Electrical Grade Fused Magnesia Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440549 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Electrical Grade Fused Magnesia Market Size

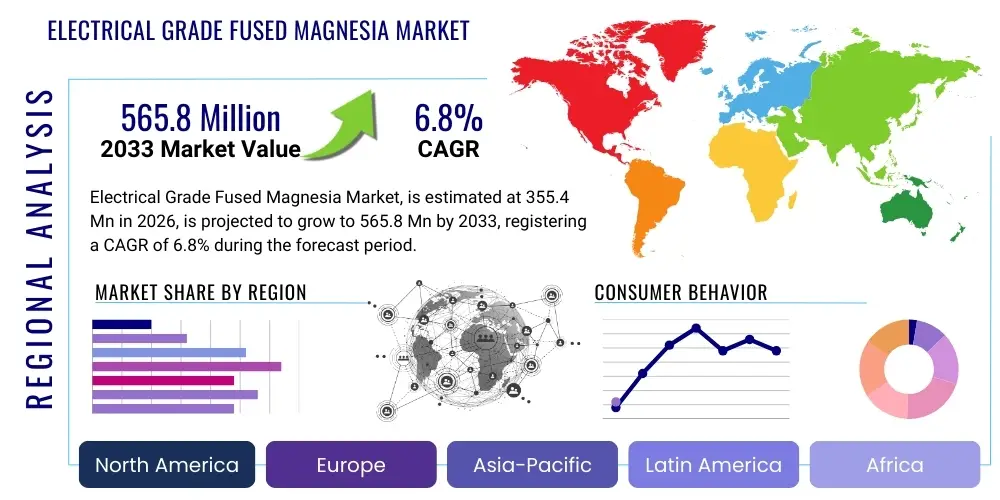

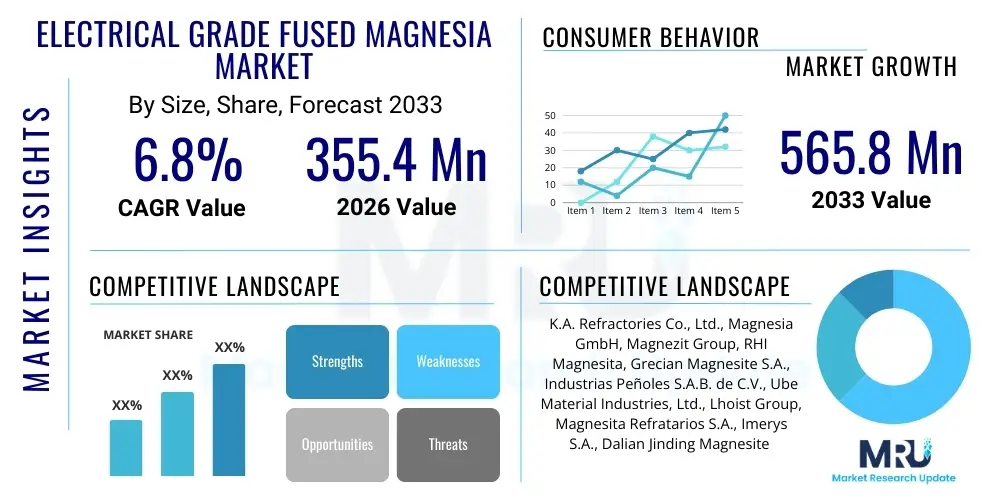

The Electrical Grade Fused Magnesia Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 355.4 Million in 2026 and is projected to reach USD 565.8 Million by the end of the forecast period in 2033.

Electrical Grade Fused Magnesia Market introduction

The Electrical Grade Fused Magnesia (EGFM) market plays a critical and foundational role in a multitude of industrial applications, primarily those demanding exceptional high-performance electrical insulation and superior thermal conductivity, especially when operating under elevated temperatures. EGFM is a high-purity, synthetically manufactured refractory material meticulously produced by fusing natural magnesite or calcined magnesia in an advanced electric arc furnace at extremely high temperatures, typically exceeding 2750°C. This rigorous and energy-intensive fusion process is instrumental in yielding a material with an exceptionally dense, non-porous structure and a highly stable crystalline form, predominantly periclase. These characteristics confer EGFM with unparalleled advantages over other forms of magnesia, particularly in terms of its electrical resistivity, thermal shock resistance, and chemical inertness, making it an indispensable component for critical industrial processes and consumer products.

The unique combination of EGFM's inherent properties, which include an extraordinarily high melting point, a very low thermal expansion coefficient, superb dielectric strength, and excellent thermal conductivity, strategically positions it as a non-negotiable material in the design and fabrication of demanding electrical heating elements, sophisticated thermal management systems, and specialized high-temperature insulation solutions across a broad and diverse spectrum of industries. The material's inherent thermal and electrical stability ensures unwavering and reliable performance even under the most arduous operating conditions, effectively preventing electrical leakage and facilitating highly efficient heat transfer. This makes EGFM a cornerstone material for ensuring both the safety and operational effectiveness of equipment where precise thermal control and robust electrical insulation are paramount. Its consistent performance across varying and often harsh environments underpins its value proposition in high-stakes applications.

The expansion of the EGFM market is fundamentally propelled by several potent and interconnected overarching factors. Foremost among these is the continuous and robust growth observed across global manufacturing sectors, particularly evident in the escalating production volumes of sophisticated consumer appliances and complex industrial machinery, all of which increasingly rely on efficient, durable, and reliable heating solutions. The escalating global emphasis on energy-efficient products and the widespread adoption of sustainable industrial processes further act as powerful catalysts for market growth, as EGFM's significant contribution to the extended operational lifespan and optimal thermal performance of electrical heating systems aligns perfectly with these critical environmental and economic objectives. Moreover, the rapid technological advancements and increasing deployment of next-generation renewable energy infrastructure, such as concentrated solar power (CSP) systems, alongside the burgeoning electric vehicle (EV) market, both present substantial new and high-growth avenues for EGFM applications. These sectors necessitate highly specialized thermal management capabilities and unparalleled high-performance electrical insulation, solidifying EGFM's essential and continuously expanding role in both modern industrial and rapidly evolving consumer-driven economies, fostering innovation, and broadening its utility into previously untapped segments.

Electrical Grade Fused Magnesia Market Executive Summary

The Electrical Grade Fused Magnesia (EGFM) market is currently undergoing a period of robust growth, primarily propelled by the accelerating pace of industrialization and urbanization across burgeoning economies, alongside a sustained and escalating demand for high-performance electrical heating solutions within more established, developed regions. Key business trends within this dynamic market indicate a significant and increasing focus on continuous product innovation. This innovation is largely aimed at achieving even higher purity levels and developing highly specialized grades of EGFM designed to meticulously meet the stringent performance requirements of increasingly sophisticated niche applications, such as high-temperature aerospace components, advanced semiconductor manufacturing equipment, and precision medical devices. Furthermore, a discernible trend towards strategic consolidation among key raw material suppliers and EGFM producers is influencing global pricing strategies and reshaping supply chain dynamics, while tactical partnerships are being actively forged to enhance distribution networks and facilitate deeper penetration into new, high-potential geographical markets. Manufacturers are also increasingly dedicating substantial investments into research and development initiatives, not only to optimize their production processes and reduce energy consumption but also to actively explore more sustainable and environmentally responsible sourcing of raw materials, aligning with broader global environmental, social, and governance (ESG) objectives.

From a regional perspective, the Asia Pacific continues to assert its formidable dominance within the EGFM market. This supremacy is largely attributable to the expansive and rapidly growing manufacturing bases for a vast array of products including consumer electronics, advanced automotive components, and heavy industrial equipment in economic powerhouses such as China, India, Japan, and South Korea. This region benefits immensely from substantial infrastructure development projects, a burgeoning middle class, and rapidly increasing disposable incomes, all of which collectively fuel an escalating demand for appliances and industrial systems that crucially incorporate EGFM. In contrast, Europe and North America, although recognized as mature markets, are distinctively characterized by an intense emphasis on premium-quality, highly specialized EGFM tailored for advanced industrial applications and stringent regulatory standards. These markets are consistently driving innovation towards the development of more energy-efficient and environmentally benign heating solutions. Emerging markets in Latin America, the Middle East, and Africa are concurrently demonstrating promising growth trajectories, underpinned by ongoing industrial expansion, strategic diversification of their economies, and a growing adoption of modern manufacturing practices, which are progressively expanding the application scope for EGFM across various developing end-use sectors.

Regarding market segmentation, significant traction is predominantly observed within the high-purity grades of EGFM. This segment's growth is predominantly driven by applications that demand truly superior electrical resistivity and exceptional thermal stability, such as in ultra-high-temperature furnaces, specialized heating elements for sensitive chemical processes, and advanced scientific instrumentation. The application segment encompassing tubular heating elements consistently remains the largest and most robust, forming the foundational bedrock of demand across both the expansive residential and the heavy industrial sectors. Emerging trends include the growing and diversified adoption of EGFM in advanced refractory linings and specialized crucible manufacturing, particularly in scenarios where unwavering resistance to extreme temperatures and highly corrosive environments is absolutely paramount for operational integrity. Furthermore, the increasing and critical integration of EGFM in sophisticated automotive heating components for electric vehicles (EVs) and hybrid vehicles represents a nascent yet rapidly expanding segment. This highlights the material's remarkable versatility, adaptability to evolving technological landscapes, and its ability to continually push the boundaries for increasingly rigorous material specification requirements in cutting-edge industries, underscoring its pivotal role in future technological advancements.

AI Impact Analysis on Electrical Grade Fused Magnesia Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Electrical Grade Fused Magnesia (EGFM) market frequently center around how AI technologies can significantly enhance operational efficiency throughout the entire production lifecycle, optimize complex supply chain networks, elevate overall product quality, and potentially uncover entirely new application areas. Common thematic questions include detailed investigations into AI's role in facilitating predictive maintenance for critical manufacturing equipment, the application of advanced machine learning algorithms for real-time process optimization within energy-intensive electric arc furnaces, and the deployment of AI-driven analytics for more accurate demand forecasting and highly efficient inventory management. Users are also keenly interested in understanding if AI can substantially accelerate research and development efforts for novel, high-performance EGFM grades or identify synergistic material combinations, and how it might contribute to sustainable manufacturing practices by minimizing waste generation and optimizing energy consumption. There is also considerable curiosity about AI's potential in revolutionizing quality control, specifically in detecting microscopic defects or subtle inconsistencies in EGFM products that might remain imperceptible through conventional, human-reliant inspection methods, thereby ensuring unprecedented levels of product integrity and reliability.

- Production Optimization: AI and sophisticated machine learning algorithms can analyze vast amounts of real-time data from electric arc furnaces and other processing units to dynamically optimize parameters such as temperature profiles, energy input, and raw material feed rates. This leads to significantly improved yield, reduced energy consumption, and highly consistent product quality in EGFM manufacturing, ensuring optimal material properties.

- Predictive Maintenance: AI-powered sensors and advanced analytics platforms can continuously monitor the operational health and performance of critical machinery involved in EGFM production, including grinders, crushers, and the furnaces themselves. This capability enables highly accurate prediction of potential equipment failures, facilitating proactive maintenance schedules and minimizing costly, unplanned downtime, thereby improving overall operational uptime and efficiency.

- Supply Chain Efficiency: AI tools are instrumental in enhancing the precision of demand forecasting, optimizing complex inventory management strategies, and streamlining logistics for both EGFM raw materials (like magnesite) and the final finished products. This results in significantly reduced holding costs, improved on-time delivery rates, and substantially greater resilience against unforeseen supply chain disruptions, ensuring a smooth and responsive flow of materials.

- Quality Control and Assurance: State-of-the-art computer vision systems integrated with powerful AI algorithms can automatically and meticulously inspect EGFM granules or finished products for even the most minute defects, precisely measure purity levels, and accurately assess particle size distribution. This ensures strict adherence to stringent specifications with significantly higher accuracy, consistency, and speed compared to traditional manual inspection processes.

- Research and Development Acceleration: AI can be leveraged to rapidly simulate various material properties, efficiently screen a multitude of potential new formulations for EGFM, and accurately identify optimal compositions tailored for specific high-performance applications. This dramatically reduces the extensive time and considerable costs traditionally associated with conventional experimental research and development cycles, accelerating innovation.

- Sustainable Manufacturing and Waste Reduction: AI can play a crucial role in identifying inefficiencies and suboptimal processes within EGFM production that lead to waste generation and excessive energy consumption. By optimizing resource utilization, energy consumption patterns, and process parameters, AI contributes significantly to more sustainable and environmentally responsible manufacturing practices for Electrical Grade Fused Magnesia.

- Market Intelligence and Strategic Planning: AI-driven analytics can process vast datasets from market trends, competitor activities, and economic indicators to provide deep insights, helping EGFM manufacturers make more informed strategic decisions regarding product development, market entry, pricing, and investment.

DRO & Impact Forces Of Electrical Grade Fused Magnesia Market

The Electrical Grade Fused Magnesia (EGFM) market is intricately shaped by a complex and dynamic interplay of interconnected drivers, formidable restraints, emerging opportunities, and powerful external impact forces. A primary and dominant driver for market expansion is the burgeoning global demand originating from the widespread manufacturing sector, particularly for residential and industrial heating elements. These elements are indispensable components ubiquitously found in a vast array of consumer appliances, sophisticated HVAC systems, and various types of industrial furnaces crucial for diverse processes. The increasing global focus on achieving enhanced energy efficiency and ensuring prolonged product longevity across an ever-growing spectrum of industries further acts as a powerful catalyst, significantly propelling the adoption of high-quality EGFM. This material is highly valued for its superior thermal conductivity and unparalleled electrical insulating properties, which directly contribute to the extended operational lifespan and optimal thermal performance of critical heating devices. Furthermore, the rapid expansion of renewable energy infrastructure, such as large-scale concentrated solar power plants, and the proliferation of electric vehicles (EVs) are creating new, highly specialized demands for high-performance thermal and electrical insulation materials, thereby significantly diversifying the application landscape for EGFM and contributing to its sustained market expansion into cutting-edge sectors.

Despite its robust growth drivers, the EGFM market is not without its significant restraints and challenges. A notable impediment is the inherent volatility in the prices of raw materials, primarily natural magnesite, which poses a considerable and unpredictable challenge, directly impacting production costs and consequently narrowing profit margins for EGFM manufacturers. The energy-intensive nature of the fusion process, which necessitates extremely high temperatures in specialized electric arc furnaces, contributes to substantial and often fluctuating operational expenses, rendering the industry susceptible to significant fluctuations in global electricity prices. Moreover, increasingly stringent environmental regulations pertaining to mining operations, complex material processing, and stringent emissions control present considerable compliance hurdles. These regulations often necessitate substantial investments in advanced technologies and sustainable practices to meet evolving environmental standards. The availability of substitute materials, although frequently exhibiting inferior performance characteristics in specific high-demand applications, can also exert downward pressure on prices and potentially limit market growth, particularly in less demanding applications where cost-effectiveness tends to outweigh premium performance, creating a competitive environment.

Opportunities for sustained and accelerated growth in the EGFM market are primarily concentrated in the rapid industrialization and extensive infrastructure development currently underway in emerging economies, particularly across the Asia Pacific region, Latin America, and parts of the Middle East, where demand for consumer appliances and heavy industrial machinery is projected to surge dramatically. Innovations in material science and the advent of advanced manufacturing techniques offer promising avenues for developing novel, enhanced grades of EGFM. These advanced grades may feature superior purity, exceptionally high thermal stability, or uniquely tailored specific dielectric properties, thereby catering to highly specialized, high-end niche applications within critical sectors such as aerospace, precision medical devices, and cutting-edge electronics. Moreover, strategic collaborations and synergistic partnerships between leading EGFM producers and key end-use manufacturers can significantly foster collaborative product co-development and facilitate more effective market penetration into rapidly evolving sectors like electric vehicle battery thermal management systems. The ongoing global pursuit of sustainable production methods, encompassing advanced energy recovery systems, comprehensive waste reduction initiatives, and eco-friendly sourcing, also presents a significant opportunity for manufacturers to decisively differentiate themselves, enhance their brand reputation, and gain a substantial competitive edge in a global market that is increasingly conscious of environmental impact and demanding greater sustainability across all supply chains.

Segmentation Analysis

The Electrical Grade Fused Magnesia (EGFM) market is comprehensively segmented across several key dimensions, including its purity grade, application type, and the specific end-use industry, thereby providing a highly granular and insightful view of complex market dynamics and effectively catering to diverse industrial requirements. These meticulously defined segmentations are absolutely crucial for discerning specific demand patterns, identifying critical technological advancements, and understanding the intricate competitive landscapes prevalent within various specialized niches of the broader EGFM market. Purity grade stands as a fundamental and critical differentiator, as higher purity levels directly and unequivocally correlate with significantly enhanced electrical insulation and superior thermal properties, which are paramount for high-performance and safety-critical applications. Application categories delineate the primary functional roles and utilization methods of EGFM, reflecting its diverse utility across a wide spectrum of products and systems. End-use industries explicitly specify the particular sectors that consume EGFM, highlighting the material's broad applicability and the varying demands and specifications originating from each industry, which can range from high-volume consumer goods manufacturing to heavy industrial processing and specialized high-tech sectors.

- By Purity Grade:

- 96% Purity Grade

- 97% Purity Grade

- 98% Purity Grade

- 99% Purity Grade and Above

- By Application:

- Tubular Heating Elements

- Refractory Linings and Bricks

- Crucibles and Saggers

- Thermocouple Insulators and Sheaths

- Specialty Ceramics and Other High-Temperature Insulation Components

- By End-Use Industry:

- Appliances (Domestic & Commercial Heating Appliances)

- Industrial Heating Equipment (Furnaces, Kilns, Ovens)

- Automotive (Electric Vehicle Battery Thermal Management, Heating Components)

- Aerospace & Defense (High-Temperature Components, Insulation)

- Electronics & Semiconductors (Heater Components, Substrates)

- Building & Construction (Specialty Fireproof Materials, Insulators)

- Power Generation (Thermal Insulation in Power Plants)

- Chemicals & Petrochemicals (Corrosion-Resistant Linings)

- Metallurgical Industry (Furnace Linings, Castables)

- By Form:

- Grain (Coarse and Fine Grains)

- Powder (Fine and Ultra-Fine Powders)

- Granular (Uniform Granules for Compaction)

Value Chain Analysis For Electrical Grade Fused Magnesia Market

The value chain for the Electrical Grade Fused Magnesia (EGFM) market commences robustly with extensive upstream activities, primarily involving the meticulous extraction and subsequent processing of vital raw materials, predominantly high-quality natural magnesite. Mining operations are strategically executed to secure superior magnesite ore, which then undergoes an initial, crucial beneficiation process. This typically includes multiple stages of crushing, precision grinding, flotation, and advanced magnetic separation techniques, all designed to effectively remove impurities and significantly enhance the magnesia content. Following this purification, the beneficiated magnesite is subjected to calcination at high temperatures to yield either caustic calcined magnesia or dead-burned magnesia, depending on the desired precursor properties. These intermediate magnesia forms are then fused in highly specialized electric arc furnaces at extremely high temperatures, often exceeding 2750°C, to produce dense, highly crystalline fused magnesia. This energy-intensive fusion process, frequently performed by specialized producers, represents a critical transformative step that directly dictates the final inherent properties and overall quality of the EGFM, including its purity, density, and crucial electrical resistivity. Upstream suppliers are thus pivotal in ensuring the consistent quality and reliable availability of these foundational raw materials, directly influencing the ultimate cost-effectiveness and performance characteristics of the final EGFM product across the entire value chain.

Further along the value chain, moving downstream, the precisely fused magnesia grains undergo additional advanced processing by dedicated EGFM manufacturers. This involves transforming them into various specific forms such as highly optimized powders, uniform granules, or tailored grain sizes, all meticulously customized to meet the exacting specifications required by diverse end-use industries. This advanced processing typically involves sophisticated grinding, ultra-fine milling, and precise sizing techniques to ensure the material adheres to the stringent quality and performance parameters essential for its intended applications. The distribution channel plays an exceptionally vital role in efficiently connecting EGFM producers with their extensive and varied customer base. This typically involves a hybrid approach, combining both direct sales and indirect channels. Direct sales are frequently preferred for managing large-volume customers, catering to highly specialized applications, or establishing strategic partnerships where bespoke technical support and customized material solutions are paramount. Conversely, indirect channels extensively utilize a network of specialty chemical distributors, industrial material suppliers, and regional agents who effectively cater to smaller customers, provide localized inventory management, and expertly handle complex logistics across a broad geographical footprint. These distributors often add significant value through customized packaging, precise blending services, and comprehensive technical assistance, thereby ensuring that the precise grade and optimal form of EGFM reach the appropriate end-user markets efficiently and effectively, optimizing the entire supply and delivery process.

Electrical Grade Fused Magnesia Market Potential Customers

The potential customer base for Electrical Grade Fused Magnesia (EGFM) is expansive, encompassing a wide array of industries that critically require superior electrical insulation and excellent thermal conductivity, particularly under conditions of extreme temperature and stress. A primary and most significant customer segment comprises manufacturers of tubular heating elements. These elements are extensively integrated into a multitude of essential domestic appliances such as ovens, stoves, water heaters, and washing machines, as well as in critical commercial and industrial applications like large industrial furnaces, specialized hot plates, and complex process heaters. These manufacturers specifically demand EGFM for its exceptional dielectric strength, high thermal conductivity, and remarkable ability to withstand prolonged high operating temperatures, all of which are crucial for ensuring the unwavering reliability and extended longevity of their heating products. The performance characteristics of EGFM directly and profoundly impact the energy efficiency, safety, and overall durability of these critical components, establishing it as an indispensable material for this sector. The continuously growing global demand for increasingly energy-efficient appliances and robust industrial heating solutions further expands and solidifies this vital customer base, driving sustained market growth.

Beyond its predominant role in heating elements, EGFM finds substantial and growing buyers within the refractory industry. This includes producers of high-performance refractory linings, specialized crucibles, and advanced kiln furniture, all of which are extensively utilized in demanding metallurgical, high-precision glass, and intricate ceramic manufacturing processes. These particular customers seek EGFM for its exceptionally high melting point, remarkable chemical inertness, and superior resistance to thermal shock, properties that are absolutely crucial for maintaining structural integrity and operational efficiency in extremely high-temperature and corrosive industrial environments. Another increasingly important segment includes manufacturers of thermocouples and sophisticated temperature sensors, where EGFM is strategically employed as an insulator for resistance wires, guaranteeing accurate and reliable temperature measurements in challenging and often hazardous industrial settings. The rapidly evolving automotive sector, particularly with the widespread proliferation of electric and hybrid vehicles, represents a burgeoning and high-potential customer base for EGFM. Here, it is utilized in advanced battery thermal management systems and specialized heating applications where robust, reliable, and high-performance insulation is critically important. Furthermore, the aerospace and defense industries, consistently requiring materials capable of performing flawlessly under extreme temperatures, pressures, and harsh operational conditions, also constitute a segment of high-value potential customers for specialized, ultra-high-purity grades of EGFM, further diversifying its strategic applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 355.4 Million |

| Market Forecast in 2033 | USD 565.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | K.A. Refractories Co., Ltd., Magnesia GmbH, Magnezit Group, RHI Magnesita, Grecian Magnesite S.A., Industrias Peñoles S.A.B. de C.V., Ube Material Industries, Ltd., Lhoist Group, Magnesita Refratarios S.A., Imerys S.A., Dalian Jinding Magnesite Group Co., Ltd., Liaoning Jinding Magnesite Co., Ltd., J. K. Minerals, Zhengzhou Longxing Chemical Co., Ltd., Liaoning Hongda High Purity Magnesia Group Co., Ltd., Qinghai Salt Lake Industry Co., Ltd., MINERALS TECHNOLOGIES INC., Premier Magnesia LLC, S.K. Minerals, Morton Industrial Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrical Grade Fused Magnesia Market Key Technology Landscape

The production of Electrical Grade Fused Magnesia (EGFM) is intricately underpinned by a sophisticated and continuously evolving technology landscape, fundamentally focused on consistently achieving ultra-high purity, exceptional density, and a precisely controlled, consistent crystalline structure. The core technological process involves the utilization of advanced, high-temperature electric arc furnaces, within which meticulously prepared raw materials, primarily high-quality calcined magnesia, are melted at extreme temperatures that often exceed 2750°C. This meticulous fusion process is absolutely critical for transforming raw magnesia into a supremely dense, non-porous material possessing outstanding electrical and thermal properties essential for its specialized applications. Significant advancements in furnace design, including the development of improved electrode technologies, highly efficient energy management systems, and sophisticated process control mechanisms, are continuously being pursued to enhance overall operational efficiency, substantially reduce the inherent high energy consumption, and meticulously optimize the entire fusion process, which remains inherently energy-intensive. Achieving precise control over temperature profiles, atmospheric conditions, and residence times within the furnace is paramount to preventing detrimental contamination and ensuring the uniform formation of high-quality periclase crystals, which are the defining characteristic and performance foundation of superior EGFM.

Beyond the initial and critical fusion stage, a suite of sophisticated beneficiation and advanced processing technologies are absolutely essential for realizing the full potential of EGFM. These technologies encompass advanced crushing and precision grinding equipment specifically engineered to achieve precise particle size distribution and optimal morphology without inadvertently introducing impurities that could compromise material performance. Techniques such as advanced magnetic separation, intricate flotation processes, and specialized chemical purification methods are extensively employed to further enhance the purity of both the raw materials and the final fused product, ensuring minimal levels of detrimental impurities like silica, iron, and calcium, which can severely compromise the critical electrical insulation properties of EGFM. Furthermore, cutting-edge surface treatment technologies are being actively explored and developed to modify EGFM particle surfaces for highly specific applications, thereby enhancing compatibility with various binders, improving flow characteristics, and optimizing overall processability. In the crucial application sphere, technological innovations in tubular heating element manufacturing, such as improved compaction techniques, advanced automated filling systems, and precise sealing methods, are vital for effectively and uniformly incorporating EGFM powders into resistance heaters, ensuring optimal density, superior thermal transfer, and prolonged operational reliability within the element structure, thereby maximizing the performance and longevity of the end product.

Regional Highlights

- Asia Pacific (APAC): This region unequivocally dominates the global EGFM market, driven by its robust and extensive industrialization, rapid urbanization rates, and a burgeoning manufacturing sector concentrated in economic powerhouses such as China, India, Japan, and South Korea. APAC serves as a major global hub for the production and consumption of consumer appliances, industrial machinery, and automotive components, collectively driving a substantial and sustained demand for EGFM across various industries.

- Europe: Characterized by a strong and unwavering emphasis on high-quality and highly specialized EGFM, particularly for advanced industrial applications in leading economies like Germany, Italy, and France. Stringent regulatory frameworks and a consistent focus on energy efficiency propel continuous innovation and the widespread adoption of premium EGFM grades in sectors such as industrial heating, aerospace, renewable energy systems, and high-performance ceramics, aligning with global sustainability goals.

- North America: A mature and technologically advanced market with significant and consistent demand for high-performance EGFM in highly specialized niche applications, including aerospace and defense, advanced electronics, and bespoke industrial heating solutions. The region places a strong emphasis on technological advancements, research and development, and adherence to stringent quality standards, often driving the development of customized EGFM solutions tailored for critical applications.

- Latin America: This region exhibits promising and accelerating growth potential, significantly fueled by expanding industrial bases in key countries like Brazil and Mexico. Increased governmental and private investment in infrastructure development, manufacturing expansion, and the rapidly growing automotive sector is progressively boosting the demand for EGFM, particularly for essential industrial heating and critical appliance applications, contributing to regional industrialization.

- Middle East and Africa (MEA): Emerging as a dynamic growth region with increasing economic diversification and industrialization efforts, particularly evident in the construction, oil and gas, and general manufacturing sectors. Government initiatives aimed at fostering economic development and industrial modernization are expected to drive the adoption of EGFM in a variety of applications, though starting from a relatively smaller base, reflecting increasing technological adoption and infrastructure build-out.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrical Grade Fused Magnesia Market.- K.A. Refractories Co., Ltd.

- Magnesia GmbH

- Magnezit Group

- RHI Magnesita

- Grecian Magnesite S.A.

- Industrias Peñoles S.A.B. de C.V.

- Ube Material Industries, Ltd.

- Lhoist Group

- Magnesita Refratarios S.A.

- Imerys S.A.

- Dalian Jinding Magnesite Group Co., Ltd.

- Liaoning Jinding Magnesite Co., Ltd.

- J. K. Minerals

- Zhengzhou Longxing Chemical Co., Ltd.

- Liaoning Hongda High Purity Magnesia Group Co., Ltd.

- Qinghai Salt Lake Industry Co., Ltd.

- MINERALS TECHNOLOGIES INC.

- Premier Magnesia LLC

- S.K. Minerals

- Morton Industrial Co., Ltd.

Frequently Asked Questions

What is Electrical Grade Fused Magnesia (EGFM) and what are its primary uses?

Electrical Grade Fused Magnesia (EGFM) is a synthetically produced, high-purity, dense, and crystalline refractory material derived from fusing natural magnesia in an electric arc furnace at extremely high temperatures. Its primary application is serving as a critical electrical insulator and an efficient heat transfer medium within tubular heating elements, which are ubiquitously found in a wide range of appliances, such as ovens and water heaters, as well as in diverse industrial furnaces. This is due to its exceptional electrical resistivity, high thermal conductivity, and remarkable stability at elevated temperatures.

What key properties make EGFM uniquely suitable for demanding electrical applications?

EGFM's unparalleled suitability for demanding electrical applications stems from its unique confluence of superior properties. These include an exceptionally high electrical resistivity and dielectric strength, outstanding thermal conductivity, and an impressively high melting point. These combined characteristics enable EGFM to effectively insulate resistance wires while simultaneously ensuring highly efficient heat transfer, even when subjected to extreme operating temperatures and harsh environmental conditions, thereby guaranteeing reliability and safety.

Which specific industries are the largest and most critical consumers of Electrical Grade Fused Magnesia?

The largest and most critical consumers of Electrical Grade Fused Magnesia are predominantly manufacturers of domestic and commercial appliances, particularly those specializing in the production of tubular heating elements. Other significantly important end-use industries include manufacturers of industrial heating equipment, the refractory industry for advanced high-temperature linings and crucibles, and an increasingly vital segment, the automotive sector, for sophisticated electric vehicle battery thermal management systems and specialized heating components, underscoring its broad industrial relevance.

What are the principal factors currently driving the growth of the Electrical Grade Fused Magnesia market?

The principal factors fueling the growth of the EGFM market are the escalating global demand for energy-efficient appliances and robust industrial heating solutions, the continuous expansion of global manufacturing sectors, and significant technological advancements within both renewable energy technologies and the rapidly growing electric vehicle market. The material's superior and consistent performance in high-temperature electrical insulation applications is paramount to its continued essential role and market expansion.

What are the primary challenges and constraints currently facing the Electrical Grade Fused Magnesia market?

The primary challenges confronting the EGFM market include substantial volatility in the prices of key raw materials like magnesite, the inherently high energy consumption and associated operational costs of the electric arc fusion production process, and increasingly stringent global environmental regulations impacting mining and manufacturing. Additionally, competition from alternative and substitute materials, particularly in less demanding applications, presents a considerable constraint on potential market expansion and pricing flexibility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager