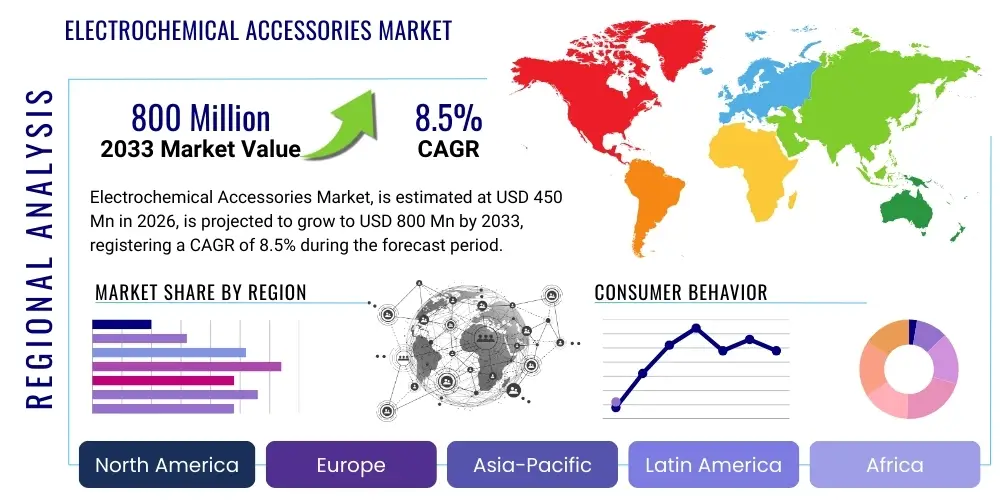

Electrochemical Accessories Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437841 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Electrochemical Accessories Market Size

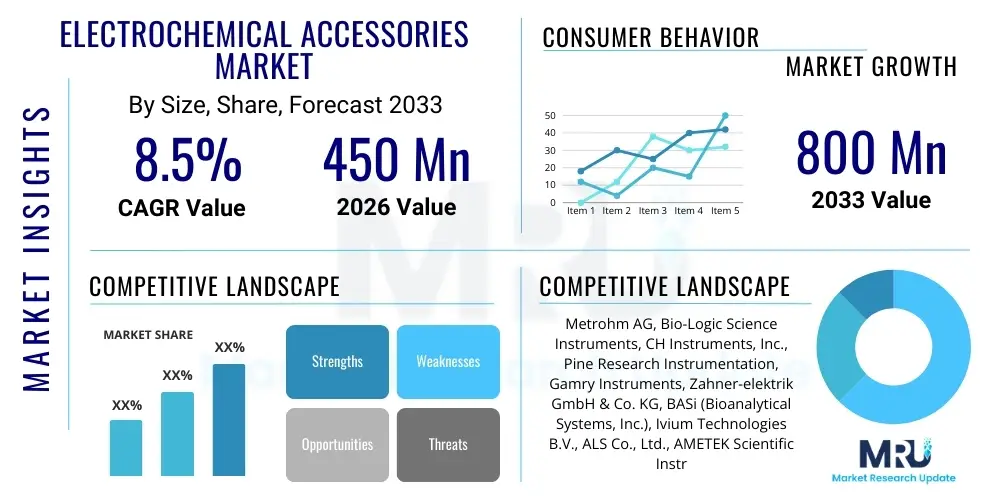

The Electrochemical Accessories Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 million in 2026 and is projected to reach USD 800 million by the end of the forecast period in 2033.

Electrochemical Accessories Market introduction

The Electrochemical Accessories Market encompasses a broad range of consumable and durable components critical for performing electrochemical measurements and experiments. These accessories are essential complements to potentiostats, galvanostats, and frequency response analyzers (FRA), providing the necessary physical interface for interaction between the electronic instrumentation and the chemical system under investigation. Key products include various types of electrodes (working, reference, and counter), electrochemical cells, specialized fixtures, polishing kits, and connection cables, all designed to ensure accurate, reproducible, and contamination-free electrochemical data acquisition across diverse fields such as energy storage, corrosion science, biomedical analysis, and fundamental material research.

These accessories facilitate highly sensitive and specific measurements, enabling researchers and industrial professionals to analyze reaction mechanisms, determine kinetic parameters, and characterize material properties. For instance, in the energy sector, specialized flow cells and gas diffusion electrodes are vital for testing fuel cells and batteries, while in pharmaceutical research, microelectrodes allow for real-time monitoring of biological processes. The demand for higher precision, smaller sample volumes, and integration with high-throughput screening methods continues to drive innovation in the accessory design, focusing on robustness, chemical resistance, and ease of use in complex environments.

Major applications of electrochemical accessories span academic research laboratories, industrial quality control, and advanced material development centers. The primary benefits include enhanced measurement accuracy, versatility across different electrochemical techniques (voltammetry, impedance spectroscopy, chronoamperometry), and the ability to operate under extreme conditions (high temperature, pressure, or corrosive media). The driving factors underpinning market expansion are the escalating global focus on sustainable energy solutions, particularly advanced battery technologies, the rapid growth in personalized medicine requiring sophisticated biosensors, and increased funding for fundamental electrochemistry research worldwide, necessitating continuous upgrades and replacements of specialized accessories.

Electrochemical Accessories Market Executive Summary

The Electrochemical Accessories Market is undergoing robust expansion, fundamentally driven by technological convergence in energy storage and biosensing applications. Business trends indicate a shift toward highly customized and integrated accessories, moving beyond standard laboratory setups to industrial-scale testing solutions and miniaturized components for portable analytical devices. Key stakeholders are focusing on materials science innovations to develop electrodes with superior conductivity and selectivity, notably leveraging carbon-based nanomaterials and specialized metal alloys. Furthermore, digitalization is influencing the market through smart accessories that incorporate integrated sensors for environmental monitoring and calibration, enhancing data traceability and experimental reliability, thus commanding a premium price point within the specialized research community.

Regionally, the market exhibits strong growth momentum in the Asia Pacific (APAC) region, primarily fueled by massive government and private sector investments in electric vehicle (EV) battery manufacturing and advanced semiconductor research in countries like China, South Korea, and Japan. North America and Europe maintain dominance in terms of technology adoption and high-value research applications, particularly in pharmaceuticals and advanced materials, characterized by a mature customer base demanding certified, high-quality, and niche accessories. Latin America and the Middle East & Africa (MEA) are emerging as growth pockets, spurred by increasing investment in renewable energy infrastructure and water quality monitoring programs, necessitating basic yet robust electrochemical sensors and cell setups.

Segment trends reveal that the electrodes segment, specifically working and reference electrodes, continues to hold the largest market share due to their high replacement frequency and foundational role in any electrochemical experiment. Within end-user segments, the energy sector (batteries and fuel cells) is projected to register the highest Compound Annual Growth Rate (CAGR), reflecting the urgent global requirement for efficient energy storage solutions, which heavily rely on rigorous electrochemical testing accessories. Academic and research institutions remain crucial foundational customers, driving demand for novel and cutting-edge electrode materials and standardized testing cells for educational purposes, ensuring a steady stream of demand irrespective of industrial cycles.

AI Impact Analysis on Electrochemical Accessories Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) algorithms are influencing the design, optimization, and utilization of electrochemical accessories. Common concerns center on whether AI can predict the optimal choice of electrode material or cell geometry for a specific reaction, thereby reducing experimental trial-and-error and the associated consumption of accessories. Users are also keen to understand the role of AI in analyzing the massive datasets generated by high-throughput electrochemical screening systems, which rely on automated accessory handling and testing. The key themes revolve around automation, predictive maintenance, material discovery, and enhanced data interpretation, ultimately seeking greater efficiency and higher fidelity in electrochemical research through AI integration.

AI's primary influence is enabling the transition from manual, hypothesis-driven accessory selection to data-driven decision-making. ML models, trained on vast repositories of electrochemical data, can correlate specific material properties (e.g., surface area, crystal structure, electrocatalytic activity) of an accessory with desired performance outcomes, accelerating the discovery of superior electrode compositions, especially for catalytic applications. This predictive capability directly impacts the manufacturing of accessories by providing manufacturers with insights into the most needed specifications, potentially leading to on-demand, customized electrode fabrication using additive manufacturing techniques guided by AI optimization.

Furthermore, AI algorithms are integral to managing and calibrating complex electrochemical setups, which frequently utilize multiple specialized accessories simultaneously. AI can monitor the real-time performance and degradation of electrodes, predicting when an accessory requires cleaning, re-calibration, or replacement. This predictive maintenance capability significantly extends the lifespan of high-value accessories, reduces experimental downtime, and ensures the reliability of long-term electrochemical studies, fundamentally transforming how laboratories manage their inventory and operational efficiency related to electrochemical testing components.

- AI-driven optimization of electrode manufacturing parameters (e.g., pore size, catalyst loading).

- Predictive modeling for selecting optimal electrochemical cell geometry for specific reaction kinetics.

- Machine Learning algorithms enhance automated data processing from high-throughput screening using multi-channel accessories.

- Integration of AI for real-time monitoring of electrode fouling and degradation, enabling predictive accessory maintenance.

- Accelerated discovery of novel electrocatalytic materials used in working electrodes via large-scale database analysis.

- Smart laboratory management systems utilizing AI to track accessory inventory and usage patterns.

DRO & Impact Forces Of Electrochemical Accessories Market

The Electrochemical Accessories Market is propelled by increasing research and development (R&D) activities in battery technology and electrocatalysis, requiring specialized testing components for validation and characterization. Restraints include the high initial investment required for advanced instrumentation (which dictates the accessory ecosystem) and the stringent requirements for accessory reproducibility and material purity, which often result in high manufacturing costs. Opportunities are abundant in the development of flexible, wearable, and disposable electrochemical sensors (biosensors) for healthcare and environmental monitoring. The impact forces acting on this market include technological advancements in miniaturization and the pervasive global policy push toward sustainable energy, creating a structural demand for superior and durable electrochemical testing components.

Key drivers include the global energy transition, specifically the proliferation of Electric Vehicles (EVs) and grid-scale energy storage, which mandates extensive electrochemical testing of battery components such as anodes, cathodes, and electrolytes, driving demand for high-pressure, high-temperature, and specialized battery testing cells and electrodes. Simultaneously, the accelerating growth of the Internet of Things (IoT) and connected healthcare necessitates the development of highly sensitive, low-cost electrochemical biosensors for point-of-care diagnostics, generating a large volume demand for disposable, functionalized electrode strips and associated accessories. The continual discovery of new functional materials in catalysis and sensing further pushes the boundaries of accessory requirements, demanding components capable of handling novel, aggressive chemical environments.

Conversely, significant market restraints include the lack of universal standardization across various electrochemical techniques, which fragments the market and necessitates the production of highly specific, non-interchangeable accessories tailored to particular instrument brands or applications. Furthermore, the specialized nature of these accessories often requires expert handling and calibration, presenting a steep learning curve for new end-users, especially in developing regions. High material costs, particularly for noble metal electrodes (platinum, gold) and chemically inert materials required for reference electrodes, impact overall pricing, limiting accessibility for resource-constrained academic laboratories. Opportunities center on developing cost-effective, easily replaceable reference electrodes that overcome current stability limitations and expanding the use of 3D printing technologies to customize cell designs rapidly and economically, addressing specific R&D needs and streamlining the supply chain.

Segmentation Analysis

The Electrochemical Accessories Market is extensively segmented based on the product type, primary application, and the end-user industry, reflecting the diverse requirements across research, industry, and healthcare sectors. The segmentation provides a clear framework for understanding market dynamics, distinguishing between high-frequency consumable items like electrodes and specialized durable components like reaction cells and high-pressure fixtures. Product complexity and standardization levels vary significantly across these segments, impacting pricing and procurement strategies for both manufacturers and end-users. Accurate segmentation analysis is essential for identifying high-growth niches, particularly those linked to advanced material science and automated testing protocols, which are currently experiencing rapid demand growth globally.

- By Product Type:

- Electrodes (Working Electrodes, Reference Electrodes, Counter Electrodes)

- Electrochemical Cells and Cell Kits

- Connectors and Cables

- Electrode Surface Preparation Accessories (Polishing Kits, Membranes)

- Auxiliary Equipment (Stirrers, Temperature Control Systems)

- By Application:

- Energy Storage and Conversion (Batteries, Fuel Cells, Supercapacitors)

- Corrosion Analysis

- Biosensing and Biomedical Analysis

- Fundamental Research and Material Characterization

- Environmental Monitoring and Water Analysis

- By End-User:

- Academic and Research Institutions

- Pharmaceutical and Biotechnology Companies

- Automotive and Energy Sector Industries

- Chemical and Petrochemical Industries

- Contract Research Organizations (CROs)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Electrochemical Accessories Market

The value chain for the Electrochemical Accessories Market begins with the highly specialized sourcing of raw materials, including high-purity noble metals (Pt, Au), specialized carbon materials (Graphene, CNTs), and chemically inert ceramics or polymers used for cell construction. Upstream activities are dominated by specialized material suppliers who ensure the stringent quality and purity standards essential for reliable electrochemical performance. Given the high precision required, material synthesis and preparation, particularly for catalyst-coated electrodes, represent a significant value addition stage. Suppliers who can guarantee lot-to-lot consistency and provide detailed material specifications hold a competitive advantage in securing contracts with primary accessory manufacturers.

The core manufacturing stage involves precision engineering, micro-fabrication, and meticulous assembly of electrodes and cells. This stage is complex, requiring highly skilled labor and often patented fabrication techniques, particularly for microelectrodes and integrated sensor arrays. Accessory manufacturers, such as specialized analytical instrument companies, invest heavily in R&D to optimize surface treatments and connection interfaces to minimize electrical noise and maximize durability. The downstream flow involves rigorous quality control, calibration, and packaging, ensuring that the accessories meet instrument compatibility standards and can withstand the varied chemical and physical stresses of laboratory or industrial use.

Distribution channels are categorized into direct and indirect methods. Direct distribution is common for large industrial customers and high-value research instruments, where manufacturers provide installation, training, and specialized technical support directly to the end-user. Indirect distribution primarily utilizes specialized scientific distributors and regional sales representatives, who manage inventory, logistics, and localized customer service, particularly for common, high-volume consumables like standard reference electrodes and disposable test strips. E-commerce platforms are increasingly utilized for smaller, standardized components, offering rapid delivery and transparency, though technical support often remains crucial due to the highly technical nature of the products.

Electrochemical Accessories Market Potential Customers

The primary consumers and end-users of electrochemical accessories are diverse, ranging from highly controlled academic research environments to demanding industrial production lines. In academia, researchers utilizing advanced electrochemical techniques such as cyclic voltammetry and impedance spectroscopy are consistent buyers, driving demand for novel, specialized electrodes and custom cell setups tailored for fundamental physics and chemistry studies. University laboratories frequently replace working and reference electrodes due to continuous experimentation and inherent material degradation, ensuring steady replenishment cycles across the globe and acting as key early adopters of new accessory technologies that promise higher sensitivity or greater throughput.

In the industrial sector, the automotive and energy storage industries represent the most significant growth area. Companies involved in manufacturing Lithium-ion, Solid-State, and Flow batteries are major purchasers of specialized accessories, including battery testing cells, high-temperature fixtures, and corrosion analysis probes necessary for quality control and R&D into enhanced battery lifespan and safety. These industrial customers demand highly durable, standardized accessories capable of operating reliably in high-volume, automated testing environments, where failure or inconsistency in the accessory can lead to substantial financial loss or delays in product development, emphasizing reliability over cost optimization.

Furthermore, the pharmaceutical and biotechnology sectors are critical end-users, driven by the need for rapid, accurate diagnostics and drug development screening. Potential customers include companies developing electrochemical biosensors for glucose monitoring, pathogen detection, and drug interaction studies, relying heavily on functionalized disposable electrode strips, microfluidic cells, and highly stable reference electrodes designed for biological compatibility. Contract research organizations (CROs) also form a substantial customer base, offering specialized testing services that require a wide array of standardized and application-specific electrochemical accessories to service their diverse clientele efficiently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 million |

| Market Forecast in 2033 | USD 800 million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Metrohm AG, Bio-Logic Science Instruments, CH Instruments, Inc., Pine Research Instrumentation, Gamry Instruments, Zahner-elektrik GmbH & Co. KG, BASi (Bioanalytical Systems, Inc.), Ivium Technologies B.V., ALS Co., Ltd., AMETEK Scientific Instruments, RotaLab, DropSens S.L., Origalys SAS, Microquimica Eletroquimica Ltda., Autolab, eDAQ Pty Ltd, Ecometrica, PGP Instruments, Spectro Inlets ApS, Elchema |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrochemical Accessories Market Key Technology Landscape

The technology landscape of the Electrochemical Accessories Market is defined by continuous advancements aimed at improving measurement sensitivity, reducing noise, and extending operational lifespan, often borrowing principles from microelectronics and advanced materials science. A pivotal technological shift involves the transition toward highly miniaturized electrode systems, particularly screen-printed electrodes (SPEs) and microelectrode arrays (MEAs). SPEs allow for mass production of low-cost, disposable sensors suitable for clinical diagnostics and field testing, leveraging printing technologies to deposit conductive inks and functional materials onto polymer substrates. MEAs enhance signal-to-noise ratios and enable high spatial resolution measurements, crucial for neuroscience research and complex material characterization studies, demanding highly precise lithography and fabrication techniques.

Another dominant technological trend involves the materials used for working and reference electrodes. There is significant R&D focus on replacing traditional, costly noble metal electrodes with advanced carbon-based materials, such as carbon nanotubes (CNTs), graphene, and boron-doped diamond (BDD) electrodes. BDD electrodes offer superior chemical inertness and a wide potential window, making them ideal for aggressive environments, while nanomaterials like graphene enhance electrocatalytic activity and surface area. Furthermore, in the realm of reference electrodes, manufacturers are actively developing solid-state reference electrode technologies that eliminate the need for liquid electrolytes, addressing issues related to leakage, contamination, and instability associated with traditional Ag/AgCl or calomel electrodes, thereby enhancing portability and long-term stability in commercial products.

Finally, the integration of electrochemical accessories with advanced temperature and pressure control systems, often managed through digital interfaces, constitutes a major technological improvement, particularly for industrial applications like high-performance battery testing. Specialized flow cells and reactors incorporate sophisticated microfluidic components to precisely control reactant delivery and reaction conditions, allowing for accurate kinetic studies under real-world operating conditions. The drive towards modularity and plug-and-play compatibility across different instrument platforms is also simplifying user experience. This technological ecosystem is highly reliant on sophisticated CAD/CAM tools for design and high-precision manufacturing processes to ensure the consistency and reliability of these complex analytical components, maintaining the market's high barrier to entry for new competitors who lack specialized fabrication capabilities.

Regional Highlights

- North America: This region holds a significant market share, driven by strong government and private funding in advanced materials science, defense research, and biomedical technology. The U.S. remains the hub for cutting-edge electrochemical research, with high demand for premium, specialized accessories used in pharmaceutical drug discovery, corrosion prevention for critical infrastructure, and advanced space battery development. Strict regulatory environments necessitate highly calibrated and certified accessories, favoring established players with comprehensive technical support networks.

- Europe: Europe is characterized by robust R&D spending, particularly in Germany and the UK, focused on sustainable energy, hydrogen technologies, and automotive electrification. European manufacturers lead in high-precision, robust accessories for industrial testing, emphasizing quality and environmental compliance. The strong presence of leading academic institutions and electrochemical instrument manufacturers ensures a continuous demand cycle for both replacement and novel accessory types, particularly those compatible with high-throughput automation.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, largely due to unprecedented investment in battery manufacturing capacity (China, South Korea) and massive expansion of electronics and semiconductor industries. The region exhibits high demand for both bulk, cost-effective accessories for quality control in manufacturing and highly advanced components for pioneering research in quantum dots and advanced catalysis, driven by rapidly increasing government scientific output and rising disposable income supporting sophisticated healthcare infrastructure.

- Latin America (LATAM): The market in LATAM is emerging, primarily focused on environmental monitoring (water quality, mining waste analysis) and resource exploration (oil and gas corrosion). Demand is centered on fundamental, durable accessories that offer reliability under varied field conditions. While currently smaller in size, increased investments in renewable energy infrastructure, particularly in Brazil and Chile, suggest future growth opportunities for standard testing cells and electrodes.

- Middle East and Africa (MEA): Growth in MEA is highly localized, driven primarily by investments in desalination technologies, oil and gas sector corrosion monitoring, and academic expansion in countries like Saudi Arabia and the UAE. Accessories required here are often specialized for extreme environmental conditions (high salinity, high temperature). The market relies heavily on imports and requires robust distribution channels capable of handling complex logistics and technical training.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrochemical Accessories Market.- Metrohm AG

- Bio-Logic Science Instruments

- CH Instruments, Inc.

- Pine Research Instrumentation

- Gamry Instruments

- Zahner-elektrik GmbH & Co. KG

- BASi (Bioanalytical Systems, Inc.)

- Ivium Technologies B.V.

- ALS Co., Ltd.

- AMETEK Scientific Instruments

- RotaLab

- DropSens S.L.

- Origalys SAS

- Microquimica Eletroquimica Ltda.

- Autolab

- eDAQ Pty Ltd

- Ecometrica

- PGP Instruments

- Spectro Inlets ApS

- Elchema

Frequently Asked Questions

Analyze common user questions about the Electrochemical Accessories market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Electrochemical Accessories Market?

The market growth is primarily propelled by massive global investment in advanced energy storage technologies (especially batteries for electric vehicles and grid storage) and the increasing development and commercialization of electrochemical biosensors for point-of-care diagnostics and environmental monitoring applications worldwide.

How is the shift toward miniaturization impacting the design of electrochemical accessories?

Miniaturization drives the adoption of screen-printed electrodes (SPEs) and microelectrode arrays (MEAs). This shift allows for the development of portable, low-cost, disposable sensors necessary for field testing and high-throughput screening, fundamentally changing manufacturing techniques from traditional machining to printing technologies.

Which end-user segment demonstrates the highest potential for market expansion?

The Automotive and Energy Sector is projected to show the highest growth rate due to the extensive need for rigorous testing and quality control of next- generation battery components (anodes, cathodes, electrolytes) required for the accelerating global transition to electrified transportation and renewable energy infrastructure.

What are the major challenges related to reference electrode stability in the market?

Reference electrode stability is challenged by liquid junction potentials, contamination risks, and the need for frequent replenishment of electrolytes. Manufacturers are addressing this by developing solid-state reference electrodes and specialized ion-selective membranes to improve long-term reliability and compatibility with portable devices.

What is the competitive landscape for specialized electrochemical cell manufacturing?

The landscape is moderately consolidated, with major instrument manufacturers often bundling their proprietary cell designs. Competition is fierce in niche areas, where smaller, specialized firms offer highly customized, high-pressure, or high-temperature cells and advanced flow cell designs utilizing precision engineering and proprietary sealing technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager