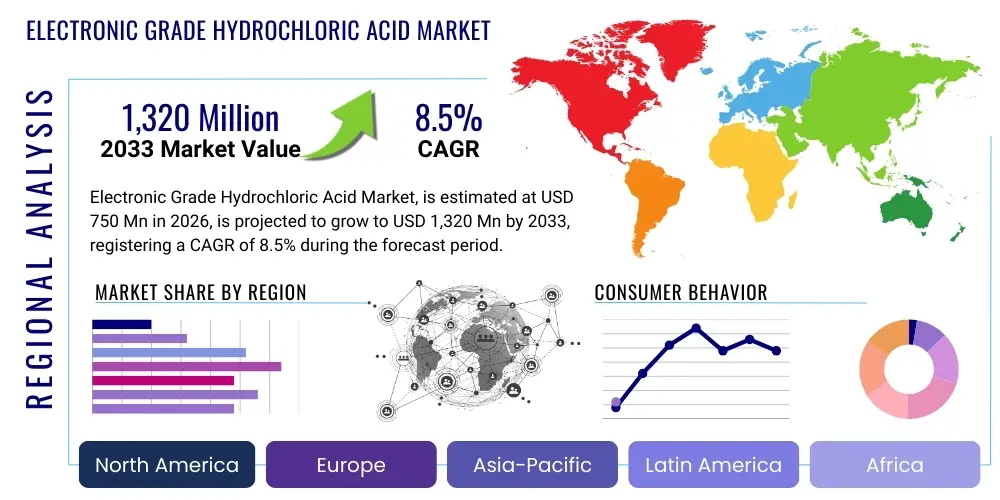

Electronic Grade Hydrochloric Acid Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434435 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Electronic Grade Hydrochloric Acid Market Size

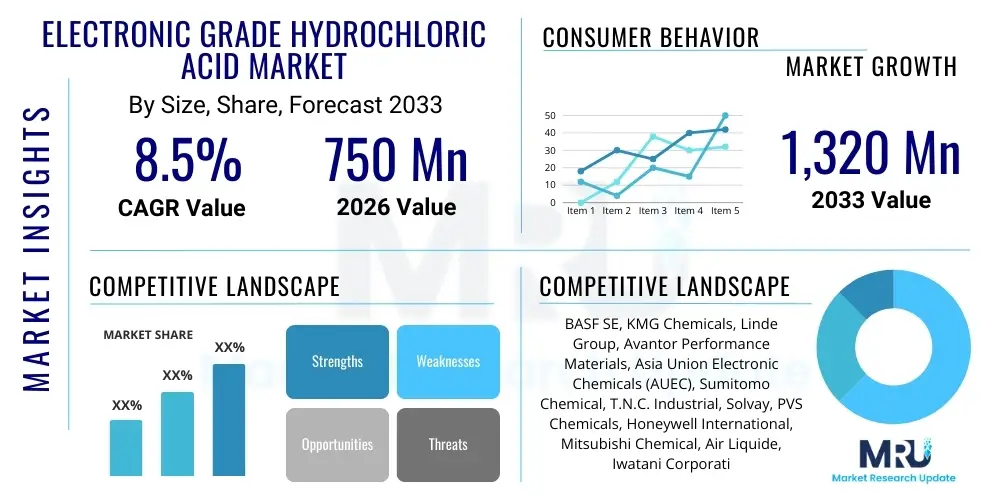

The Electronic Grade Hydrochloric Acid Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,320 Million by the end of the forecast period in 2033.

Electronic Grade Hydrochloric Acid Market introduction

Electronic Grade Hydrochloric Acid (E-HCl) is a highly purified chemical essential for the semiconductor and electronics manufacturing industries. This chemical, often manufactured to stringent specifications such as those defined by SEMI standards (e.g., SEMI C7, C8), is utilized primarily in critical cleaning, etching, and processing steps where ultra-low levels of metallic impurities and particulates are mandatory. The market for E-HCl is fundamentally driven by the relentless miniaturization trend in microelectronics, which demands chemicals of purity levels ranging from parts per billion (ppb) down to parts per trillion (ppt). The integrity of advanced semiconductor devices, including 3D NAND, DRAM, and leading-edge logic chips, directly relies on the quality of these high-purity process chemicals, making E-HCl an indispensable input for global chip production facilities, or fabs.

The primary applications of Electronic Grade Hydrochloric Acid center around wafer surface preparation and cleaning processes. E-HCl is a critical component in the Standard Clean 1 (SC-1) and Standard Clean 2 (SC-2) sequences, used to remove metallic contaminants and native oxides without damaging the delicate circuit patterns etched onto silicon wafers. Its role is becoming increasingly complex as feature sizes shrink below 10nm, necessitating even stricter impurity controls to prevent defects that could compromise device yield and performance. Furthermore, E-HCl is employed in specific etching operations and in the fabrication of photovoltaic cells and flat panel displays (FPDs), though its highest value application remains in advanced semiconductor manufacturing where purity requirements are the most demanding and cost-intensive.

Key driving factors propelling market growth include the massive global expansion of semiconductor fabrication capacity, particularly in regions like Asia Pacific (APAC) where governments are incentivizing domestic chip production. The proliferation of complex electronic devices, coupled with the build-out of 5G infrastructure, artificial intelligence accelerators, and high-performance computing (HPC) centers, is accelerating demand for high-quality integrated circuits (ICs), thereby increasing the consumption of E-HCl. Continuous technological advancements in chemical synthesis and purification techniques are also contributing to market expansion by enabling the production of E-HCl grades that meet the exacting specifications of next-generation fabrication processes.

- Product Description: Ultra-high purity liquid acid (HCl) with metallic impurity content typically below 1 ppb, specifically tailored for microelectronics.

- Major Applications: Silicon wafer cleaning (post-etch residue removal, metallic contaminant scrubbing), silicon etching, epitaxy processes, and manufacturing of FPDs and solar cells.

- Benefits: Ensures high device yield, prevents gate oxide breakdown, maintains structural integrity of nanoscale circuits, and meets stringent industry cleanliness standards.

- Driving Factors: Expansion of semiconductor manufacturing capacity globally, increasing adoption of advanced process nodes (below 14nm), and rising demand for high-density memory and logic chips.

Electronic Grade Hydrochloric Acid Market Executive Summary

The Electronic Grade Hydrochloric Acid market is undergoing significant transformation, primarily characterized by accelerating demand in the Asia Pacific region, driven by massive investments in new fabrication facilities in China, South Korea, and Taiwan. Current business trends indicate a critical shift towards higher purity grades (G5/ppt level), necessitated by the adoption of multi-patterning techniques and extreme ultraviolet (EUV) lithography, which are extremely sensitive to chemical contaminants. Suppliers are concentrating efforts on optimizing their purification technologies, such as advanced distillation and ion exchange systems, to meet these exacting standards, thereby increasing R&D expenditures. Geopolitical influences, including trade disputes and governmental mandates for supply chain localization, are forcing semiconductor chemical users to diversify their sourcing strategies, leading to greater capacity expansion among regional chemical providers to ensure supply resilience and quality control.

Regionally, Asia Pacific holds the dominant position in the consumption of E-HCl, directly corresponding to the concentration of major semiconductor manufacturers and foundries in this area. North America and Europe maintain critical roles as innovation hubs, focusing primarily on the development and production of specialized, ultra-high-purity chemical grades, often serving captive demand or highly specialized niche segments. The stringent regulatory environment in developed economies, particularly regarding chemical handling and waste disposal, adds complexity but also drives innovation in closed-loop recycling and sustainable chemical management practices. The competitive landscape is intensely focused on vertical integration and localized distribution networks to ensure swift delivery and minimize the risk of contamination during transit, which is paramount for maintaining chemical integrity.

Segment trends reveal that the G4 (parts per billion or ppb) grade currently commands the largest market share by volume, serving mature nodes and general cleaning applications, but the G5 (parts per trillion or ppt) segment is projected to exhibit the highest CAGR through the forecast period. This rapid growth in the G5 segment is directly linked to the production ramp-up of cutting-edge memory and logic chips (e.g., 5nm and below). Application-wise, wafer cleaning remains the most significant consumer segment, continuously expanding due to the increasing number of cleaning steps required in advanced fabrication flows. Companies are strategically investing in capacity expansion dedicated solely to these high-purity grades to capitalize on the increasing capital expenditures of leading chipmakers.

- Business Trends: Emphasis on supply chain resilience, shift toward G5 (ppt) purity grades, consolidation among specialized chemical suppliers, and heavy capital expenditure in advanced purification technologies.

- Regional Trends: APAC dominating consumption due to centralized semiconductor fabrication; rising importance of localized supply chains in North America and Europe.

- Segments Trends: G5 Grade exhibiting the fastest growth rate; Wafer Cleaning application segment maintaining the largest market share due to increasing process complexity.

AI Impact Analysis on Electronic Grade Hydrochloric Acid Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Electronic Grade Hydrochloric Acid market frequently revolve around two main themes: the immediate demand spike generated by AI hardware and the long-term operational efficiencies introduced by AI in chemical manufacturing and quality control. Common questions address how the intense need for AI accelerators (GPUs, TPUs) and high-bandwidth memory (HBM) impacts E-HCl consumption, given that these components require the most advanced and rigorous semiconductor manufacturing processes. Additionally, users are keenly interested in how AI-driven predictive maintenance and quality assurance systems, which utilize sophisticated sensor data and machine learning, can enhance the purity and consistency of E-HCl production, thereby reducing defects and operating costs for suppliers.

The most immediate and profound impact of AI is its role as a key demand accelerator. The manufacturing of AI chips—characterized by massive die sizes, complex heterogeneous integration, and advanced packaging techniques—necessitates a significantly higher volume and higher purity level of process chemicals, including E-HCl, per wafer compared to standard commodity chips. The shift to advanced nodes (5nm, 3nm) required for these high-performance applications mandates increased cleaning cycles and meticulous control over contamination, directly translating into greater E-HCl consumption. Furthermore, the global race to establish leading AI computing infrastructure fuels substantial capital investment in new fabs, which inherently drives market growth for all upstream materials like E-HCl.

Beyond demand generation, AI is beginning to optimize the E-HCl supply chain itself. Manufacturers are deploying AI and machine learning algorithms to monitor real-time data from purification columns, distillation units, and quality control instruments. These AI systems can rapidly detect minute deviations in impurity levels, predict equipment failures before they occur, and automatically adjust process parameters to maintain ultra-stable chemical purity. This enhanced precision in manufacturing reduces batch variability, improves overall chemical yield, and ensures that the stringent G5 (ppt) standards required by advanced chipmakers are consistently met. This operational enhancement driven by AI is crucial for mitigating the extremely high cost associated with chemical contamination in semiconductor production.

- AI hardware drives substantial consumption of E-HCl due to reliance on advanced semiconductor nodes (5nm and below).

- Increased cleaning cycles for complex AI chips necessitates higher volumes of ultra-pure E-HCl per wafer.

- AI and machine learning algorithms are utilized in manufacturing processes for predictive quality control and maintaining ultra-high purity levels (ppt).

- Predictive maintenance driven by AI optimizes production efficiency and reduces downtime in E-HCl purification plants.

- Automation and smart monitoring minimize human handling, further reducing contamination risks in chemical delivery and storage.

DRO & Impact Forces Of Electronic Grade Hydrochloric Acid Market

The dynamics of the Electronic Grade Hydrochloric Acid market are governed by a robust interplay of driving forces, restrictive limitations, and emerging opportunities, all of which are amplified by significant impact forces inherent to the semiconductor ecosystem. The primary drivers include sustained global growth in semiconductor demand, particularly from advanced applications like 5G, AI, and automotive electronics, which necessitate continuous expansion of fabrication capacity. Simultaneously, restraints, such as the extremely high capital investment required for maintaining G5 purification facilities and the inherent volatility of raw material sourcing, temper market growth. Opportunities arise from technological advancements allowing for specialized, higher-margin grades, and the increasing trend toward chemical recycling and resource efficiency, which addresses both environmental concerns and supply chain risks. These internal market forces are powerfully impacted by geopolitical stability, regulatory mandates concerning chemical safety, and the intense competitive pressure from localized suppliers aiming to achieve supply chain independence.

Key drivers center on the technological requirements of modern integrated circuits. As chip geometries shrink and 3D structures (like 3D NAND) become standard, the number of required wet cleaning steps in the manufacturing process drastically increases, directly escalating E-HCl consumption per finished device. This trend is compounded by the high capacity utilization rates observed across major semiconductor foundries globally, ensuring consistent demand. Furthermore, the increasing complexity of materials used in advanced semiconductor stacks, which requires selective and highly controlled etching chemistries, reinforces the need for extremely pure E-HCl, as even minute impurities can lead to catastrophic yield loss during sophisticated processing steps.

However, the market faces significant restraints. Manufacturing E-HCl to G4 and especially G5 standards demands state-of-the-art purification infrastructure, which is highly capital intensive and requires specialized operational expertise, creating high barriers to entry for new players. Additionally, the handling, storage, and transportation of hazardous chemical substances are subject to stringent environmental and safety regulations, increasing operational costs. Opportunities are abundant in the development of closed-loop systems for purifying and reusing spent E-HCl mixtures, driven by both sustainability goals and the necessity to secure stable, domestic chemical sources. The greatest impact forces remain the global semiconductor capital expenditure cycles and the critical need for regional supply security, especially as leading economies prioritize domestic technology independence, leading to unprecedented investment in localized chemical supply capabilities to mitigate geopolitical and logistics risks.

Segmentation Analysis

The Electronic Grade Hydrochloric Acid market is highly segmented based on the required purity level, reflecting the varying demands across different stages of semiconductor manufacturing and diverse end-user applications. The purity classification—typically categorized based on maximum metallic impurity content (e.g., parts per billion or ppb, and parts per trillion or ppt)—is the most critical determinant of value and technological complexity in this market. Further segmentation by application highlights the dominant role of wafer cleaning, which consumes the bulk of the volume, followed by specialized etching processes and usage in supporting electronic components like solar cells and flat panel displays. Geographical segmentation underscores the critical manufacturing concentration in the Asia Pacific region, which dictates global consumption patterns and supply chain requirements.

- By Grade:

- G4 Grade (PPB Level)

- G5 Grade (PPT Level)

- By Application:

- Wafer Cleaning and Surface Preparation

- Etching Processes (Wet Etching)

- Solar Cell Manufacturing

- Flat Panel Display (FPD) Fabrication

- Other Electronic Processes

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Electronic Grade Hydrochloric Acid Market

The value chain for Electronic Grade Hydrochloric Acid is characterized by extremely specialized processes and high quality control demands, starting from basic raw material procurement (upstream) through purification, distribution, and final usage (downstream). Upstream, the primary raw material is industrial-grade hydrochloric acid, typically derived as a co-product of chlor-alkali production or through synthesis from hydrogen and chlorine. The crucial step occurs at the refining stage, where standard HCl undergoes rigorous purification processes—including multiple stages of distillation, ion exchange, and membrane filtration—to reduce metallic ions, non-volatile residues, and particulates to ppt levels. This purification step represents the highest value-add activity and is a significant differentiator among competitors, necessitating extensive capital investment and proprietary technology.

Midstream activities involve the highly controlled packaging and logistics of the ultra-pure chemical. E-HCl must be packaged in specialized, non-contaminating containers, often made of high-density polyethylene (HDPE) or PFA, within Class 100 or better cleanroom environments. Distribution channels are highly secure and often dedicated, prioritizing direct and short supply routes to minimize the risk of external contamination or degradation. Direct distribution, where the supplier delivers directly to the fab, is predominant for G5 grades, ensuring maximum quality control. Indirect channels, involving specialized chemical distributors or third-party logistics providers, are sometimes used for lower grades or smaller end-users, but require strict adherence to purity protocols.

Downstream, the end-users are primarily advanced semiconductor fabrication facilities, followed by FPD and solar manufacturers. The efficiency and yield of the downstream manufacturing process are critically dependent on the purity consistency of the E-HCl supplied. Waste management and disposal of spent chemicals form a final, integral part of the value chain. As regulatory scrutiny increases, the demand for suppliers capable of offering full lifecycle chemical management, including reclaiming and recycling spent acid, is growing. This integrated approach not only addresses environmental mandates but also helps secure stable supply in regions facing resource constraints, solidifying the relationship between supplier and high-volume consumer.

Electronic Grade Hydrochloric Acid Market Potential Customers

The primary consumers and end-users of Electronic Grade Hydrochloric Acid are major global corporations operating within the microelectronics manufacturing sphere, characterized by intense capital expenditure and rigorous quality demands. These customers can be broadly segmented into integrated device manufacturers (IDMs), pure-play semiconductor foundries, and memory chip specialists. IDMs such as Intel and Samsung use E-HCl internally across their entire manufacturing process, from raw wafer preparation to final device assembly. Foundries like TSMC and GlobalFoundries, which produce chips for a vast array of fabless companies, represent massive, centralized consumers whose demand dictates much of the market’s volume and purity requirements.

Memory manufacturers, particularly those focusing on advanced DRAM and high-density 3D NAND flash, represent a segment with exceptionally stringent purity requirements, driving demand for G5 (ppt) grade E-HCl. The complexity and layering of 3D structures require numerous, highly controlled cleaning steps, significantly boosting the consumption intensity of ultra-pure chemicals. Beyond traditional semiconductor players, the market extends to manufacturers of photovoltaic (PV) solar cells, which use E-HCl for surface texturing and impurity removal, and companies involved in the production of large-area display technologies, such as TFT-LCD and OLED panels, where surface cleaning is essential to prevent pixel defects.

The procurement strategies of these potential customers are heavily focused on establishing long-term, qualified vendor relationships to ensure a guaranteed, consistent supply of chemicals that meet specific internal specifications, often exceeding general industry standards. Supply chain redundancy and geographical proximity are key purchasing criteria, especially for customers located in regions promoting technology self-sufficiency. Consequently, E-HCl suppliers must not only demonstrate ultra-high purification capability but also robust, reliable logistics and exceptional technical support to maintain their status as preferred vendors for these critical high-tech customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,320 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, KMG Chemicals, Linde Group, Avantor Performance Materials, Asia Union Electronic Chemicals (AUEC), Sumitomo Chemical, T.N.C. Industrial, Solvay, PVS Chemicals, Honeywell International, Mitsubishi Chemical, Air Liquide, Iwatani Corporation, Showa Denko, Eastman Chemical Company, Formosa Plastics Corporation, Merck KGaA, Stella Chemifa Corporation, Guangdong Xinyang, Suzhou Crystal Clear Chemical. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electronic Grade Hydrochloric Acid Market Key Technology Landscape

The technology landscape governing the Electronic Grade Hydrochloric Acid market is defined by continuous innovation in ultra-purification and analytical detection methodologies, driven by the semiconductor industry’s unrelenting demand for higher purity. The primary technological focus involves advanced distillation techniques, particularly azeotropic or fractional distillation under controlled atmospheric conditions, which are critical for separating HCl from volatile impurities and reducing overall non-volatile residue (NVR). However, achieving G5 (ppt) purity requires integration of secondary and tertiary purification steps. Ion exchange resins and sophisticated membrane filtration systems are utilized to scavenge residual metallic ions and minute particulates that distillation alone cannot eliminate. The effectiveness of these technologies hinges on the maintenance of impeccable cleanroom environments and utilization of advanced materials in construction to prevent leaching from equipment surfaces, maintaining chemical integrity throughout the process.

Furthermore, the ability to accurately verify and certify the purity level is as important as the purification process itself, leading to significant advancements in analytical technology. Suppliers heavily rely on advanced trace element detection equipment, such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Glow Discharge Mass Spectrometry (GD-MS), which can quantify metallic impurities down to the parts per trillion range. The trend is moving towards in-line, real-time purity monitoring systems integrated with AI-driven analytics, ensuring that any deviation in the chemical composition is instantaneously corrected or flagged, preventing the shipment of contaminated batches. This technological necessity for real-time validation imposes substantial investment burdens but is crucial for securing qualification with leading-edge semiconductor fabricators who require statistical process control data for every shipment.

A key evolving technology is the development of robust chemical recycling and repurification solutions. As the consumption of ultra-pure chemicals increases, the environmental and economic pressures to recycle spent E-HCl grow stronger. Specialized systems employing proprietary membrane separation and electrochemical processes are being developed to recover and upgrade contaminated waste acid back to electronic grade standards. This circular economy approach not only offers an opportunity for suppliers to provide a full chemical lifecycle service but also addresses the strategic imperative of resource security, mitigating risks associated with raw material sourcing and waste disposal costs. These technological capabilities are increasingly viewed as a competitive advantage within the highly regulated chemical supply sector.

Regional Highlights

Regional dynamics in the Electronic Grade Hydrochloric Acid market are fundamentally determined by the location of high-volume, advanced semiconductor manufacturing facilities, leading to a profound geographical concentration of demand.

- Asia Pacific (APAC): This region is the undisputed global leader in E-HCl consumption, accounting for the largest market share due to the centralized presence of major global foundries, IDMs, and memory manufacturers in countries like China, South Korea, Taiwan, and Japan. Massive government investments in semiconductor localization (especially in China) are driving rapid capacity expansion, fueling unparalleled demand for both G4 and fast-growing G5 purity grades. Taiwan and South Korea remain critical hubs, constantly pushing the purity requirements due to their pioneering role in sub-7nm node technologies.

- North America: Characterized by high technological intensity and strong R&D capabilities, North America is a key market for specialized, extremely high-purity chemical grades, often supporting pilot production lines and advanced materials research. Recent legislative initiatives aimed at bolstering domestic chip production (e.g., the CHIPS Act) are driving significant investment in new U.S.-based fabrication plants, which is projected to rapidly increase regional E-HCl demand and localize supply chains over the forecast period.

- Europe: The European market is growing steadily, supported by regional initiatives designed to strengthen the domestic semiconductor ecosystem, particularly in Germany and Ireland. Demand is driven by established IDMs and the increasing need for advanced chips in the burgeoning automotive electronics sector. The region focuses strongly on sustainable chemical practices and localized supply security, driving demand for innovative, resource-efficient purification and distribution solutions.

- Middle East and Africa (MEA) and Latin America: These regions currently represent nascent or smaller-scale markets for Electronic Grade Hydrochloric Acid, primarily serving smaller electronics assembly operations or less advanced semiconductor processing. Growth prospects are modest but tied to potential future investments in regional industrial diversification and technology manufacturing hubs, requiring specialized logistical solutions for chemical delivery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electronic Grade Hydrochloric Acid Market.- BASF SE

- KMG Chemicals (now part of Cabot Microelectronics)

- Linde Group

- Avantor Performance Materials

- Asia Union Electronic Chemicals (AUEC)

- Sumitomo Chemical

- T.N.C. Industrial

- Solvay

- PVS Chemicals

- Honeywell International

- Mitsubishi Chemical

- Air Liquide

- Iwatani Corporation

- Showa Denko

- Eastman Chemical Company

- Formosa Plastics Corporation

- Merck KGaA

- Stella Chemifa Corporation

- Guangdong Xinyang

- Suzhou Crystal Clear Chemical

Frequently Asked Questions

Analyze common user questions about the Electronic Grade Hydrochloric Acid market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between G4 and G5 Electronic Grade Hydrochloric Acid?

The distinction lies in the maximum allowable concentration of metallic impurities. G4 grade E-HCl typically guarantees impurity levels in the parts per billion (ppb) range, suitable for mainstream manufacturing. G5 grade mandates ultra-low purity, with impurities measured in the parts per trillion (ppt) range, essential for advanced semiconductor nodes (e.g., 7nm and below) and high-density memory production to prevent defects.

How does the shift to smaller semiconductor nodes impact E-HCl consumption?

The miniaturization of semiconductor nodes significantly increases E-HCl consumption per wafer. Smaller features require more sophisticated processing and numerous cleaning steps throughout the fabrication sequence to remove ultra-fine contaminants, resulting in a higher overall chemical volume requirement and a greater demand for the most expensive G5 (ppt) grades.

Which region dominates the consumption of Electronic Grade Hydrochloric Acid?

Asia Pacific (APAC) dominates the consumption of Electronic Grade Hydrochloric Acid. This is due to the high concentration of advanced semiconductor manufacturing foundries and integrated device manufacturers located in Taiwan, South Korea, Japan, and mainland China, which collectively account for the majority of global chip production.

What technological advancements are crucial for E-HCl purification?

Key technological advancements include multi-stage fractional and azeotropic distillation, specialized ion exchange systems for trace metallic removal, and advanced membrane filtration for particulate control. Real-time analytical monitoring using ICP-MS is also critical to verify and maintain ppt purity standards consistently throughout manufacturing and packaging.

What are the main supply chain risks associated with Electronic Grade Hydrochloric Acid?

The primary risks include the difficulty and expense of maintaining ultra-pure supply chains over long distances, geopolitical factors influencing trade and chemical logistics, and high barriers to entry for purification technology. Ensuring consistent supply integrity without external contamination during transit is a constant logistical challenge that drives the trend toward localized sourcing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager