Elastomeric Couplings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435771 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Elastomeric Couplings Market Size

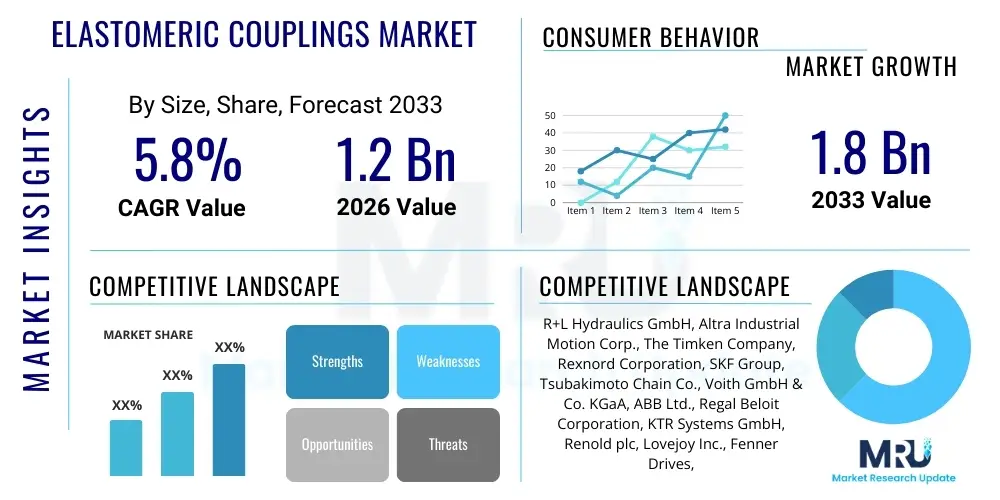

The Elastomeric Couplings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.8 Billion by the end of the forecast period in 2033.

Elastomeric Couplings Market introduction

The Elastomeric Couplings Market encompasses the global trade and utilization of flexible mechanical power transmission components designed primarily to connect two shafts while accommodating inevitable misalignment, damping vibration, and absorbing shock loads. These couplings utilize a flexible element, often made from natural rubber, synthetic rubber (such as Neoprene or EPDM), or polyurethane, positioned between the hubs. This structure allows them to transmit torque reliably while protecting adjacent equipment from operational stresses. They are crucial components in systems requiring reliable, low-maintenance connections, particularly where slight shaft movement or operational noise reduction is necessary.

Elastomeric couplings are deployed extensively across heavy industries, including oil and gas, chemical processing, material handling, power generation, and wastewater treatment. Their primary product description highlights characteristics such as non-lubricated operation, ease of installation, and inherent resistance to various environmental factors like moisture and dust. Major applications include connecting electric motors to pumps, compressors, blowers, gearboxes, and industrial fans. The benefits derived from using these couplings are substantial, primarily focusing on prolonging the operational lifespan of rotating machinery by isolating destructive vibrational energy and compensating for angular, parallel, and axial misalignments that occur during installation or normal operation.

The market growth is fundamentally driven by the robust expansion of the global industrial infrastructure, particularly in developing economies, which necessitates continuous investment in new machinery and maintenance operations. Furthermore, the increasing emphasis on optimizing operational efficiency and reducing downtime across manufacturing sectors pushes end-users toward reliable, high-performance power transmission solutions like elastomeric couplings. Regulatory mandates emphasizing energy efficiency and safety in industrial equipment also indirectly support the adoption of couplings that minimize energy losses associated with misalignment and wear, positioning them as essential elements in modern industrial drive systems.

Elastomeric Couplings Market Executive Summary

The Elastomeric Couplings Market is experiencing steady expansion, driven by accelerating industrialization and the critical need for effective vibration management in sophisticated machinery across diversified sectors. Key business trends indicate a strong move toward advanced elastomeric materials offering superior torque density and greater thermal stability, such as high-grade polyurethane and specialized synthetic rubbers designed for high-temperature and chemically corrosive environments. Manufacturers are also focusing on modular designs that simplify coupling installation and replacement, reducing maintenance costs and downtime for end-users. Strategic mergers and acquisitions, coupled with an increased emphasis on expanding distribution networks, are shaping the competitive landscape, especially as key players seek to solidify their presence in high-growth emerging markets.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive infrastructure projects, burgeoning manufacturing capabilities, and rapid industrial automation adoption in countries like China and India. North America and Europe, characterized by highly mature industrial bases, demonstrate robust demand driven primarily by replacement cycles, stringent equipment performance standards, and the adoption of advanced, high-precision coupling solutions in specialized fields like aerospace and renewable energy generation. Latin America, the Middle East, and Africa (MEA) present significant opportunities due to ongoing investments in oil and gas infrastructure and mining operations, sectors where durable, anti-vibration couplings are indispensable.

Segment-wise, jaw couplings and tire couplings maintain significant market share due to their ease of maintenance and high misalignment tolerance, respectively. The material segment dominated by synthetic rubber continues to evolve, seeing rapid penetration from advanced polymer composites offering enhanced durability. In terms of end-use, the pump and compressor segment remains the largest consumer, reflecting their ubiquity across nearly all industrial processes, while the power generation sector, especially wind turbines and thermal power plants, showcases the fastest growth potential owing to the harsh operating conditions and the high reliability standards required for continuous power production.

AI Impact Analysis on Elastomeric Couplings Market

Common user questions regarding AI's impact on the Elastomeric Couplings Market revolve around predictive maintenance integration, optimal coupling selection algorithms, and the potential for AI-driven material science to innovate coupling design. Users are primarily concerned with how AI can minimize unexpected coupling failures, optimize inventory management for replacement parts, and ensure that the selected coupling is perfectly matched to the specific operational load profile (torque, speed, and environmental stress). The key themes emerging include the expectation of lower operational expenditure (OPEX) through reduced manual inspections, enhanced component reliability via real-time diagnostics, and the development of 'smart' couplings embedded with sensors capable of transmitting performance data for machine learning analysis.

- AI facilitates predictive maintenance programs by analyzing sensor data (vibration, temperature) to forecast elastomeric element wear and potential failure points.

- Machine learning algorithms optimize coupling sizing and material selection based on historical performance data and complex operational parameters, improving application efficiency.

- AI-driven supply chain management improves inventory accuracy for elastomeric replacement parts, reducing lead times and overall holding costs.

- Generative design and AI simulation tools accelerate the development of novel coupling geometries and advanced material compositions (e.g., self-healing polymers).

- Enhanced equipment monitoring through AI reduces costly unplanned downtime associated with coupling malfunctions.

DRO & Impact Forces Of Elastomeric Couplings Market

The Elastomeric Couplings Market is shaped by powerful Drivers (D), significant Restraints (R), and compelling Opportunities (O), which collectively exert substantial Impact Forces on market trajectory and competitive dynamics. The main driver is the universal requirement for vibration damping and misalignment compensation in rotating industrial machinery, ensuring operational longevity and compliance with stringent industrial safety standards. Counteracting this growth are restraints such such as the relatively limited temperature and chemical resistance of some standard elastomeric materials compared to rigid metallic couplings, alongside the increasing adoption of variable speed drives (VSDs) that require highly specialized coupling characteristics.

Opportunities are strongly rooted in the advancement of high-performance elastomers, including specialized compounds that offer superior resistance to oil, ozone, and extreme temperatures, allowing these couplings to penetrate demanding sectors like aerospace and heavy-duty marine applications. Furthermore, the rise of Industry 4.0 creates an opportunity for integrating sensor technology directly into couplings for condition monitoring, transforming a passive mechanical component into an active data point within a connected industrial ecosystem. The net impact of these forces suggests a sustained growth trajectory, moderated by the necessity for continuous material innovation and adaptation to evolving power transmission technologies.

The primary impact forces driving the market include macroeconomic factors such as global industrial output and capital expenditure on new plant installations, alongside technological influences related to material science breakthroughs and digital integration in maintenance protocols. Environmental forces, specifically the push for quieter and more energy-efficient machinery, also favor elastomeric solutions. The inherent shock-absorbing capability of these components provides a compelling argument for their usage, particularly in applications prone to sudden load changes or cyclic stress, reinforcing their indispensable nature in modern industrial power trains and ensuring their sustained market relevance.

Segmentation Analysis

The Elastomeric Couplings Market is systematically segmented based on Product Type, Material Type, End-Use Industry, and Region, providing a multi-faceted view of market dynamics and identifying distinct growth pockets. Understanding these segments is crucial for strategic decision-making, as different product types cater to varying levels of torque requirements and misalignment tolerance, while material choices are dictated by environmental operating conditions such as temperature, chemical exposure, and operational speed. The diversity in end-use applications, ranging from basic material handling to highly critical oil and gas operations, dictates component specification and required reliability levels.

The segmentation by Product Type, encompassing jaw, tire, sleeve, and grid couplings, reveals specific application preferences. Jaw couplings, offering backlash-free operation and low maintenance, dominate smaller to medium-sized drives. Material segmentation, particularly the reliance on synthetic rubber (like Nitrile and EPDM) and advanced polyurethane, reflects the industry's shift towards enhanced performance characteristics, including higher shear strength and chemical stability. Geographically, segmentation highlights the differential growth rates and technology adoption levels across developed industrial hubs in North America and Europe, versus rapidly industrializing nations in Asia Pacific.

Analyzing the End-Use Industry segmentation underscores the market's dependence on capital expenditure in infrastructure and manufacturing. The high demand from the Pump and Compressor industry segment underscores the fundamental role these machines play in nearly all process industries. The rapid modernization and expansion of the Power Generation sector, particularly in renewable energy where vibration dampening is critical for turbine longevity, is a key driver for specialized, large-diameter elastomeric couplings, making this segment a focal point for future market expansion and technological innovation.

- By Product Type:

- Jaw Couplings (Spider, Curved Jaw)

- Tire Couplings (Flexible Element)

- Sleeve Couplings (Bushings)

- Grid Couplings

- Disc Couplings (With Elastomeric Inserts)

- By Material Type:

- Synthetic Rubber (Nitrile, Neoprene, EPDM)

- Natural Rubber

- Polyurethane

- Composite Materials

- By End-Use Industry:

- Pumps and Compressors

- Power Generation (Wind, Thermal, Hydro)

- Oil & Gas and Petrochemical

- Mining and Metals

- Pulp and Paper

- Material Handling Equipment (Conveyors)

- Water and Wastewater Treatment

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy)

- Asia Pacific (China, India, Japan, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (MEA)

Value Chain Analysis For Elastomeric Couplings Market

The value chain for the Elastomeric Couplings Market begins with the Upstream Analysis, which involves the sourcing and processing of raw materials. Key raw materials include various polymers and chemical additives (for the elastomeric element), as well as high-grade metals (steel, aluminum, cast iron) used for the coupling hubs and flanges. Manufacturers must maintain strong relationships with specialized chemical suppliers and metal foundries to ensure consistent quality and controlled input costs. Fluctuations in crude oil prices directly impact the cost of synthetic rubber and polyurethane, creating volatility in the upstream segment, which coupling producers must strategically manage through long-term procurement contracts and hedging strategies.

Midstream activities encompass the core manufacturing process, involving precision machining of the hubs, molding or casting of the elastomeric inserts, and final assembly and quality testing. Efficiency in this stage is critical, requiring advanced CNC machinery for hub production and specialized injection molding techniques to achieve the precise durometer hardness and geometry of the flexible element. Distribution Channel analysis highlights both direct and indirect sales approaches. Large original equipment manufacturers (OEMs) often purchase directly from coupling producers due to customized volume requirements, while indirect channels—comprising industrial distributors, value-added resellers (VARs), and maintenance, repair, and overhaul (MRO) service providers—handle the high-volume replacement and aftermarket sales, particularly serving smaller end-users and geographically dispersed locations.

The Downstream Analysis focuses on the end-users across various industries, where installation, maintenance, and replacement drive long-term revenue. Effective post-sales support, technical consultation, and readily available local inventory are crucial downstream success factors. The value chain is constantly optimized for speed and resilience; direct sales ensure deeper technical interaction and tailored solutions for complex projects, whereas the expansive indirect distribution network guarantees rapid availability of standard components, significantly impacting customer satisfaction and market reach. The complexity of the product, requiring specific application knowledge, necessitates strong technical training for channel partners to maintain product integrity during the selling process.

Elastomeric Couplings Market Potential Customers

Potential customers, or End-Users/Buyers, for elastomeric couplings are defined by the presence of rotating equipment requiring flexible power transmission and vibration isolation. The largest customer base resides within the heavy processing industries, specifically companies operating large-scale centrifugal pumps, reciprocating compressors, and industrial blowers, where coupling failure can result in substantial operational losses and safety hazards. These customers prioritize coupling reliability, high torque capacity relative to size, and resistance to environmental contaminants like oil, dust, and moisture, making specialized elastomer formulations a key purchasing criterion.

Secondary but rapidly growing customer segments include the renewable energy sector, primarily wind farm operators and solar power generation facilities. Wind turbines, in particular, utilize elastomeric couplings in pitch drives and high-speed shafts to dampen torque spikes and manage inherent misalignments caused by structural flexing and thermal expansion. This segment emphasizes components with long lifespan, minimal maintenance requirements, and demonstrated resilience under continuous, high-stress, cyclic loading conditions, driving demand for premium, highly durable elastomeric products, often with condition monitoring capabilities integrated into the coupling design.

Furthermore, customers involved in material handling (e.g., large conveyor systems in mining, bulk material terminals, and manufacturing assembly lines) represent a stable demand source for standard, rugged elastomeric couplings due to their ability to tolerate substantial shaft misalignments often present in long drive chains and outdoor installations. For all customer types, purchasing decisions are influenced not only by initial product cost but increasingly by Total Cost of Ownership (TCO), maintenance ease, Mean Time Between Failures (MTBF), and the availability of responsive local technical support and replacement parts, emphasizing the critical role of the aftermarket in this industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | R+L Hydraulics GmbH, Altra Industrial Motion Corp., The Timken Company, Rexnord Corporation, SKF Group, Tsubakimoto Chain Co., Voith GmbH & Co. KGaA, ABB Ltd., Regal Beloit Corporation, KTR Systems GmbH, Renold plc, Lovejoy Inc., Fenner Drives, John Crane (Smiths Group plc), RINGFEDER POWER TRANSMISSION GMBH, Shaftloc Couplings, GAM Enterprises, ComInTec, NBK, Flender GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Elastomeric Couplings Market Key Technology Landscape

The technological landscape within the Elastomeric Couplings Market is predominantly focused on material science advancements and integration of digital monitoring capabilities. Significant research and development efforts are dedicated to formulating proprietary high-performance elastomers that can withstand increasingly aggressive operating conditions, including higher rotational speeds, elevated temperatures, and exposure to corrosive chemicals and solvents. The development of advanced polyurethane blends, for example, allows for higher torque transmission with minimal deflection and increased fatigue life compared to traditional rubber compounds. Furthermore, technologies that simplify installation, such as keyless locking devices or split coupling designs, are being widely adopted to reduce assembly time and the technical skill required for maintenance teams.

A crucial technological shift is the incorporation of sensors and communication modules—an essential element of the Industry 4.0 movement. Modern elastomeric couplings are increasingly being paired with microelectromechanical systems (MEMS) sensors that monitor real-time parameters such as vibration levels, temperature spikes, and angular misalignment. This data is processed through condition monitoring systems (CMS) to provide predictive insights, allowing operators to schedule maintenance proactively before catastrophic failure occurs. The technology effectively transforms the coupling from a passive mechanical link into an active diagnostic tool, significantly enhancing overall plant reliability and operational efficiency, especially in remote or difficult-to-access industrial environments.

Innovation also centers on optimizing the geometry of the elastomeric element itself. Finite Element Analysis (FEA) and computational fluid dynamics (CFD) are extensively used during the design phase to refine the shape of the internal elements (like the 'spider' in a jaw coupling or the internal geometry of a tire element) to distribute stress more evenly, maximizing both the service life and the damping capabilities. These simulation technologies enable manufacturers to create tailored solutions for niche applications, ensuring optimal dynamic performance, minimizing undesirable resonance characteristics, and achieving a perfect balance between torsional flexibility and necessary stiffness required for precise power transmission, solidifying the market's trajectory towards highly engineered, application-specific products.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing market, driven by massive public and private investment in manufacturing (especially automotive and electronics), infrastructure development, and substantial expansion of the industrial base in China, India, and Southeast Asian nations. The region’s focus on establishing new process plants and upgrading existing facilities ensures sustained, high demand for new and replacement elastomeric couplings.

- North America: Characterized by mature industrial sectors, demand in North America is stable, largely driven by replacement cycles, modernization of aging infrastructure, and strict regulatory requirements mandating high-reliability components in oil & gas, aerospace, and wastewater treatment sectors. High-performance, low-maintenance couplings are highly valued here.

- Europe: Europe exhibits strong demand for technologically advanced couplings, influenced by rigorous environmental and energy efficiency standards. Germany, as a manufacturing powerhouse, leads in adopting specialized, customized elastomeric solutions in high-precision machinery, emphasizing sustainability and the integration of condition monitoring technologies into couplings.

- Latin America (LATAM): Growth is primarily linked to the resource extraction industries (mining, agriculture) and ongoing development of regional energy infrastructure. The market requires durable, rugged couplings capable of withstanding harsh, corrosive environments and heavy shock loads typical of these applications.

- Middle East & Africa (MEA): Demand is concentrated heavily within the extensive oil and gas production facilities, refining operations, and growing utility sector. Extreme temperature environments necessitate couplings made from specific, heat-resistant elastomeric materials (e.g., HNBR or specialized EPDM), driving demand for niche, high-specification products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Elastomeric Couplings Market.- R+L Hydraulics GmbH

- Altra Industrial Motion Corp.

- The Timken Company

- Rexnord Corporation

- SKF Group

- Tsubakimoto Chain Co.

- Voith GmbH & Co. KGaA

- ABB Ltd.

- Regal Beloit Corporation

- KTR Systems GmbH

- Renold plc

- Lovejoy Inc.

- Fenner Drives

- John Crane (Smiths Group plc)

- RINGFEDER POWER TRANSMISSION GMBH

- Shaftloc Couplings

- GAM Enterprises

- ComInTec

- NBK

- Flender GmbH

Frequently Asked Questions

Analyze common user questions about the Elastomeric Couplings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using elastomeric couplings over metallic couplings?

Elastomeric couplings offer superior vibration dampening and shock absorption, protecting adjacent machinery from dynamic stresses. They require no lubrication, inherently tolerate greater shaft misalignment (angular, parallel, and axial), and reduce operational noise, leading to lower maintenance costs and extended equipment life compared to rigid metallic designs.

Which elastomeric material is best suited for high-temperature industrial applications?

For high-temperature applications, specific synthetic elastomers such as EPDM (Ethylene Propylene Diene Monomer) or specialized blends of high-performance polyurethane are generally preferred over standard natural rubber or Nitrile, due to their enhanced thermal stability and resistance to oxidation and ozone degradation, maintaining flexibility and strength under continuous heat exposure.

How does shaft misalignment impact the lifespan of an elastomeric coupling?

While elastomeric couplings are designed to accommodate misalignment, excessive misalignment significantly accelerates the wear, heating, and fatigue failure of the flexible element. Proper alignment is critical; minimizing misalignment ensures that the coupling operates within its rated stress limits, maximizing service life and preventing premature equipment failure.

What is the role of Industry 4.0 in the future development of elastomeric couplings?

Industry 4.0 is integrating sensor technology and AI into couplings for condition monitoring. This enables predictive maintenance by collecting real-time data on vibration and temperature, allowing manufacturers to move beyond traditional time-based maintenance models toward highly efficient, data-driven preventative strategies, enhancing reliability and reducing downtime across industrial plants.

Which end-use industry is the major driver for high-torque elastomeric couplings?

The Oil & Gas and Power Generation sectors, particularly applications involving high-capacity compressors, heavy-duty pumps, and large industrial turbines, are the major drivers for high-torque elastomeric couplings. These environments require robust components capable of handling substantial power transmission while effectively isolating the drivetrain from severe shock loads.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager