Electric Lifting Columns Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433503 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Electric Lifting Columns Market Size

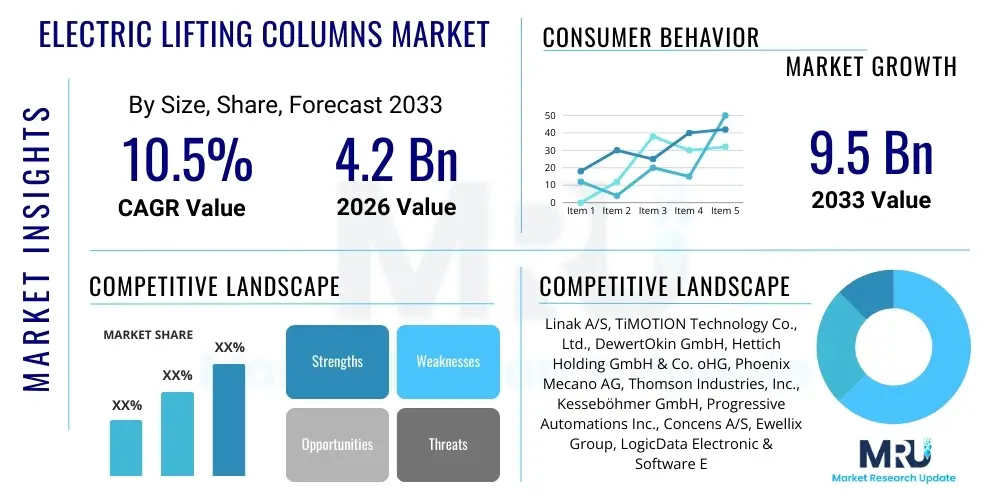

The Electric Lifting Columns Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 9.5 Billion by the end of the forecast period in 2033.

Electric Lifting Columns Market introduction

Electric lifting columns are self-supporting linear actuators designed to handle vertical load applications requiring smooth, precise, and controlled height adjustment. These systems typically consist of multiple telescoping profiles driven by an internal motor and gearbox assembly, often integrated with advanced control units. The core function is to provide ergonomic, stable, and dynamic motion solutions across various industries. They replace manual adjustment mechanisms, offering significant benefits in terms of ease of use, safety, repeatability, and integration into smart environments, particularly in settings that require frequent changes in working height or posture.

The primary applications for electric lifting columns are highly diverse, spanning ergonomic office furniture, industrial automation systems, and advanced medical equipment. In the commercial sector, they are pivotal in the rise of sit-stand desks and adaptable workstations, addressing growing global concerns regarding sedentary lifestyles and workplace well-being. Industrially, they are integrated into assembly lines, machinery interfaces, and heavy-duty logistics platforms where precise height positioning is critical for operational efficiency and worker safety. The benefits extend beyond mere adjustment, encompassing features like quiet operation, high duty cycles, integrated collision detection, and synchronization capabilities for multi-column systems.

Driving factors underpinning the market growth include the robust adoption of ergonomic standards mandated by regulatory bodies globally, rapid expansion in manufacturing automation (Industry 4.0), and the increasing prevalence of advanced home and clinical healthcare settings requiring adjustable examination tables, operating room equipment, and mobility aids. The shift towards dynamic, intelligent workspaces, both commercial and residential, coupled with technological advancements leading to more powerful, compact, and energy-efficient column designs, continues to fuel sustained demand across mature and emerging economies.

Electric Lifting Columns Market Executive Summary

The Electric Lifting Columns Market is undergoing substantial growth, driven primarily by the global emphasis on workplace ergonomics and the accelerated implementation of smart factory automation. Business trends indicate a strong move toward customization and integration of advanced features such as Bluetooth connectivity, programmable memory functions, and sophisticated anti-collision sensors, enhancing user interaction and safety. Manufacturers are strategically focusing on developing lighter, high-load-capacity columns with minimal noise profiles to meet the demanding specifications of premium furniture and critical medical applications. Furthermore, sustainability is becoming a key business differentiator, with companies investing in recyclable materials and energy-efficient motor technologies to align with corporate social responsibility goals and capture environmentally conscious consumers.

Regionally, North America and Europe maintain dominance, characterized by stringent occupational safety regulations and high penetration of ergonomic office solutions. However, the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by rapid industrialization, burgeoning medical infrastructure development (particularly in China and India), and the swift adoption of automated assembly and testing equipment across diverse manufacturing hubs. Emerging markets are increasingly recognizing the productivity gains associated with ergonomic workstations, creating significant untapped opportunities for low-cost, high-reliability lifting column solutions tailored to specific regional economic profiles.

Segment trends reveal that the three-stage column design is gaining traction over two-stage designs due to its superior stroke-to-retracted-height ratio, offering greater flexibility and applicability across diverse height requirements, especially in desk and medical bed applications. Application-wise, the Ergonomic Furniture segment remains the largest volume driver, while the Industrial Automation segment is projected to exhibit the fastest growth, reflective of continuous capital expenditure in modernizing industrial processes. Manufacturers are also seeing increasing demand for heavy-duty columns capable of supporting sophisticated machinery and bariatric medical equipment, demanding continuous innovation in material strength and motor torque capabilities.

AI Impact Analysis on Electric Lifting Columns Market

User inquiries regarding AI's impact on the Electric Lifting Columns Market primarily revolve around how machine learning can optimize column performance, predict maintenance needs, and integrate the columns into broader IoT and smart building management systems. Common questions address the potential for AI-driven collision avoidance mechanisms to become more predictive rather than reactive, utilizing environmental sensors and learned user behavior. Additionally, users are keen to understand how AI algorithms can personalize ergonomic settings based on continuous user monitoring (e.g., posture tracking) and how this data can be utilized by facility managers for space optimization and energy management. The core thematic concern is the shift from passive, motor-driven hardware to proactive, intelligent motion solutions that enhance user safety and operational efficiency without requiring manual intervention.

AI integration is expected to revolutionize the control units of electric lifting columns, transforming them from simple up/down actuators into intelligent edge devices. For instance, AI can analyze motor load fluctuation patterns in real-time to detect minor mechanical wear or potential component failure before it impacts functionality, enabling predictive maintenance scheduling and minimizing downtime, which is crucial in critical environments like operating rooms or high-throughput assembly lines. This predictive capability significantly extends the operational lifespan of the columns and ensures consistent performance stability, which is highly valued in industrial and medical applications where reliability is non-negotiable.

Furthermore, Generative AI and advanced machine learning models are playing a role in the design and prototyping phase, optimizing the structural integrity of the telescoping mechanism while minimizing material use and weight. In the application space, particularly ergonomic furniture, AI-powered systems can learn individual user preferences and automatically adjust height, tilt, and depth based on the specific task being performed (e.g., video conferencing versus focused writing), creating truly dynamic and personalized ergonomic environments. This deep level of personalization, facilitated by behavioral data processing, elevates the value proposition of premium electric lifting column systems.

- Enhanced Predictive Maintenance: AI algorithms analyze motor vibration and current draw to predict component failure, reducing unexpected downtime.

- Intelligent Anti-Collision: Machine learning enables columns to differentiate between obstacles and environmental features, improving responsiveness and safety.

- Personalized Ergonomics: AI tracks user posture and task context to automatically adjust column height for optimal ergonomic positioning.

- Seamless IoT Integration: AI serves as a central hub, allowing lifting columns to communicate with smart lighting, HVAC, and building management systems for energy optimization.

- Optimized Design and Manufacturing: Generative AI assists in designing lighter, stronger column profiles and optimizing manufacturing tolerances.

DRO & Impact Forces Of Electric Lifting Columns Market

The market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the principal impact forces. Primary drivers include the global push for ergonomic compliance in commercial spaces, heightened investments in industrial automation fueled by Industry 4.0 initiatives, and the rapid expansion of the healthcare sector necessitating advanced adjustable patient-handling equipment. These factors create strong fundamental demand across all geographical areas. Concurrently, opportunities arise from the increasing adoption of smart home technology, offering new consumer markets for adjustable kitchen systems and personalized home office solutions, and the development of lightweight, high-performance composite materials that can improve load capacity while reducing product footprint.

Restraints, however, pose challenges to market expansion. The most significant restraint is the high initial cost associated with premium electric lifting column systems compared to manual or gas-spring alternatives, particularly sensitive in price-conscious emerging markets. Furthermore, the complexity of integrating advanced electronic control systems with existing furniture designs or industrial infrastructure can deter smaller businesses. Trade volatility and fluctuating costs of key components, such as electric motors, precision gears, and specialized control chips, also impact manufacturing margins and final product pricing, exerting downward pressure on volume growth in certain price segments. Intellectual property disputes related to patented telescoping mechanisms and control software also occasionally create market friction.

The overall impact forces are strongly positive. The dominant force is the societal shift towards wellness and productivity, translating directly into corporate mandates for ergonomic furniture, ensuring sustained long-term demand regardless of short-term economic fluctuations. Regulatory forces, particularly in mature markets like the EU and North America, mandate specific safety standards for industrial lifting equipment and medical devices, driving manufacturers toward high-quality, certified lifting column solutions. The rapid pace of technological innovation, particularly in miniaturization and connectivity (IoT), acts as a continuous accelerant, making the columns more versatile and easier to integrate, thereby overcoming price barriers through added value and improved functionality.

Segmentation Analysis

The Electric Lifting Columns Market is meticulously segmented based on key structural, performance, and application criteria, allowing for granular analysis of demand patterns and strategic opportunities. Segmentation by Type focuses on the physical structure of the column (e.g., two-stage vs. three-stage), directly impacting the stroke length and stability ratio. Application segmentation defines the end-use environment, ranging from dynamic office environments to rigorous industrial assembly lines and highly regulated medical settings. Furthermore, segmentation by Lifting Capacity categorizes products based on their maximum supported weight, which is a critical specification for industrial and bariatric applications, dictating material requirements and motor specifications, thereby influencing pricing and market positioning.

Understanding these segments is crucial for manufacturers to tailor their R&D and marketing efforts. For instance, the demand drivers in the medical segment (reliability, silent operation, compliance) differ significantly from those in the office segment (aesthetics, speed, connectivity). The ongoing trend towards multi-stage columns highlights the market preference for maximizing stroke length within minimal retracted heights, optimizing space utilization. This detailed segmentation analysis provides the necessary framework for identifying high-growth niches, assessing competitive intensity within specific product categories, and forecasting regional demand shifts based on local industry focus and regulatory environments.

The interplay between technical specifications and end-user requirements defines market segmentation strategy. For example, a heavy-duty, two-stage column might be ideal for a simple industrial workbench, prioritizing robustness over stroke length, whereas a sleek, three-stage column with advanced electronic controls is mandated for a premium ergonomic desk or sophisticated surgical trolley. The convergence of hardware capability with intelligent control software is increasingly blurring the lines between these segments, demanding that modern lifting column manufacturers offer scalable and adaptable platforms capable of serving multiple applications with minimal component modification, thus streamlining production and inventory management.

- By Type:

- Two-Stage Columns

- Three-Stage Columns

- Multi-Stage/Custom Columns

- By Application:

- Ergonomic Furniture (Desks, Workstations)

- Industrial Automation (Assembly Lines, Workbenches, Material Handling)

- Medical Devices (Hospital Beds, Examination Tables, Operating Tables, Mobility Aids)

- Residential Applications (Kitchen Lifts, Home Office)

- By Lifting Capacity:

- Light Duty (Below 100 kg)

- Medium Duty (100 kg – 300 kg)

- Heavy Duty (Above 300 kg)

Value Chain Analysis For Electric Lifting Columns Market

The value chain for electric lifting columns commences with upstream activities involving the sourcing and refinement of specialized raw materials and precision components. This includes aluminum and steel for column profiles, specialized plastics for guides and bearings, and, crucially, high-performance DC motors, gearboxes, and sophisticated electronic control units (ECUs) and microprocessors. Key suppliers in the upstream segment are highly specialized motor manufacturers and component integrators, where quality, precision engineering, and consistency are paramount, directly impacting the final product's reliability and noise level. Relationships with these specialized suppliers, particularly those providing proprietary motor technologies, are critical for maintaining a competitive edge and ensuring supply chain resilience.

Midstream activities involve the design, assembly, and quality assurance of the lifting columns themselves. Manufacturers focus heavily on precision machining, assembly line automation, and rigorous testing for load capacity, speed, noise levels, and compliance with international standards (e.g., UL, CE, FDA). Design innovation is crucial here, particularly in developing compact motor housings, improving telescoping synchronization for multi-column systems, and integrating intelligent features like anti-collision sensors. This stage is capital-intensive, requiring advanced manufacturing facilities and highly skilled engineering teams focused on optimizing performance metrics and cost efficiency. Vertical integration, where core components like gearboxes or controls are produced internally, can offer significant competitive advantages in cost control and quality oversight.

Downstream activities involve distribution, sales, installation, and aftermarket services. Distribution channels are highly dependent on the target application: direct sales and B2B contracts dominate the industrial and medical segments, often requiring complex integration support. Conversely, the ergonomic furniture segment heavily utilizes OEM agreements, specialized furniture wholesalers, and increasingly, direct-to-consumer (D2C) e-commerce platforms, particularly for home office solutions. Aftermarket support, including warranty services, maintenance, and the provision of replacement control units, forms a critical part of the value proposition, ensuring customer satisfaction and long-term brand loyalty. Successful market penetration relies on efficient logistics networks and knowledgeable installation support to maintain product integrity and performance upon delivery.

Electric Lifting Columns Market Potential Customers

The primary customers for electric lifting columns are diverse, encompassing major original equipment manufacturers (OEMs) of commercial furniture, systems integrators for industrial automation, and specialized producers of advanced medical equipment. In the furniture sector, these include global manufacturers of sit-stand desks, adjustable conference tables, and specialized retail display systems that require dynamic height adjustments. These customers demand aesthetically pleasing, quiet, and highly customizable columns that integrate seamlessly into modern interior designs and provide robust control features such as Bluetooth capability and memory presets for multiple users. Reliability and long-term warranty support are critical considerations for large-volume OEM buyers.

In the industrial sphere, end-users include discrete manufacturing facilities, automotive assembly plants, and logistics and warehousing operations. Here, electric lifting columns are purchased by system integrators who incorporate them into custom assembly workbenches, inspection stations, material lifts, and automated guided vehicles (AGVs). These customers prioritize high load capacity, rugged durability, high duty cycles (ability to operate continuously), and precise synchronization capabilities, as performance directly impacts operational throughput and worker safety on the factory floor. They often procure heavy-duty, customized columns designed to withstand harsh operational environments involving dust, vibration, and significant torque loads.

The medical and healthcare sector represents a high-value customer base, including hospitals, clinics, and manufacturers of patient-handling devices. Key purchases involve columns for height-adjustable operating tables, advanced diagnostic imaging equipment (like CT scanners), patient lift systems, and specialized bariatric beds. For this segment, the critical purchasing criteria are silent operation (crucial in clinical settings), absolute reliability, strict adherence to medical device regulations (e.g., IEC 60601 compliance), and resistance to cleaning agents. The columns must offer extremely precise, smooth movement to ensure patient comfort and clinical accuracy during sensitive procedures, making them premium customers focused on quality over cost minimization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 9.5 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linak A/S, TiMOTION Technology Co., Ltd., DewertOkin GmbH, Hettich Holding GmbH & Co. oHG, Phoenix Mecano AG, Thomson Industries, Inc., Kesseböhmer GmbH, Progressive Automations Inc., Concens A/S, Ewellix Group, LogicData Electronic & Software Entwicklungs GmbH, Kinet-X Motion Control, Hafele GmbH & Co KG, Ketterer GmbH & Co. KG, Bosch Rexroth AG, Venture Mfg. Co., Novanda SA. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Lifting Columns Market Key Technology Landscape

The technological landscape of the electric lifting columns market is defined by innovation focused on enhancing motor efficiency, control precision, and connectivity. Key technologies include advanced brushless DC (BLDC) motor systems, which offer superior energy efficiency, longer lifecycles, and significantly reduced noise levels compared to traditional brushed motors, making them essential for premium ergonomic and medical applications. Furthermore, the development of sophisticated Hall effect sensors and encoders allows for highly accurate positional feedback, critical for ensuring synchronous movement across multiple columns in heavy-duty or large-surface applications, where even minor discrepancies can lead to structural instability or operational failure.

A critical area of technological advancement lies in the control units and software integration. Modern columns utilize CAN bus (Controller Area Network) or proprietary bus systems for reliable communication between multiple columns, a central control box, and external interfaces. The inclusion of integrated microprocessors and proprietary firmware facilitates advanced functionalities such as programmable height memory, soft start/stop routines, and sophisticated real-time load monitoring. More recently, Bluetooth and Wi-Fi connectivity have become standard in high-end models, enabling users to control columns via smartphone applications or integrate them into broader smart home or smart office ecosystems, facilitating complex scheduling and automation routines.

Materials science and mechanical engineering also drive the technology landscape. Manufacturers are leveraging advanced aluminum extrusion techniques to create lighter yet structurally rigid column profiles that maximize stability at full extension while maintaining a sleek aesthetic profile. The integration of patented, low-friction guiding systems, often involving specialized plastic compounds (e.g., PTFE-based components), minimizes wear and tear and further contributes to silent operation. The push for collision detection has evolved from simple pressure sensors to gyroscopic sensors and inertia monitoring, using real-time acceleration data to quickly identify and halt movement upon impact, significantly enhancing safety and protecting expensive equipment or furniture from damage, reflecting a proactive approach to motion control.

Regional Highlights

- North America: North America represents a mature and dominant market for electric lifting columns, particularly driven by the stringent adoption of ergonomic standards within corporate offices and the rapid technological upgrade cycles in the medical sector. The U.S. and Canada lead in the implementation of "wellness" policies, resulting in high demand for premium sit-stand desks and adjustable workstations across major metropolitan areas and technology hubs. The region benefits from a robust ecosystem of specialized component suppliers and leading furniture OEMs, fostering continuous innovation in control systems and connectivity features. Furthermore, high capital expenditure in the healthcare industry necessitates the procurement of advanced, compliant, and highly reliable electric lifting columns for specialized hospital equipment, underpinning stable growth in the medical application segment.

- Europe: Europe maintains a strong market position, fueled by highly developed industrial automation sectors (particularly in Germany and Scandinavia) and strong regulatory support for occupational health and safety (OHS). European manufacturers are renowned for high-quality engineering, emphasizing product durability, energy efficiency, and adherence to noise reduction standards. Germany, as a major manufacturing and automation hub, drives demand for medium and heavy-duty industrial columns, while Nordic countries are pioneers in integrating ergonomic design into all aspects of commercial and public furniture. The shift towards circular economy principles also pressures manufacturers to utilize sustainable materials and design columns for ease of repair and recycling, driving technological focus on material science and lifecycle management.

- Asia Pacific (APAC): The APAC region is the fastest-growing market globally, characterized by explosive growth in manufacturing output, rapid urbanization, and significant government investment in healthcare infrastructure, particularly in countries like China, India, Japan, and South Korea. China, as a major global furniture manufacturing center and consumer market, drives massive volume demand for columns, catering both to domestic ergonomic needs and global export requirements. The rise of industrial automation, spurred by wage inflation and government-backed initiatives like "Made in China 2025," accelerates the adoption of lifting columns in factory workbenches and automated material handling systems. While price sensitivity remains higher than in Western markets, there is increasing demand for quality, mid-range products that offer reliable performance and cost efficiency.

- Latin America (LATAM): The LATAM market is emerging, demonstrating steady but moderate growth, primarily concentrated in economically developed countries such as Brazil and Mexico. Demand is generally restricted to high-end commercial office projects, multinational corporate branches, and specialized medical facilities that adhere to international standards. Market growth is often dependent on foreign direct investment and the expansion of international corporations that bring established ergonomic workplace standards with them. Logistics and distribution channels pose ongoing challenges, leading to higher final product costs compared to other regions. However, the burgeoning middle class and increasing focus on industrial modernization projects promise incremental expansion in the medium term.

- Middle East and Africa (MEA): The MEA region exhibits heterogeneous market characteristics. The Gulf Cooperation Council (GCC) countries drive demand due to massive investments in new infrastructure, smart city development (e.g., NEOM), and state-of-the-art hospitals, prioritizing premium, technologically advanced column solutions. Economic diversification away from oil, particularly into non-oil sectors like finance and technology, is spurring demand for modern commercial fit-outs. In contrast, the African continent remains a small market, where demand is primarily limited to resource extraction industries requiring heavy-duty industrial solutions and aid-funded healthcare projects. Growth potential relies heavily on large-scale infrastructure projects and stabilizing economic conditions across key African nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Lifting Columns Market.- Linak A/S

- TiMOTION Technology Co., Ltd.

- DewertOkin GmbH

- Hettich Holding GmbH & Co. oHG

- Phoenix Mecano AG

- Thomson Industries, Inc.

- Kesseböhmer GmbH

- Progressive Automations Inc.

- Concens A/S

- Ewellix Group

- LogicData Electronic & Software Entwicklungs GmbH

- Kinet-X Motion Control

- Hafele GmbH & Co KG

- Ketterer GmbH & Co. KG

- Bosch Rexroth AG

- Venture Mfg. Co.

- Novanda SA

- SKF Group

- Movetec Oy

- Suspa GmbH

Frequently Asked Questions

Analyze common user questions about the Electric Lifting Columns market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the adoption of electric lifting columns in the office furniture segment?

Adoption is primarily driven by global health concerns regarding sedentary behavior, leading to regulatory and corporate mandates for ergonomic workstations (sit-stand desks). Key drivers include improved employee productivity, workplace wellness initiatives, and the integration of smart, customizable height adjustment technology.

How do two-stage columns compare structurally and functionally to three-stage columns?

Two-stage columns offer robust stability and lower cost but provide a shorter stroke length. Three-stage columns, preferred for ergonomic desks and medical tables, offer a significantly greater stroke-to-retracted-height ratio, allowing for a wider adjustment range while maintaining structural integrity at maximum extension.

What role does the Internet of Things (IoT) play in the future development of lifting columns?

IoT enables electric lifting columns to become smart, connected devices. This facilitates remote control via mobile apps, seamless integration with building management systems for environmental control, and the collection of usage data for predictive maintenance and personalized ergonomic adjustments based on real-time behavior.

What are the most stringent technical requirements for electric lifting columns used in medical applications?

Medical applications require silent operation, high reliability (long duty cycles), absolute precision in movement, and strict adherence to medical standards such as IEC 60601 for electrical safety. They must also be resistant to common cleaning and disinfection chemicals used in clinical environments.

Which geographical region is expected to demonstrate the highest growth rate during the forecast period?

The Asia Pacific (APAC) region is projected to exhibit the highest CAGR, primarily fueled by rapid industrialization, massive government investment in healthcare infrastructure, and the expanding adoption of ergonomic solutions within China, India, and other rapidly developing economies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager