Electrical Insulation Presspaper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439119 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Electrical Insulation Presspaper Market Size

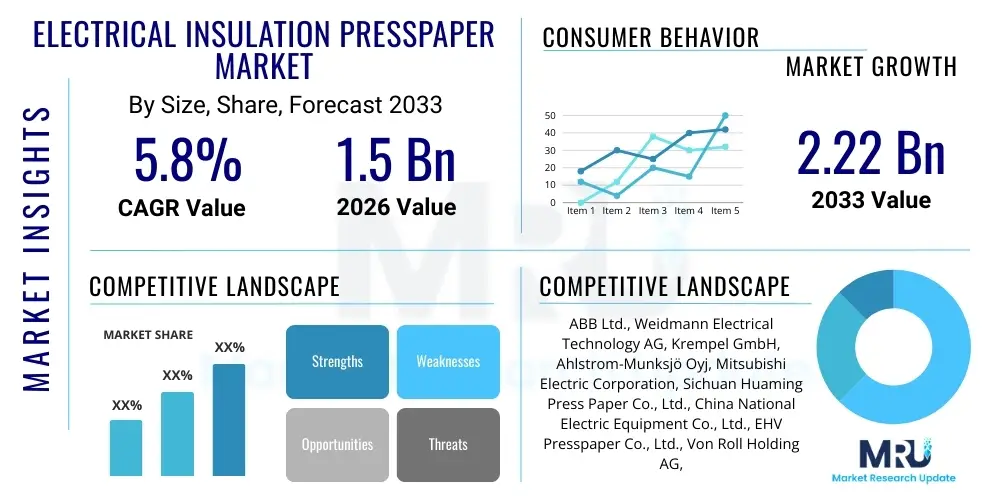

The Electrical Insulation Presspaper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.22 Billion by the end of the forecast period in 2033.

Electrical Insulation Presspaper Market introduction

The Electrical Insulation Presspaper Market encompasses the production and distribution of specialized cellulosic materials designed primarily for use in high-voltage electrical apparatus, particularly transformers, switchgear, and capacitors. Presspaper is fundamentally a paperboard product manufactured from unbleached sulfate pulp or cotton rags, highly compressed and optimized for superior dielectric strength and mechanical stability under thermal stress. Its essential function is to provide reliable insulation and structural support within oil-filled or dry-type electrical systems, preventing short circuits and ensuring the longevity and efficiency of the equipment. This market segment is crucial for the global power infrastructure, driven directly by investments in grid modernization and renewable energy integration.

The product is characterized by exceptional purity, low dissipation factor, and resistance to chemical degradation when immersed in insulating liquids like mineral oil or ester fluids. Major applications span utility-scale power transformers, distribution transformers, and specialized industrial equipment requiring robust electrical separation. The intrinsic benefits of presspaper include its environmental compatibility (being cellulose-based), high volume resistivity, and cost-effectiveness compared to synthetic polymer alternatives in large-scale electrical apparatus. Furthermore, presspaper serves as a barrier, spacer, and winding support, maintaining critical clearances and structural integrity within complex winding geometries.

Driving factors for sustained market growth include the increasing global demand for electricity, necessitating the expansion and replacement of aging transformer fleets across developed and developing economies. Rapid industrialization and urbanization in Asia Pacific are creating significant demand for new power generation and transmission infrastructure, acting as a primary catalyst. Additionally, the proliferation of renewable energy sources, such as wind and solar farms, which require specialized step-up transformers and efficient grid integration solutions, further boosts the adoption of high-quality electrical insulation presspaper materials.

Electrical Insulation Presspaper Market Executive Summary

The Electrical Insulation Presspaper Market is poised for stable growth, fueled predominantly by global energy transition efforts and critical infrastructure investments. Business trends indicate a shift towards advanced, thermally upgraded presspaper (like TUK grades) to meet the requirements of compact, high-efficiency transformers that operate at elevated temperatures, thereby supporting smart grid deployment. Manufacturers are focusing on backward integration and process optimization to ensure pulp purity, which is critical for maintaining high dielectric performance and achieving compliance with stringent international standards (e.g., IEC and ASTM). The competitive landscape is moderately consolidated, with major players emphasizing customized solutions and long-term supply agreements with transformer Original Equipment Manufacturers (OEMs).

Regionally, Asia Pacific maintains the highest growth trajectory, driven by massive public sector spending on electricity infrastructure development in China, India, and Southeast Asian nations. North America and Europe show steady demand, primarily centered around grid stability projects, replacement cycles of aging equipment, and increasing penetration of offshore wind farm projects. Regulatory mandates encouraging energy efficiency and the phasing out of older, less-efficient transformers are further accelerating the replacement market across these mature regions. This dynamic fosters innovation in material science aimed at enhancing the lifespan and performance characteristics of the insulation system.

Segment trends reveal that the Power Transformer application segment remains the largest consumer due to the sheer volume of insulation required in high-voltage apparatus. However, the Distribution Transformer segment is exhibiting faster growth aligned with rapid urbanization and the need for decentralized power networks. Based on product type, the demand for high-density pressboard is dominating due to its superior mechanical strength, though low-density variants are critical for specific applications requiring enhanced impregnability. The increasing focus on sustainability is also pushing R&D towards developing presspaper manufactured using sustainable forestry practices and minimizing chemical use in the manufacturing process.

AI Impact Analysis on Electrical Insulation Presspaper Market

Common user inquiries regarding AI’s impact on the Electrical Insulation Presspaper Market typically revolve around predictive maintenance, quality control automation, and supply chain optimization rather than direct product transformation. Users are concerned about how AI tools can enhance the reliability of the transformers that utilize presspaper insulation and whether AI-driven manufacturing processes can reduce defects in presspaper sheets. Key themes highlight the expectation that AI will primarily serve to extend the operational life of existing electrical apparatus by monitoring the degradation status of the insulation system (including presspaper) and optimizing the manufacturing processes to improve consistency, purity, and overall material quality. There is strong interest in using machine learning models to forecast demand based on regional infrastructure projects, thereby streamlining raw material procurement and production scheduling for presspaper manufacturers.

The implementation of AI and machine learning (ML) models in the manufacturing phase of electrical presspaper is focused on optimizing energy consumption during the pressing and drying stages, which are historically energy-intensive. ML algorithms analyze real-time data from moisture content sensors, temperature gauges, and pressure applications to ensure optimal density uniformity and dielectric properties across every batch. This leads to reduced material waste, lower operational costs, and, crucially, superior product consistency, meeting the high-reliability standards demanded by transformer OEMs. Furthermore, AI-powered visual inspection systems can quickly identify microscopic impurities or structural flaws that human inspectors might miss, significantly boosting final product quality assurance.

In the end-use market, the integration of smart sensors into transformers allows for continuous monitoring of key parameters, such as dissolved gas analysis and partial discharge activity. AI uses this data to assess the health of the insulation system, providing early warnings about potential failures. Since presspaper degradation is often correlated with operational temperature and moisture ingress, AI models can precisely estimate the remaining useful life of the transformer (RUL), thus optimizing maintenance schedules and minimizing costly downtime. This analytical capability directly enhances the perceived value and reliability of the presspaper used within these smart assets.

- AI enhances quality control through automated visual inspection systems, detecting subtle flaws and impurities in presspaper manufacturing.

- Machine learning optimizes production parameters (pressure, temperature, drying time) to ensure consistent density and superior dielectric strength.

- Predictive maintenance analytics, powered by AI, forecast the degradation rate of presspaper insulation within operational transformers, extending asset life.

- AI algorithms improve supply chain efficiency by accurately predicting raw material (pulp) demand based on energy infrastructure project pipelines.

- Integration of smart sensors and AI enables real-time assessment of transformer insulation health, validating the long-term performance of presspaper materials.

DRO & Impact Forces Of Electrical Insulation Presspaper Market

The Electrical Insulation Presspaper Market is influenced by a dynamic interplay of factors that dictate its trajectory. Primary drivers include rapid urbanization and industrialization, particularly in emerging economies, generating substantial demand for power transmission and distribution equipment. Simultaneously, the global mandate for grid modernization, aiming to improve reliability and efficiency through the integration of smart grid technologies and high-voltage direct current (HVDC) systems, necessitates high-performance insulation materials. Restraints largely stem from the volatile cost and availability of high-purity cellulose pulp, the primary raw material, coupled with the high capital investment required for specialized manufacturing facilities to meet stringent purity and quality standards. Furthermore, the long replacement cycles of large power transformers limit immediate demand surges in mature markets.

Opportunities are abundant in the field of thermal upgrading and nanotechnology integration. Developing presspaper with enhanced thermal classes (e.g., TUK or thermally stabilized paper) allows transformers to operate efficiently at higher temperatures, enabling more compact and powerful designs suitable for congested urban environments and renewable energy installations. There is also a significant market opportunity in providing customized solutions for specialty transformers, such as those used in electric vehicle charging infrastructure and industrial furnace applications, which demand unique insulation characteristics. Sustainability initiatives further drive opportunities for biodegradable and environmentally certified presspaper products, appealing to utilities focused on green procurement policies.

The impact forces within the market are predominantly technological and regulatory. Regulatory forces, centered around IEC and IEEE standards for dielectric performance and fire safety, compel manufacturers to continuously innovate and certify their products, acting as a barrier to entry for lower-quality producers. Technological forces include the competitive threat from alternative insulation materials like aramid papers and advanced synthetic films in certain specialized, compact applications. However, the cost-effectiveness and proven long-term reliability of cellulosic presspaper ensure its dominance in bulk insulation applications within traditional liquid-filled transformers. The ongoing push for renewable integration means that demand for reliable, large-scale insulation components will continue to exert positive pressure on market growth.

Segmentation Analysis

The Electrical Insulation Presspaper Market is comprehensively segmented primarily by product type, application, and density. Analyzing these segments provides critical insights into market dynamics and growth potential across different end-use sectors. The product type segmentation typically includes electrical pressboard and crepe paper, both derived from the same cellulose base but manufactured differently to offer distinct mechanical properties and flexibility tailored to specific transformer parts. The application segmentation delineates demand across power transformers, distribution transformers, and other specialized electrical apparatus, reflecting the varying insulation needs based on voltage levels and physical size. Understanding these segments is vital for targeted marketing and strategic capacity planning by market participants.

Density segmentation is crucial as it directly correlates with the dielectric strength and mechanical robustness of the final product. High-density pressboard (used for structural components like clamping rings and spacers) offers superior mechanical properties and dielectric strength, while medium and low-density pressboards are favored for applications requiring higher oil impregnation rates and enhanced flexibility, such as winding supports and corrugated structures. The interplay between density and thermal class, such as thermally upgraded presspaper (TUK), determines suitability for modern, high-efficiency transformers that run hotter. These nuanced product differences allow manufacturers to cater to the exacting specifications of Tier 1 transformer OEMs who demand specialized insulation solutions for different components within the core-and-coil assembly.

Geographical segmentation, while not explicitly listed as a primary product segment, heavily influences demand, with Asia Pacific driving volume growth and North America/Europe focusing on high-specification, premium-grade materials used in refurbishment and smart grid projects. The segmentation analysis confirms the maturity of the technology while highlighting pockets of high growth driven by material optimization, particularly focusing on improving moisture resistance and partial discharge performance under critical operating conditions. Strategic investment across these segments, especially in higher-value, thermally stable products, is key to maximizing market share and profitability over the forecast period.

- Product Type: Pressboard, Presspaper (sheets and rolls), Thermally Upgraded Presspaper (TUK), Crepe Paper.

- Density: High Density (HDP), Medium Density (MDP), Low Density (LDP).

- Application: Power Transformers, Distribution Transformers, Instrument Transformers, Bushings and Tap Changers, Capacitors and other Electrical Apparatus.

- Voltage Range: High Voltage (HV), Medium Voltage (MV), Low Voltage (LV).

- End-Use Industry: Utilities (Power Generation & Transmission), Industrial (Manufacturing & Processing), Residential & Commercial.

Value Chain Analysis For Electrical Insulation Presspaper Market

The value chain for the Electrical Insulation Presspaper Market begins with the upstream segment, primarily involving the sourcing and processing of high-purity, unbleached sulfate wood pulp or cotton linters. The quality of this raw material is paramount, as impurities directly compromise the dielectric integrity of the final product. Key upstream suppliers include specialized pulp mills that adhere to strict purity standards, often requiring dedicated processing lines to prevent contamination. Managing the cost volatility and ensuring a consistent supply of this specific grade of cellulosic fiber are crucial challenges at this stage, dictating the manufacturing economics for presspaper producers. Vertical integration by presspaper manufacturers into pulp sourcing is sometimes employed to gain better control over quality and cost.

The core manufacturing process, or midstream activity, involves highly specialized machinery for slurry preparation, wet-laid sheet formation, and critically, the high-pressure calendaring and drying processes that give the presspaper its characteristic density, mechanical strength, and dielectric properties. This stage requires significant energy consumption and capital investment in precision equipment. Manufacturers then process the base material into various forms—sheets, rolls, punched parts, molded components, and corrugated structures—tailored to specific transformer insulation designs. Quality control, including rigorous testing for dielectric strength, dissipation factor, and moisture content, is centralized here before the product moves downstream.

The downstream segment involves distribution and the end-use applications. Presspaper is distributed both directly to large transformer Original Equipment Manufacturers (OEMs) and indirectly through specialized electrical material distributors who handle smaller orders and custom fabrication services. Direct sales allow for closer technical collaboration between the presspaper manufacturer and the OEM design team, especially for high-voltage power transformers. Indirect channels provide market coverage for maintenance, repair, and overhaul (MRO) operations, as well as smaller transformer manufacturers. The final buyers—power utilities, industrial facilities, and large infrastructure projects—are highly dependent on the timely and accurate supply of fabricated presspaper components for transformer assembly and winding processes.

Electrical Insulation Presspaper Market Potential Customers

The primary customers for electrical insulation presspaper are global transformer and electrical apparatus manufacturers, ranging from large multinational corporations to regional specialized workshops. These companies require presspaper in various forms—sheets, pre-cut shapes, and molded parts—to construct the intricate insulation barriers, spacers, and structural components within their products. Given the criticality of insulation to the reliability and safety of electrical grids, these OEMs prioritize suppliers who offer consistent material properties, certified compliance with international standards (IEC, ASTM), and the capability for high-volume, precision manufacturing. Long-term contracts and technical partnerships are common features of the relationship between presspaper suppliers and major OEMs.

Beyond the initial equipment manufacturers, power utilities and grid operators represent a significant secondary customer base, primarily driving the demand for MRO (Maintenance, Repair, and Overhaul) services. When power transformers undergo refurbishment or are repaired following failure, fresh insulation materials, including presspaper components, are required. This segment often relies on specialized service companies and independent repair shops that source presspaper from distributors. Utilities are increasingly focused on procuring high-performance, thermally upgraded presspaper for their replacement assets to maximize operational efficiency and reduce the risk of premature failure, reflecting a focus on total lifecycle cost rather than initial material cost.

Furthermore, specialized industrial sectors, such as metallurgy, mining, traction (railways), and renewable energy projects (wind/solar farms), also represent key customer segments. These industries utilize custom or heavy-duty transformers that require high-specification insulation tailored to unique operational stresses, such as high vibrations, frequent thermal cycling, or exposure to specific contaminants. The demand from these sectors is highly sensitive to capital expenditure cycles and infrastructure development spending. Capacitor manufacturers and producers of high-voltage bushings are also consistent, though smaller, buyers, utilizing presspaper for its excellent dielectric constant and mechanical stability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.22 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Weidmann Electrical Technology AG, Krempel GmbH, Ahlstrom-Munksjö Oyj, Mitsubishi Electric Corporation, Sichuan Huaming Press Paper Co., Ltd., China National Electric Equipment Co., Ltd., EHV Presspaper Co., Ltd., Von Roll Holding AG, Cottrell Paper Company Inc., Hokuetsu Paper Mills, OJI Holdings Corporation, Kamteks Company, Industrial Paper Corporation, Pucaro Elektro-Isolierstoffe GmbH, Shenzhen Guanghua Electrical Material Co., Ltd., Hangzhou Zhongda Electrical Insulation Co., Ltd., L&M Electric Insulation Material Co., Ltd., and Associated Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrical Insulation Presspaper Market Key Technology Landscape

The technological landscape of the Electrical Insulation Presspaper Market is defined by continuous advancements aimed at improving dielectric performance, thermal stability, and mechanical precision. A key focus area is the implementation of advanced pulping and washing technologies to achieve ultra-high purity cellulose, minimizing ionic contaminants that could reduce the insulation's long-term partial discharge resistance and overall lifespan. Manufacturers leverage sophisticated closed-loop water systems and specialized chemical treatment processes to meet the exacting low conductivity requirements mandated by high-voltage applications. The pressing stage employs high-tonnage hydraulic presses and calibrated drying ovens, utilizing precise pressure and temperature profiling to ensure uniform density and eliminate internal stresses in the final pressboard sheets, critical for robust structural integrity within the transformer core.

Another prominent technological trend is the development and commercialization of Thermally Upgraded Presspaper (TUP or TUK), often achieved through chemical modification of the cellulose structure, typically using dicyandiamide or similar stabilizing agents. This process significantly increases the thermal endurance class (moving from Class A, 105°C, to Class E, 120°C or higher), allowing transformer oils to be replaced with high-temperature ester fluids and enabling the design of smaller, more power-dense transformers. Manufacturers utilize complex coating or impregnation baths, followed by specific curing cycles, to ensure the modifying agent is uniformly distributed throughout the paper fibers without compromising the essential dielectric properties. This technology is vital for the modern, high-efficiency transformer segment.

Furthermore, precision fabrication technology plays an essential role downstream. Computer Numerical Control (CNC) cutting, laser cutting, and advanced die-stamping techniques are employed to accurately produce complex presspaper components (spacers, caps, clamping plates) with minimal tolerances, ensuring perfect fit within highly engineered transformer designs. Automated optical inspection systems are increasingly used during the fabrication phase to verify dimensions and check for edge defects. Lastly, ongoing research focuses on enhancing the material's resistance to mineral oil aging and moisture absorption by exploring nanoscale fiber reinforcements and surface treatments, though maintaining the cost-effectiveness of the material remains a crucial barrier for widespread adoption of these cutting-edge innovations.

Regional Highlights

- Asia Pacific (APAC) Dominance and Growth Catalyst: APAC is the largest and fastest-growing market for electrical insulation presspaper, driven by unprecedented infrastructure development, particularly in China and India. Both countries are heavily investing in expanding their power generation capacity and upgrading high-voltage transmission networks to support rapid industrial growth and urbanization. The sheer scale of new transformer installations—ranging from ultra-high voltage (UHV) transmission transformers to numerous distribution units—creates massive demand. Localized manufacturing capabilities are rapidly expanding, but the reliance on imported high-purity pulp remains a supply chain consideration. The region’s aggressive adoption of renewable energy technologies further necessitates grid stabilization investments, boosting demand for high-performance insulation.

- North America (NA) Focus on Refurbishment and Grid Modernization: The North American market is characterized by stable demand primarily driven by the replacement and refurbishment of aging utility infrastructure. Utilities in the U.S. and Canada are focused on improving grid resilience and integrating smart grid technologies. This often involves replacing legacy transformers with more thermally efficient units, driving demand for high-specification and thermally upgraded presspaper. Compliance with stringent quality and environmental standards is paramount, favoring established global suppliers. Demand is closely tied to capital expenditure cycles of major utility companies and regulatory mandates pushing for increased energy efficiency.

- Europe's Emphasis on Renewable Integration and Efficiency Standards: Europe is a mature market demonstrating steady, quality-driven growth, heavily influenced by the EU’s ambitious climate goals. The market here is buoyed by investments in large-scale offshore wind farms and the associated HVDC interconnectors, which require specialized power transformers demanding the highest reliability presspaper. Strict EcoDesign directives pushing for higher transformer efficiency classes mandate the use of premium insulation materials that can withstand higher thermal loads in compact designs. Germany, France, and the UK remain key consuming nations, emphasizing sustainable sourcing and localized technical support from suppliers.

- Latin America (LATAM) Infrastructure Development and Electrification: The LATAM market, while smaller in volume than APAC, presents significant long-term potential tied to electrification projects and mining expansion in Brazil, Mexico, and Chile. Investment volatility and economic cycles influence market stability. The demand is primarily focused on conventional pressboard for standard distribution and regional power transformers, though increasing focus on energy security and efficiency is starting to drive interest in thermally upgraded options, particularly in areas integrating intermittent renewable sources.

- Middle East and Africa (MEA) Energy Export and Diversification Projects: The MEA region is witnessing high demand driven by massive investments in energy infrastructure, both for internal consumption (due to population growth and cooling demands) and for supporting large petrochemical and industrial complexes. Gulf Cooperation Council (GCC) countries are investing heavily in new power plants and transmission networks, providing a stable source of large-scale transformer projects. The market requires materials that can perform reliably under extremely high ambient temperatures, often favoring suppliers who can provide tailored solutions certified for harsh environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrical Insulation Presspaper Market.- Weidmann Electrical Technology AG

- Krempel GmbH

- Ahlstrom-Munksjö Oyj

- ABB Ltd. (as a major consumer and sometimes a technology partner)

- Mitsubishi Electric Corporation

- Von Roll Holding AG

- Sichuan Huaming Press Paper Co., Ltd.

- China National Electric Equipment Co., Ltd.

- EHV Presspaper Co., Ltd.

- Cottrell Paper Company Inc.

- Hokuetsu Paper Mills

- OJI Holdings Corporation

- Kamteks Company

- Pucaro Elektro-Isolierstoffe GmbH

- Shenzhen Guanghua Electrical Material Co., Ltd.

- Industrial Paper Corporation

- Hangzhou Zhongda Electrical Insulation Co., Ltd.

- L&M Electric Insulation Material Co., Ltd.

- Associated Industries

- Mizuno Paper Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Electrical Insulation Presspaper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Electrical Insulation Presspaper over synthetic polymer insulation materials?

Electrical Insulation Presspaper, being cellulose-based, offers several key advantages including superior cost-effectiveness for bulk insulation applications, high compatibility with transformer oil (impregnability), and excellent long-term mechanical strength. It also boasts environmental benefits as a renewable, biodegradable material, unlike most synthetic polymers, making it preferred for large, liquid-filled transformers where robust structural integrity is required.

How does Thermally Upgraded Presspaper (TUK) impact transformer design and lifespan?

TUK is chemically treated to significantly increase its thermal endurance, allowing transformers to operate safely at higher temperatures (e.g., 120°C instead of 105°C). This thermal resilience permits transformer designers to create smaller, lighter, and more power-dense units while maintaining reliability. TUK also extends the transformer's overall lifespan by slowing the rate of cellulose degradation, reducing the need for premature replacements and maintenance, particularly in smart grid applications.

What factors determine the quality and dielectric strength of Electrical Presspaper?

The quality of electrical presspaper is determined by the purity of the raw material (unbleached sulfate pulp or cotton linters), minimizing ionic contaminants that compromise insulation integrity. Key factors include uniform density and thickness, low moisture content, and a very low dissipation factor (tan delta). Strict control over the calendaring process ensures high mechanical and dielectric strength, confirmed by partial discharge tests and standardized quality assessments (IEC 60641).

Which application segment holds the largest share in the Electrical Insulation Presspaper Market?

The Power Transformer segment currently holds the largest market share. This is due to the sheer volume and thickness of presspaper required to insulate the massive windings and internal structures of high-voltage and ultra-high voltage (UHV) power transformers used in transmission networks. While the Distribution Transformer segment shows faster growth, the core requirements of utility-scale power transmission ensure the dominance of the Power Transformer application in terms of material consumption volume.

What is the influence of global electrification and renewable energy projects on presspaper demand?

Global electrification and renewable energy integration are major market drivers. New solar and wind farms require large volumes of step-up transformers, creating direct demand. Furthermore, the variability of renewable sources necessitates significant grid upgrades and stability equipment (like FACTS devices), all of which rely on high-reliability, long-lasting insulation presspaper. This shift mandates higher quality material specifications to ensure seamless operation under dynamic load conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager