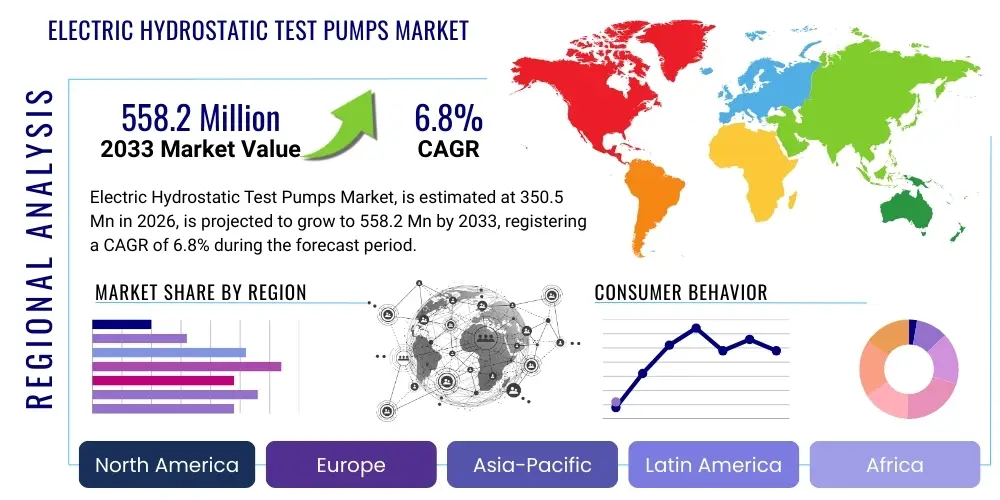

Electric Hydrostatic Test Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440317 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Electric Hydrostatic Test Pumps Market Size

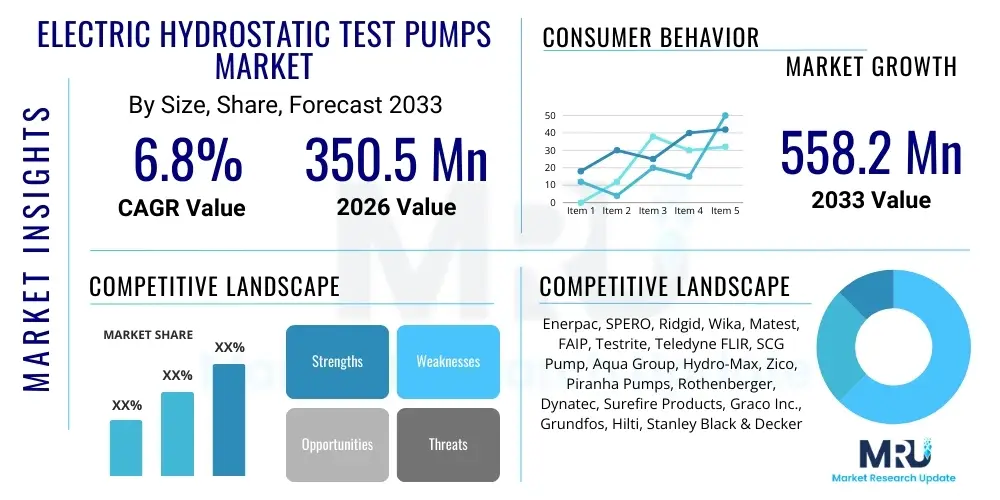

The Electric Hydrostatic Test Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350.5 million in 2026 and is projected to reach USD 558.2 million by the end of the forecast period in 2033.

Electric Hydrostatic Test Pumps Market introduction

Electric hydrostatic test pumps are specialized devices designed to verify the integrity and leak-proof nature of pressure containment systems such as pipelines, boilers, pressure vessels, fire sprinkler systems, and HVAC installations. These pumps utilize an electric motor to generate pressurized water or other test fluid, which is then used to subject a system to a specified test pressure, often significantly higher than its operational pressure, to detect leaks or structural weaknesses. Their primary function is to ensure safety, compliance with regulatory standards, and operational reliability across various industrial and commercial applications.

The market for electric hydrostatic test pumps is fundamentally driven by the critical need for safety and adherence to stringent industry regulations worldwide. These pumps offer significant benefits including high accuracy in pressure application, efficiency in testing procedures, enhanced safety for operators by minimizing manual effort, and portability for on-site applications. Key applications span across the oil and gas industry, manufacturing, construction, marine, and fire protection sectors, where reliable pressure testing is paramount. Factors such as rapid industrialization, expansion of critical infrastructure, and the continuous maintenance and upgrade of existing systems are consistently fueling market expansion, positioning these pumps as indispensable tools in modern engineering and maintenance protocols.

Electric Hydrostatic Test Pumps Market Executive Summary

The Electric Hydrostatic Test Pumps Market is experiencing robust growth driven by escalating industrial safety regulations and expanding infrastructure projects globally. Business trends indicate a strong move towards enhanced automation, data logging capabilities, and improved portability in pump designs, catering to a diverse range of end-user needs. Manufacturers are focusing on developing smart pumps integrated with digital interfaces to offer more precise control and detailed reporting, streamlining compliance and operational efficiency for clients. The competitive landscape is characterized by innovation aimed at making pumps more user-friendly, durable, and energy-efficient, responding to market demands for sustainable and cost-effective solutions.

Regionally, Asia Pacific emerges as a pivotal growth hub, propelled by extensive industrial development, construction booms, and significant investments in energy infrastructure. North America and Europe continue to maintain substantial market shares due to stringent regulatory frameworks and continuous infrastructure upgrades, fostering consistent demand for reliable testing equipment. Segment-wise, the market sees dynamic growth in both portable and stationary pump categories, with portable units gaining traction for their versatility in field applications and stationary units remaining essential for large-scale, factory-based testing. The fire protection and oil & gas sectors are particularly strong drivers, necessitating frequent and rigorous pressure testing for safety and operational continuity.

AI Impact Analysis on Electric Hydrostatic Test Pumps Market

Users frequently inquire about how artificial intelligence can transform the efficiency, accuracy, and safety of hydrostatic testing. The primary themes revolve around predictive maintenance for the pumps themselves, smart diagnostic capabilities for the tested systems, and the potential for autonomous or semi-autonomous testing processes. Concerns often include the cost of integration, data security, and the need for skilled personnel to manage AI-driven systems. Expectations are high for AI to reduce human error, optimize testing parameters, and provide more insightful analysis of test data, ultimately leading to significant operational improvements and enhanced safety compliance.

- AI can enable predictive maintenance for test pumps, minimizing downtime and optimizing service schedules.

- Integration of AI can lead to smart diagnostics within tested systems, identifying anomalies and potential failure points more accurately.

- AI algorithms can optimize testing parameters (pressure, duration) based on material properties and historical data, improving efficiency.

- Autonomous data logging and real-time analysis through AI can generate comprehensive compliance reports instantly.

- AI-powered visual inspection systems can augment human operators in identifying subtle leaks or structural weaknesses during testing.

- Enhanced safety protocols through AI-driven risk assessment and automated emergency shutdowns.

DRO & Impact Forces Of Electric Hydrostatic Test Pumps Market

The Electric Hydrostatic Test Pumps Market is significantly influenced by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include stringent regulatory mandates globally, particularly in sectors such as oil & gas, construction, and fire protection, which necessitate regular integrity testing for safety and operational compliance. Rapid infrastructure development, especially in emerging economies, and the ongoing maintenance and upgrade of aging infrastructure in developed regions, create a sustained demand for reliable testing equipment. Furthermore, the inherent benefits of electric pumps—precision, efficiency, and reduced manual labor—contribute to their increasing adoption.

However, the market faces several restraints, including the relatively high initial capital expenditure for advanced electric hydrostatic test pumps, which can be a barrier for smaller businesses. The need for skilled personnel to operate and maintain these sophisticated devices, especially those with integrated digital and AI features, presents another challenge. Additionally, economic downturns or fluctuations in raw material prices can impact manufacturing costs and market growth. Despite these, significant opportunities exist in the expansion into new application areas, the integration of IoT and Industry 4.0 technologies for smart testing solutions, and the growth of the rental market for specialized equipment, allowing broader access to these essential tools.

Impact forces such as technological advancements in sensor technology, battery life for portable units, and software for data analysis continually reshape product offerings and market competitiveness. Changes in environmental regulations promoting leak prevention and energy efficiency also drive innovation. Global economic stability directly influences investment in infrastructure and industrial projects, while geopolitical factors can impact supply chains and market access. The continuous evolution of safety standards acts as a perpetual force, pushing for more advanced and reliable testing solutions, reinforcing the market's fundamental importance.

Segmentation Analysis

The Electric Hydrostatic Test Pumps Market is comprehensively segmented to provide a detailed understanding of its diverse landscape and growth opportunities. This segmentation helps in identifying specific market niches, understanding user needs across different applications, and analyzing regional consumption patterns. Key segments are defined by pump type, pressure range, application, and the end-user industry, reflecting the varied requirements for hydrostatic testing across the global industrial and commercial sectors. Each segment exhibits unique growth trajectories influenced by specific technological advancements, regulatory pressures, and investment trends, making granular analysis crucial for strategic market planning.

- By Type:

- Portable Electric Hydrostatic Test Pumps

- Stationary Electric Hydrostatic Test Pumps

- By Pressure Range:

- Low Pressure (Up to 500 psi)

- Medium Pressure (501-5000 psi)

- High Pressure (Above 5000 psi)

- By Application:

- Pipeline Testing

- Pressure Vessel Testing

- Fire Sprinkler Systems Testing

- HVAC Systems Testing

- Boiler Testing

- Industrial System Integrity Testing

- Hydraulic Systems Testing

- Others (e.g., Solar Water Heaters, Geothermal Systems)

- By End-User Industry:

- Oil and Gas

- Manufacturing

- Construction

- Marine

- Chemical and Petrochemical

- Pharmaceutical

- Power Generation

- HVAC & Plumbing Contractors

- Fire Protection Services

- Utilities (Water and Wastewater Management)

- Others (e.g., Mining, Aerospace)

Value Chain Analysis For Electric Hydrostatic Test Pumps Market

The value chain for the Electric Hydrostatic Test Pumps Market begins with upstream activities involving the sourcing of raw materials and the manufacturing of critical components. This phase includes suppliers of electric motors, pumps, pressure gauges, control systems, and durable materials such as specialized plastics and metals. Component manufacturers often specialize in specific parts, ensuring high quality and precision, which are crucial for the safety and reliability of the final product. The integration of advanced electronics and software components is also increasingly important at this stage, setting the foundation for the pump's performance and smart capabilities.

Midstream activities involve the assembly, testing, and quality control of the electric hydrostatic test pumps by the original equipment manufacturers (OEMs). This stage focuses on integrating all components, ensuring the pump meets specified pressure ratings, flow rates, and safety standards. Extensive testing is conducted to verify performance under various conditions before the product is released for distribution. Downstream activities encompass the distribution, sales, and post-sales support, connecting the manufactured pumps with the end-users. Distribution channels are varied, involving both direct sales and indirect networks.

Direct distribution channels involve manufacturers selling directly to large industrial clients, government entities, or through their own dedicated sales forces and online portals, enabling closer customer relationships and bespoke solutions. Indirect channels primarily involve a network of authorized distributors, wholesalers, and retailers who cater to a broader range of smaller businesses, contractors, and individual professionals. These channels are crucial for market penetration and providing local support, maintenance services, and spare parts. The efficiency of both upstream component supply and downstream distribution networks significantly impacts market reach, pricing, and overall customer satisfaction, making effective value chain management critical for market success.

Electric Hydrostatic Test Pumps Market Potential Customers

The primary potential customers for electric hydrostatic test pumps span across a wide spectrum of industries where system integrity, safety, and regulatory compliance are paramount. These end-users are typically responsible for maintaining, installing, or inspecting pressure-containing systems and infrastructure. The demand stems from the continuous need to prevent leaks, structural failures, and ensure the operational efficiency and safety of various critical assets.

Key segments include construction companies involved in building new pipelines, residential and commercial structures with extensive plumbing, and fire protection systems installers who require precise pressure testing before commissioning. The oil and gas industry, encompassing upstream, midstream, and downstream operations, is a significant consumer for testing pipelines, pressure vessels, and storage tanks. Manufacturing plants, particularly in chemical, pharmaceutical, and power generation sectors, rely on these pumps for quality assurance of their process equipment and boiler systems. HVAC contractors regularly use them for testing refrigeration lines and hydronic systems, while the marine industry utilizes them for ship piping and ballast tanks. Utilities involved in water and wastewater management also constitute a substantial customer base, ensuring the integrity of their vast networks. This diverse customer landscape underscores the widespread applicability and indispensable nature of electric hydrostatic test pumps in modern industrial and commercial environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 million |

| Market Forecast in 2033 | USD 558.2 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Enerpac, SPERO, Ridgid, Wika, Matest, FAIP, Testrite, Teledyne FLIR, SCG Pump, Aqua Group, Hydro-Max, Zico, Piranha Pumps, Rothenberger, Dynatec, Surefire Products, Graco Inc., Grundfos, Hilti, Stanley Black & Decker |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Hydrostatic Test Pumps Market Key Technology Landscape

The Electric Hydrostatic Test Pumps Market is continuously evolving with technological advancements aimed at improving efficiency, accuracy, safety, and user-friendliness. A significant trend is the integration of digital interfaces, replacing traditional analog gauges with high-precision digital pressure gauges and readouts. These digital systems offer superior accuracy, often displaying pressure in multiple units, and can be calibrated more easily. Furthermore, the incorporation of data logging capabilities allows operators to record test parameters, durations, and results, which is crucial for regulatory compliance, traceability, and detailed reporting. This feature streamlines the documentation process and minimizes manual error, making testing procedures more reliable and efficient.

Another crucial technological development involves the adoption of variable frequency drives (VFDs) and advanced motor control systems. VFDs enable precise control over pump speed and, consequently, pressure output, allowing for smoother pressure ramps and more stable holding pressures. This not only enhances testing accuracy but also contributes to energy efficiency by only drawing the power needed for the specific test. For portable units, advancements in battery technology are extending operational times and reducing charging cycles, making these pumps more versatile for remote and off-grid applications. The emphasis on robust, lightweight materials also contributes to the portability and durability of these devices.

Looking ahead, the market is increasingly seeing the integration of IoT (Internet of Things) connectivity and remote monitoring capabilities. This allows for real-time data transmission from the test site to a central system, enabling supervisors to monitor multiple tests simultaneously, troubleshoot remotely, and access historical data from any location. Some advanced models are even incorporating features like automated pressure relief valves and programmable test cycles, further enhancing safety and reducing the need for constant operator intervention. These technological enhancements are transforming electric hydrostatic test pumps from mere mechanical devices into intelligent, data-driven tools integral to modern industrial maintenance and quality assurance.

Regional Highlights

- North America: A mature market characterized by stringent safety regulations and a robust industrial sector, particularly in oil & gas, manufacturing, and construction. Demand is consistent due to ongoing infrastructure maintenance, upgrades, and new project developments. The region leads in adopting advanced, digital, and automated testing solutions.

- Europe: Driven by strict environmental and safety standards, particularly in Germany, the UK, and France. Strong emphasis on quality assurance in manufacturing, chemical, and energy sectors. The market benefits from a well-established industrial base and a focus on sustainable and energy-efficient testing equipment.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, urbanization, and massive infrastructure investments in countries like China, India, and Southeast Asian nations. Significant expansion in manufacturing, construction, and oil & gas projects creates immense demand for hydrostatic testing equipment. Cost-effectiveness and localized manufacturing are key competitive factors.

- Latin America: Experiencing growth from increasing investments in oil & gas exploration, mining, and public infrastructure projects. Brazil and Mexico are leading markets, with a growing need for reliable and efficient testing solutions to meet developing regulatory frameworks.

- Middle East and Africa (MEA): Growth is primarily driven by large-scale oil & gas projects, infrastructure development (e.g., smart cities), and industrial diversification initiatives. Saudi Arabia, UAE, and Qatar are significant contributors, with increasing focus on international safety standards and the adoption of advanced testing technologies for new installations and maintenance of existing infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Hydrostatic Test Pumps Market.- Enerpac

- SPERO

- Ridgid

- Wika

- Matest

- FAIP

- Testrite

- Teledyne FLIR

- SCG Pump

- Aqua Group

- Hydro-Max

- Zico

- Piranha Pumps

- Rothenberger

- Dynatec

- Surefire Products

- Graco Inc.

- Grundfos

- Hilti

- Stanley Black & Decker

Frequently Asked Questions

Analyze common user questions about the Electric Hydrostatic Test Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of electric hydrostatic test pumps?

Electric hydrostatic test pumps are primarily used for verifying the integrity and leak-proof nature of pipelines, pressure vessels, fire sprinkler systems, HVAC systems, boilers, and other pressure containment systems across various industries like oil & gas, construction, and manufacturing.

How do electric hydrostatic test pumps contribute to safety?

These pumps ensure safety by accurately testing systems to detect leaks or structural weaknesses before they are put into operation, preventing potential failures, accidents, and environmental hazards, thereby complying with stringent safety regulations.

What are the key advantages of using electric models over manual or pneumatic pumps?

Electric models offer superior precision in pressure application, higher efficiency through reduced manual effort, faster testing cycles, consistent performance, and often include advanced features like digital readouts and data logging, enhancing overall reliability and compliance.

Which regions are driving the growth of the Electric Hydrostatic Test Pumps Market?

The Asia Pacific region is the fastest-growing market due to rapid industrialization and infrastructure development. North America and Europe also maintain significant market shares owing to stringent regulations and continuous infrastructure maintenance needs.

What technological advancements are influencing the market?

Key technological advancements include the integration of digital pressure gauges, data logging capabilities, variable frequency drives (VFDs) for precise control, enhanced battery life for portable units, and emerging IoT connectivity for remote monitoring and predictive maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager