Electrical Equipment Manufacturing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437228 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Electrical Equipment Manufacturing Market Size

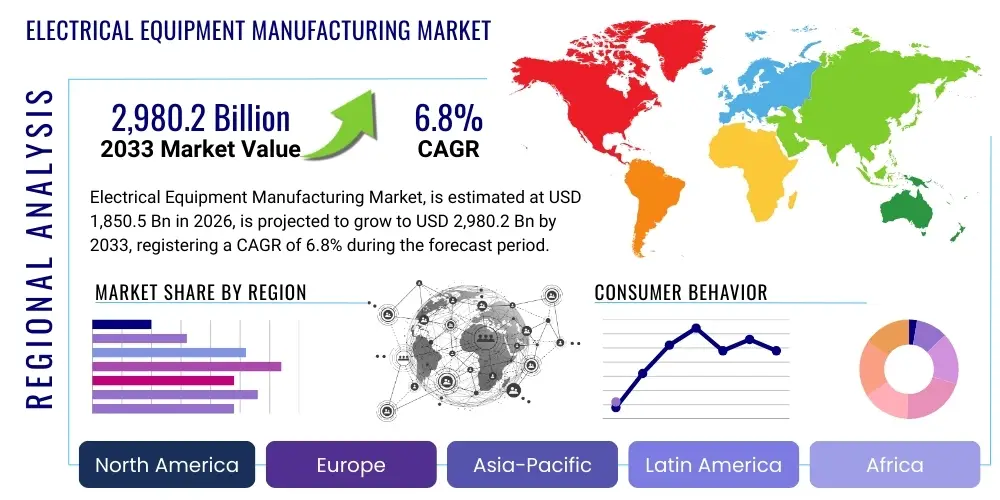

The Electrical Equipment Manufacturing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $1,850.5 Billion in 2026 and is projected to reach $2,980.2 Billion by the end of the forecast period in 2033.

Electrical Equipment Manufacturing Market introduction

The Electrical Equipment Manufacturing Market encompasses the design, production, and distribution of components and systems used for the generation, transmission, distribution, and utilization of electrical energy. This broad sector includes essential products such as transformers, switchgear, motors, generators, cables, and various control and protection apparatus. Growth in this market is intrinsically linked to global industrial expansion, urbanization trends, and the necessity for robust and modernized electrical infrastructure worldwide. The transition toward smart grids and sustainable energy solutions further dictates the trajectory of manufacturing processes and product innovation within this sector.

Major applications of electrical equipment span across critical sectors, including utilities (power generation and distribution networks), industrial operations (heavy machinery, automation), commercial buildings (HVAC, lighting, safety systems), and residential construction. The continuous global push for electrification, driven by environmental mandates and energy efficiency goals, ensures sustained demand. Key benefits derived from modern electrical equipment include enhanced operational efficiency, reduced energy losses, improved system reliability, and increased safety across power networks and end-user applications. Furthermore, the integration of digital technologies, such as IoT and advanced sensors, is transforming traditional equipment into smart, connected assets capable of predictive maintenance and optimized performance.

The market is significantly driven by global investment in renewable energy sources, notably solar and wind power, which require extensive new electrical infrastructure, including high-voltage direct current (HVDC) transmission lines and specialized power converters. Concurrently, the proliferation of electric vehicles (EVs) necessitates massive upgrades to existing grids and the deployment of advanced charging infrastructure, acting as a powerful stimulant for equipment manufacturers. Additionally, industrial automation (Industry 4.0) relies heavily on high-efficiency motors, sophisticated control gear, and dependable power supply systems, cementing the market’s positive outlook through technological integration and infrastructural modernization projects globally.

Electrical Equipment Manufacturing Market Executive Summary

The Electrical Equipment Manufacturing Market is experiencing robust expansion fueled primarily by global decarbonization initiatives and widespread grid modernization efforts. Business trends indicate a strong shift towards intelligent, modular, and sustainable manufacturing practices, with leading corporations investing heavily in digitalization to enhance product efficiency and responsiveness to volatile energy demands. Strategic mergers and acquisitions are common as companies seek to expand their technological portfolios, particularly in areas like high-voltage components and smart distribution systems, ensuring competitive advantage in the rapidly evolving energy landscape.

Regionally, the Asia Pacific (APAC) continues to dominate the market share, driven by rapid industrialization, extensive urban development in countries like China and India, and significant government spending on establishing renewable energy capacity and upgrading legacy transmission networks. North America and Europe, while mature, exhibit high growth rates in niche segments such as smart grid technology, energy storage integration, and specialized equipment required for offshore wind farms, focusing on replacing aging infrastructure with resilient, digitally enabled solutions. The Middle East and Africa (MEA) and Latin America are emerging as crucial markets, driven by necessary infrastructural investments to support burgeoning populations and diversify energy sources away from fossil fuels.

Segmentation trends highlight the increasing demand for high-efficiency motors and generators, critical for reducing industrial energy consumption, aligning with stringent global efficiency standards. The cables and wires segment is witnessing growth due to extensive transmission and distribution expansion projects, while the switchgear segment is rapidly adopting smart features for remote monitoring and fault detection. Furthermore, the growing adoption of modular substations and compact power equipment, optimized for urban environments and rapid deployment, signifies a major technological shift aimed at improving reliability and reducing installation time across all end-user segments, particularly within the utility and industrial sectors.

AI Impact Analysis on Electrical Equipment Manufacturing Market

User queries regarding the influence of Artificial Intelligence (AI) on the Electrical Equipment Manufacturing Market frequently revolve around optimizing production efficiency, enhancing predictive maintenance capabilities, and accelerating smart grid integration. Users are keen to understand how AI algorithms can improve quality control on the assembly line, reduce material waste, and streamline supply chain logistics. A major theme is the expectation that AI will transition equipment from reactive maintenance schedules to proactive, condition-based monitoring, fundamentally altering the lifecycle management of complex assets like transformers and switchgear. Furthermore, common questions address the role of machine learning in optimizing grid performance, balancing intermittent renewable energy inputs, and forecasting demand more accurately across diverse electrical networks.

- AI-driven Predictive Maintenance: Utilizing machine learning to analyze sensor data from installed equipment, forecasting potential failures, and optimizing service intervals, thereby minimizing unplanned downtime and extending asset lifespan.

- Enhanced Manufacturing Quality Control: Implementing computer vision and AI algorithms for real-time defect detection during assembly, significantly improving product reliability and reducing production errors.

- Optimized Grid Management: AI tools enable utilities to dynamically manage complex distribution networks, optimizing power flow, integrating variable renewable energy sources efficiently, and responding instantaneously to network disturbances.

- Supply Chain Optimization: Leveraging AI for demand forecasting, inventory management, and logistics planning, leading to reduced warehousing costs and accelerated responsiveness to material shortages.

- Generative Design for Equipment: Employing AI to explore complex design parameters for components (e.g., cooling systems for transformers) that maximize efficiency and minimize material usage based on specified operational constraints.

- Accelerated Product Development: Using AI models to simulate equipment performance under various conditions, significantly shortening the research and development cycle for new electrical apparatus.

DRO & Impact Forces Of Electrical Equipment Manufacturing Market

The Electrical Equipment Manufacturing Market is propelled by powerful drivers centered around global sustainability goals and necessary infrastructural development, while simultaneously being constrained by complex regulatory hurdles and fluctuating raw material costs. The integration of renewable energy mandates, necessitating billions in grid modernization and interconnectivity projects, serves as the primary impetus for market expansion. This driver is counterbalanced by significant restraints, particularly the high initial capital expenditure required for adopting advanced manufacturing technologies and the pervasive challenge of cybersecurity threats targeting increasingly connected industrial control systems. Opportunities abound in emerging economies and through niche specialization, such as high-voltage direct current (HVDC) systems, which offer superior efficiency for long-distance power transmission.

Key drivers include the global mandate for decarbonization, which necessitates widespread electrification across transport and industry, boosting demand for high-efficiency motors, advanced charging infrastructure, and robust transmission components. Furthermore, rapid urbanization, particularly in Asia and Africa, continuously requires new distribution infrastructure and residential electrical installations. These drivers create an overarching positive force, amplified by governmental incentives and subsidies aimed at promoting energy efficiency and infrastructure resilience, making the investment environment highly favorable for innovation and expansion.

The significant restraints impacting the market include the price volatility of key raw materials like copper, steel, and aluminum, which directly affects production costs and profit margins. Additionally, the fragmented regulatory landscape across different regions often mandates complex, localized compliance standards for equipment certification, posing a barrier to market entry and standardization. The high cost of specialized labor and the slow pace of integration of digital tools in some legacy manufacturing facilities further act as limiting factors, demanding sustained investment in training and automation to maintain global competitiveness against highly automated manufacturing hubs.

Opportunities for growth are concentrated in the development and deployment of smart grid components, enabling bidirectional power flow and optimized management of distributed energy resources. The escalating global demand for energy storage solutions, both at the utility scale and decentralized levels, opens up new avenues for specialized power electronics and conversion equipment manufacturers. Impact forces, therefore, lean heavily towards technological adoption—where the push for smarter, greener energy infrastructure (Impact Force) outweighs the constraints imposed by material costs and regulatory complexities (Restraining Force), resulting in sustained positive market growth throughout the forecast period.

Segmentation Analysis

The Electrical Equipment Manufacturing Market is meticulously segmented based on product type, end-user industry, and geographical region, providing a granular view of demand patterns and technological adoption across diverse applications. Product segmentation is crucial, differentiating high-value items like power transformers and switchgear from mass-produced components such as cables and lighting equipment, each governed by distinct market dynamics and technological cycles. Understanding these segments is vital for manufacturers to tailor their R&D investments and sales strategies, focusing on sectors demonstrating the highest expected growth due to ongoing electrification and infrastructural renewal projects worldwide.

The end-user segmentation clearly reflects the primary demand drivers, with the industrial sector, encompassing heavy manufacturing and utilities, remaining the largest consumer due to continuous operational upgrades and mandatory efficiency improvements. The rising residential demand, driven by smart home integration and new construction, also contributes significantly, particularly for low-voltage equipment. The detailed analysis of these segments reveals that demand for modular and pre-fabricated equipment is rising across all categories, optimizing installation timelines and ensuring consistent quality in large-scale projects, reflecting a trend towards standardized, plug-and-play solutions.

- By Product Type:

- Transformers (Power, Distribution, Specialty)

- Motors and Generators (AC Motors, DC Motors, Synchronous Generators, Asynchronous Generators)

- Switchgear (Low Voltage, Medium Voltage, High Voltage)

- Transmission and Distribution Equipment (Insulators, Arresters, Capacitors, Circuit Breakers)

- Cables and Wires

- Lighting Equipment

- Other Electrical Components (Batteries and Storage Systems, Relays, Control Panels)

- By End-User:

- Utilities & Power Generation

- Industrial (Manufacturing, Oil & Gas, Mining, Construction)

- Commercial (Data Centers, Office Buildings, Retail)

- Residential

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Southeast Asia, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of LATAM)

- Middle East and Africa (Saudi Arabia, UAE, South Africa, Rest of MEA)

Value Chain Analysis For Electrical Equipment Manufacturing Market

The value chain for the Electrical Equipment Manufacturing Market begins with the highly specialized upstream analysis, focusing on the sourcing and processing of critical raw materials, primarily copper, steel, aluminum, and specialized magnetic materials. Efficiency and stability in this upstream segment are crucial, as material costs constitute a significant portion of the final product price, driving manufacturers to establish robust supply agreements and hedge against price volatility. Key upstream activities include refining, specialized metallurgical processes, and the production of advanced insulating materials, all of which directly influence the performance and durability of the finished electrical apparatus. Strategic vertical integration, where companies control or own material supply capabilities, is increasingly observed among major players to mitigate supply chain risks and ensure quality control from the initial stages.

The core manufacturing stage involves the highly technical process of designing, assembling, and rigorously testing the equipment, adhering to complex international safety and performance standards (e.g., IEC, ANSI). This stage is characterized by significant capital investment in advanced machinery, automation, and sophisticated R&D facilities, especially for high-voltage and complex equipment like power transformers and high-speed generators. Downstream analysis involves installation, commissioning, maintenance, and end-of-life management. Service contracts and aftermarket support, including spare parts supply and modernization services, constitute a growing and highly profitable segment of the downstream market, emphasizing the shift toward solutions-based offerings rather than just transactional equipment sales.

Distribution channels in this market are typically multi-layered, relying heavily on specialized distributors and authorized system integrators who possess the technical expertise to handle complex installations for utility and industrial clients. Direct sales channels are often employed for very large, custom-engineered projects, such as major substation builds or specific industrial plant upgrades, ensuring direct manufacturer oversight and project management. Indirect channels, utilizing wholesalers and retailers, are more common for standardized, lower-voltage components and lighting equipment. The increasing reliance on digitalization facilitates more efficient inventory management across the distribution network, ensuring faster delivery and reduced logistics complexity for critical electrical infrastructure components.

Electrical Equipment Manufacturing Market Potential Customers

The primary end-users and buyers in the Electrical Equipment Manufacturing Market are segmented into three dominant groups: Utility Providers, Industrial Operators, and the Construction/Infrastructure Sector. Utility providers, including independent power producers and national grid operators, represent the largest customer base, consistently demanding high-voltage transmission equipment, advanced switchgear, and digital control systems necessary for modernizing and expanding the electrical grid to handle increasing loads and renewable energy integration. Their purchasing decisions are driven by reliability, regulatory compliance, long operational lifespans, and total cost of ownership (TCO).

Industrial operators, spanning discrete manufacturing, process industries (like petrochemicals and cement), and resource extraction (mining and oil & gas), are significant buyers of medium-voltage switchgear, specialized motors, variable speed drives, and energy management systems. These customers prioritize equipment efficiency, robustness against harsh operating conditions, and compatibility with industrial automation standards (Industry 4.0). The continuous push for energy savings and operational safety mandates regular investment in upgrading and replacing existing electrical apparatus with newer, higher-performing models.

The third major category includes contractors and developers in the commercial and residential construction sectors, alongside large-scale infrastructure projects (transportation systems, data centers, hospitals). These buyers require standardized distribution transformers, low-voltage switchboards, power cables, and extensive lighting solutions. Their purchasing behavior is often dictated by project timelines, upfront costs, ease of installation, and adherence to local building codes. Emerging potential customers also include electric vehicle infrastructure developers and large-scale data center operators, whose rapid growth necessitates specialized, high-density power distribution and cooling equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1,850.5 Billion |

| Market Forecast in 2033 | $2,980.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, ABB Ltd., General Electric Company, Schneider Electric SE, Eaton Corporation plc, Mitsubishi Electric Corporation, Toshiba Corporation, Hitachi Ltd., WEG S.A., Hubbell Incorporated, Legrand SA, Crompton Greaves Power and Industrial Solutions Ltd., Hyundai Electric & Energy Systems Co., Ltd., Bharat Heavy Electricals Limited (BHEL), TE Connectivity Ltd., Prysmian Group, LS Electric Co., Ltd., NKT A/S, Regal Rexnord Corporation, Delta Electronics, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrical Equipment Manufacturing Market Key Technology Landscape

The technological landscape of the Electrical Equipment Manufacturing Market is rapidly evolving, moving away from conventional electromechanical systems towards digitally integrated, high-efficiency solutions. A central innovation is the development of Smart Grid technologies, which involve embedding advanced sensors, communication modules, and processing capabilities into traditional equipment like transformers and switchgear. This digitalization enables real-time monitoring, remote diagnostics, and sophisticated load balancing, significantly improving grid reliability and responsiveness, which is essential for managing the intermittent nature of renewable energy sources. Furthermore, the adoption of digital twin technology allows manufacturers to create virtual replicas of equipment and entire substations, enabling rigorous simulation and testing before physical deployment, thereby accelerating product cycles and minimizing installation risks.

Another crucial technological advancement is in High-Voltage Direct Current (HVDC) transmission systems. As power generation shifts to remote locations (e.g., large solar farms in deserts or offshore wind parks), HVDC technology provides the most efficient means of transmitting bulk power over long distances with minimal losses, demanding specialized converters, power semiconductors (like IGBTs), and highly reliable DC switchgear. This technological segment is experiencing intensive R&D, focused on increasing voltage ratings and improving the robustness and compactness of converter stations. The drive for sustainability also pushes innovation in insulation materials, with sulfur hexafluoride (SF6) alternatives, such as eco-friendly gas-insulated switchgear (GIS), gaining prominence to reduce the global warming potential associated with electrical infrastructure.

Moreover, the integration of Additive Manufacturing (3D Printing) is transforming the prototyping and production of complex equipment components, particularly for custom parts and specialized tooling, offering faster iteration and material optimization. In motor and generator manufacturing, the focus is heavily on ultra-high-efficiency designs (IE4 and IE5 standards) and the use of advanced magnetic materials to reduce energy consumption in industrial applications. The overall technological thrust is toward creating equipment that is not only highly efficient and durable but also seamlessly interoperable within broader digital ecosystems, enabling proactive asset management and leveraging AI for optimal operational performance across all major segments.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market globally, driven by unprecedented rates of urbanization and industrial expansion, particularly in China and India. Massive governmental investments in renewable energy targets, coupled with the need to build entirely new transmission and distribution infrastructure, fuel high demand for power transformers, high-voltage cables, and industrial motors. The region is also becoming a global manufacturing hub, necessitating continuous investment in modern, high-efficiency electrical components to support large-scale production facilities. South Korea and Japan focus heavily on technological refinement, smart grid deployment, and domestic EV charging infrastructure build-out.

- North America: The North American market is characterized by significant grid modernization efforts aimed at replacing aging infrastructure and enhancing resilience against extreme weather events. The focus is on implementing smart grid components, integrating distributed energy resources (DERs), and building robust EV charging networks, particularly in the U.S. and Canada. The region demonstrates strong demand for high-reliability switchgear, advanced metering infrastructure (AMI), and specialized equipment for data centers and decentralized power generation, supported by federal policies promoting energy efficiency and infrastructure renewal.

- Europe: Europe exhibits leadership in adopting advanced, sustainable electrical equipment, strongly mandated by the European Green Deal. Key drivers include the rapid expansion of offshore wind power and the consequent requirement for HVDC transmission links, alongside the phase-out of SF6-containing switchgear in favor of eco-friendly alternatives. Germany, the UK, and France are leading in smart metering deployment and the modernization of urban distribution grids, driving innovation in medium-voltage components and power electronics necessary for the continent’s ambitious energy transition.

- Latin America (LATAM): The LATAM market growth is driven by increasing electrification rates in rural areas and investments in leveraging abundant renewable resources, notably hydro, solar, and wind power in Brazil, Chile, and Mexico. The market requires substantial investment in transmission infrastructure to connect remote generation sources to population centers. Challenges include political and economic instability, but underlying infrastructure deficits ensure long-term demand for reliable distribution equipment and efficient industrial power solutions.

- Middle East and Africa (MEA): MEA is highly dynamic, fueled by mega-projects in the GCC countries (Saudi Arabia, UAE) focused on utility-scale solar energy, smart city development, and diversifying economies away from oil dependence. This necessitates major upgrades to power generation and HVAC systems. In Africa, the market is characterized by urgent needs for basic electrification, driving demand for low-voltage components, small distribution transformers, and grid stabilization solutions, supported by international development financing aimed at energy access improvement.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrical Equipment Manufacturing Market.- Siemens AG

- ABB Ltd.

- General Electric Company

- Schneider Electric SE

- Eaton Corporation plc

- Mitsubishi Electric Corporation

- Toshiba Corporation

- Hitachi Ltd.

- WEG S.A.

- Hubbell Incorporated

- Legrand SA

- Crompton Greaves Power and Industrial Solutions Ltd.

- Hyundai Electric & Energy Systems Co., Ltd.

- Bharat Heavy Electricals Limited (BHEL)

- TE Connectivity Ltd.

- Prysmian Group

- LS Electric Co., Ltd.

- NKT A/S

- Regal Rexnord Corporation

- Delta Electronics, Inc.

Frequently Asked Questions

Analyze common user questions about the Electrical Equipment Manufacturing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the market growth for Electrical Equipment Manufacturing?

The primary drivers are global renewable energy integration (solar and wind), mandatory grid modernization projects to improve reliability, and accelerated investment in infrastructure for industrial automation (Industry 4.0) and Electric Vehicles (EVs).

Which product segment holds the largest share in the market?

The Transformers and Switchgear segments typically hold the largest market share due to their critical role in transmission and distribution networks, requiring continuous upgrades and replacements to handle higher power capacities and smart grid integration.

How is digitalization impacting electrical equipment manufacturing?

Digitalization is transforming equipment into 'smart' assets by integrating sensors and IoT connectivity. This enables predictive maintenance, remote diagnostics, and optimized power flow management, significantly improving efficiency and reducing operational costs for utility providers.

What are the key technological trends in the high-voltage segment?

Key trends include the development of High-Voltage Direct Current (HVDC) systems for long-distance bulk power transmission and the adoption of environmentally friendly gas-insulated switchgear (GIS) that utilize alternatives to SF6 gas to minimize global warming impact.

Which region is expected to demonstrate the highest growth rate?

The Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by aggressive urbanization, massive industrial expansion, and extensive governmental infrastructure spending aimed at expanding power access and meeting national renewable energy targets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager