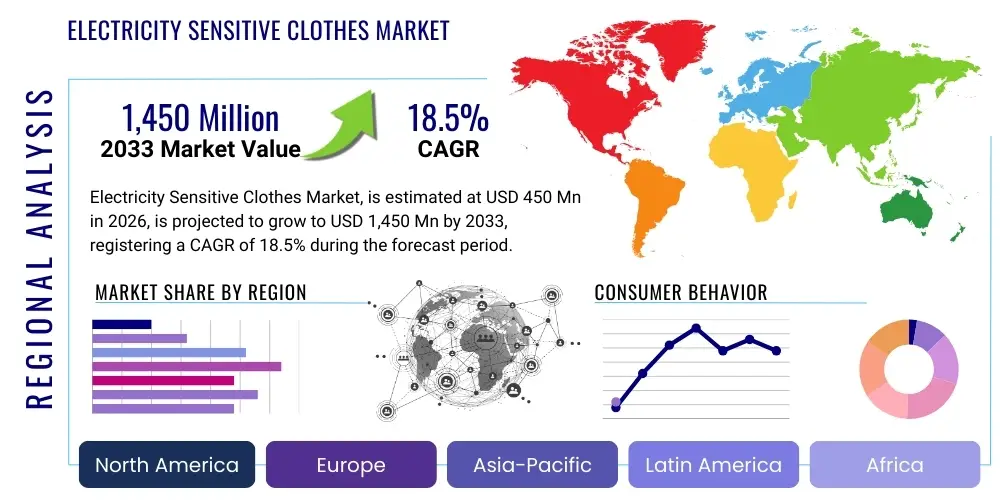

Electricity Sensitive Clothes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434885 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Electricity Sensitive Clothes Market Size

The Electricity Sensitive Clothes Market, a specialized subset of the smart textiles industry, is experiencing exponential growth driven by advancements in miniaturized sensor technology and flexible circuitry integration. This market segment focuses on fabrics capable of sensing, storing, or reacting to electrical stimuli, offering functionalities ranging from physiological monitoring to active thermal regulation. The increasing demand from high-growth sectors such as healthcare, defense, and high-performance sports is fundamentally altering the scope and scalability of production techniques, moving e-textiles from niche prototypes into viable commercial products. Adoption is further catalyzed by diminishing costs associated with flexible electronics and improved washability standards for integrated garments.

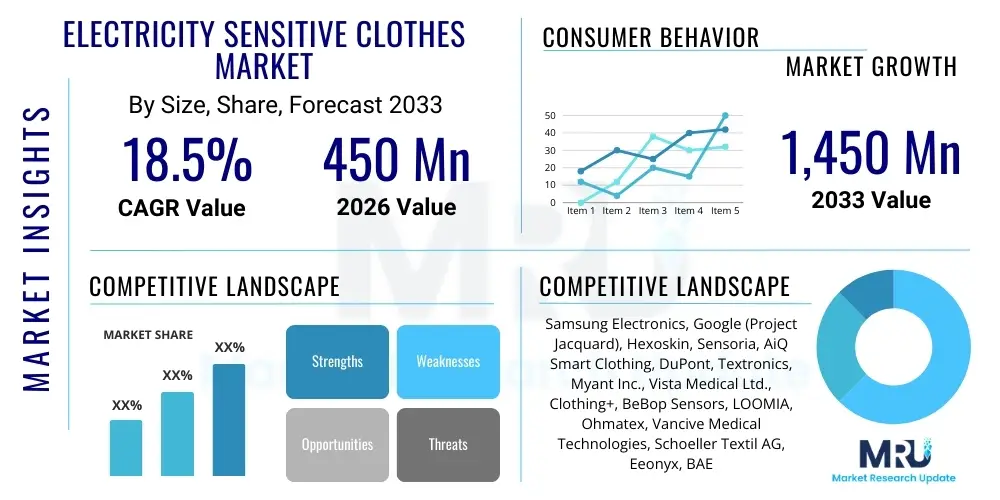

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2026 and 2033. This robust growth rate reflects significant investment in research and development aimed at improving battery life, wearer comfort, and data security protocols inherent to these intelligent garments. Key market players are increasingly focusing on developing seamless integration methods that maintain the aesthetic and tactile qualities of traditional clothing while embedding complex electronic functionalities, thus overcoming previous consumer acceptance hurdles related to bulky or stiff electronic components. Standardization initiatives across the global textile and electronics industries are expected to streamline manufacturing processes, contributing significantly to future market expansion.

The market is estimated at USD 450 Million in 2026 and is projected to reach USD 1,450 Million by the end of the forecast period in 2033. This valuation underscores the shift towards proactive health management solutions and the military’s ongoing need for enhanced situational awareness and protective gear. The revenue growth is highly dependent on breakthroughs in sustainable energy harvesting technologies embedded within the textiles, reducing reliance on conventional batteries, which is a major area of current research expenditure. Furthermore, expansion into mass-market consumer applications, particularly wellness and fitness tracking, promises to open substantial revenue streams beyond traditional industrial and medical uses.

Electricity Sensitive Clothes Market introduction

The Electricity Sensitive Clothes Market encompasses textiles and garments embedded with conductive fibers, electronic components, and smart materials that respond to or generate electrical signals. These garments, often termed e-textiles or smart fabrics, utilize various technologies, including piezoresistive, thermoelectric, and electrochromic components, to perform advanced functions. Product descriptions often highlight key capabilities such as biometric data collection (ECG, heart rate, respiration), environmental sensing, active heating/cooling, and integration with external computational devices via wireless communication protocols. These clothes represent the intersection of material science, electrical engineering, and apparel design, aiming to provide enhanced utility and interactive experiences for the wearer.

Major applications for electricity sensitive clothes span several critical sectors. In healthcare, they enable continuous, non-invasive patient monitoring for chronic conditions, remote diagnostics, and rehabilitation tracking, moving clinical data collection out of traditional hospital settings. Military and defense applications rely on these textiles for soldier monitoring, camouflage adaptation (electrochromic), and integrated communication systems, enhancing mission effectiveness and safety. Consumer applications are centered on fitness tracking, performance optimization in professional sports, and fashion items that incorporate dynamic lighting or responsive elements. The versatility across these diverse segments validates the substantial market potential.

The core benefits of these garments include improved safety through real-time feedback, enhanced comfort via automated environmental response (e.g., cooling), and superior data fidelity compared to traditional wearable gadgets. Driving factors include the global surge in demand for remote patient monitoring technologies due to aging populations, increasing investment by defense organizations in soldier modernization programs, and rapid miniaturization and cost reduction of semiconductor components suitable for textile integration. The seamless integration and improved durability of modern conductive materials are crucial in driving consumer acceptance and broadening the market appeal beyond specialized industrial uses.

Electricity Sensitive Clothes Market Executive Summary

The Electricity Sensitive Clothes Market is characterized by vigorous innovation and strategic partnerships between textile manufacturers, technology firms, and apparel brands. Business trends indicate a strong focus on intellectual property creation surrounding flexible power sources and washable electronic encapsulation methods, crucial barriers to entry for new competitors. Regional trends show North America and Europe leading in terms of R&D expenditure and high-value defense procurement, while the Asia Pacific region is rapidly dominating the manufacturing and mass-market consumer application space due to established electronics supply chains and large-scale textile production capabilities. Investment in regulatory compliance, particularly concerning medical device certification and data privacy standards (like GDPR and HIPAA), is a pivotal ongoing strategic requirement for global players operating in the healthcare segment.

Segment trends highlight the dominance of the healthcare sector, particularly for remote diagnostic and monitoring systems, which command premium pricing due to regulatory requirements and critical application nature. Technology segmentation is shifting towards textile-based sensors (conductive polymers and nanomaterials) over embedded discrete components, favoring comfort and washability. The Military & Defense segment remains a significant driver for advanced material research, specifically concerning energy harvesting (thermoelectric) and robust communication features. The consumer segment, while growing rapidly, is highly price-sensitive and focuses more on aesthetic integration and basic physiological monitoring functionalities like heart rate variability.

Overall, the market trajectory is strongly upward, contingent upon achieving scalable, cost-effective manufacturing processes for seamlessly integrated smart yarns and fabrics. Key challenges remain in ensuring long-term durability, reliable power management in dynamic environments, and developing robust, standardized protocols for data transmission from garment to platform. Strategic acquisitions of specialized material science companies by large apparel conglomerates underscore the urgency for market leadership in integrating advanced electrical sensitivity into everyday wear. The next phase of growth will be defined by the successful commercialization of self-powered textiles and the expansion into sophisticated diagnostic capabilities beyond simple physiological metrics.

AI Impact Analysis on Electricity Sensitive Clothes Market

User inquiries regarding AI's influence on the Electricity Sensitive Clothes Market frequently revolve around three core themes: predictive maintenance, personalized textile performance, and accelerated material discovery. Users seek to understand how AI can optimize the textile weaving process to maintain conductivity and integrity, how machine learning algorithms personalize the garment's functionality (e.g., adjusting thermal output based on real-time biometric data and learned user preferences), and whether AI can expedite the identification of novel conductive polymers or self-healing materials suitable for integration. The primary concern is often related to the computational requirements of embedded AI and maintaining privacy while processing continuous, sensitive physiological data collected by these garments. Users expect AI to reduce design cycles, minimize manufacturing waste, and enable true customization at scale.

The integration of Artificial Intelligence is revolutionizing the research and development phase of electricity sensitive clothes, primarily by simulating material behaviors under stress and predicting the longevity of electronic components embedded in dynamic fabric structures. AI-driven simulation tools allow developers to rapidly iterate on yarn composition, circuit layout, and protective encapsulation methods, significantly reducing the reliance on costly, time-consuming physical prototyping. Furthermore, during manufacturing, AI-powered quality control systems utilize computer vision to inspect complex conductive paths woven into textiles, ensuring extremely high precision and consistency, thereby overcoming the significant challenge of achieving reliable electrical performance in a flexible medium. This ensures that the garments meet stringent performance standards required in clinical or military applications.

In post-production use, AI algorithms are vital for data processing and personalized user interaction. Smart clothing generates massive streams of raw physiological and environmental data; AI is essential for filtering noise, extracting meaningful biomarkers, and providing actionable insights. For instance, in therapeutic applications, machine learning models can detect subtle changes in gait or cardiac rhythm indicative of potential medical events long before human observation. This predictive capability transforms electricity-sensitive clothing from a simple data collector into a critical proactive health management tool. Enhanced personalization is also achieved as AI tunes the garment’s response—such as modulating haptic feedback or optimizing power usage—based on deep learning from the individual user’s behavior patterns and specific needs, maximizing both efficiency and wearer satisfaction.

- AI-driven material discovery accelerates the development of novel conductive and flexible polymers, optimizing conductivity-to-weight ratios.

- Predictive modeling simulates the mechanical stress and electrical degradation of smart textiles during washing and rigorous use, ensuring durability.

- Machine learning algorithms enhance data analysis from biometric sensors, translating raw signals into actionable, personalized health insights.

- Computer vision systems improve manufacturing quality control, detecting micro-defects in woven conductive circuits with high precision.

- Embedded AI enables real-time, adaptive garment functionality, such as dynamic thermal regulation or posture correction via integrated actuators.

- Optimization of power management systems using neural networks maximizes battery life and efficiency in complex sensor networks.

DRO & Impact Forces Of Electricity Sensitive Clothes Market

The market dynamics of Electricity Sensitive Clothes are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO). The primary drivers propelling the market include the accelerating global shift towards preventive healthcare and remote patient monitoring, coupled with sustained, high levels of investment in military modernization programs that require integrated electronic capabilities for situational awareness and protection. However, significant restraints impede faster adoption, notably the high initial cost of smart garments compared to traditional apparel, persistent challenges related to long-term durability, and the crucial regulatory hurdles concerning data privacy and medical device certification. Opportunities are vast, particularly in leveraging breakthroughs in nanofiber technology and developing self-charging or energy-harvesting textiles, which would effectively eliminate the primary constraint of battery reliance and significantly broaden consumer appeal. Strategic partnerships between textile giants and technology innovators are key to capitalizing on these opportunities.

The crucial drivers are intrinsically linked to technological maturation. The continuous miniaturization of Micro-Electro-Mechanical Systems (MEMS) sensors and flexible Printed Circuit Boards (PCBs) allows for unobtrusive integration into fabrics, maintaining high comfort and aesthetic appeal. Furthermore, the standardization efforts led by organizations like IEEE and ISO concerning e-textile performance and data exchange protocols are lowering technical barriers and fostering greater interoperability across different platforms and brands. The increasing penetration of 5G infrastructure also acts as a powerful driver, enabling the high-speed, reliable transmission of large volumes of biometric data collected by these smart garments in real-time, which is essential for critical applications like remote surgery assistance or urgent tactical communication.

Restraints are deeply rooted in manufacturing complexity and consumer psychology. Integrating conductive elements requires specialized weaving or printing processes that are often more expensive and less scalable than conventional textile manufacturing. Moreover, consumer hesitancy persists due to concerns about the garment's lifespan after repeated washing cycles and the complexity of maintenance. The impact forces acting on the market are high, driven primarily by technological advancements (high impact) and regulatory pressures (medium to high impact). Technology acts as the accelerating force, constantly introducing smaller, more powerful, and more comfortable solutions. Conversely, regulatory impact forces ensure market stability and trustworthiness, particularly in medical applications, but also impose significant time and cost overheads for product development and market entry. Competitive intensity is rapidly increasing as major players from the sportswear, medical device, and defense industries converge on this domain, necessitating continuous innovation in proprietary material science.

Segmentation Analysis

The Electricity Sensitive Clothes Market is segmented based on the core Technology utilized, the specific Application domain, and the distribution channel employed for sales. This segmentation offers a granular understanding of the market structure, allowing stakeholders to target specific niches based on required functionality, material robustness, and price sensitivity. The Technology segment differentiates between fabrics embedded with flexible electronics (e.g., circuit boards) and those relying on intrinsic smart materials like conductive polymers or optical fibers woven directly into the fabric, reflecting differing approaches to durability and flexibility. Application segmentation highlights the stark difference in regulatory requirements and procurement processes between highly regulated sectors like healthcare and defense versus the fast-moving consumer sports and fashion industries.

The primary technological segmentation reveals a continuous shift from discrete, embedded hardware towards textile-integrated solutions, often involving advanced conductive inks or inherently conductive polymers (ICPs). This trend is motivated by the critical need to enhance wearer comfort and allow for industrial-scale washing. The healthcare segment remains the largest revenue generator, demanding medical-grade accuracy and strict adherence to certification standards, contrasting sharply with the consumer segment, which prioritizes lightweight design and integration with popular fitness ecosystems. Analyzing distribution channels confirms the growing importance of e-commerce platforms, particularly for direct-to-consumer sales in the fitness and wellness categories, while specialized industrial and military contracts rely predominantly on direct sales and specialized tender processes.

Understanding these segments is crucial for strategic planning. For instance, companies targeting the defense sector must prioritize high tensile strength, electromagnetic shielding capabilities, and rugged power management systems, regardless of marginal cost increase. Conversely, firms focusing on the fashion segment must ensure minimal visibility of electronic components and integrate sophisticated haptic or lighting feedback systems, often making design aesthetics paramount over highly complex sensing capabilities. The most promising growth area is the industrial segment, specifically in worker safety and monitoring (e.g., monitoring vital signs in hazardous environments or tracking fatigue levels in long-haul transport workers), which demands durable, practical, and highly scalable solutions.

- By Technology:

- Conductive Polymer-based E-Textiles

- Fiber Optic Integrated Fabrics

- Electronic Component-Embedded Textiles (Flexible PCBs, Discrete Sensors)

- Nanomaterial and Graphene-based Fabrics

- Thermoelectric and Piezoelectric Fabrics (Energy Harvesting)

- By Application:

- Healthcare and Medical Monitoring (Remote Diagnostics, Patient Tracking)

- Military and Defense (Soldier Monitoring, Communication, Adaptive Camouflage)

- Sports and Fitness (Performance Tracking, Injury Prevention)

- Industrial and Workplace Safety (Hazardous Environment Monitoring)

- Consumer Electronics and Fashion (Haptic Feedback, Smart Lighting)

- By Distribution Channel:

- Online Retail

- Specialty Stores and Apparel Chains

- Direct Sales (B2B for Military and Medical Institutions)

Value Chain Analysis For Electricity Sensitive Clothes Market

The value chain for the Electricity Sensitive Clothes Market begins with the highly specialized upstream analysis focused on raw material procurement and advanced component manufacturing. This stage involves sourcing flexible and highly conductive materials, such as silver-coated yarns, conductive polymers, specialized carbon nanotubes, and flexible silicon chips. Key upstream players are chemical companies and specialized semiconductor manufacturers who provide miniaturized, low-power electronic modules compatible with textile integration. The complexity lies in maintaining material performance through the textile manufacturing process, requiring precise coordination between material science experts and textile engineers to ensure conductivity, durability, and non-toxicity of the end products. The quality and cost of these proprietary raw materials significantly influence the final product pricing and performance characteristics.

The midstream phase, focused on manufacturing and integration, is characterized by complex processes, including advanced weaving techniques (jacquard or specialized knitting) to integrate conductive fibers, electronic printing (e.g., using conductive inks), and precise encapsulation of sensor elements to ensure protection against moisture and mechanical stress. This phase requires significant capital investment in specialized machinery and highly skilled labor capable of managing both textile and electronic assembly processes. The successful execution of this phase determines scalability and the aesthetic appeal of the final product, directly impacting consumer acceptance. Rigorous testing and quality assurance procedures are paramount here, ensuring the garment meets required electrical performance and durability standards.

Downstream analysis involves distribution channels, market reach, and end-user engagement. Distribution is bifurcated: direct channels dominate military, defense, and specialized medical device sales, ensuring technical support and strict contractual compliance. Indirect channels, including online retail and specialty sports stores, handle the high-volume consumer segment. Marketing strategies must clearly articulate the complex technological benefits in accessible terms. Post-sale services, including software updates, data analytics platforms, and technical support, form a critical part of the value proposition, particularly in data-intensive applications. Ultimately, achieving maximum market value requires seamless vertical integration or robust partnerships across the semiconductor, material science, and traditional apparel industries.

Electricity Sensitive Clothes Market Potential Customers

The potential customer base for Electricity Sensitive Clothes is diverse, spanning institutional, industrial, and individual segments, each with unique requirements and purchasing criteria. Institutional buyers, particularly hospitals, specialized clinics, and senior care facilities, are major end-users. They seek reliable, clinically validated monitoring systems for remote patient management, focusing on chronic disease monitoring, post-operative rehabilitation tracking, and preventing hospital readmissions. Their purchasing decisions are driven by regulatory compliance, data security, system integration capabilities with existing Electronic Health Records (EHR), and evidence of clinical efficacy. These customers prefer solutions procured through specialized medical device distributors or direct partnerships with manufacturers providing extensive technical and analytical support.

Governmental and defense organizations represent another critical segment, investing heavily in smart uniforms to enhance soldier performance, monitor physiological status in extreme conditions, and integrate advanced communication and situational awareness tools. Their requirements emphasize ruggedness, electromagnetic compatibility (EMC), high resilience to environmental factors, and seamless integration with existing command and control infrastructure. Procurement often involves large, multi-year contracts awarded through competitive tender processes, placing high value on proprietary technology and proven field performance. Industrial sectors, including mining, oil and gas, and construction, purchase these clothes for worker safety, focusing on fatigue monitoring, hazardous gas detection, and locating personnel in emergency situations, driven by stringent occupational health and safety regulations.

The mass consumer market is segmented into two main groups: professional athletes and wellness enthusiasts. Professional teams and athletes use these garments for granular performance metrics, biomechanical analysis, and optimizing training regimens, demanding highly accurate, research-backed data. The broader wellness enthusiast segment seeks stylish, comfortable, and easy-to-use garments for basic fitness tracking (steps, sleep, heart rate), purchased primarily through online retail and driven heavily by brand reputation, integration with popular smart devices, and affordability. For all segments, minimizing the visibility and intrusion of electronic components is paramount, shifting the focus towards garments that feel and look like conventional clothing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 1,450 Million |

| Growth Rate | CAGR 18.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Samsung Electronics, Google (Project Jacquard), Hexoskin, Sensoria, AiQ Smart Clothing, DuPont, Textronics, Myant Inc., Vista Medical Ltd., Clothing+, BeBop Sensors, LOOMIA, Ohmatex, Vancive Medical Technologies, Schoeller Textil AG, Eeonyx, BAE Systems, Jabil Inc., Toray Industries, Intelligent Textiles Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electricity Sensitive Clothes Market Key Technology Landscape

The core technological landscape of the Electricity Sensitive Clothes Market is defined by innovations in materials science and seamless integration methods. The foundation rests on highly conductive textiles, moving beyond simple metallic threads to advanced materials like conductive polymer coatings, carbon nanotubes (CNTs), and graphene-integrated fibers. These next-generation materials offer superior flexibility, enhanced washability, and increased surface area for sensing applications, minimizing the visibility and rigidity often associated with early e-textiles. Furthermore, the development of stretchable electronics and flexible circuit boards, often utilizing thermoplastic polyurethanes (TPU) as substrates, is crucial for maintaining the natural drape and movement of the fabric, a key differentiator for successful commercial adoption in high-movement applications such as sports and military wear.

A major focus area is energy management, driving research into self-powered textiles. This includes the proliferation of thermoelectric generators (TEGs) that harness heat differences between the body and the environment to generate small amounts of electricity, and piezoelectric fibers that convert mechanical strain (movement) into electrical energy. While current energy yield from these technologies is often insufficient to power high-demand components, they are critical for supporting low-power sensors and extending the battery life of integrated systems, gradually reducing reliance on bulky external power sources. Advances in supercapacitors and flexible battery technology, which can be woven or printed directly onto the fabric, are also critical for achieving truly autonomous smart garments capable of continuous operation over long durations.

The integration of sensing and actuation technologies is sophisticated, utilizing various electrical principles. Piezoresistive sensing relies on changes in electrical resistance due to pressure or strain, commonly used for monitoring respiration, posture, and joint movement. Electrodes woven into the fabric capture bio-potential signals like ECG or EMG with high fidelity. Furthermore, electrochromic technology allows fabrics to dynamically change color or opacity when an electrical current is applied, finding specific niche applications in adaptive camouflage for military purposes or high-fashion responsive textiles. The convergence of these material and electronic integration technologies defines the competitive edge, prioritizing low power consumption, high data accuracy, and robust durability against environmental stressors.

Regional Highlights

Geographically, the Electricity Sensitive Clothes Market exhibits varying dynamics shaped by R&D infrastructure, consumer purchasing power, and regional regulatory frameworks. North America, particularly the United States, commands a leading market share driven by substantial government investment in military programs (e.g., soldier systems modernization) and a mature, technologically advanced healthcare sector eager to adopt remote patient monitoring solutions. The presence of leading technology companies and specialized research institutions focused on material science and wearable technology ensures continuous innovation and rapid commercialization. High consumer acceptance of premium smart gadgets in the fitness segment further boosts market penetration, although the region faces high labor costs for specialized textile assembly.

Europe represents another key region, characterized by stringent medical device regulations (such as the Medical Device Regulation, MDR) which, while slowing time-to-market, ensures high product quality and clinical validation, appealing to established healthcare systems. Countries like Germany, Switzerland, and the UK are strong centers for textile research and specialized engineering, driving innovation in high-durability, professional-grade e-textiles for industrial safety and niche medical applications. The European market focuses heavily on ethical manufacturing and sustainable textile integration, influencing the choice of conductive materials and power sources. Furthermore, privacy regulations like GDPR mandate sophisticated data security protocols for all smart garments collecting sensitive user information, setting a global standard for data handling.

The Asia Pacific (APAC) region is projected to be the fastest-growing market due to rapid urbanization, increasing disposable incomes, and the presence of the world's largest textile and electronics manufacturing hubs (China, South Korea, Japan). This region excels in scalable production and cost-effective manufacturing, making it critical for the mass-market consumer segment. South Korea and Japan lead in integrating smart clothing with consumer electronics ecosystems, while China's substantial investments in indigenous technology and smart city initiatives are accelerating the adoption of connected apparel across various sectors. While the market here is more fragmented and price-sensitive, the sheer volume of production and local consumption potential makes it central to future global market expansion.

- North America: Dominates high-value segments (Defense, Clinical Monitoring). High R&D spending and strong presence of major technology and defense contractors.

- Europe: Focuses on high-quality, regulated medical and industrial safety textiles. Driven by strict regulatory standards (MDR, GDPR) and strong engineering tradition.

- Asia Pacific (APAC): Highest projected growth rate due to massive manufacturing capacity and rising consumer adoption of health and fitness technology. Key in consumer and lower-cost production.

- Latin America (LATAM) & Middle East and Africa (MEA): Emerging markets with potential in infrastructure monitoring and specialized defense procurement. Growth is tied to improving digital infrastructure and disposable income levels.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electricity Sensitive Clothes Market. These companies are instrumental in material innovation, electronic integration, and strategic market penetration, often through cross-industry partnerships to leverage both textile expertise and electronic prowess.- Samsung Electronics

- Google (Project Jacquard)

- Hexoskin

- Sensoria

- AiQ Smart Clothing

- DuPont

- Textronics (acquired by multiple entities, historically significant)

- Myant Inc.

- Vista Medical Ltd.

- Clothing+ (part of Jabil Inc.)

- BeBop Sensors

- LOOMIA

- Ohmatex

- Vancive Medical Technologies

- Schoeller Textil AG

- Eeonyx

- BAE Systems

- Jabil Inc.

- Toray Industries

- Intelligent Textiles Limited

Frequently Asked Questions

Analyze common user questions about the Electricity Sensitive Clothes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of electricity sensitive clothes in the healthcare sector?

The primary healthcare applications include continuous, non-invasive physiological monitoring (ECG, respiration, temperature), remote diagnostics for chronic conditions (e.g., cardiac disease), and rehabilitation tracking. These garments provide clinical-grade data accuracy without interfering with daily life, enabling personalized and proactive patient management outside traditional hospital settings, which is essential for telehealth expansion.

How is the durability and washability of integrated electronic components ensured in smart textiles?

Durability is ensured through several advanced encapsulation techniques, including polymer coatings, flexible silicone potting, and seamless integration methods where conductive elements are woven or knitted directly using robust, insulated fibers. Manufacturers must comply with specific textile testing standards that certify the garment's ability to withstand dozens of industrial or home wash cycles without significant degradation of electrical performance, often requiring specialized textile-grade electronic components.

What role does energy harvesting play in the future development of electricity sensitive clothes?

Energy harvesting is crucial for achieving true autonomy in smart clothing by minimizing or eliminating the need for external batteries. Technologies like thermoelectric generators (converting body heat) and piezoelectric fibers (converting movement) are being integrated to power low-consumption sensors. Successful implementation of self-powered textiles will significantly enhance user convenience, reduce garment weight, and broaden applicability for long-duration missions or continuous health monitoring.

What are the key regulatory challenges facing the commercialization of electricity sensitive clothes?

Key regulatory challenges involve obtaining necessary medical device certifications (like FDA approval or EU MDR compliance) if the garment claims diagnostic capabilities. Furthermore, strict adherence to global data privacy regulations (e.g., GDPR, HIPAA) is mandatory, as these clothes collect highly sensitive biometric data. Navigating these compliance pathways is time-consuming and costly but vital for market credibility, especially in clinical applications.

Which material innovations are driving increased market adoption and comfort in smart apparel?

Material innovations center on high-performance conductive materials such as silver-coated nylon, carbon nanotubes, and graphene inks, which provide superior electrical performance while maintaining textile flexibility and softness. Furthermore, the development of stretchable and printable electronics allows for circuits to be seamlessly integrated into ergonomic, form-fitting designs, overcoming the historical restraint of rigid, uncomfortable electronic patches and significantly increasing consumer willingness to adopt the technology.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager