superior fatigue resistance and reduced hysteresis, directly contributing to longer service life and improved energy efficiency. The emphasis is on creating materials that not only meet stringent performance requirements but also adhere to environmental regulations through improved recyclability and sustainable manufacturing processes.

Another pivotal technological development involves the integration of sensor technology and the Internet of Things (IoT) into elastic couplets. Smart couplets equipped with embedded sensors can monitor critical parameters such as vibration, temperature, and torque in real-time. This data, when analyzed using advanced analytics and Artificial Intelligence (AI) algorithms, facilitates predictive maintenance, allowing operators to identify potential failures before they occur and schedule maintenance proactively, thereby minimizing unscheduled downtime and optimizing operational efficiency. Furthermore, advanced simulation software and digital twinning technologies are revolutionizing the design process. Engineers can now create virtual models of couplets and simulate their behavior under various operating conditions, optimizing designs for specific applications, reducing physical prototyping, and accelerating product development cycles. These computational tools enable fine-tuning of stiffness, damping characteristics, and misalignment capabilities, ensuring that the designed couplet performs optimally under intended operational stresses. These technological advancements collectively contribute to the development of more robust, intelligent, and cost-effective elastic couplet solutions, ultimately enhancing the reliability and longevity of industrial machinery.

Regional Highlights

- North America: Characterized by a mature industrial base with a strong focus on advanced manufacturing, aerospace, automotive, and oil & gas sectors. Demand is driven by replacement markets, technological upgrades, and the adoption of Industry 4.0, emphasizing high-performance and intelligent coupling solutions. The region benefits from significant R&D investments and a strong OEM presence.

- Europe: A key market with a strong emphasis on precision engineering, automation, and sustainable manufacturing practices, particularly in Germany, Italy, and the UK. Demand is fueled by the automotive, machinery, and renewable energy sectors. Strict environmental regulations and a focus on energy efficiency drive innovation in couplet materials and design.

- Asia Pacific (APAC): The largest and fastest-growing market globally, propelled by rapid industrialization, extensive manufacturing activities, and infrastructure development in countries like China, India, Japan, and South Korea. Cost-effective production capabilities, increasing foreign direct investment, and a burgeoning middle class contribute to substantial market expansion.

- Latin America: Experiencing steady growth due to expanding industrial sectors, significant investments in mining, oil & gas, and agriculture. Countries like Brazil and Mexico are leading the demand, driven by increasing automation and the need for reliable power transmission components in harsh operating environments.

- Middle East & Africa (MEA): A developing market with growing investments in infrastructure, oil & gas, and manufacturing diversification initiatives. Demand for elastic couplets is rising in construction, energy, and process industries, with a focus on durable and high-temperature resistant components due to the region's climate and operational conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Elastic Couplet Market.- Siemens AG

- SKF Group

- Rexnord Corporation

- The Timken Company

- KTR Systems GmbH

- Altra Industrial Motion Corp.

- Fenner Drives

- TB Wood's Inc.

- TSUBAKIMOTO CHAIN Co.

- Gates Corporation

- Voith GmbH & Co. KGaA

- J.H. Fenner & Co. Ltd.

- Vulkan Group

- Cross+Morse

- Ringfeder Power Transmission GmbH

- Renold plc

- Rotex Couplings GmbH

- Guardian Couplings

- Flender GmbH

- KOP-FLEX (Regal Beloit Corporation)

Frequently Asked Questions

What is an elastic couplet and its primary function?

An elastic couplet is a mechanical device used to connect two rotating shafts, primarily to transmit torque while simultaneously accommodating angular, parallel, and axial misalignments. Its key function is to absorb shock loads and dampen torsional vibrations, protecting interconnected machinery from excessive stresses and extending their operational lifespan, thereby ensuring smoother and more reliable power transmission in industrial applications.

How does an elastic couplet contribute to industrial machinery longevity?

Elastic couplets significantly enhance machinery longevity by absorbing vibrations and shocks, which reduces wear and tear on bearings, seals, and other sensitive components. By compensating for shaft misalignments, they prevent unnecessary stress on rotating parts, minimizing fatigue and preventing premature failure. This protective action leads to fewer breakdowns, lower maintenance costs, and a longer operational life for the entire industrial system.

What are the main types of elastic couplets used in the market?

The main types of elastic couplets include jaw couplings, which use an elastomeric spider; sleeve couplings, featuring a flexible sleeve; tire couplings, designed with a rubber or polyurethane tire-shaped element; and grid couplings, which incorporate a serpentine grid spring. Other types like pin and bush, disc (with elastic elements), and gear couplings also utilize elastic principles to varying degrees, each suited for specific applications based on their flexibility, torque capacity, and damping characteristics.

How is the Elastic Couplet market influenced by industrial automation?

Industrial automation significantly drives the Elastic Couplet market by increasing the demand for precise, reliable, and maintenance-free power transmission components. Automated systems and robotics require couplets that can handle higher speeds, increased torque density, and offer superior vibration damping and misalignment compensation to ensure continuous, high-efficiency operation. This trend also fosters innovation in smart couplets with integrated sensors for predictive maintenance, aligning with Industry 4.0 initiatives.

What are the future trends in elastic couplet materials and design?

Future trends in elastic couplet materials and design are focused on enhanced performance and sustainability. This includes the development of advanced elastomers and composite materials offering superior chemical resistance, temperature tolerance, and fatigue life. Design innovations will leverage AI and simulation software for optimized geometries, enabling lighter, more compact, and highly efficient couplets. Integration of IoT sensors for real-time monitoring and predictive maintenance, along with a focus on recyclable and energy-efficient designs, will also be prominent trends.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager