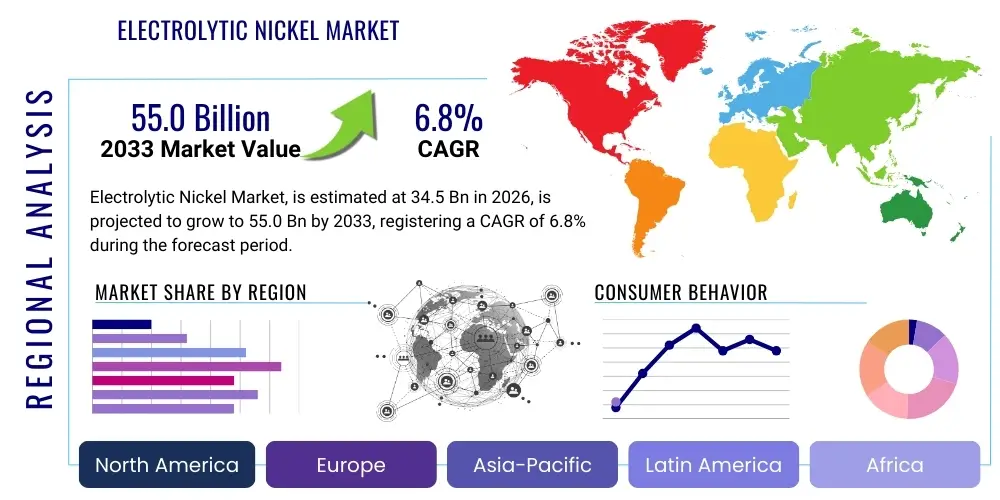

Electrolytic Nickel Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439408 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Electrolytic Nickel Market Size

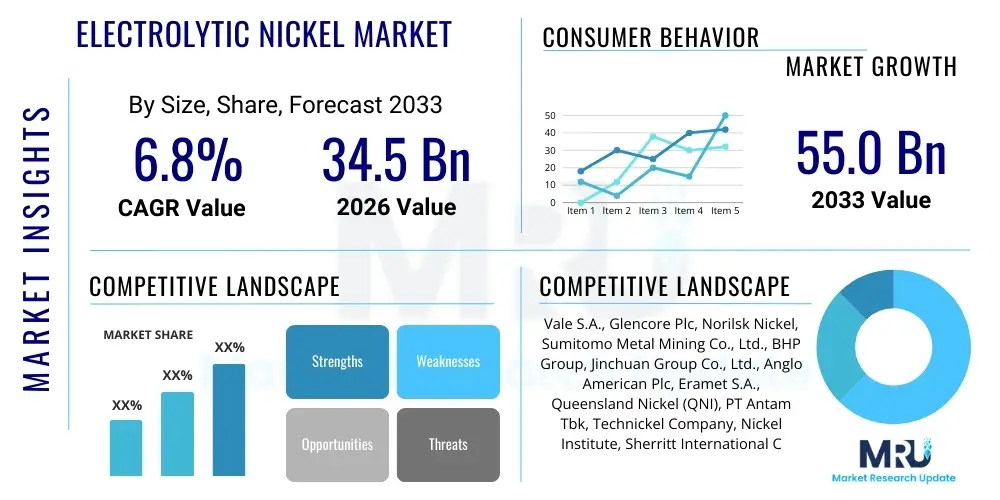

The Electrolytic Nickel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 34.5 Billion in 2026 and is projected to reach USD 55.0 Billion by the end of the forecast period in 2033.

Electrolytic Nickel Market introduction

The Electrolytic Nickel Market encompasses the production, distribution, and consumption of high-purity nickel obtained through electrolytic refining processes. This highly refined form of nickel, often referred to as cathodes, squares, pellets, or briquettes, is characterized by its exceptional purity, typically ranging from 99.8% to 99.99% or higher. Its superior quality makes it indispensable across a spectrum of advanced industrial applications where impurities can compromise performance and longevity. The product's inherent properties, such as excellent corrosion resistance, high electrical conductivity, and magnetic properties, are crucial for its diverse utility.

Major applications for electrolytic nickel span critical sectors including battery manufacturing, particularly for electric vehicle (EV) cathodes, where its high energy density and stability are paramount. It is also extensively used in electroplating for protective and decorative coatings on various metals, enhancing durability and aesthetic appeal. Furthermore, electrolytic nickel is a vital component in the production of specialty alloys, superalloys, and stainless steel, which are integral to industries like aerospace, defense, and chemical processing due to their enhanced strength and resistance to extreme environments. Its catalytic properties also find use in various chemical reactions.

The market benefits from several intrinsic advantages, including the product's consistent purity levels, which ensure reliability in sensitive applications, and the ability to produce nickel in various forms tailored to specific industrial needs. Key driving factors for market growth include the accelerating global demand for electric vehicles, which directly correlates with the need for high-performance nickel-rich batteries, and the expansion of renewable energy infrastructure. Additionally, continued industrialization in emerging economies, coupled with advancements in material science requiring high-purity metals, further fuels the market's trajectory.

Electrolytic Nickel Market Executive Summary

The Electrolytic Nickel Market is undergoing significant expansion, primarily fueled by the burgeoning demand from the electric vehicle (EV) battery sector and sustained growth in traditional industrial applications. Business trends indicate a strong focus on enhancing production capacities and improving energy efficiency in refining processes to meet the escalating global requirements. Manufacturers are investing in advanced electrolytic technologies to ensure higher purity levels and diverse product forms, catering to the stringent specifications of modern applications. Strategic collaborations and partnerships between nickel producers and battery manufacturers are becoming increasingly prevalent, aiming to secure stable supply chains and foster innovation in material development. Furthermore, sustainability and ethical sourcing practices are emerging as critical differentiators, influencing procurement decisions across various industries and driving producers to adopt more environmentally responsible operations.

Regionally, Asia Pacific continues to dominate the market, largely driven by its robust EV manufacturing base in countries like China, Japan, and South Korea, coupled with extensive industrial growth and infrastructure development. Europe and North America are also experiencing substantial growth, propelled by their respective automotive electrification targets, aerospace industry demands, and increasing adoption of advanced materials. Emerging economies in Latin America, the Middle East, and Africa are showing promising potential, with investments in mining and processing capabilities aiming to leverage abundant natural resources and cater to localized industrial expansion. Each region presents unique market dynamics influenced by regulatory frameworks, technological adoption rates, and economic policies, shaping the competitive landscape and investment opportunities.

Segmentation trends highlight the increasing importance of high-purity electrolytic nickel (99.95% and above) due to its critical role in advanced battery chemistries and specialized aerospace alloys. The battery manufacturing application segment is projected to exhibit the fastest growth, underscoring the profound impact of the EV revolution. In terms of form, nickel cathodes remain foundational, while specialized forms like squares and pellets gain traction for specific industrial processes. End-use industries such as automotive and electronics are poised for significant expansion, whereas sectors like construction and chemical processing maintain steady demand, contributing to a diversified yet increasingly technology-driven market landscape. The interplay of these trends defines the evolving structure and future direction of the global electrolytic nickel market, necessitating adaptive strategies from market participants.

AI Impact Analysis on Electrolytic Nickel Market

The integration of Artificial Intelligence (AI) across the Electrolytic Nickel Market is generating considerable interest, with users frequently inquiring about its potential to revolutionize efficiency, sustainability, and market predictability. Common questions revolve around how AI can optimize complex production processes, predict demand fluctuations, enhance material quality, and mitigate supply chain risks. Users are keen to understand the practical applications of AI in refining, from real-time process control to predictive maintenance of equipment, aiming for reduced operational costs and improved resource utilization. There's also a significant focus on AI's role in discovering new high-performance nickel alloys and accelerating R&D, as well as its capacity to analyze vast datasets for market trend forecasting and strategic decision-making. Overall, the expectation is that AI will introduce unprecedented levels of precision, automation, and intelligence, transforming various facets of the electrolytic nickel value chain.

- AI-driven predictive analytics optimize raw material sourcing and inventory management, minimizing waste and ensuring timely supply.

- Automated quality control systems using computer vision and machine learning enhance the consistency and purity of electrolytic nickel products, reducing human error.

- AI algorithms analyze energy consumption patterns in electrolytic refining cells, enabling real-time adjustments for significant energy savings and reduced environmental footprint.

- Predictive maintenance for production equipment, powered by AI, anticipates failures, extends asset lifespan, and reduces costly downtime.

- Machine learning models improve demand forecasting accuracy for electrolytic nickel, allowing producers to align production schedules more closely with market needs.

- AI facilitates the rapid exploration and design of new nickel-based alloys and battery chemistries by simulating material properties and performance.

- Enhanced supply chain visibility and resilience through AI-powered risk assessment and disruption prediction tools.

- Data analytics and AI contribute to better compliance monitoring for environmental regulations and ethical sourcing practices.

DRO & Impact Forces Of Electrolytic Nickel Market

The Electrolytic Nickel Market is shaped by a dynamic interplay of drivers, restraints, and opportunities, all influenced by a range of internal and external impact forces. A primary driver is the surging global demand for electric vehicles, which heavily relies on nickel-rich battery chemistries for high energy density and range, pushing the need for high-purity electrolytic nickel. Concurrently, the robust growth in stainless steel production, especially in emerging economies, and the continuous demand from the aerospace and defense sectors for high-performance alloys further underpin market expansion. These factors are compounded by ongoing industrialization and urbanization trends, creating a sustained requirement for durable and corrosion-resistant materials across various infrastructure and manufacturing applications. Technological advancements in electroplating processes also contribute to demand, offering enhanced surface protection and aesthetic finishes.

However, the market faces significant restraints that temper its growth trajectory. The inherent volatility of nickel prices, influenced by global commodity markets, geopolitical events, and supply-demand imbalances, presents a considerable challenge for both producers and consumers in terms of cost predictability and investment planning. Environmental concerns associated with nickel mining and processing, including carbon emissions and waste management, lead to increasing regulatory scrutiny and public pressure, necessitating costly compliance measures and sustainable practices. Geopolitical risks, trade disputes, and supply chain disruptions, particularly impacting key producing or consuming regions, can also severely affect market stability and access to critical raw materials, thereby restricting steady growth.

Despite these challenges, substantial opportunities exist for market players to innovate and expand. The burgeoning trend of nickel recycling, especially from end-of-life EV batteries, offers a sustainable alternative to primary mining, addressing environmental concerns and providing a circular economy approach to resource management. Furthermore, continuous research and development into advanced battery technologies, such as solid-state batteries or next-generation chemistries that still rely on high-purity nickel, present avenues for new product development and market penetration. The expansion of renewable energy infrastructure, including wind turbines and solar panels, also creates demand for nickel-containing components, while the growing industrial base in developing countries provides untapped markets for diverse applications of electrolytic nickel. These opportunities require strategic investments in R&D, sustainable practices, and robust supply chain management to be fully realized.

Segmentation Analysis

The Electrolytic Nickel Market is extensively segmented to provide granular insights into its diverse components and applications. This segmentation allows for a detailed analysis of market dynamics across different purity levels, physical forms, application areas, and end-use industries, enabling stakeholders to identify key growth drivers and niche opportunities. Understanding these segments is crucial for strategic planning, product development, and market positioning within the highly specialized and evolving nickel industry. Each segment exhibits unique demand characteristics and growth potentials, driven by specific technological requirements and market trends.

- By Purity

- 99.8% to 99.95%

- 99.95% & Above

- By Form

- Cathodes

- Squares

- Pellets

- Briquettes

- Others

- By Application

- Electroplating

- Battery Manufacturing

- Specialty Alloys

- Catalysis

- Others (e.g., Coinage, Chemical Industry)

- By End-Use Industry

- Automotive (including EV)

- Electronics

- Aerospace & Defense

- Chemical

- Construction

- Others (e.g., Medical, Consumer Goods)

Value Chain Analysis For Electrolytic Nickel Market

The value chain for the Electrolytic Nickel Market begins with extensive upstream activities, primarily involving nickel mining and ore processing. This stage is capital-intensive and geographically concentrated, with major mining operations extracting nickel ore, which then undergoes beneficiation to produce concentrates. These concentrates are subsequently smelted and refined to produce an intermediate product, which is then fed into the electrolytic refining process. Key players at this stage are large-scale mining companies that control significant reserves and possess the technological expertise for efficient extraction and initial processing. The quality of raw materials and the efficiency of these upstream operations significantly influence the cost and purity of the final electrolytic nickel product. Innovations in sustainable mining practices and ore processing technologies are critical to maintaining competitiveness and addressing environmental concerns.

The midstream segment of the value chain focuses on the actual electrolytic refining process, where intermediate nickel products are subjected to electrolysis to achieve high purity. This stage requires specialized infrastructure, considerable energy input, and precise control mechanisms to produce nickel cathodes, squares, or pellets meeting stringent quality specifications for various applications. Refiners optimize cell design, electrolyte composition, and current density to maximize efficiency and purity. This segment is characterized by a relatively smaller number of highly specialized companies that possess the proprietary technology and expertise for electrolytic refining. The quality and cost-effectiveness of these refining operations are paramount for ensuring a competitive final product that meets the demanding requirements of downstream industries.

Downstream activities involve the distribution and utilization of electrolytic nickel in various end-use industries. Once refined, electrolytic nickel is supplied to manufacturers of EV batteries, electroplating facilities, specialty alloy producers, and chemical companies. The distribution channel plays a critical role, encompassing direct sales from refiners to large industrial customers as well as indirect channels through global metal exchanges, traders, and distributors who provide logistics, warehousing, and financial services. Direct sales facilitate strong relationships and tailored supply agreements for major consumers, while indirect channels offer flexibility and market access for smaller players and regional needs. The effectiveness of these distribution networks ensures the timely and efficient delivery of high-purity nickel to its diverse range of end-users, thereby completing the value chain.

Electrolytic Nickel Market Potential Customers

Potential customers for electrolytic nickel are diverse and span across multiple high-value industries, primarily driven by the material's unparalleled purity, corrosion resistance, and specific electrochemical properties. The largest and fastest-growing segment of end-users are manufacturers of electric vehicle (EV) batteries, particularly those producing nickel-manganese-cobalt (NMC) and nickel-cobalt-aluminum (NCA) cathodes. These battery producers require vast quantities of high-purity nickel to achieve the energy density and cycle life essential for modern EVs. As the automotive industry rapidly electrifies, the demand from this sector is expected to escalate significantly, making EV battery manufacturers a critical customer segment for electrolytic nickel.

Another significant customer base includes electroplating companies that utilize electrolytic nickel for protective and decorative coatings on a wide array of products. This ranges from automotive components and plumbing fixtures to electronic connectors and industrial machinery, where nickel plating enhances corrosion resistance, hardness, and aesthetic appeal. Specialty alloy and superalloy manufacturers, particularly those serving the aerospace, defense, and power generation industries, represent a premium customer segment. These manufacturers incorporate electrolytic nickel into high-performance alloys that operate under extreme temperatures and corrosive environments, demanding the highest purity to maintain structural integrity and functional reliability. The precision and consistency offered by electrolytic nickel are critical for these applications, where material failure can have catastrophic consequences.

Furthermore, the chemical industry utilizes electrolytic nickel as a catalyst in various hydrogenation and other chemical processes, while the electronics sector employs it in components requiring high electrical conductivity and corrosion resistance. The construction industry also uses nickel in certain architectural applications and high-strength steels. With its broad utility, the market for electrolytic nickel extends to any industry requiring a high-purity, versatile metal with superior metallurgical characteristics. The consistent quality and specific forms of electrolytic nickel make it the preferred choice for applications where performance and reliability are non-negotiable, solidifying its position as a vital industrial commodity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 34.5 Billion |

| Market Forecast in 2033 | USD 55.0 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Vale S.A., Glencore Plc, Norilsk Nickel, Sumitomo Metal Mining Co., Ltd., BHP Group, Jinchuan Group Co., Ltd., Anglo American Plc, Eramet S.A., Queensland Nickel (QNI), PT Antam Tbk, Technickel Company, Nickel Institute, Sherritt International Corporation, Codelco, Zhejiang Huayou Cobalt Co., Ltd., GEM Co., Ltd., Trafigura Group Pte. Ltd., Eurasian Resources Group (ERG), Tsingshan Holding Group, Shanghai Jinfeng Nickel Industry Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrolytic Nickel Market Key Technology Landscape

The Electrolytic Nickel Market is underpinned by a sophisticated technology landscape primarily centered around the electrowinning and electrorefining processes. Electrowinning involves the extraction of nickel from leached solutions using an electric current, typically from lateritic ores or recycled materials, resulting in high-purity nickel cathodes. Electrorefining, on the other hand, takes impure nickel anodes and refines them electrolytically to produce very high-purity nickel cathodes, a process essential for demanding applications like superalloys and advanced batteries. Both processes rely heavily on precisely controlled electrochemical parameters, including current density, electrolyte composition, temperature, and pH, to ensure consistent product quality and process efficiency. Continuous advancements in cell design, electrode materials, and electrolyte purification systems are central to reducing energy consumption and enhancing overall productivity in these operations.

Beyond the core electrolytic processes, the technology landscape extends to advanced material handling and quality assurance systems. Automation and robotics are increasingly integrated into production lines for cathode stripping, cutting, and packaging, improving operational safety and throughput. Spectroscopic analysis techniques, such as X-ray fluorescence (XRF) and inductively coupled plasma (ICP) spectrometry, are critical for real-time monitoring of impurity levels throughout the refining process, guaranteeing the stringent purity specifications required by downstream industries, especially battery manufacturers. Innovations in solvent extraction and ion exchange technologies are also vital for pre-treatment of nickel-containing solutions, efficiently removing undesirable impurities before the electrolysis stage, thereby improving the overall purity of the final product and reducing processing costs.

Furthermore, the industry is witnessing significant technological shifts driven by sustainability imperatives and the circular economy. This includes the development and adoption of advanced hydrometallurgical routes for processing complex nickel ores and, more importantly, for recycling nickel from spent batteries. These technologies, often coupled with AI and machine learning for process optimization, aim to recover high-purity nickel with a lower environmental footprint compared to traditional pyrometallurgical methods. Research into more energy-efficient electrolysis cells, use of renewable energy sources for power, and novel wastewater treatment solutions are also integral to the evolving technology landscape, positioning the electrolytic nickel market at the forefront of sustainable metal production and high-tech material supply. The integration of digital twins and predictive maintenance analytics is further optimizing operational efficiency and reliability across refining facilities.

Regional Highlights

- Asia Pacific: The largest and fastest-growing market, primarily driven by China, Japan, and South Korea's dominance in EV battery manufacturing and robust industrialization. Significant demand from electronics, stainless steel production, and infrastructure development.

- Europe: A key market propelled by stringent emission regulations and ambitious EV adoption targets, particularly in Germany, France, and the UK. Strong presence of aerospace, automotive, and specialty alloy industries requiring high-purity nickel.

- North America: Experiencing substantial growth due to increasing investments in domestic EV battery production and a strong demand from the aerospace, defense, and electroplating sectors in the United States and Canada. Focus on supply chain security and resource independence.

- Latin America: Emerging as a region with significant nickel mining potential, particularly in countries like Brazil. Growing industrial base and increasing foreign investments in processing capabilities are expected to drive future market expansion.

- Middle East & Africa (MEA): This region holds strategic importance due to its raw material reserves. While currently smaller in consumption, growing industrialization, infrastructure projects, and diversification efforts are creating new demand centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrolytic Nickel Market.- Vale S.A.

- Glencore Plc

- Norilsk Nickel

- Sumitomo Metal Mining Co., Ltd.

- BHP Group

- Jinchuan Group Co., Ltd.

- Anglo American Plc

- Eramet S.A.

- Queensland Nickel (QNI)

- PT Antam Tbk

- Technickel Company

- Nickel Institute

- Sherritt International Corporation

- Codelco

- Zhejiang Huayou Cobalt Co., Ltd.

- GEM Co., Ltd.

- Trafigura Group Pte. Ltd.

- Eurasian Resources Group (ERG)

- Tsingshan Holding Group

- Shanghai Jinfeng Nickel Industry Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Electrolytic Nickel market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is electrolytic nickel and what are its primary uses?

Electrolytic nickel is a high-purity form of nickel produced through an electrochemical refining process. Its primary uses include battery manufacturing (especially for EVs), electroplating, specialty alloys (aerospace, defense), and as a catalyst in various chemical processes due to its purity and specific properties.

How is the demand for electrolytic nickel influenced by the electric vehicle (EV) market?

The EV market is a major driver for electrolytic nickel demand. High-energy-density EV battery cathodes, such as NMC and NCA, rely heavily on high-purity nickel. As EV adoption accelerates globally, the demand for electrolytic nickel for battery production is projected to grow significantly.

What are the main factors restraining the growth of the electrolytic nickel market?

Key restraints include the volatility of global nickel prices, which impacts production costs and consumer purchasing. Environmental regulations related to mining and processing, alongside geopolitical instability affecting supply chains, also pose significant challenges to market growth and stability.

Which regions are leading in the consumption and production of electrolytic nickel?

Asia Pacific, particularly China, Japan, and South Korea, leads in consumption due to its extensive EV battery manufacturing and industrial base. Major production regions include countries with significant nickel reserves and advanced refining capabilities globally, such as Russia, Canada, Australia, and Indonesia.

What role does recycling play in the future of the electrolytic nickel market?

Nickel recycling, especially from spent EV batteries, is increasingly vital for the electrolytic nickel market. It offers a sustainable supply source, reduces reliance on primary mining, mitigates environmental impact, and addresses potential supply chain vulnerabilities, contributing to a circular economy for critical metals.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Electrolytic Nickel Market Statistics 2025 Analysis By Application (Stainless Steel, Alloy, Electroplated Steel), By Type (Ni 9999, Ni 9996, Ni 9990, Ni 9950, Ni 9920), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Nickel Powder Market Statistics 2025 Analysis By Application (Alloy, Functional Materials, Electroplate & Battery), By Type (Carbonyl Nickel Powder, Electrolytic Nickel Powder), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager