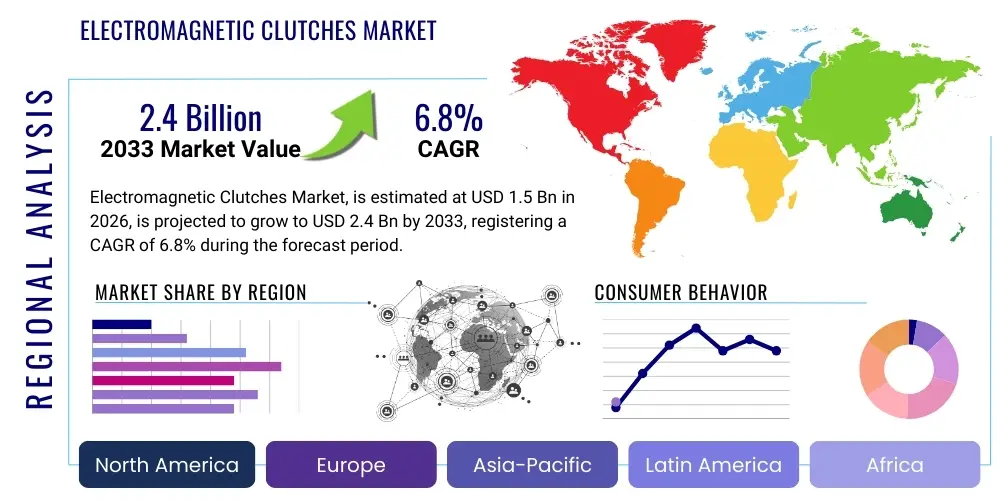

Electromagnetic Clutches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436234 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Electromagnetic Clutches Market Size

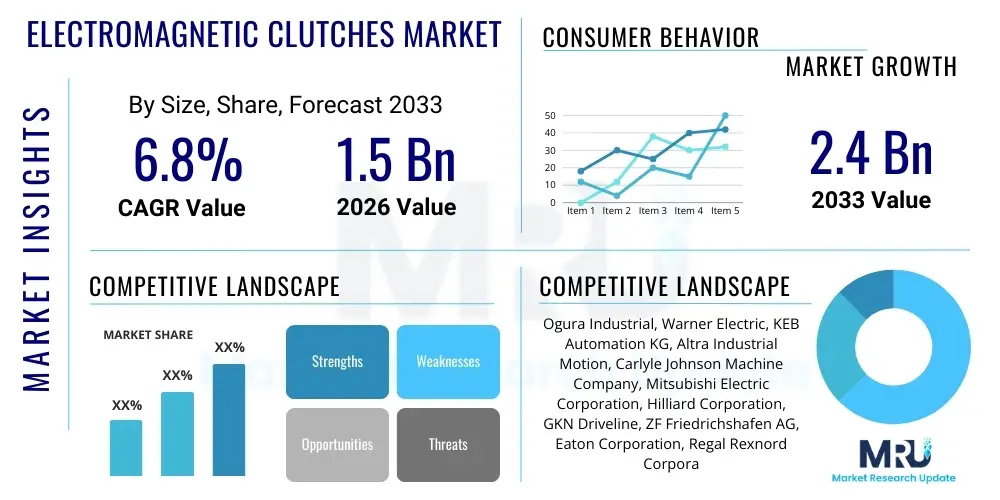

The Electromagnetic Clutches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Electromagnetic Clutches Market introduction

The Electromagnetic Clutches Market encompasses devices that use an electrical current to create a magnetic field, facilitating torque transfer between two rotating components. These clutches offer superior engagement speed, reliability, and precision control compared to mechanical alternatives, making them integral components in various sophisticated machinery and industrial automation systems. The product primarily functions by engaging a rotor, armature, and field assembly, providing smooth, shock-less power transmission essential for high-performance applications. Modern electromagnetic clutches are designed for low power consumption and high torque density, catering to the growing demand for energy-efficient motion control solutions across industries globally.

Major applications of electromagnetic clutches span across industrial sectors, including packaging machinery, printing presses, machine tools, medical equipment, and heavy-duty robotics. Furthermore, their crucial role in the automotive sector, specifically within air conditioning compressors and auxiliary drive systems, significantly contributes to market expansion. The core benefits derived from utilizing these clutches include rapid response times, precise indexing capabilities, simplified installation, minimal maintenance requirements, and the ability to operate effectively in varying environmental conditions, thereby enhancing overall system efficiency and reducing downtime in critical operations. This reliability profile is highly valued in continuous production environments.

Key driving factors accelerating the growth of the Electromagnetic Clutches Market include the robust expansion of the global manufacturing sector, particularly in emerging economies emphasizing automation and high-speed production. The increasing complexity and sophistication of industrial machinery necessitate highly controllable motion components, favoring electromagnetic clutch systems. Furthermore, the persistent demand for compact, lightweight, and high-performance vehicles fuels their integration into automotive subsystems. Strict regulatory mandates emphasizing energy efficiency in industrial equipment also push manufacturers toward adopting advanced clutch technologies that minimize power loss during operation, cementing the market’s positive trajectory through the forecast period.

Electromagnetic Clutches Market Executive Summary

The Electromagnetic Clutches Market is experiencing sustained growth, driven primarily by accelerating industrial automation and significant investments in advanced manufacturing technologies across Asia Pacific and North America. Current business trends indicate a strong shift towards developing miniature and high-torque-density clutches capable of operating reliably in harsh environments, catering specifically to the aerospace and defense sectors, alongside demanding packaging applications. Leading manufacturers are focusing heavily on integrating smart features, such as condition monitoring sensors and digital control interfaces, into clutch systems to facilitate predictive maintenance and enhance operational longevity, thus aligning with Industry 4.0 paradigms. Mergers and acquisitions focused on securing proprietary control technology and expanding regional distribution networks characterize the competitive landscape.

Regionally, Asia Pacific maintains its dominance, spurred by the explosive growth of its domestic automotive manufacturing base and extensive governmental support for industrial modernization in countries like China, India, and South Korea. Europe presents a mature market characterized by stringent quality standards, driving demand for premium, precision-engineered clutches for specialized machine tools and high-end robotics. North America demonstrates consistent growth, largely attributed to the robust aerospace and defense industries and increasing automation adoption in logistics and material handling. Emerging markets in Latin America and MEA are beginning to show significant potential as local manufacturing capabilities expand, creating new opportunities for standardization and volume sales, particularly in mining and construction equipment.

Segment trends reveal that the dry clutch segment, favored for its simple construction and ease of maintenance, holds the largest market share, especially in general industrial applications. However, the wet clutch segment is projected to exhibit the highest Compound Annual Growth Rate (CAGR), driven by increasing adoption in high-power transmission applications and specialized automotive systems where heat dissipation and smooth engagement are critical performance metrics. Furthermore, within the application segments, machine tools and robotics are experiencing substantial growth due to global industrial optimization efforts. The 24V DC segment remains the standard for industrial applications, although there is a notable rise in demand for lower voltage clutches suited for battery-operated or portable machinery, reflecting the ongoing push toward energy optimization and system portability.

AI Impact Analysis on Electromagnetic Clutches Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Electromagnetic Clutches Market predominantly center on how AI can optimize clutch performance, predict component failure, and integrate these components within complex, self-regulating industrial ecosystems. Key concerns revolve around the potential for AI-driven controllers to enhance torque management precision, thereby extending the lifespan of the clutches and associated mechanical systems, and facilitating real-time fault detection. Users are keenly interested in understanding if AI algorithms can optimize engagement timing and slip control in variable load conditions, moving beyond traditional PID control loops. Expectations include AI providing sophisticated predictive maintenance schedules, reducing catastrophic failures, and enabling entirely autonomous system operation where clutches are dynamically managed based on ambient conditions and operational history, leading to higher throughput and reduced operational expenditure across various manufacturing lines globally.

- AI-Enhanced Predictive Maintenance: Utilizing machine learning algorithms to analyze vibration, temperature, and current consumption data streamed from smart clutches, predicting failure points before they occur, significantly extending Mean Time Between Failures (MTBF).

- Optimized Engagement Control: AI-driven controllers can learn complex system dynamics, optimizing the clutch engagement and disengagement profiles in real-time to minimize mechanical shock and wear, especially in high-cycle, high-precision applications like indexing tables.

- Energy Efficiency Management: Implementing AI to dynamically adjust power supply to the clutch based on required torque and load conditions, ensuring minimal energy dissipation and heat generation, which is crucial for maximizing efficiency in continuous operations.

- Automated Calibration and Tuning: AI systems can automate the initial calibration and subsequent fine-tuning of clutch parameters following wear or environmental changes, reducing the dependency on specialized technicians and improving operational consistency.

- Integration with Digital Twins: AI facilitates the seamless integration of clutch performance data into digital twin models of manufacturing plants, allowing engineers to simulate various operational scenarios and optimize the overall system layout and control architecture.

- Fault Isolation and Diagnostics: Leveraging neural networks to instantaneously diagnose the specific cause of a malfunction within the clutch mechanism or its control system, speeding up repair times and reducing production bottlenecks.

- Supply Chain Optimization: AI can forecast demand variability for specific clutch types based on sector growth and inventory levels, assisting manufacturers in optimizing production schedules and raw material procurement, thereby stabilizing pricing and delivery timelines.

- Advanced Robotics Integration: Enabling highly fluid and responsive motion control in complex multi-axis robotic arms by dynamically managing clutch engagement during rapid shifts in trajectory and payload, critical for advanced collaborative robots (cobots).

- Cybersecurity Protocols: Integrating AI-based anomaly detection systems within smart clutch controllers to identify and flag unauthorized control modifications or malicious data injections, protecting sensitive industrial operations from cyber threats.

DRO & Impact Forces Of Electromagnetic Clutches Market

The Electromagnetic Clutches Market growth is robustly supported by several dynamic factors, notably the unrelenting global push toward automation across manufacturing, logistics, and material handling sectors, which necessitates high-precision motion control components. Major drivers include the increasing adoption of automated guided vehicles (AGVs) and specialized machinery in packaging and printing, where quick, repeatable, and accurate indexing is mandatory. Conversely, the market faces restraints, primarily the high initial cost associated with specialized electromagnetic systems compared to conventional mechanical alternatives, and the complexity involved in maintaining and troubleshooting the integrated electrical and mechanical components. Opportunities are emerging through the development of hybrid clutch systems combining electromagnetic actuation with advanced braking technologies, and significant potential exists in retrofitting older industrial equipment with modern, energy-efficient electromagnetic solutions to comply with modern industrial standards.

Market dynamics are intensely influenced by the crucial role of electromagnetic clutches in mission-critical applications where failure is highly undesirable, such as aerospace systems and specialized medical devices. The primary impact forces driving demand stem from industrial consolidation and standardization efforts globally, which favor suppliers capable of delivering highly reliable, globally certified components with extensive technical support. Furthermore, rapid technological evolution in materials science, leading to lighter, more durable, and thermally stable friction materials, significantly influences product performance and lifespan. The competitive rivalry is high, particularly among established players seeking to maintain market share through proprietary control technology and patented coil designs, thereby impacting pricing strategies and new product development timelines.

Specifically regarding restraints, the sensitivity of electromagnetic clutch performance to temperature variations, especially in heavy-duty or continuous slip applications, requires sophisticated cooling systems, adding complexity and cost to the final product installation. Furthermore, the inherent need for a consistent and clean power supply can be a limiting factor in certain remote or unstable industrial environments. The market attempts to mitigate these restraints by innovating in thermal management techniques and developing clutches capable of tolerating wider voltage fluctuations. Opportunities are vast in customizing clutch solutions for emerging niche applications, such as wind turbine yaw drives or specialized agricultural machinery, where durability under adverse conditions and precision control are paramount.

Segmentation Analysis

The Electromagnetic Clutches Market is highly fragmented and analyzed based on comprehensive criteria including product type, operational design, voltage rating, and end-use application, providing a granular view of market dynamics and adoption patterns across different industrial landscapes. Product differentiation, particularly between single-face and multi-disc clutches, dictates their suitability for specific torque and speed requirements, directly influencing market penetration in respective sectors. The operational design segmentation, focusing on wet versus dry friction mechanisms, is crucial for determining performance characteristics like heat dissipation and maximum torque transfer capacity, essential for high-duty cycle environments. Voltage ratings determine compatibility with prevalent industrial power systems, ensuring smooth integration into existing machinery, while end-use segmentation highlights primary consumption drivers such as automotive, industrial machinery, and aerospace, revealing key areas for targeted commercial strategy development.

Analyzing these segments provides strategic insights into investment areas. For instance, the multi-disc segment, favored for high torque transmission in a compact space, shows robust growth tied to heavy machinery manufacturing and robotics, while the single-face segment maintains a steady base in general automation and office equipment due to its cost-effectiveness and simplicity. The segmentation by application clearly indicates that the Automotive sector, heavily utilizing clutches for air conditioning and driveline components, remains a cornerstone market, but industrial applications, driven by automation expansion, are emerging as the fastest-growing segment. Understanding the voltage preference (e.g., 24V DC being standard versus 90V DC for heavier machinery) allows manufacturers to tailor their product lines to regional industrial standards and technological adoption levels.

- By Product Type

- Single-Face Clutches: Dominant in general industrial applications requiring simple on/off engagement and moderate torque.

- Multi-Disc Clutches: Essential for heavy-duty applications demanding high torque transmission in restricted radial space, common in machine tools and construction equipment.

- Clutch-Brake Combinations: Integrated units offering both coupling and stopping functions, optimizing space and control complexity, heavily used in printing and packaging machinery.

- Permanent Magnet Clutches: Used where precise, fail-safe engagement is necessary, leveraging residual magnetism for power-off braking capabilities.

- By Operational Design

- Dry Clutches: Easier to maintain and install, suitable for lower torque and less continuous slip applications; holds the largest volumetric share.

- Wet Clutches: Immersed in oil or fluid, providing superior heat dissipation and smoother engagement; critical for high-speed, high-power automotive and heavy machinery transmissions.

- By Voltage Rating

- 12V DC: Predominantly used in small vehicle systems, auxiliary drives, and portable equipment where low power consumption is prioritized.

- 24V DC: The industry standard for most industrial machinery, including conveyors, packaging, and general automation systems globally.

- 90V DC: Utilized in heavy industrial applications requiring higher power density and maximum torque output, such as large presses and specialized tooling machines.

- By End-Use Application

- Automotive: Includes AC compressors, supercharger drives, and various auxiliary systems; segment driven by vehicle production volumes.

- Industrial Machinery: Encompassing robotics, machine tools, textile machinery, and printing presses; highly sensitive to global manufacturing indices.

- Aerospace and Defense: Requiring specialized, high-reliability clutches for actuator control and flight surface manipulation; characterized by high barriers to entry and stringent certification.

- Packaging and Material Handling: Essential for precise indexing, sorting, and conveyor belt control; highly sensitive to e-commerce and logistics growth.

- Medical Equipment: Used in precision instruments, dialysis machines, and specialized diagnostic imaging devices requiring silent operation and absolute accuracy.

Value Chain Analysis For Electromagnetic Clutches Market

The value chain for the Electromagnetic Clutches Market starts with the rigorous procurement of high-quality raw materials, primarily focusing on specialized ferromagnetic alloys, copper wiring for coils, advanced friction materials (sintered metals, organic composites), and specialized insulation polymers. Upstream activities are dominated by highly specialized material suppliers and precision machining firms that process the core components like rotors and armatures. The quality and purity of these materials directly impact the clutch’s maximum torque, thermal capacity, and operational lifespan. Manufacturing complexity involves precision winding of the electromagnetic coils and strict quality control over air gaps and component tolerances to ensure smooth and reliable operation, making this stage highly capital-intensive and reliant on proprietary manufacturing know-how. Key players often vertically integrate the winding and assembly processes to maintain intellectual property advantage and quality control.

The downstream analysis focuses on the distribution and integration channels. Direct distribution is common for Original Equipment Manufacturers (OEMs) in high-volume sectors like automotive and major industrial machinery, where manufacturers negotiate long-term supply contracts directly with the clutch producers. This channel provides technical specificity and guaranteed supply stability. Indirect distribution involves a network of specialized industrial distributors, component resellers, and maintenance repair and overhaul (MRO) service providers, who cater to smaller volume users, general industrial maintenance, and localized machinery builders. These indirect partners often provide crucial local technical support and application expertise, playing a vital role in market accessibility for smaller enterprises and regional end-users.

The selection of the distribution channel is highly dependent on the target end-user. For highly customized, niche applications such as aerospace or medical devices, the manufacturer often maintains a direct, high-touch relationship to ensure compliance and precision application engineering. Conversely, standardized product lines, especially those used in general conveyors or pumps, rely heavily on efficient and widespread indirect distribution networks to ensure immediate availability and competitive pricing. The efficiency of the logistics chain, coupled with the effectiveness of post-sale technical training and warranty support provided by both direct and indirect channels, significantly determines customer satisfaction and repeat business in this highly technical market segment.

Electromagnetic Clutches Market Potential Customers

The primary customer base for the Electromagnetic Clutches Market encompasses large-scale industrial machinery manufacturers, automotive Tier 1 and Tier 2 suppliers, robotics and automation system integrators, and specialized equipment builders across various high-tech sectors. These end-users are primarily motivated by the need for precise motion control, durability, and reliability in critical power transmission applications. Automotive manufacturers, for instance, utilize these components extensively in compressor drive systems and increasingly within hybrid and electric vehicle auxiliary systems, focusing on lightweight design and high-efficiency performance metrics. The industrial sector, particularly those involved in high-speed printing, complex textile production, and specialized packaging, seeks clutches capable of rapid cycling and accurate positional indexing.

Beyond traditional industrial applications, a growing segment of potential customers includes infrastructure and resource extraction industries. Companies manufacturing heavy construction equipment, mining machinery, and specialized agricultural tractors represent substantial buyers, demanding high-torque, robust clutches capable of withstanding extreme temperatures, dust, and continuous heavy loading cycles. Furthermore, the burgeoning field of collaborative robotics and advanced medical device manufacturing presents a critical, albeit smaller, segment focused on ultra-quiet operation, minimal vibration, and absolute fail-safe engagement mechanisms, prioritizing precision over sheer power. These buyers typically require highly customized solutions that meet stringent industry certifications and regulatory standards.

The aftermarket segment also represents a significant and stable customer base, comprising MRO (Maintenance, Repair, and Overhaul) service providers and facility management teams responsible for maintaining large fleets of older industrial equipment. These customers prioritize clutch interchangeability, immediate availability of standard models, and competitive pricing for replacements. Strategic focus on this segment involves ensuring broad availability through distributor networks and providing detailed technical manuals for ease of installation, thereby securing loyalty in the long-term operational lifespan of industrial assets globally. The convergence of smart manufacturing also positions technology integrators as key customers, seeking clutches equipped with embedded sensors and digital interfaces compatible with cloud-based monitoring platforms.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ogura Industrial, Warner Electric, KEB Automation KG, Altra Industrial Motion, Carlyle Johnson Machine Company, Mitsubishi Electric Corporation, Hilliard Corporation, GKN Driveline, ZF Friedrichshafen AG, Eaton Corporation, Regal Rexnord Corporation, Thomson Industries, SINFONIA TECHNOLOGY CO., LTD., WATT Drive Antriebstechnik GmbH, Miki Pulley Co., Ltd., Matrix International, Magnetic Technologies Ltd., EIDE, Inc., Coremo Ocmea SpA, Electroid Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electromagnetic Clutches Market Key Technology Landscape

The technological landscape of the Electromagnetic Clutches Market is rapidly evolving, driven by the demand for higher efficiency, compactness, and integrated intelligence, moving beyond simple torque transfer mechanisms. A crucial area of innovation is the development of advanced friction materials, such as specialized ceramic and carbon composites, which significantly improve the clutch’s thermal stability, increase the coefficient of friction, and extend service life under high-slip conditions without requiring cumbersome cooling systems. Furthermore, advancements in coil winding technology, including proprietary techniques for achieving higher flux density within smaller volumes, are enabling the production of electromagnetic clutches with superior torque-to-size ratios, essential for miniature robotics and space-constrained automotive applications. This focus on material and design efficiency addresses the perennial market challenge of balancing torque capacity with size and weight constraints, especially critical in mobility-focused sectors.

Another significant technological shift involves the integration of smart electronics and sensors directly into the clutch assembly, transforming them into intelligent motion components ready for Industry 4.0 environments. This includes embedding Hall Effect sensors or sophisticated encoders to precisely monitor rotational speed and engagement status, facilitating highly accurate indexing and synchronous operation across multi-component systems. Crucially, the development of sophisticated pulse-width modulation (PWM) controllers is allowing for nuanced control over the magnetic field strength, leading to significantly smoother engagement profiles, minimizing mechanical wear, and offering variable torque settings tailored to dynamic load requirements. These smart technologies are foundational to enabling predictive maintenance capabilities by providing continuous operational data streams.

Furthermore, research into contactless magnetic clutches, utilizing principles of hysteresis or eddy current, is opening up new avenues for applications requiring absolute minimal wear and ultra-clean operation, such as those found in cleanroom manufacturing or high-purity medical devices. While conventional friction-based clutches dominate the volume market, the development of magnetorheological (MR) fluid clutches, which use controllable fluids to modulate torque, offers unparalleled precision and response speed, positioning them as a high-potential future technology for specialized, demanding control systems. The overarching technological direction aims at modularity, enabling easy integration of clutch-brake assemblies with standard motor and gear reducer configurations, simplifying the process of designing and deploying automated systems.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market due to massive investments in industrial infrastructure and the rapid expansion of the automotive manufacturing base, particularly in China, Japan, and India. The region benefits from lower manufacturing costs, which attracts global players establishing production hubs. Key demand drivers include high-volume production of consumer electronics, increased factory automation penetration in robotics, and significant growth in electric vehicle (EV) component manufacturing, requiring efficient auxiliary clutches. Standardization efforts in manufacturing processes across Southeast Asia further bolster demand, making APAC the engine of global market growth.

- North America: Characterized by strong demand from high-technology sectors, including aerospace, defense, and specialized medical equipment, North America is a mature market focused on high-reliability, customized solutions. The ongoing rejuvenation of the domestic manufacturing sector, coupled with robust investment in automation for logistics and warehousing, drives the need for sophisticated, sensor-equipped electromagnetic clutches. The region prioritizes quality, technological leadership, and compliance with strict performance standards, often leading the adoption curve for AI-integrated clutch control systems and advanced materials.

- Europe: Europe is a hub for precision engineering, reflected in high demand for clutches used in advanced machine tools, high-speed printing presses, and sophisticated industrial robotics. Germany and Italy are major contributors, emphasizing energy efficiency, compact design, and adherence to stringent EU environmental and safety regulations. The market here is defined by a preference for long-lasting, high-precision components and a strong aftermarket focused on maintaining the extensive installed base of complex industrial machinery. Growth is moderate but stable, concentrated in high-value, niche industrial automation projects.

- Latin America (LATAM): LATAM remains an emerging market with growth concentrated in sectors such as mining, construction, and localized automotive assembly, primarily Brazil and Mexico. Demand is generally focused on cost-effective, durable clutches capable of handling harsh operating environments common in heavy industry. Market growth is closely tied to commodity pricing and infrastructure investment cycles. Suppliers typically penetrate this market through strong local distribution partners capable of providing technical support and managing complex import logistics, focusing on reliability and robust design over cutting-edge technology.

- Middle East and Africa (MEA): This region shows potential, especially in the oil and gas sector, construction, and nascent domestic manufacturing in countries like Saudi Arabia and the UAE. Demand for electromagnetic clutches is linked to port modernization, material handling systems, and water treatment facilities. The market is smaller but expanding, requiring components capable of operating efficiently in high-temperature conditions. Infrastructure development projects across Africa are slowly increasing the need for heavy machinery components, opening opportunities for standardized, high-reliability dry clutch systems in the medium term.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electromagnetic Clutches Market.- Ogura Industrial Corp.

- Warner Electric (Regal Rexnord Corporation)

- KEB Automation KG

- Altra Industrial Motion Corp.

- Carlyle Johnson Machine Company

- Mitsubishi Electric Corporation

- Hilliard Corporation

- GKN Driveline

- ZF Friedrichshafen AG

- Eaton Corporation

- Thomson Industries

- SINFONIA TECHNOLOGY CO., LTD.

- WATT Drive Antriebstechnik GmbH

- Miki Pulley Co., Ltd.

- Matrix International (Regal Rexnord Corporation)

- Magnetic Technologies Ltd.

- EIDE, Inc.

- Coremo Ocmea SpA

- Electroid Company

- Suco GmbH

Frequently Asked Questions

Analyze common user questions about the Electromagnetic Clutches market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for electromagnetic clutches in industrial applications?

The primary driver is the pervasive trend toward industrial automation and the necessity for precise, high-speed motion control. Electromagnetic clutches offer fast response times and superior control accuracy, making them indispensable components for sophisticated machinery like CNC tools, packaging lines, and advanced robotics where repeatable precision is paramount for operational efficiency and product quality.

How do electromagnetic dry clutches differ structurally and functionally from wet clutches?

Electromagnetic dry clutches operate without lubricating fluids; they are simpler in design and easier to maintain, favored for general industrial use and environments sensitive to contamination. Wet clutches, conversely, use oil immersion to manage heat dissipation and provide smoother engagement under continuous slip conditions, making them ideal for high-torque automotive transmissions and heavy machinery requiring extended operational life and high thermal capacity.

What role does the adoption of Industry 4.0 technologies play in the evolution of the electromagnetic clutches market?

Industry 4.0 facilitates the integration of smart electromagnetic clutches equipped with sensors and digital control systems. This enables real-time performance monitoring, AI-driven predictive maintenance, optimized energy consumption, and seamless connectivity within larger industrial IoT ecosystems, significantly improving operational uptime and reducing overall ownership costs for end-users.

Which geographical region holds the largest market share for electromagnetic clutches, and what fuels its dominance?

The Asia Pacific (APAC) region currently holds the largest market share. This dominance is primarily fueled by the rapid expansion of manufacturing bases, high-volume production across automotive and electronics sectors, and extensive government initiatives promoting factory automation and industrial modernization in countries such as China and India, creating massive demand for motion control components.

What are the main performance trade-offs associated with increasing the torque density of electromagnetic clutches?

Increasing the torque density, often achieved by utilizing multi-disc designs or higher-flux materials, generally results in trade-offs concerning heat generation and physical size constraints. Higher density necessitates more efficient thermal management, sometimes requiring external cooling, and may increase complexity in maintenance. Manufacturers must balance compactness and torque output with thermal durability and cost efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager