Electrolytic Marking Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433124 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Electrolytic Marking Machine Market Size

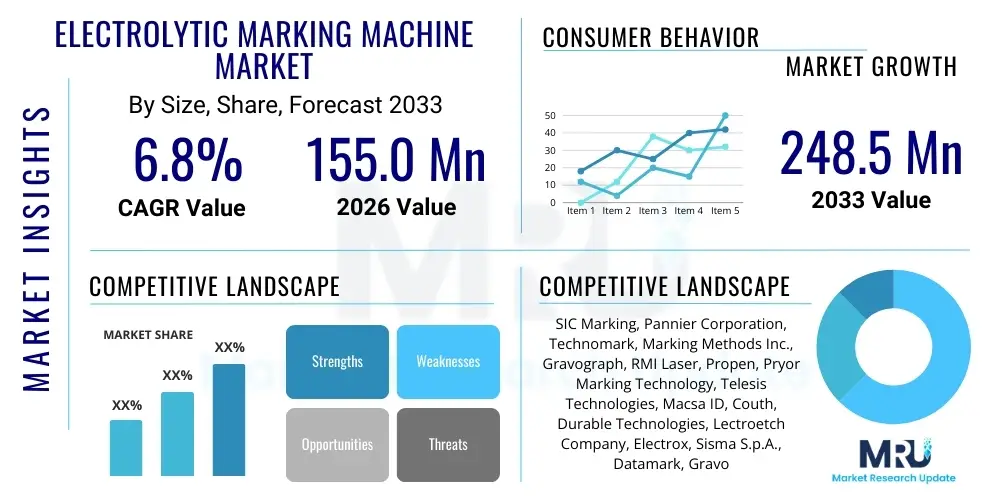

The Electrolytic Marking Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 155.0 Million in 2026 and is projected to reach USD 248.5 Million by the end of the forecast period in 2033.

Electrolytic Marking Machine Market introduction

The Electrolytic Marking Machine Market encompasses specialized equipment utilized for creating permanent, high-contrast, stress-free marks on conductive metal surfaces, ranging from steel and stainless steel to carbides and aluminum. These markings are crucial for traceability, branding, and quality control, offering a highly precise alternative to traditional methods like stamping or laser etching in certain applications. The core technology relies on an electrochemical process involving an electrolyte solution, a stencil, and a low-voltage electrical current, ensuring that the marking process is fast, quiet, and avoids material stress or deformation, which is particularly vital for precision components used in critical industries.

Major applications for electrolytic marking machines span across the automotive sector for component identification, the aerospace and defense industry for compliance and serialized parts, and the medical device manufacturing industry where non-damaging, sterile marking is mandatory for surgical tools and implants. Furthermore, the general manufacturing, tool and die, and oil and gas sectors heavily rely on this technology for durable identification in harsh environments. The versatility of the process allows for marking complex geometries and producing highly legible logos, serial numbers, date codes, and QR codes, fulfilling stringent industry standards such as MIL-STD-130N and GS1 regulations.

The primary benefits driving market adoption include the speed and cost-effectiveness of the marking process, coupled with the ability to mark surfaces without altering their metallurgical properties or inducing micro-cracking, which is a common concern with mechanical engraving or high-power laser etching. The increasing global focus on robust product traceability, driven by regulatory mandates in industries like medical and automotive safety, serves as a significant driving factor. Additionally, advancements in stencil technology and electrolyte formulation are enhancing the quality and permanence of marks, solidifying the electrolytic marking method as a critical tool in modern industrial identification strategies.

Electrolytic Marking Machine Market Executive Summary

The Electrolytic Marking Machine Market is characterized by steady growth, primarily fueled by stringent regulatory requirements for part traceability across key industrial verticals, notably in North America and Europe. Business trends indicate a strong demand for portable and semi-automatic systems, driven by the need for flexible marking solutions on large or installed equipment that cannot be easily brought to fixed marking stations. Manufacturers are focusing on developing advanced power supplies and non-toxic, eco-friendly electrolyte solutions to address increasing environmental scrutiny and operational safety concerns. Strategic partnerships with specialized stencil and electrolyte providers are becoming vital for competitive differentiation, particularly regarding high-volume, continuous operation environments.

Regional trends demonstrate Asia Pacific (APAC) emerging as the fastest-growing market, propelled by rapid industrialization, expansion of the regional automotive and electronics manufacturing bases, and increasing foreign direct investment in precision engineering. North America remains a dominant market, largely due to the robust presence of aerospace and medical device manufacturers who prioritize high-integrity, stress-free marking solutions. European growth is stable, underpinned by established automotive and heavy machinery sectors adhering to strict EU-mandated traceability protocols. The trend globally suggests a shift toward integrating these machines into existing production lines, necessitating highly durable, automated solutions capable of interfacing seamlessly with Manufacturing Execution Systems (MES).

Segmentation trends highlight the increasing prominence of portable electrolytic marking machines, valued for their flexibility in maintenance, repair, and overhaul (MRO) applications, particularly in infrastructure and energy sectors. By application, the Medical Devices segment exhibits high growth due to zero-tolerance policies for structural changes on surgical instruments and implants, mandating stress-free marking techniques. Furthermore, the market for fully automatic systems, often integrated with robotic handling and vision systems for quality verification, is expanding rapidly in high-throughput manufacturing environments, promising enhanced operational efficiency and reduced labor costs. This trajectory reinforces the market's movement toward automation and precision marking capabilities across diverse industrial requirements.

AI Impact Analysis on Electrolytic Marking Machine Market

Common user inquiries regarding AI’s influence on the Electrolytic Marking Machine Market center on how artificial intelligence can enhance marking quality control, automate error detection, and optimize machine maintenance scheduling. Users are keenly interested in the potential for AI-driven vision systems to ensure mark quality consistency, particularly concerning legibility, depth, and placement accuracy on complex component surfaces. Key concerns revolve around the integration cost of sophisticated AI algorithms with existing legacy marking equipment and the necessity of highly trained personnel to manage these smart systems. The consensus expectation is that AI will transform the pre-marking setup (stencil alignment, parameter optimization based on material) and the post-marking verification process, significantly reducing scrap rates and improving overall throughput efficiency, thereby transitioning electrolytic marking from a manual or semi-automated process into a highly data-driven manufacturing step.

- AI-Powered Vision Systems: Enhancing mark quality verification, pattern recognition, and defect detection in real-time, drastically reducing human error in complex inspection tasks.

- Predictive Maintenance: AI algorithms analyze machine performance data (current draw, cycle time, electrolyte usage) to forecast component failure, maximizing uptime and machine longevity.

- Parameter Optimization: Automated calibration of marking parameters (voltage, time, electrolyte concentration) based on material type and ambient conditions, ensuring optimal mark depth and contrast consistently.

- Automated Stencil Alignment: Using machine learning to refine stencil positioning on irregular surfaces, speeding up setup time for customized or geometrically challenging parts.

- Supply Chain Integration: AI-enhanced traceability systems linking marked parts directly to manufacturing data, inventory, and supply chain records for seamless compliance reporting.

DRO & Impact Forces Of Electrolytic Marking Machine Market

The growth trajectory of the Electrolytic Marking Machine Market is heavily influenced by stringent global regulatory mandates for product serialization and component traceability, serving as the primary driver. However, the market faces restraints due to competition from advanced laser marking technologies, which offer greater versatility in terms of material compatibility and high-speed marking capabilities, although they may introduce thermal stress. Significant opportunities exist in the development of specialized, environmentally friendly, and non-hazardous electrolyte solutions that address growing sustainability concerns and enhance worker safety. These factors collectively exert moderate to high impact forces on market expansion, with regulatory pressure dictating adoption rates in high-value sectors, while technological substitution requires continuous innovation in electrolytic processes to maintain competitiveness.

Key drivers include the imperative for stress-free marking in critical applications, particularly in the aerospace and medical industries where material integrity cannot be compromised. Electrolytic marking provides a cold process, ideal for thin-walled or hardened components where heat distortion is unacceptable. Furthermore, the relatively low capital investment compared to high-power laser systems makes electrolytic markers highly attractive for small to medium-sized enterprises (SMEs) and specialized workshops. The demand for permanent, corrosion-resistant marks that withstand harsh industrial environments, such as chemical exposure or extreme temperatures, further solidifies its market position, especially in the oil and gas and heavy machinery sectors, where durability is paramount for the lifespan of the identifying mark.

Restraints primarily revolve around the process limitations, including the necessity of using specialized stencils for each design iteration and the restriction to conductive materials, making it unsuitable for plastics or ceramics. Additionally, the handling and disposal of electrolyte solutions present operational challenges, often requiring specialized safety protocols and waste management, which can increase operational costs. Opportunities, conversely, lie in expanding the application scope through enhanced electrolyte and stencil durability, allowing for faster cycle times and better integration into fully automated, high-volume production lines. The penetration of portable solutions into the burgeoning MRO sector represents a crucial avenue for sustained market growth and revenue generation, especially where asset marking is required on-site or in remote locations without extensive infrastructure.

Segmentation Analysis

The Electrolytic Marking Machine Market is meticulously segmented based on Type, Application, and Operation, allowing for a detailed analysis of specific product functionalities and end-user requirements across various industries. The segmentation by Type primarily differentiates between standard, off-the-shelf models, customized solutions tailored for specific production environments, and highly flexible portable units. Application segmentation provides insights into the dominant industry users, such as Automotive and Medical Devices, which drive demand for compliance-driven marking. Finally, operational segmentation highlights the industry's shift toward increased automation, comparing Manual, Semi-Automatic, and Fully Automatic systems in terms of efficiency and integration complexity.

- By Type:

- Standard Machines

- Customized Machines

- Portable Machines

- By Application:

- Aerospace & Defense

- Automotive

- Medical Devices

- General Manufacturing (Tools & Dies, Machinery)

- Oil and Gas

- Electronics and Semiconductors

- By Operation:

- Manual

- Semi-Automatic

- Fully Automatic

Value Chain Analysis For Electrolytic Marking Machine Market

The value chain for the Electrolytic Marking Machine Market commences with the upstream supply of core raw materials, primarily electronic components for power supply units (rectifiers, transformers), high-grade metallic alloys for machine casings, and specialized chemicals required for manufacturing the electrolyte solutions and long-lasting stencils (often composed of polymer-coated films or high-precision metallic meshes). Efficiency at this stage is crucial, as the quality and non-toxicity of the electrolyte directly impact the final marking result and compliance with environmental regulations. Key upstream risks involve the fluctuating cost and availability of specialized electronic components necessary for precision current control, which defines the consistency of the electrochemical process.

The midstream stage involves the design, assembly, and integration of the core marking systems. Manufacturers focus heavily on R&D to enhance machine robustness, increase marking speed, and improve user interface simplicity. This stage includes sophisticated calibration and testing to ensure compliance with industry standards like ISO 9001. Direct distribution channels, where manufacturers sell directly to large end-users (e.g., major aerospace or automotive OEMs), are preferred for high-value customized systems, allowing for direct integration support and specialized training. Conversely, indirect distribution, utilizing a network of regional distributors, systems integrators, and value-added resellers (VARs), is common for standard and portable models, providing broader market reach and localized technical support for smaller manufacturers.

The downstream segment is defined by the end-user applications, requiring consistent supplies of consumable materials, including proprietary electrolytes and disposable or long-life stencils. Post-sales support, encompassing maintenance contracts, repairs, and the supply of specialized consumables, forms a significant portion of the downstream value. The demand for integration services, linking the marking machines to existing production management software (MES/ERP), is growing, increasing the importance of systems integrators in the value chain. Ultimately, the successful execution of the value chain is measured by the longevity and clarity of the mark, enabling end-users to meet mandatory traceability standards and maintain brand integrity on critical components throughout their lifecycle.

Electrolytic Marking Machine Market Potential Customers

The primary customers for Electrolytic Marking Machines are manufacturing entities operating in regulated and high-precision industries where component traceability and material integrity are non-negotiable requirements. These end-users are characterized by their need for permanent identification without causing micro-structural changes to the marked part. The medical device sector represents a major segment, where manufacturers of surgical instruments, orthopedic implants, and diagnostic equipment utilize electrolytic marking to meet FDA and MDR traceability requirements while ensuring the instruments remain sterile and structurally sound for patient safety. Similarly, aerospace and defense contractors are crucial buyers, using these systems for serialization and part authentication on engine components, airframe parts, and specialized tools, ensuring compliance with strict military and civil aviation specifications.

The automotive industry, particularly Tier 1 suppliers and specialized engine component manufacturers, constitutes another significant customer base, employing electrolytic marking for identifying powertrain components, safety critical parts (e.g., brake systems), and specialized tooling used in engine assembly. General manufacturing customers, including producers of high-value tools, dies, and gauges, rely on this technology to mark proprietary intellectual property and ensure quality control throughout their product lines. These buyers prioritize systems offering flexibility for small batch customization and durable marking capabilities that withstand abrasive operational conditions. Furthermore, companies involved in maintenance, repair, and overhaul (MRO) activities across energy, infrastructure, and mining sectors are increasingly adopting portable electrolytic markers for on-site asset management and certification.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.0 Million |

| Market Forecast in 2033 | USD 248.5 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SIC Marking, Pannier Corporation, Technomark, Marking Methods Inc., Gravograph, RMI Laser, Propen, Pryor Marking Technology, Telesis Technologies, Macsa ID, Couth, Durable Technologies, Lectroetch Company, Electrox, Sisma S.p.A., Datamark, Gravotech, Ostling Marking Systems, Technifor, Markforged (indirectly via process comparison) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrolytic Marking Machine Market Key Technology Landscape

The core technology underpinning the Electrolytic Marking Machine Market remains the electrochemical process, which requires precise control over voltage, time, and the chemical composition of the electrolyte solution. Recent technological advancements primarily focus on enhancing the consistency and quality of the electrical impulse generation. Modern power supplies utilize high-frequency switching technology and microprocessors to deliver highly regulated, low-voltage direct or alternating current pulses, crucial for achieving deep, dark marks (AC) or light, etching marks (DC) without causing electrical pitting or surface discoloration. This precise electrical control is essential for managing the heat generated during the process, ensuring the mark is truly stress-free, a key competitive advantage over thermal marking techniques.

Significant innovation is concentrated in the area of consumables, specifically high-durability stencils and specialized electrolyte formulations. Stencils have evolved from simple paper-based materials to advanced polymer films or electrochemical photo-stencils, capable of supporting extremely high resolution for complex logos or miniature data matrix codes, while also offering extended operational lifecycles for high-volume production runs. Electrolyte technology is moving towards bio-degradable and non-corrosive formulations, reducing environmental impact and operator exposure risks. These next-generation electrolytes are optimized for specific metals (e.g., titanium, tool steel, inconel), ensuring superior mark quality and minimizing post-marking neutralization requirements, streamlining the production process.

Furthermore, the integration of automation and digitalization technologies is reshaping the operational landscape. Modern electrolytic marking systems are increasingly equipped with PLC (Programmable Logic Controller) interfaces, enabling seamless integration into automated production lines and allowing remote control and monitoring. Vision systems, often leveraging AI capabilities, are becoming standard for automated mark registration, component orientation verification, and immediate quality inspection. This combination of robust electrochemical marking mechanisms with smart factory integration facilitates high-speed, verifiable identification, aligning the technology with Industry 4.0 standards and enhancing overall manufacturing efficiency and compliance reporting capabilities.

Regional Highlights

- North America: North America holds a substantial market share, driven primarily by the stringent regulatory environments in the aerospace, defense, and medical device manufacturing sectors. These industries prioritize stress-free and non-damaging marking solutions, making electrolytic technology highly favored. The United States, in particular, exhibits high adoption rates due to the presence of major OEMs and a mature infrastructure supporting high-precision manufacturing. Continuous investment in MRO activities across energy and military assets further sustains demand for high-quality, portable marking solutions.

- Europe: Europe is characterized by stable and consistent growth, anchored by its robust automotive, heavy machinery, and tool manufacturing industries, particularly in Germany, France, and Italy. European manufacturers strictly adhere to global traceability standards (e.g., REACH, RoHS, and sector-specific serialization mandates), fueling the demand for reliable and verifiable marking equipment. The region shows a strong trend toward automated and fully integrated electrolytic marking systems that comply with advanced safety and environmental standards regarding electrolyte disposal.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region during the forecast period. This rapid expansion is attributed to large-scale industrialization, massive growth in automotive production (China, India), and the increasing establishment of sophisticated electronics and medical device manufacturing hubs (South Korea, Japan). Economic policies favoring local manufacturing and increasing foreign direct investment into precision engineering facilities necessitate adoption of permanent marking solutions for quality assurance and export compliance, propelling demand for both standard and high-speed automated systems.

- Latin America (LATAM): The LATAM market, while smaller, exhibits potential growth, primarily concentrated in Brazil and Mexico, driven by localized automotive assembly and resource extraction industries (Oil & Gas, Mining). Demand is typically focused on cost-effective, durable marking solutions, often favoring standard and portable electrolytic machines for basic identification and asset tracking in challenging industrial environments.

- Middle East and Africa (MEA): Growth in MEA is largely concentrated in the GCC states, driven by significant investments in the energy sector (Oil & Gas) and infrastructure projects. Electrolytic marking is crucial here for maintaining traceability and integrity of pipelines, specialized tools, and machinery exposed to extreme climate conditions and corrosive elements, demanding highly robust and corrosion-resistant identification methods.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrolytic Marking Machine Market.- SIC Marking

- Pannier Corporation

- Technomark

- Marking Methods Inc.

- Gravograph

- RMI Laser

- Propen

- Pryor Marking Technology

- Telesis Technologies

- Macsa ID

- Couth

- Durable Technologies

- Lectroetch Company

- Electrox

- Sisma S.p.A.

- Datamark

- Gravotech

- Ostling Marking Systems

- Technifor

- HeatSign

Frequently Asked Questions

Analyze common user questions about the Electrolytic Marking Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of electrolytic marking over laser marking for precision components?

The primary benefit is that electrolytic marking is a cold, stress-free process. Unlike laser marking, it does not induce heat stress, material distortion, or micro-cracking, making it ideal for highly sensitive components like surgical implants, hardened tools, and aerospace parts where material integrity must be strictly maintained.

Which industries are the major drivers of demand for portable electrolytic marking machines?

The major drivers are the Maintenance, Repair, and Overhaul (MRO) sectors, particularly in the Oil & Gas, Aviation, and Infrastructure industries. Portable machines allow operators to mark large, installed assets or components directly on-site, fulfilling traceability requirements without disassembling the equipment.

Is the electrolytic marking process compatible with all types of metal surfaces?

Electrolytic marking is highly compatible with most conductive metals, including various grades of stainless steel, tool steel, carbon steel, nickel alloys (Inconel), chrome plating, and carbides. However, specialized electrolytes are often required to achieve optimal mark quality on materials like aluminum or titanium, and it is not suitable for non-conductive materials.

How do modern electrolytic systems comply with increasing environmental and safety regulations?

Compliance is achieved through the development and adoption of advanced, non-toxic, and bio-degradable electrolyte solutions, minimizing the need for hazardous chemical disposal. Manufacturers are also integrating closed-loop waste management systems and improving machine design to prevent operator exposure to chemical consumables.

What are the key technological advancements enhancing the speed and quality of electrolytic marking?

Key advancements include the use of high-precision electronic power supplies for regulated AC/DC pulses, which optimize mark depth and contrast; the development of highly durable, high-resolution stencils; and the integration of automated vision systems for precise component alignment and immediate, AI-enhanced quality verification.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager