Electro Hydraulic Servo Valve Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434876 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Electro Hydraulic Servo Valve Market Size

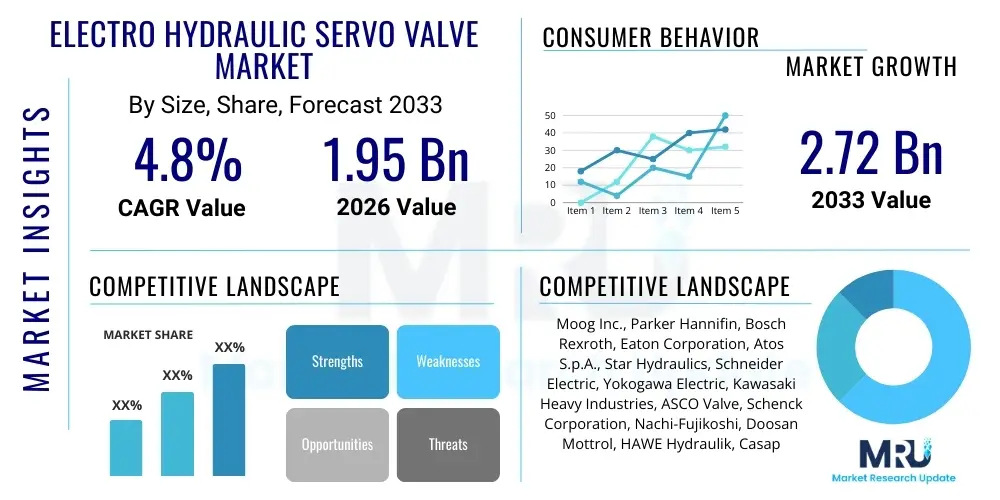

The Electro Hydraulic Servo Valve Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $1.95 Billion in 2026 and is projected to reach $2.72 Billion by the end of the forecast period in 2033.

Electro Hydraulic Servo Valve Market introduction

Electro Hydraulic Servo Valves (EHSVs) are critical components in sophisticated hydraulic control systems, serving as the interface between low-power electronic control signals and high-power hydraulic fluid flow. These valves are essential for achieving precise, high-speed control over position, velocity, and force in demanding industrial and aerospace applications. EHSVs operate by utilizing an electrical input to control a small pilot stage, which in turn directs hydraulic fluid to position a main spool, thereby modulating the flow and pressure to an actuator. This closed-loop control mechanism offers superior dynamic response and accuracy compared to standard proportional valves, making them indispensable in environments requiring stringent performance criteria such as flight control surfaces, test rigs, and high-precision manufacturing equipment.

The primary applications driving the adoption of EHSVs include their extensive use in heavy machinery for construction and mining, critical motion control in aerospace systems, specialized machine tools requiring nanometer precision, and high-fidelity simulation and testing equipment. The robust design and capability of EHSVs to handle extreme pressures and temperatures while maintaining repeatability distinguish them in the fluid power sector. Key benefits derived from utilizing EHSVs encompass enhanced system efficiency due to minimized energy losses, superior control resolution that translates to higher product quality, and improved operational safety through rapid response times to electronic commands.

Market expansion is fundamentally driven by the accelerating demand for automation across manufacturing sectors, particularly in regions undergoing rapid industrialization. The increased complexity of modern industrial processes necessitates control components that offer higher reliability and faster bandwidth. Furthermore, technological advancements in material science and miniaturization are enabling the development of smaller, more robust EHSVs, broadening their applicability in portable and confined spaces. The continuous push toward energy-efficient hydraulic solutions, coupled with stringent regulatory requirements in safety-critical applications like aviation, further solidifies the market's growth trajectory.

Electro Hydraulic Servo Valve Market Executive Summary

The Electro Hydraulic Servo Valve (EHSV) market is characterized by moderate but stable growth, driven predominantly by modernization initiatives in the aerospace and heavy machinery sectors which prioritize precision and dynamic performance. Business trends indicate a strong focus among key manufacturers on developing digital servo valves and integrating IoT capabilities for predictive maintenance and enhanced diagnostic features, moving away from purely analog systems. Geographically, Asia Pacific remains the central growth engine, fueled by massive investments in automation infrastructure in countries like China and India, while North America and Europe maintain dominance in high-reliability segments such as aerospace and advanced manufacturing test systems. Segment trends show that the two-stage valve segment holds the largest market share due to its optimal balance of flow capacity and dynamic response, though the single-stage segment is gaining traction in applications requiring ultra-high frequency response at lower flow rates, primarily in high-speed robotics and smaller industrial machine tools. Furthermore, the industrial application segment, encompassing machine tools and robotics, is projected to exhibit the fastest CAGR, reflecting the global transition towards Industry 4.0 principles and automated production lines.

AI Impact Analysis on Electro Hydraulic Servo Valve Market

Users frequently inquire about how Artificial Intelligence (AI) will enhance the precision, maintenance, and longevity of Electro Hydraulic Servo Valves. Common concerns revolve around AI's capability to compensate for internal wear, predict catastrophic failures, and optimize system performance beyond traditional closed-loop control algorithms. The consensus expectation is that AI will transition EHSVs from reactive control components to proactive, self-optimizing system elements. AI models applied to servo valve data streams—including pressure, flow rate, temperature, and electrical input signals—enable sophisticated condition monitoring, allowing operators to move from time-based maintenance schedules to highly efficient, predictive maintenance protocols. This capability significantly reduces unscheduled downtime and maximizes the operational lifespan of expensive hydraulic systems. Furthermore, AI-driven control algorithms can dynamically fine-tune valve parameters in real-time, compensating for fluid viscosity changes or minor spool wear, thereby maintaining peak performance and extremely tight tolerances throughout the valve’s lifecycle, particularly crucial in aerospace simulation and high-precision manufacturing.

- AI facilitates real-time predictive maintenance by analyzing operational data, anticipating wear, and scheduling proactive interventions for EHSVs.

- AI enhances control loop optimization, enabling dynamic adjustment of PID (Proportional-Integral-Derivative) parameters to maintain ultra-high precision under varying load conditions.

- Fault detection capabilities are significantly improved, allowing AI to identify subtle anomalies indicative of impending valve failure before major system disruption occurs.

- Digital Twin integration, powered by AI, simulates EHSV performance across various scenarios, aiding system design, testing, and training without physical wear.

- Energy consumption optimization through AI-driven flow modulation reduces hydraulic system inefficiencies, leading to lower operating costs.

DRO & Impact Forces Of Electro Hydraulic Servo Valve Market

The dynamics of the Electro Hydraulic Servo Valve (EHSV) market are governed by a complex interplay of strong technological drivers and persistent industry restraints, alongside significant long-term opportunities. The primary driver is the pervasive trend toward industrial automation and the necessity for highly precise motion control systems in industries ranging from medical equipment to advanced manufacturing and aviation. Simultaneously, the market is constrained by the relatively high initial cost of EHSVs compared to simpler proportional valves, coupled with the need for specialized technical expertise for installation, calibration, and troubleshooting complex hydraulic circuits. Opportunities arise from the ongoing development of digital servo valves, which offer enhanced communication protocols and diagnostics, making them more adaptable to Industry 4.0 environments, and the increasing investment in renewable energy sectors, where precise hydraulic pitch control systems are essential for wind turbines. These forces together define the market's moderate growth trajectory, pushing manufacturers towards developing cost-effective, smart, and highly reliable products that can justify the premium price point through superior long-term performance and efficiency.

Segmentation Analysis

The Electro Hydraulic Servo Valve (EHSV) market is comprehensively segmented based on Type, Application, and End-Use, reflecting the diverse requirements across various industries utilizing advanced fluid power control. The Type segmentation divides the market based on the hydraulic stage design—Single Stage, Two Stage, and Three Stage—each offering a distinct trade-off between dynamic response, flow capacity, and complexity. Application segmentation focuses on the sectors where EHSVs are deployed, highlighting major end-user verticals such as Aerospace & Defense, demanding maximum reliability, and Industrial applications, requiring high cycling rates and precision. End-Use analysis details the specific equipment utilizing these valves, including sophisticated Test Rigs and large-scale Heavy Machinery, providing granular insights into demand patterns and growth potential across specific product categories.

- Type:

- Single Stage EHSVs

- Two Stage EHSVs

- Three Stage EHSVs

- Application:

- Aerospace & Defense

- Industrial

- Oil & Gas

- Medical Equipment

- Marine

- Power Generation (e.g., wind turbine pitch control)

- End-Use:

- Heavy Machinery

- Machine Tools

- Robotics

- Test Rigs and Simulators

- Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Electro Hydraulic Servo Valve Market

The value chain for the Electro Hydraulic Servo Valve market begins with upstream activities centered around the procurement and precision manufacturing of highly specialized materials. Key upstream components include high-grade stainless steel and aluminum alloys for the valve body, sophisticated solenoid coils, and extremely precise spool and sleeve assemblies, often manufactured using nano-level precision grinding and lapping techniques to minimize internal leakage and maximize control fidelity. Suppliers of microelectronics and sensor technology (LVDTs, pressure sensors) form another critical segment, providing the necessary feedback mechanisms that define the 'servo' capability. The cost structure at the upstream level is heavily influenced by quality control and the rarity of the specialized machining expertise required, creating high barriers to entry for new suppliers.

Midstream activities involve the core manufacturing and assembly of the EHSV units, including rigorous testing and calibration to meet specific performance parameters, often tailored to specific OEM requirements in aerospace or heavy industry. This stage requires significant capital investment in cleanroom facilities and advanced testing rigs capable of simulating high-pressure, high-frequency operational environments. Distribution channels are varied but rely heavily on specialized direct sales teams for large-scale OEMs and a network of highly technical, authorized fluid power distributors capable of offering system integration and post-sale technical support. Due to the high-reliability nature of the product, direct engagement with major end-users (e.g., aircraft manufacturers, naval defense contractors) is often preferred to ensure precise application matching and compliance with strict standards.

Downstream analysis focuses on installation, integration, and aftermarket services. EHSVs are typically integrated into complex hydraulic manifolds and systems, requiring specialized engineering consultants or the OEM's in-house team. Aftermarket demand is driven by the necessity for periodic refurbishment, repair, and replacement, given the valve's exposure to high wear conditions. Indirect channels, such as third-party maintenance providers specializing in hydraulic repair, also play a role, particularly in industrial sectors where quick turnaround times are essential. Optimization of the value chain is increasingly focused on digitizing the distribution network and leveraging smart logistics to manage the high value and critical nature of the inventory.

Electro Hydraulic Servo Valve Market Potential Customers

Potential customers for Electro Hydraulic Servo Valves span several high-value industries where performance and reliability cannot be compromised, making EHSVs a necessary investment rather than a cost-saving component choice. Primary end-users include major aerospace primes and subcontractors who utilize these valves extensively in flight control actuation systems, landing gear synchronization, and missile steering mechanisms, where failure is not an option. These customers prioritize adherence to strict regulatory standards (e.g., FAA, EASA) and demonstrable Mean Time Between Failure (MTBF) statistics.

In the industrial sector, the core clientele comprises large-scale Original Equipment Manufacturers (OEMs) of plastic injection molding machines, die-casting machinery, and sophisticated machine tools (CNC), which require micron-level positional accuracy and repeatable force control for high-quality production outputs. Furthermore, the energy sector, particularly companies involved in high-end power generation and wind farm operators, are significant buyers, utilizing EHSVs for precise blade pitch and yaw control necessary to maximize energy capture and minimize structural stress. These customers demand long service life and robust resistance to environmental factors.

A rapidly expanding segment of buyers includes developers and operators of advanced testing and simulation equipment, especially those serving automotive, defense, and material testing laboratories. These test rigs rely entirely on the high-fidelity, high-bandwidth response of EHSVs to accurately replicate dynamic operating conditions, such as simulating road impacts or extreme fatigue cycles on structural components. These highly technical buyers require tailored solutions and often engage manufacturers in custom design projects to meet specific testing profiles and complex simulation requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.95 Billion |

| Market Forecast in 2033 | $2.72 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Moog Inc., Parker Hannifin, Bosch Rexroth, Eaton Corporation, Atos S.p.A., Star Hydraulics, Schneider Electric, Yokogawa Electric, Kawasaki Heavy Industries, ASCO Valve, Schenck Corporation, Nachi-Fujikoshi, Doosan Mottrol, HAWE Hydraulik, Casappa S.p.A., HUSCO International, Oilgear Company, Continental Hydraulics, Vickers (Eaton), Honeywell International |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electro Hydraulic Servo Valve Market Key Technology Landscape

The technological landscape of the Electro Hydraulic Servo Valve (EHSV) market is rapidly evolving, moving beyond traditional analog operation to incorporate advanced digital control and sensing capabilities. A crucial technological shift is the transition toward digital servo valves (DSVs). Unlike their analog counterparts, DSVs integrate microprocessors directly into the valve body, enabling advanced diagnostics, fieldbus communication (e.g., EtherCAT, PROFINET), and sophisticated self-calibration routines. This integration significantly improves data acquisition regarding valve status, temperature, and wear, directly supporting Industry 4.0 and predictive maintenance strategies. Furthermore, digital control minimizes the effects of electrical noise and signal degradation, which are common issues in long cable runs associated with large industrial installations, enhancing overall system reliability and control fidelity.

Another significant area of innovation involves miniaturization and materials science. Manufacturers are leveraging advanced ceramics and high-performance engineered plastics for critical internal components to improve contamination tolerance and reduce weight, particularly vital for mobile hydraulics and aerospace applications. The development of direct-drive servo valves (DDSVs) is also a key technological trend. DDSVs eliminate the hydraulic pilot stage entirely, using highly specialized voice coils or torque motors to actuate the main spool directly. This configuration dramatically improves dynamic response speed and resolution by eliminating the inherent phase lag of the pilot stage, albeit usually at the expense of maximum flow capacity. DDSVs are increasingly favored in specialized test rigs and robotics requiring extreme acceleration and frequency response.

Furthermore, the incorporation of advanced sensing technology, such as Linear Variable Differential Transformers (LVDTs) with higher resolution and integrated force sensors, provides superior feedback to the electronic controller. This enhanced feedback allows for tighter closed-loop control and minimizes hysteresis and non-linearity errors. The standardization of mounting interfaces and software protocols also contributes to market growth by simplifying the integration of EHSVs into complex hydraulic systems from various manufacturers. The continued focus is on developing valves that can maintain high performance under extreme environmental conditions, characterized by high temperatures, extreme vibrations, and aggressive contaminants, demanding continual refinement in sealing technologies and internal component resilience.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to massive governmental and private investments in manufacturing automation, infrastructure, and defense modernization, particularly in emerging economies like China, India, South Korea, and Southeast Asia. The region’s burgeoning automotive, heavy machinery, and construction sectors are fueling robust demand for high-precision motion control components.

- North America: North America holds a substantial market share, driven primarily by the high-value aerospace & defense sector, which mandates EHSVs for mission-critical flight control systems, and a strong presence of sophisticated test and simulation rig manufacturers. The region places a premium on high-performance, quality-certified components, supporting steady market maturity.

- Europe: Europe represents a mature but highly innovative market, characterized by stringent industrial standards (e.g., in Germany's machine tool industry) and significant investments in renewable energy, specifically offshore wind farms. The European market focuses heavily on energy efficiency and the integration of digital, smart hydraulic components aligned with European Industry 4.0 standards.

- Latin America (LATAM): Growth in LATAM is moderately accelerating, tied to the stabilization and expansion of mining, oil & gas exploration, and agricultural machinery industries, all of which utilize heavy hydraulic equipment requiring precise control. Market growth is sensitive to commodity price fluctuations.

- Middle East and Africa (MEA): The MEA region's market demand is closely linked to large-scale infrastructure projects and continued investments in the oil and gas extraction sector, where EHSVs are critical for drilling equipment and pipeline control. Defense expenditure also remains a significant, though volatile, driver.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electro Hydraulic Servo Valve Market.- Moog Inc.

- Parker Hannifin

- Bosch Rexroth

- Eaton Corporation

- Atos S.p.A.

- Star Hydraulics

- Schneider Electric

- Yokogawa Electric

- Kawasaki Heavy Industries

- ASCO Valve

- Schenck Corporation

- Nachi-Fujikoshi

- Doosan Mottrol

- HAWE Hydraulik

- Casappa S.p.A.

- HUSCO International

- Oilgear Company

- Continental Hydraulics

- Vickers (Eaton)

- Honeywell International

Frequently Asked Questions

Analyze common user questions about the Electro Hydraulic Servo Valve market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a servo valve and a proportional valve?

Servo valves offer significantly higher bandwidth, precision, and dynamic response capabilities compared to proportional valves. EHSVs utilize closed-loop feedback (e.g., LVDTs) to continuously adjust spool position, ensuring high accuracy and repeatability, while proportional valves are typically open-loop or use less precise feedback mechanisms.

Which industry accounts for the highest demand for Electro Hydraulic Servo Valves?

The Industrial sector, encompassing machine tools, plastic molding, and heavy machinery, generally accounts for the largest volume demand. However, the Aerospace and Defense sector drives the highest requirement for specialized, high-reliability, and custom-engineered EHSVs due to stringent safety and performance standards.

How does fluid contamination affect EHSV performance and lifespan?

EHSVs are highly sensitive to fluid contamination due to the extremely tight clearances (often measured in microns) between the spool and sleeve. Contaminants can cause stiction, internal leakage, excessive wear, and ultimately catastrophic failure, necessitating rigorous fluid filtration and maintenance protocols for prolonged lifespan.

What major technological advancement is currently shaping the servo valve market?

The transition from analog to digital servo valves (DSVs) is the major technological shift. DSVs integrate microprocessors for diagnostics, fieldbus communication, and enhanced self-optimization capabilities, making them integral components within advanced Industry 4.0 automation architectures.

Why are two-stage servo valves the most commonly adopted type?

Two-stage EHSVs strike an optimal balance between high flow capacity and excellent dynamic response. They use a small pilot stage to hydraulically position a larger main spool, allowing them to control large flow rates with speed and precision, suitable for most high-performance industrial and mobile applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager