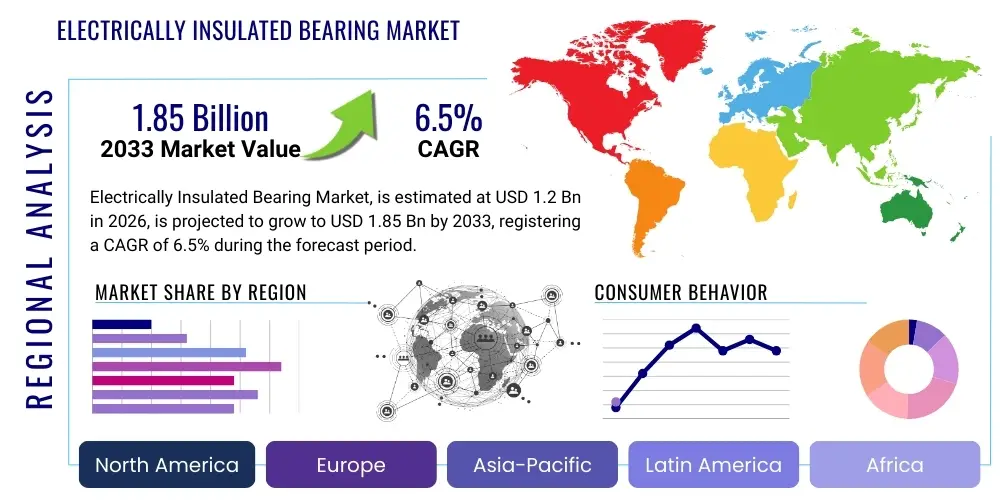

Electrically Insulated Bearing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438452 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Electrically Insulated Bearing Market Size

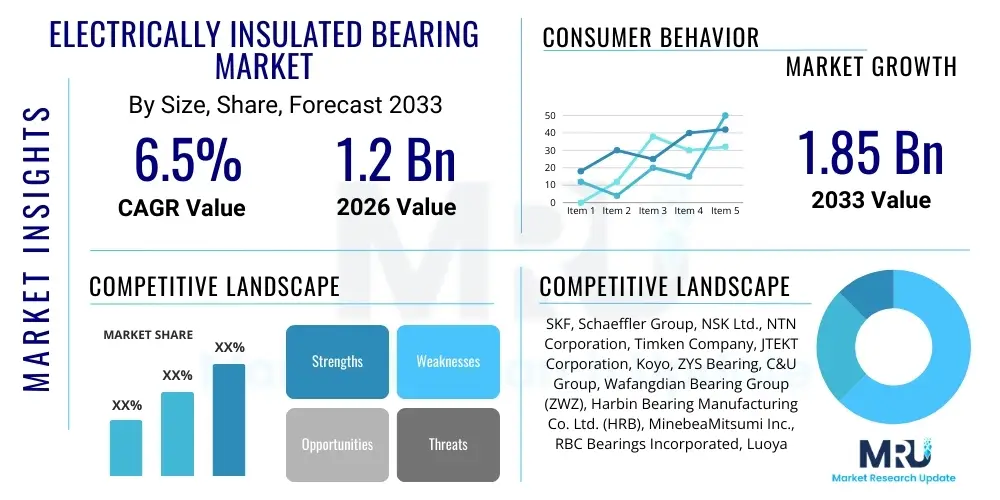

The Electrically Insulated Bearing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033.

Electrically Insulated Bearing Market introduction

Electrically insulated bearings are engineered components designed to prevent the passage of electrical current through the bearing elements, thereby protecting machinery from electrical corrosion and premature failure. This electrical erosion, often caused by stray currents generated by Variable Frequency Drives (VFDs) or electrical leakage in high-power machinery, severely degrades the lubricant and damages the rolling elements and raceways, leading to costly downtime. The core innovation lies in applying a highly resistant ceramic coating, typically aluminum oxide, to the outer or inner ring, effectively breaking the electrical circuit. This design ensures that equipment utilizing VFDs, such as motors in industrial automation, pumps, generators, and compressors, maintain operational integrity and extended service life, addressing a critical vulnerability in modern electrified systems.

The primary driving factor for market expansion is the pervasive global adoption of VFDs across virtually all industrial sectors seeking energy efficiency and precise motor control. VFDs inherently generate shaft voltages that seek the path of least resistance, often through the motor bearings. Insulated bearings are the most reliable and cost-effective countermeasure against this phenomenon. Furthermore, the massive push toward electrification in transportation, particularly high-speed rail and electric vehicles (EVs), utilizes powerful traction motors and high-voltage systems, mandating the use of insulated bearing technology to ensure reliability and safety in these critical applications. The demanding operating environments in renewable energy, specifically wind turbines, where high potential differences can occur due to static electricity or lightning strikes, further solidify the necessity for these specialized components.

Major applications span heavy industry, transportation, and power generation. In heavy industry, insulated bearings are crucial for large motors, pumps, and fans operating under continuous load. The railway sector employs them extensively in traction motors and generator sets to withstand high levels of electromagnetic interference and current leakage. Benefits include dramatically improved Mean Time Between Failures (MTBF), reduced maintenance costs associated with bearing replacement, and enhanced operational reliability. The shift towards higher power density and faster switching frequencies in power electronics continues to escalate the risk of bearing damage, cementing the position of electrically insulated bearings as an essential component for system longevity and performance optimization.

Electrically Insulated Bearing Market Executive Summary

The Electrically Insulated Bearing Market is characterized by robust growth driven primarily by the escalating demand for energy-efficient industrial machinery utilizing Variable Frequency Drives (VFDs) and the global trend toward transportation electrification. Business trends indicate a focus on technological refinement, including the shift from conventional coated bearings (aluminum oxide) towards highly advanced hybrid ceramic bearings, which offer superior insulation properties, higher speeds, and reduced friction. Key players are investing heavily in expanding manufacturing capacity, particularly in Asia Pacific, to capitalize on the rapid industrialization and infrastructure development occurring in countries such as China and India. Strategic partnerships and long-term contracts with major industrial motor manufacturers and wind turbine OEMs are central to maintaining market share and securing stable revenue streams.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market segment, underpinned by massive investments in new manufacturing plants, railway modernization projects, and the installation of large-scale renewable energy infrastructure. Europe and North America remain mature markets, focusing on replacing existing equipment with higher-efficiency VFD-driven systems and maintaining extensive high-speed rail networks, driving significant aftermarket demand. European Union directives promoting energy efficiency and sustainable manufacturing further accelerate the mandatory integration of insulated components. The competitive landscape is dominated by a few global giants who leverage their established distribution networks, brand reputation, and patented coating technologies to dictate market standards, although specialized niche players are emerging with innovative hybrid material solutions.

Segmentation trends reveal that the bearing type segment is dominated by deep groove ball bearings due to their high volume use in standard industrial motors, followed closely by cylindrical roller bearings for heavy-duty applications like traction motors. Materially, ceramic-coated steel bearings hold the largest market share owing to their cost-effectiveness and proven performance, while hybrid bearings utilizing ceramic balls are registering the fastest growth due due to their exceptional dielectric strength and high-speed capabilities, particularly in critical applications such as high-performance EVs and specialized industrial equipment. The end-use application segment shows transportation (rail and automotive) and power generation (wind turbines) as the dominant sectors generating the highest revenue, reflecting the critical need for long-term reliability in infrastructure investments.

AI Impact Analysis on Electrically Insulated Bearing Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on the Electrically Insulated Bearing Market largely center on predictive maintenance capabilities, optimized manufacturing processes, and quality control systems. Users frequently ask how AI models can leverage sensor data (vibration, temperature, current leakage) to predict the exact moment an insulated bearing might fail due to coating breakdown or current passage, moving beyond basic scheduled maintenance. Another key theme involves AI-driven optimization of the bearing manufacturing process itself, particularly the precision coating deposition and curing stages, aiming for zero-defect insulation layers. Concerns often relate to the integration costs of AI systems and the necessary sensorization of machinery to capture high-fidelity data relevant to bearing health and electrical integrity. Expectations are high regarding significant reductions in unexpected machine downtime and substantial extensions of bearing life cycle management enabled by AI.

AI's primary influence is manifesting in enhancing the intelligence and lifespan of the machinery that utilizes these bearings, indirectly creating a demand for higher-quality, more reliably insulated components. Predictive maintenance (PdM) systems powered by Machine Learning (ML) algorithms are increasingly crucial for monitoring critical assets like large motors, generators, and wind turbine gearboxes. These systems analyze operational data streams, including slight variations in shaft voltage or vibration signatures indicative of early stage electrical erosion, allowing operators to intervene before the insulating layer is compromised. This capability shifts the focus from reactive replacement to proactive health management, requiring insulated bearings that are compatible with advanced sensor integration and real-time monitoring environments.

Furthermore, AI is pivotal in streamlining the complex and sensitive manufacturing processes involved in producing high-quality insulated bearings. Computer Vision and ML algorithms are utilized for automated quality inspection of the ceramic coatings, ensuring uniform thickness, porosity, and adhesion across the entire surface. This reduces manufacturing variability and enhances the bearing's dielectric strength consistency, which is crucial for high-voltage applications. By optimizing energy consumption during the plasma spray deposition process and predicting material yield based on real-time feedback loops, AI contributes to lowering production costs and improving the overall sustainability of the supply chain, ultimately reinforcing the market position of premium, defect-free insulated bearings.

- AI-driven Predictive Maintenance (PdM) reduces unplanned downtime by forecasting bearing failure through electrical signature analysis.

- Machine Learning optimizes ceramic coating application (plasma spray) for enhanced insulation consistency and reduced manufacturing defects.

- Increased sensor integration in motors and generators, facilitated by AI analytics, boosts demand for smarter, sensor-ready insulated bearings.

- AI improves supply chain visibility and efficiency, ensuring timely delivery of specialized raw materials (ceramics, specialized steel).

- Automated quality control systems using Computer Vision ensure zero-defect electrical insulation layers, enhancing product reliability.

DRO & Impact Forces Of Electrically Insulated Bearing Market

The dynamic interplay of Drivers, Restraints, and Opportunities significantly shapes the trajectory of the Electrically Insulated Bearing Market, creating robust growth but also necessitating technological adaptation. The primary drivers are centered around the ubiquity of Variable Frequency Drives (VFDs) in industrial settings, which inherently generate damaging shaft voltages, making insulated bearings a protective necessity rather than an optional upgrade. Parallel to this is the massive global investment in electric transportation, including high-speed trains, metros, and the burgeoning Electric Vehicle (EV) sector, all relying on high-power motors susceptible to electrical erosion. These factors create a powerful, non-negotiable demand foundation for insulation technology. However, the market faces restraints, primarily the significantly higher initial cost of insulated and hybrid bearings compared to conventional steel bearings, which can deter adoption in price-sensitive emerging markets or smaller industrial operations. Furthermore, the lack of universal standardization across all VFD applications regarding maximum permissible shaft voltage levels complicates product specification and implementation.

The key opportunities lie in addressing high-growth, high-performance niches. The transition to higher power density motors and faster switching semiconductor technologies (like SiC and GaN used in VFDs) is increasing the severity of electrical discharge damage, creating an urgent need for hybrid ceramic bearings which offer superior dielectric properties over standard coated bearings. The expansion of wind energy, particularly in offshore installations where maintenance costs are prohibitive, offers a major avenue for growth as operators prioritize maximum reliability through premium insulated components. Geographically, emerging economies in APAC present unparalleled opportunities through greenfield industrial projects and extensive railway network expansion. The impact forces indicate that technological advancement (Opportunity) is actively working to overcome the cost barrier (Restraint), while regulatory pushes for energy efficiency (Driver) are mandating the adoption of the required protection measures.

The impact forces within the market are predominantly strong and favorable. The substitution threat is relatively low; while alternative solutions like grounding brushes exist, they require frequent maintenance and offer less reliable protection than permanently installed insulation. Buyer power is moderate; while major OEMs (Original Equipment Manufacturers) leverage their volume to negotiate prices, the technical necessity and mission-critical nature of bearing insulation often limit the willingness to compromise on quality or specification. Supplier power is also moderate, concentrated among a few key raw material providers for specialized ceramics and coating equipment. Overall, the market momentum is strongly positive, sustained by non-discretionary demand stemming from electrical physics and global electrification trends, meaning that the penetration rate of insulated bearings in new VFD installations is expected to climb steadily throughout the forecast period.

Segmentation Analysis

The Electrically Insulated Bearing Market segmentation provides a crucial framework for understanding supply dynamics and demand heterogeneity across various industrial and transportation applications. The market is primarily segmented by Bearing Type, Material Type, Application, and End-Use Industry, reflecting the diversity of functional requirements and performance envelopes. The analysis indicates that Material Type is the most dynamic segment, showing a clear shift towards higher-performance solutions. While traditional coated bearings remain the volume leader due to cost-effectiveness in standard VFD applications, the rapid technological advancement in hybrid bearings—which incorporate ceramic rolling elements—is reshaping the high-end market. These hybrid types are essential for high-speed, high-temperature, and ultra-reliable environments where absolute electrical immunity is required, such as in high-speed rail traction motors and critical renewable energy infrastructure components.

Segmentation by Application highlights the crucial role of insulated bearings in motor and generator protection. The pervasive use of VFDs across all industrial motors, from small pumps to massive compressors, forms the largest application category. Furthermore, the segmentation by End-Use Industry clearly delineates the major consumption bases, with Transportation (Railways and Automotive) and Power Generation (Wind Turbines) exhibiting the highest growth and largest market shares. Railway applications mandate the highest level of reliability due to safety concerns and demanding operational cycles, typically requiring larger, robust cylindrical roller insulated bearings. Conversely, the rapidly growing Electric Vehicle (EV) sector demands compact, high-speed, and low-friction hybrid bearings to optimize drivetrain efficiency and longevity, driving significant innovation in smaller bearing sizes and advanced ceramic materials.

The interaction between the segments reflects market maturity and technological adoption rates. Deep Groove Ball Bearings (DGBBs) dominate the Type segment and are predominantly coated with aluminum oxide (Material Segment) for general industrial use, offering an optimal balance between cost and electrical protection for lower voltage applications. However, the rising complexity and power of electrical systems necessitate the adoption of Cylindrical Roller Bearings (Type Segment) combined with hybrid materials (Material Segment) for heavy-duty End-Use applications like large wind turbines and rail traction motors. This segmentation analysis is vital for strategic market entry, allowing manufacturers to tailor their production, distribution, and marketing efforts to the specific technical demands and procurement cycles of these diverse end-user groups.

- By Bearing Type:

- Deep Groove Ball Bearings (DGBB)

- Cylindrical Roller Bearings (CRB)

- Spherical Roller Bearings (SRB)

- Angular Contact Ball Bearings (ACBB)

- By Material Type:

- Ceramic Coated Bearings (Aluminum Oxide)

- Hybrid Bearings (Ceramic Rolling Elements and Steel Rings)

- By Application:

- AC Motors and Generators

- Pumps and Compressors

- Wind Turbines

- Traction Motors (Rail and EV)

- Industrial Fans and Blowers

- By End-Use Industry:

- Industrial Machinery

- Transportation (Railways, Automotive/EVs)

- Energy & Power (Wind, Hydro)

- Oil & Gas

- Mining & Metals

Value Chain Analysis For Electrically Insulated Bearing Market

The value chain for the Electrically Insulated Bearing Market is complex, involving specialized material suppliers, high-precision manufacturing processes, and intricate distribution channels connecting producers to highly specific end-user applications. The upstream segment is characterized by the sourcing of high-grade bearing steel (chrome steel or specialized alloys) and advanced ceramic materials, primarily aluminum oxide powder for coatings or silicon nitride for hybrid rolling elements. Supplier relationships in this segment are critical, as the quality of the raw materials directly impacts the bearing's dielectric strength and overall lifespan. Manufacturers often maintain stringent control over material specifications and processing, distinguishing them from standard bearing producers. Key upstream activities include metallurgical treatment, ceramic synthesis, and advanced plasma spray equipment procurement necessary for insulation deposition.

The core manufacturing stage involves conventional bearing production combined with specialized insulation application. This process often includes grinding, heat treatment, assembly, and crucially, the application of the ceramic coating, typically through Plasma Sprayed Ceramic (PSC) technology. Direct distribution channels are paramount, particularly for Original Equipment Manufacturers (OEMs) in sectors like wind energy and rail traction motors, where technical expertise and customization are required. Major bearing manufacturers maintain dedicated sales forces and engineering support teams to liaise directly with OEMs during the design and integration phases. This direct approach ensures that the insulated bearing specifications precisely match the demanding electrical and mechanical load profiles of the final application, minimizing the risk of failure.

Downstream analysis reveals that indirect distribution—through authorized industrial distributors and aftermarket service providers—is crucial for the replacement market (MRO). These indirect channels stock a wide range of standard insulated bearing sizes, providing quick access for general industry users replacing damaged components in existing VFD-driven machinery. The end-users, encompassing large industrial conglomerates, railway operators, and utility companies, prioritize product reliability and total cost of ownership (TCO) over marginal initial price differences. Therefore, the value derived by the customer is not just the product itself, but the technical support, warranty, and proven reliability provided through both direct OEM supply and robust aftermarket channels, emphasizing the importance of brand reputation and service quality throughout the value chain.

Electrically Insulated Bearing Market Potential Customers

The potential customer base for the Electrically Insulated Bearing Market spans several capital-intensive industries where operational reliability and minimized downtime are mission-critical. The primary end-users are entities that heavily rely on Variable Frequency Drives (VFDs) to control large electric motors, generators, and rotating equipment. This includes major industrial manufacturers, particularly in the chemicals, metals, paper, and mining sectors, where continuous operations are vital and motor failure can lead to catastrophic losses. These buyers seek insulated bearings as a standard specification for all new motor installations connected to VFDs, viewing them as essential protective equipment to guarantee the longevity of high-value assets and reduce long-term maintenance expenses associated with electrical erosion damage.

Another significant segment comprises the global transportation sector, dominated by national and private railway operators. Railways are key customers, purchasing large volumes of highly specified cylindrical roller insulated bearings for use in traction motors, which operate under extreme load, speed, and environmental conditions. The increasing adoption of high-speed rail necessitates bearings with superior electrical resistance and mechanical robustness. Similarly, the rapidly expanding electric vehicle (EV) manufacturing industry represents a burgeoning customer segment, demanding specialized, compact, and high-performance hybrid bearings for efficient and reliable e-axle assemblies and traction drivetrains. In both rail and automotive applications, failure prevention is paramount due to safety and performance requirements, driving demand for premium products.

Furthermore, the energy and power sector, specifically wind turbine operators and original equipment manufacturers (OEMs), constitutes a substantial customer base. Wind turbines are inherently susceptible to electrical discharge currents, both from VFDs controlling pitch/yaw mechanisms and from stray currents generated by the generator itself, compounded by environmental factors. Turbine operators prioritize high-reliability insulated and hybrid bearings for gearboxes and main shafts, aiming for extremely long service intervals (e.g., 20+ years) given the difficulty and high cost of offshore maintenance. Therefore, potential customers are typically highly sophisticated buyers whose procurement decisions are driven by Total Cost of Ownership (TCO), guaranteed uptime, and stringent performance specifications, reinforcing the market’s reliance on quality and technical assurance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SKF, Schaeffler Group, NSK Ltd., NTN Corporation, Timken Company, JTEKT Corporation, Koyo, ZYS Bearing, C&U Group, Wafangdian Bearing Group (ZWZ), Harbin Bearing Manufacturing Co. Ltd. (HRB), MinebeaMitsumi Inc., RBC Bearings Incorporated, Luoyang Bearing Corporation, AST Bearings LLC, Nachi-Fujikoshi Corp., Hiwin Corporation, FAG, Rexnord Corporation, General Bearing Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrically Insulated Bearing Market Key Technology Landscape

The technology landscape of the Electrically Insulated Bearing Market is defined by continuous innovation in coating materials and deposition methods aimed at maximizing dielectric strength and ensuring mechanical durability. The dominant technology remains Plasma Sprayed Ceramic (PSC) coating, typically utilizing aluminum oxide (Al2O3). This process involves thermally spraying fine ceramic powder onto the bearing ring surface, creating a thin, dense, non-conductive layer capable of withstanding thousands of volts. Recent advancements focus on optimizing the plasma spray parameters—such as gas flow, temperature, and power—to achieve highly uniform coating thickness and minimize porosity. Manufacturers are also developing advanced sealing technologies to protect the coated surface from environmental contaminants like moisture and dust, which can compromise the insulation integrity over time and reduce the bearing's effective lifespan in harsh industrial environments.

The fastest-growing and most advanced segment involves Hybrid Bearing Technology. These bearings incorporate ceramic rolling elements (typically silicon nitride, Si3N4) instead of ceramic coatings on the steel rings. Hybrid bearings offer unparalleled electrical insulation, capable of withstanding extremely high voltages generated by the latest high-frequency VFDs utilizing silicon carbide (SiC) power modules. Beyond insulation, ceramic balls are significantly lighter, harder, and offer lower friction and higher limiting speeds than steel balls, making them ideal for high-performance applications such as high-speed machine tools, aerospace components, and electric vehicle traction motors operating at high RPMs. The material science focus is on improving the fracture toughness and fatigue life of the ceramic elements under extreme loading conditions, thereby enhancing the overall reliability of the hybrid solution.

Beyond material composition, technology development is also centered on integrated monitoring solutions. Smart bearings, while still nascent in the insulated segment, incorporate micro-sensors for real-time monitoring of vibration, temperature, and critically, the shaft voltage or current leakage. These integrated solutions leverage miniaturization and wireless data transmission to provide actionable intelligence regarding the health of the insulation layer. The integration of such sensing capabilities is essential for feeding data into AI-driven predictive maintenance systems. Furthermore, ongoing research explores alternative insulating materials, including specialized polymers or multilayer composite coatings, which could offer comparable electrical resistance at a lower manufacturing cost or easier processing compared to high-temperature ceramic plasma spraying, potentially democratizing the technology for broader industrial adoption.

Regional Highlights

Regional dynamics play a crucial role in the market's overall expansion, reflecting varying rates of industrialization, infrastructure investment, and regulatory adoption of energy-efficient technologies worldwide.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market due to rapid urbanization, massive investments in industrial infrastructure (including robotics and automation), and aggressive expansion of railway networks (especially in China and India). The region is a global manufacturing hub for industrial motors and is seeing strong adoption of VFDs across textiles, steel, and cement industries. Furthermore, government mandates supporting renewable energy, particularly wind power installation in countries like China, significantly boosts the demand for high-reliability insulated bearings.

- Europe: Europe is a mature market characterized by stringent environmental regulations and high emphasis on energy efficiency, strongly driving the adoption of premium insulated bearings. The region has extensive high-speed rail networks requiring constant maintenance and upgrades using specialized traction motor bearings. Germany, Italy, and France are key consumers, driven by advanced manufacturing and a substantial installed base of wind turbines. The focus here is often on high-quality hybrid bearings and MRO (Maintenance, Repair, and Overhaul) activities.

- North America: North America demonstrates steady growth, propelled by the modernization of aging industrial infrastructure and substantial investment in electric vehicle manufacturing. The US and Canada are large consumers of insulated bearings in the oil & gas sector (pumps and compressors) and high-power industrial fan applications. The demand is heavily influenced by the replacement cycle in heavy machinery and the increasing deployment of high-voltage VFD systems in manufacturing facilities seeking operational cost reduction.

- Latin America (LATAM): Growth in LATAM is moderate but concentrated, primarily driven by resource-intensive sectors such as mining and primary processing (metals and minerals). These industries require extremely robust bearings to operate in harsh conditions, making insulated components essential for maximizing uptime in remote locations. Infrastructure projects, particularly in Brazil and Mexico, also contribute significantly to regional demand.

- Middle East and Africa (MEA): This region is characterized by high demand from the Oil & Gas sector, where insulated bearings are critical for pumps, compressors, and pipeline systems. Investments in renewable energy (solar and wind) and diversification away from fossil fuels, particularly in Gulf nations, present long-term growth opportunities, although the market size remains smaller compared to APAC or Europe.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrically Insulated Bearing Market.- SKF

- Schaeffler Group

- NSK Ltd.

- NTN Corporation

- Timken Company

- JTEKT Corporation

- Koyo

- ZYS Bearing

- C&U Group

- Wafangdian Bearing Group (ZWZ)

- Harbin Bearing Manufacturing Co. Ltd. (HRB)

- MinebeaMitsumi Inc.

- RBC Bearings Incorporated

- Luoyang Bearing Corporation

- AST Bearings LLC

- Nachi-Fujikoshi Corp.

- Hiwin Corporation

- FAG

- Rexnord Corporation

- General Bearing Corporation

Frequently Asked Questions

Analyze common user questions about the Electrically Insulated Bearing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function and necessity of an electrically insulated bearing?

The primary function of an electrically insulated bearing is to prevent the passage of damaging electrical currents through the bearing elements and lubricant film. This necessity arises mainly from the use of Variable Frequency Drives (VFDs) and high-power electronics, which induce shaft voltages that cause electrical erosion (pitting and fluting), leading to premature bearing failure, costly machine downtime, and increased maintenance expenses.

How do hybrid bearings compare to standard ceramic-coated bearings in terms of performance?

Hybrid bearings, which feature ceramic rolling elements (balls or rollers) and steel rings, offer significantly superior performance compared to standard ceramic-coated bearings (which have a coating on the steel ring). Hybrid bearings provide absolute insulation, lower friction, higher operating speeds, reduced risk of skidding, and better thermal stability, making them preferred for critical high-voltage and high-speed applications like high-performance EVs and rail traction motors.

Which end-use industries drive the highest demand for insulated bearing technology?

The highest demand is driven by the Transportation sector (specifically railways for traction motors and the rapidly growing electric vehicle industry for e-axles) and the Energy & Power sector, dominated by wind turbine installations (main shafts, gearboxes, and pitch systems). Industrial machinery relying on VFDs, such as compressors, pumps, and large industrial fans, also constitutes a massive and stable demand base.

What are the key technical constraints limiting the mass adoption of insulated bearings?

The primary technical constraint is the relatively high initial cost compared to conventional steel bearings, often deterring adoption in non-critical or price-sensitive applications. Furthermore, while highly durable, ceramic coatings can be susceptible to damage during mounting if improper installation practices are used, potentially compromising the integrity of the insulating layer and requiring specialized handling procedures.

How does the widespread use of Variable Frequency Drives (VFDs) correlate with market growth?

VFDs are the central driver of market growth. As industries globally adopt VFDs to achieve energy efficiency and precise motor control, they simultaneously introduce the risk of electrical discharge damage to motor bearings. Since insulated bearings are the most reliable long-term solution to mitigate this risk, the increasing penetration rate of VFDs across all industrial sectors directly translates into a proportional and mandatory increase in the demand for insulated bearing components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager