Electric Linear Actuators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433403 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Electric Linear Actuators Market Size

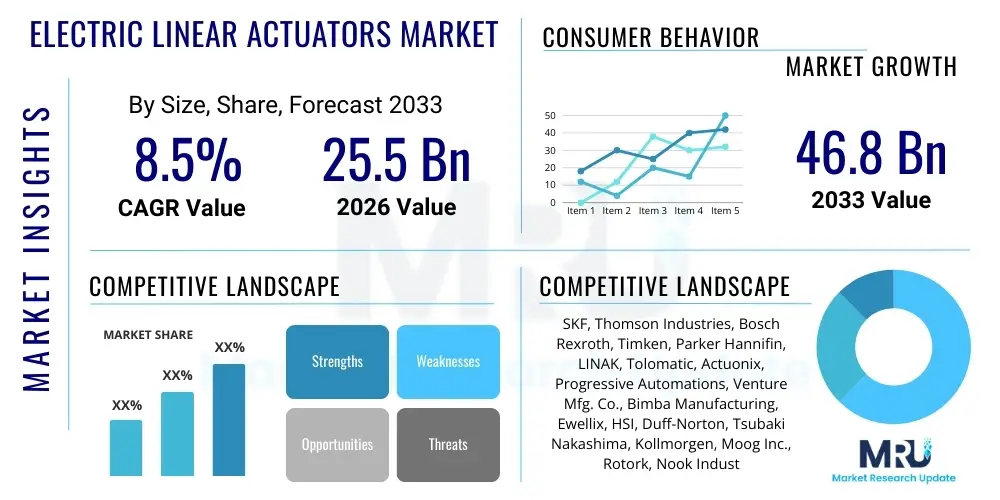

The Electric Linear Actuators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 25.5 Billion in 2026 and is projected to reach USD 46.8 Billion by the end of the forecast period in 2033.

Electric Linear Actuators Market introduction

Electric linear actuators are devices designed to convert rotational motion into linear motion, utilizing electric motors coupled with components such as lead screws, ball screws, or roller screws. These systems offer precise control, high repeatability, and energy efficiency compared to traditional hydraulic or pneumatic systems, making them indispensable components in modern automation and motion control applications. The fundamental product description centers on their ability to provide controlled push and pull movements based on electrical input, facilitating complex automated tasks across various industrial settings. Their increasing adoption is driven by the growing demand for automation and the shift towards cleaner, more precise motion control solutions, especially in environments where cleanliness and low maintenance are critical factors.

The major applications of electric linear actuators span diverse sectors, including industrial automation (material handling, robotics, assembly lines), medical devices (patient positioning, surgical equipment), automotive manufacturing (painting and welding robots), and aerospace (flight control surfaces, landing gear mechanisms). Furthermore, they are widely utilized in ergonomic applications such as height-adjustable desks and specialized furniture, reflecting their versatility. The inherent benefits, such as programmability, digital communication capabilities (e.g., bus systems integration), and high force density, significantly contribute to operational efficiency and reduced downtime for end-users. Unlike fluid-power systems, electric actuators eliminate leaks, noise, and complex plumbing, simplifying system design and maintenance.

Key driving factors accelerating market growth include the robust expansion of the manufacturing sector globally, particularly the push toward Industry 4.0 paradigms necessitating highly interconnected and flexible machinery. Stringent environmental regulations encouraging the adoption of energy-efficient machinery also favor electric solutions over hydraulic alternatives. Moreover, continuous technological advancements, such as the miniaturization of components, increased power density of motors, and enhanced software control, are expanding the application scope into high-precision and niche markets. The burgeoning demand for sophisticated medical equipment and the rise in factory automation penetration rates, especially in Asia Pacific economies, further underpin the positive market trajectory.

Electric Linear Actuators Market Executive Summary

The Electric Linear Actuators Market is defined by intense competition and rapid technological evolution, primarily driven by the global imperative for enhanced industrial automation and digitalization (Industry 4.0). Current business trends indicate a strong focus on developing actuators that are smarter, smaller, and more integrated, featuring built-in feedback systems, predictive maintenance capabilities, and high-speed bus communication protocols like EtherCAT and PROFINET. The shift towards modular manufacturing processes necessitates flexible motion control, giving electric actuators a significant advantage over rigid hydraulic or pneumatic systems. Furthermore, market players are concentrating on niche markets requiring extreme precision, such as surgical robotics and semiconductor manufacturing, expanding the total addressable market beyond traditional heavy industry.

Regionally, the market demonstrates distinct growth patterns. Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive investment in automotive production, electronics manufacturing, and infrastructure development in China, South Korea, and Japan. North America and Europe, characterized by high adoption rates of advanced automation technologies, remain key revenue generators, emphasizing high-performance and specialty actuators compliant with rigorous regulatory standards (e.g., FDA approval for medical applications). Emerging economies in Latin America and MEA are showing promising growth, primarily driven by the modernization of their existing manufacturing bases and the need for energy-efficient machinery replacements.

Segment trends reveal that the type segment dominated by linear actuators based on ball screw technology, which offers the best balance of speed, precision, and load capacity. However, roller screw actuators are gaining traction in ultra-heavy-duty and high-cycle applications due to their superior durability and force handling capabilities. The end-user analysis highlights the dominance of the industrial automation sector, but the medical and aerospace sectors are exhibiting the fastest compound annual growth rates, attributed to the critical requirement for repeatable, clean, and reliable motion control in these highly regulated environments. The market is also seeing increased demand for customized solutions, moving away from off-the-shelf products to application-specific designs tailored for extreme temperatures or hazardous environments.

AI Impact Analysis on Electric Linear Actuators Market

User inquiries regarding AI's influence on the Electric Linear Actuators Market primarily revolve around themes of predictive maintenance, optimization of actuation cycles, and integration with broader smart factory ecosystems. Common concerns focus on how AI algorithms can enhance actuator lifespan, minimize unexpected downtime, and improve energy consumption without requiring complex reconfiguration. Users are highly interested in the potential for self-calibrating actuators that adapt to changing load conditions or environmental factors in real-time. This user intent underscores a market expectation for actuators to transition from simple electro-mechanical devices into intelligent, self-diagnosing components integral to IIoT (Industrial Internet of Things) architectures.

- AI enables predictive maintenance by analyzing vibration, temperature, and current draw data, reducing unplanned failures by optimizing service schedules.

- Machine Learning algorithms optimize motion profiles and cycle times, leading to significant improvements in production throughput and energy efficiency.

- Integration of AI facilitates self-tuning and adaptive control, allowing actuators to dynamically adjust parameters based on real-time feedback and load variations.

- AI-powered diagnostics enhance fault detection accuracy, isolating minor issues before they escalate into major operational disruptions.

- Deep learning is used in quality control systems where actuators are utilized, ensuring consistent precision and repeatability across complex assembly tasks.

- Intelligent scheduling systems use AI to coordinate multiple actuator movements concurrently, improving overall robotic and automated system efficiency.

DRO & Impact Forces Of Electric Linear Actuators Market

The dynamics of the Electric Linear Actuators Market are governed by powerful driving forces centered on technological innovation and industrial structural shifts, tempered by specific technical restraints, while ample opportunities exist in developing customized, niche applications. Key drivers include the pervasive global trend toward factory automation, driven by high labor costs and the necessity for increased production quality and speed. The superior energy efficiency and inherent precision of electric actuators compared to legacy pneumatic and hydraulic systems position them favorably under increasingly stringent environmental and operational cost reduction mandates. Furthermore, the rapid growth of the medical device and clean room industries necessitates the use of sealed, non-contaminating, and highly reliable electric solutions, accelerating their market penetration.

However, the market faces significant restraints, primarily related to the high initial capital expenditure associated with purchasing and implementing sophisticated electric actuation systems, especially those incorporating advanced feedback and communication technologies. For extremely high-force applications, traditional hydraulic systems still often provide a better power-to-size ratio, challenging electric actuator viability in heavy-duty sectors like mining or large-scale construction. Technical limitations regarding heat dissipation, particularly in high-speed, high-duty-cycle environments, and the overall size requirements for high-power electric motors can sometimes restrict their integration into space-constrained machinery. These factors require continuous engineering innovation to overcome.

Opportunities abound in the development of specialized actuators incorporating advanced materials and smart functionalities. The integration of high-resolution absolute encoders, coupled with advanced diagnostics (facilitated by AI/ML), represents a major opportunity to create premium, value-added products suitable for demanding Industry 4.0 environments. Furthermore, untapped market potential exists in customizing actuators for extreme conditions, such as ultra-low temperatures in cryogenics or high radiation environments in nuclear facilities, where standard components fail. The rising demand for decentralized manufacturing and agile production lines also creates opportunities for modular, plug-and-play electric actuator units that simplify installation and maintenance. The five major impact forces shaping the market are the proliferation of the Industrial Internet of Things (IIoT), escalating manufacturing labor costs, advancements in motor and gearing technology, heightened demand for energy efficiency, and regulatory pressure for cleaner manufacturing processes.

Segmentation Analysis

The segmentation of the Electric Linear Actuators Market provides crucial insights into product adoption patterns and application dominance. The market is primarily segmented based on product type, mechanism, force, application, and end-user industry. Analyzing these segments helps stakeholders understand where technological investment is most critical and which sectors offer the highest growth potential. The Type segmentation, specifically differentiating between various screw mechanisms (ball, lead, roller), is fundamental, as it dictates the actuator’s performance profile regarding speed, load capacity, and lifespan. Geographically, the segmentation highlights the varying pace of automation adoption and regulatory environments across major global regions, impacting regional market strategies and supply chain placement.

The core of the segmentation analysis rests on identifying the dominant end-use sectors. While the Industrial Automation and Robotics sector historically represents the largest share due to widespread application in material handling, packaging, and assembly, faster growth is anticipated in the Medical and Aerospace & Defense segments. These sectors demand actuators that meet stringent certification requirements (e.g., ISO, FDA) and offer exceptional reliability and precision. Furthermore, segmentation by force type (low, medium, high) indicates the balance between high-volume, general-purpose applications (low to medium force) and high-value, heavy-duty industrial tasks (high force), influencing the required technological architecture, such as motor sizing and gearing ratios. The preference for DC-powered actuators often prevails in portable or battery-operated equipment, while AC-powered units dominate fixed industrial machinery.

- By Product Type:

- AC Linear Actuators

- DC Linear Actuators

- By Mechanism:

- Ball Screw Actuators

- Lead Screw Actuators

- Roller Screw Actuators

- Others (Rack and Pinion, Belt-driven)

- By Force:

- Low Force (Up to 1,000 N)

- Medium Force (1,000 N – 10,000 N)

- High Force (Above 10,000 N)

- By Application:

- Material Handling and Lifting

- Positioning and Clamping

- Opening and Closing

- Dosing and Dispensing

- By End-User Industry:

- Industrial Automation and Robotics

- Automotive

- Aerospace and Defense

- Medical and Healthcare

- Packaging and Processing

- Agriculture

- Infrastructure and Construction

Value Chain Analysis For Electric Linear Actuators Market

The value chain for the Electric Linear Actuators Market begins with upstream activities involving raw material procurement and the manufacturing of critical components. Upstream analysis focuses on suppliers of precision mechanical components (screws, nuts, guides, bearings), advanced electric motors (BLDC, stepper), and sophisticated electronic control systems (drives, controllers, sensors). The efficiency and reliability of the final actuator heavily depend on the quality and miniaturization capabilities offered by these suppliers. Key challenges upstream include managing the volatility of raw material prices (steel, aluminum, rare earth magnets) and ensuring a stable supply of high-precision components necessary for high-performance motion control systems. Strategic partnerships with specialized component manufacturers are vital for market players to maintain technological leads.

Midstream activities involve the design, assembly, testing, and certification of the electric linear actuators. This phase includes extensive R&D focused on developing high-density motors, advanced gear reduction systems, and integrated electronic feedback systems. Downstream analysis covers the distribution channels and the ultimate interaction with the end-user. Distribution is multifaceted, involving both direct sales channels for large original equipment manufacturers (OEMs) who require custom integration and specialized application support, and indirect channels relying on a global network of authorized distributors, system integrators, and value-added resellers (VARs). These VARs often provide localized installation, maintenance, and system integration services, particularly crucial for complex industrial automation projects.

The effectiveness of the distribution network is crucial for market penetration. Direct distribution ensures tighter control over application engineering and intellectual property, favored by large global manufacturers like Bosch Rexroth and Parker Hannifin for high-value contracts. Conversely, indirect channels provide broader market reach, catering to smaller and medium-sized enterprises (SMEs) requiring off-the-shelf or slightly modified products. A key trend in the distribution channel is the growing utilization of e-commerce platforms and digital tools for product selection and configuration, especially for standard actuators. The successful market player must balance the precision and customization offered by direct interaction with the geographical breadth and speed provided by a well-managed indirect network, ensuring high levels of after-sales service and technical support.

Electric Linear Actuators Market Potential Customers

Potential customers, or end-users/buyers, of electric linear actuators are highly diverse, spanning sectors that require automated, precise, and repeatable linear motion control. The primary segment comprises Original Equipment Manufacturers (OEMs) in industrial automation and robotics who integrate these actuators directly into their machinery, such as CNC machines, automated guided vehicles (AGVs), packaging systems, and assembly robots. These buyers prioritize technical specifications like force rating, speed, cycle life, and compatibility with industrial communication protocols (e.g., EtherCAT, Profibus). Their purchasing decisions are often based on long-term supply contracts and reliability metrics, as actuator failure can shut down entire production lines.

Another major category includes systems integrators and engineering, procurement, and construction (EPC) firms that purchase actuators as part of larger, custom-built industrial solutions for end-users in sectors like power generation, water treatment, and infrastructure. These customers require flexibility and robust technical support for integrating components into complex, large-scale projects. Furthermore, a highly lucrative customer base is found within the medical and healthcare industries, including manufacturers of hospital beds, MRI equipment, surgical robots, and diagnostic devices. These buyers are extremely sensitive to compliance (FDA, CE), requiring clean, quiet, and absolutely reliable actuators with specialized wash-down or sterile-environment capabilities, focusing heavily on certifications and quality documentation.

Emerging and high-growth potential customers include agricultural technology (AgriTech) firms utilizing actuators for precision farming equipment (e.g., automated seeding mechanisms, ventilation control) and the flourishing aerospace sector, which requires highly specialized, lightweight, and redundant actuators for critical flight control and utility systems. Maintenance, Repair, and Operations (MRO) departments across all manufacturing sectors also represent recurring customers, purchasing replacement units or upgraded components during system refurbishments. Understanding the specific regulatory and performance thresholds of each customer segment is crucial for effective market targeting and product portfolio development.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 25.5 Billion |

| Market Forecast in 2033 | USD 46.8 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SKF, Thomson Industries, Bosch Rexroth, Timken, Parker Hannifin, LINAK, Tolomatic, Actuonix, Progressive Automations, Venture Mfg. Co., Bimba Manufacturing, Ewellix, HSI, Duff-Norton, Tsubaki Nakashima, Kollmorgen, Moog Inc., Rotork, Nook Industries, SMAC Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Linear Actuators Market Key Technology Landscape

The technological landscape of the Electric Linear Actuators Market is rapidly evolving, driven by the convergence of advanced mechanical engineering and digital control systems. A key technology is the development and refinement of roller screw mechanisms, which offer superior durability and dynamic load capacity compared to traditional ball screws, particularly essential for applications requiring extremely high cycle life and force density, such as metal forming or heavy-duty presses. Simultaneously, advancements in core motor technology, notably high-torque density brushless DC (BLDC) motors, allow manufacturers to achieve higher output forces in smaller, lighter actuator footprints, addressing space constraints prevalent in modern machinery and mobile applications. This push for miniaturization without sacrificing performance defines much of the contemporary R&D effort.

The second critical technological pillar is the integration of sophisticated electronic controls and feedback mechanisms. Modern electric linear actuators often incorporate high-resolution absolute encoders for extremely precise positioning and repeatability, minimizing cumulative errors in complex sequential tasks. Furthermore, the adoption of Fieldbus communication protocols (e.g., EtherCAT, Profinet, CANopen) enables seamless integration of actuators into centralized control architectures, facilitating real-time data exchange, remote monitoring, and complex synchronized multi-axis movements. This integration is vital for achieving the flexible manufacturing capabilities demanded by Industry 4.0. The ability to monitor critical parameters like temperature, current draw, and vibration also enables condition monitoring and predictive maintenance, significantly enhancing operational uptime and longevity.

Another emerging technology area focuses on enhancing the energy efficiency and robustness of the units. This includes utilizing advanced lubrication technologies and low-friction coatings to reduce mechanical losses, thus improving overall system efficiency and reducing heat generation. Environmental sealing standards (IP ratings) are continuously being raised to allow these actuators to perform reliably in harsh environments, including exposure to dust, chemicals, and wash-down procedures common in food and beverage or pharmaceutical manufacturing. The development of self-locking mechanisms and integrated brakes based on electromagnetic principles is also a key technology, ensuring load retention and safety, even during power loss, which is essential for vertical positioning and lifting applications across diverse industrial and medical settings.

Regional Highlights

The market dynamics for electric linear actuators are distinctly regional, reflecting varying industrialization levels, investment in automation, and regulatory environments. North America, encompassing the United States and Canada, represents a mature market characterized by high technology adoption rates, particularly in the aerospace, defense, and specialized medical device manufacturing sectors. This region places a high premium on precision, reliability, and regulatory compliance (e.g., FAA standards, stringent medical certifications), favoring high-end, customized actuator solutions. The drive towards localized manufacturing and sophisticated automation systems continues to ensure stable demand, focusing on retrofit and modernization projects replacing older fluid-power technology.

Europe holds a commanding position, largely driven by Germany's strong engineering base and the widespread implementation of Industry 4.0 across the manufacturing core of the continent. Countries like Germany, Italy, and France are major consumers, especially in automotive production, complex machine tool manufacturing, and specialized industrial machinery. European demand is often focused on energy efficiency (driven by EU directives) and actuators that can seamlessly integrate into standardized automated production lines using common industrial Ethernet protocols. Scandinavia also shows robust adoption in marine and renewable energy applications, utilizing heavy-duty, corrosion-resistant electric actuators for precision tasks in challenging environments.

Asia Pacific (APAC) is projected to experience the highest growth rate globally throughout the forecast period. This acceleration is predominantly fueled by rapid industrialization in China, extensive investment in electronics and automotive manufacturing in South Korea and Japan, and massive infrastructure development across Southeast Asia. APAC is both a major consumer and a significant manufacturing hub for actuators. While the demand for cost-effective solutions is high, there is a growing parallel demand for high-precision, technologically advanced actuators necessary for the burgeoning semiconductor fabrication and advanced robotics industries in the region. The sheer scale of industrial expansion makes APAC the critical future market.

- Asia Pacific (APAC): Dominates growth due to extensive factory automation investments in China and South Korea, coupled with strong electronics and automotive sector expansion.

- North America: Focuses on high-value applications in Aerospace & Defense and Medical technology; high demand for sophisticated, integrated smart actuators.

- Europe: Characterized by early adoption of Industry 4.0; strong regulatory push for energy-efficient solutions in general manufacturing and machinery construction, particularly in Germany.

- Latin America (LATAM): Emerging market driven by modernization of existing infrastructure, agriculture, and mining industries, seeking cost-effective and reliable solutions.

- Middle East and Africa (MEA): Growth centered around oil & gas infrastructure maintenance, construction projects, and increasing adoption in the utilities sector for valve automation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Linear Actuators Market.- SKF

- Thomson Industries

- Bosch Rexroth

- Timken

- Parker Hannifin

- LINAK

- Tolomatic

- Actuonix

- Progressive Automations

- Venture Mfg. Co.

- Bimba Manufacturing

- Ewellix

- HSI

- Duff-Norton

- Tsubaki Nakashima

- Kollmorgen

- Moog Inc.

- Rotork

- Nook Industries

- SMAC Corporation

Frequently Asked Questions

Analyze common user questions about the Electric Linear Actuators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Electric Linear Actuators Market?

The primary factor driving market growth is the widespread global adoption of industrial automation and Industry 4.0 technologies, necessitating highly precise, energy-efficient, and digitally integrated motion control systems across all manufacturing sectors.

How do electric linear actuators compare to traditional hydraulic and pneumatic systems?

Electric linear actuators offer superior precision, repeatability, higher energy efficiency, simplified maintenance (no leaks or complex plumbing), and inherent programmability, making them preferred for applications requiring tight control and digital integration, although hydraulics may still offer a better power density for extreme forces.

Which mechanism type holds the largest market share in the actuator segment?

Ball screw actuators currently hold the largest market share due to their proven reliability, good balance between speed and load capacity, and high efficiency, serving a wide range of general and precision industrial applications.

What role does AI play in the future development of electric linear actuators?

AI's role involves enabling predictive maintenance through data analysis, optimizing motion profiles for energy savings, and facilitating self-tuning and adaptive control, thereby transforming actuators into intelligent components within IIoT frameworks.

Which regional market is projected to exhibit the fastest growth rate?

The Asia Pacific (APAC) region is projected to exhibit the fastest Compound Annual Growth Rate (CAGR), driven primarily by rapid expansion in high-tech manufacturing, automotive production, and massive governmental investment in industrial modernization across key economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager