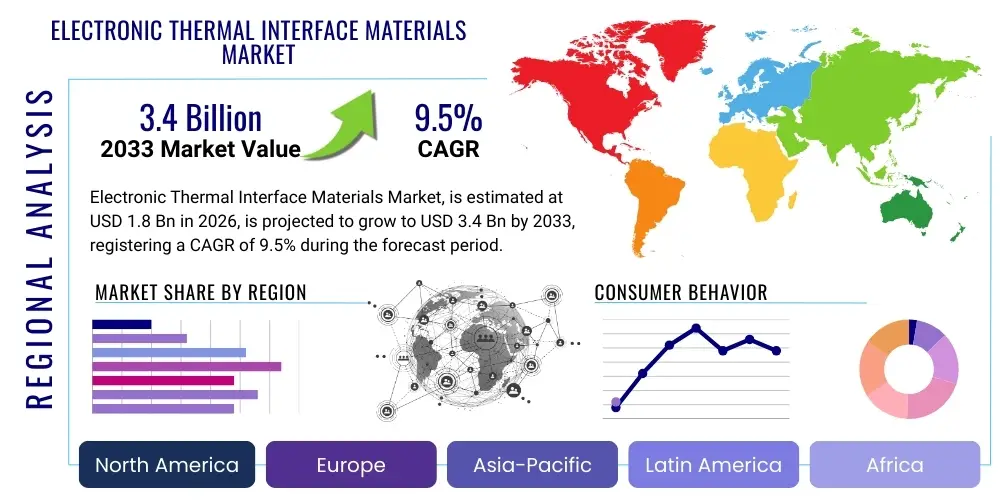

Electronic Thermal Interface Materials Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439159 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Electronic Thermal Interface Materials Market Size

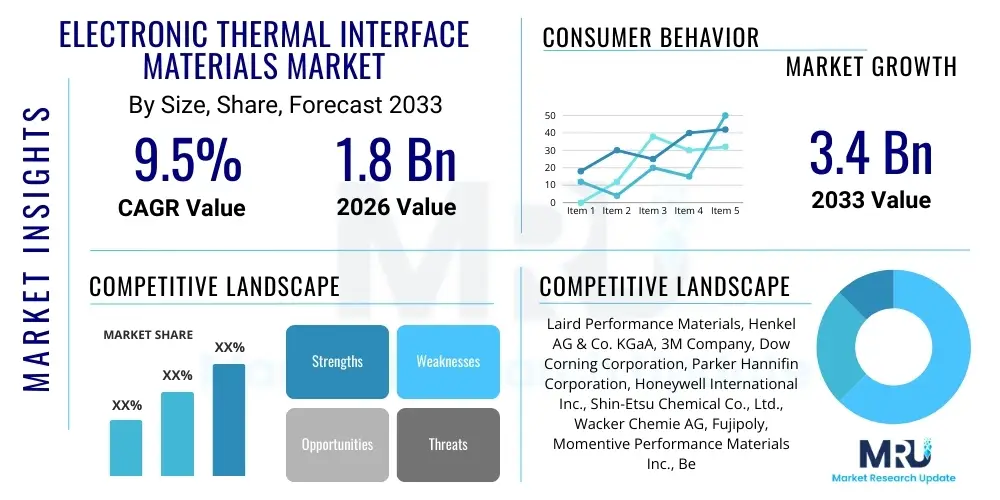

The Electronic Thermal Interface Materials Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at $1.8 Billion in 2026 and is projected to reach $3.4 Billion by the end of the forecast period in 2033.

Electronic Thermal Interface Materials Market introduction

Electronic Thermal Interface Materials (TIMs) are crucial components used in high-performance electronic devices to facilitate efficient heat transfer between two surfaces, typically a heat-generating component (like a microprocessor or power semiconductor) and a heat dissipation mechanism (such as a heatsink or cold plate). These materials are specifically designed to fill microscopic air gaps and surface imperfections that inherently exist between mating surfaces, which act as thermal insulators and significantly impede heat flow. The primary function of TIMs is to minimize thermal resistance at the interface, thereby maintaining the operating temperature of electronic components within safe limits, ensuring reliability, and maximizing performance longevity. The effectiveness of a TIM is primarily defined by its thermal conductivity, thickness, and ease of application, making material science a critical factor in product development across this sector.

The product portfolio within the Electronic Thermal Interface Materials market is highly diversified, encompassing a range of formulations tailored for specific applications and thermal requirements. Key product types include thermal greases (non-curing compounds offering high performance but potential pump-out issues), thermal pads (pre-formed elastomers providing ease of use and reworkability), phase change materials (PCMs) (which transition state at operating temperature for optimal wetting), and sophisticated thermal adhesives and gap fillers. Major applications driving the market expansion include the rapidly growing sectors of high-performance computing (HPC), advanced automotive electronics (especially in electric vehicle battery management and power inverters), consumer electronics miniaturization, and the massive buildout of 5G infrastructure and data centers. These sectors demand increasingly robust thermal management solutions capable of handling extreme heat fluxes generated by modern high-density integrated circuits.

The inherent benefits derived from employing advanced TIMs are central to the continued performance scaling of electronics. By significantly lowering the operating temperature, TIMs prevent thermal throttling, which is essential for maintaining consistent processing speed in CPUs and GPUs. Furthermore, effective thermal management dramatically increases the Mean Time Between Failures (MTBF) for sensitive electronic components, reducing warranty claims and maintenance costs for end-users. The major driving factors supporting market growth include the inexorable trend towards device miniaturization, which concentrates high power output into smaller volumes, and the escalating power density of chips used in next-generation AI and autonomous systems. Regulatory standards promoting energy efficiency and the global push toward vehicle electrification further solidify the market's robust growth trajectory, demanding specialized, durable, and highly conductive TIM solutions.

Electronic Thermal Interface Materials Market Executive Summary

The Electronic Thermal Interface Materials market is experiencing profound shifts driven by transformative business trends centered on material innovation and strategic integration into complex electronic assemblies. A key business trend involves the shift away from traditional silicone-based greases toward advanced polymer matrices loaded with high-conductivity fillers, such as boron nitride, aluminum nitride, or even diamond particles, to achieve thermal conductivity values exceeding 10 W/mK. Manufacturers are focused on developing materials that offer exceptional long-term reliability under severe thermal cycling conditions, critical for automotive and aerospace applications. Furthermore, the market structure is becoming increasingly competitive, prompting key players to engage in strategic partnerships with chip manufacturers (OEMs) early in the design phase to ensure custom TIM solutions are integrated seamlessly, thereby accelerating product adoption and capturing specialized segments like high-end server processors.

Regionally, the Asia Pacific (APAC) region maintains its undeniable dominance, driven by the concentration of global electronic manufacturing hubs, large-scale semiconductor production facilities, and rapid expansion of data centers, particularly in countries like China, South Korea, and Taiwan. APAC's sheer volume of production across consumer electronics, telecommunications equipment, and automotive manufacturing makes it the largest consumer base for TIMs. However, North America and Europe are exhibiting the fastest growth in terms of value, largely propelled by escalating investments in advanced High-Performance Computing (HPC) infrastructure, 5G network deployment, and stringent energy efficiency regulations mandating highly effective cooling solutions for enterprise and defense sectors. The need for advanced liquid cooling integration, often requiring specialized TIMs for cold plate applications, is particularly prevalent in the US and European data center markets, pushing innovation in higher-performance thermal pads and gap fillers.

Analysis of market segmentation trends reveals that gap fillers and thermal pads collectively represent the fastest-growing segment, primarily due to their increasing adoption in automotive battery packs, complex electronic control units (ECUs), and telecommunication base stations where ease of automation and high compressibility are paramount. Within the chemistry segment, silicone-free alternatives are gaining traction, especially in sensitive optical and aerospace applications where outgassing is strictly prohibited. The application segment growth is overwhelmingly steered by the automotive sector, benefiting from the global pivot towards electric and hybrid vehicles. Specifically, the demanding thermal requirements of traction inverters, onboard chargers, and battery modules necessitate large volumes of high-performance gap fillers, ensuring that the automotive category is poised to overshadow traditional consumer electronics applications in terms of future growth value and material performance specifications.

AI Impact Analysis on Electronic Thermal Interface Materials Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Electronic Thermal Interface Materials market overwhelmingly center on the exponential rise in heat flux densities generated by modern AI accelerators, such as specialized GPUs and Tensor Processing Units (TPUs). Common user concerns revolve around whether existing TIM technologies can sustain the temperatures and power consumption levels inherent in large-scale AI training models and inference data centers. Users frequently seek information on the viability of exotic materials like liquid metals or hybrid phase change materials to handle chip-level thermal loads exceeding 500 Watts. Furthermore, there is significant interest in how AI systems influence the adoption of direct-to-chip liquid cooling solutions, and what role TIMs play in enabling the transition from traditional air cooling to these high-efficiency liquid systems, often requiring materials resistant to chemical interaction with dielectric fluids.

The proliferation of AI infrastructure demands an unprecedented level of thermal management efficiency, translating directly into heightened demand for ultra-high thermal conductivity TIMs. AI chips, optimized for parallel processing, consume vastly more power than traditional microprocessors, packing hundreds of billions of transistors into increasingly confined spaces. This concentrated heat generation renders standard thermal greases inadequate, compelling major data center operators and hardware manufacturers (like NVIDIA and AMD) to mandate the use of advanced, high-reliability TIM solutions. This shift is not merely an incremental upgrade but a fundamental pivot towards specialized formulations designed for extreme environments, significantly boosting the average selling price and technical complexity of materials required in the server and supercomputing segment. The integration of AI extends beyond the data center, influencing edge computing devices, where miniaturization coupled with AI processing power demands compact, highly effective thermal solutions like specialized thermal tapes and thin-film coatings.

The impact of AI also drives material selection innovation through manufacturing precision. The need to optimize every micromillimeter of the thermal path in AI accelerator modules means that TIM application processes must be highly automated and consistently precise. This favors materials like pre-cured gap pads and highly controlled dispensing systems for gap fillers, reducing human error and ensuring uniform thermal impedance across complex stacks of chips (e.g., stacked memory architectures). Moreover, AI development cycles often involve rapid hardware iterations, necessitating TIMs that are reliable, easily applied, and, crucially, easily reworkable without damaging expensive silicon, reinforcing the market trend towards phase change materials and certain classes of gap pads in professional AI hardware environments.

- Increased heat flux demands ultra-high thermal conductivity TIMs (>12 W/mK).

- AI data centers drive demand for TIMs compatible with liquid cooling cold plates and dielectric fluids.

- Greater adoption of specialized materials (e.g., Liquid Metal TIMs, advanced carbon-based composites) for core processors.

- Focus shifts towards high-reliability and reworkability due to high cost of AI accelerator chips.

- AI integration in edge computing necessitates compact and thin-form factor TIM solutions.

DRO & Impact Forces Of Electronic Thermal Interface Materials Market

The Electronic Thermal Interface Materials market is strongly propelled by continuous advancements in electronics performance (Drivers), yet constrained by material cost and application challenges (Restraints), while presenting significant growth opportunities stemming from emerging applications in electrification and high-speed data transfer (Opportunity). The primary driver is the pervasive trend of increasing power density in semiconductor devices across all sectors, necessitating better thermal management to prevent catastrophic failure and maintain performance specifications. Restraints include the high cost associated with manufacturing exotic filler materials (like silver, diamond, or certain ceramics), complex application processes requiring specialized equipment, and the persistent challenge of material long-term reliability, particularly regarding pump-out and dry-out phenomena in high-stress environments. Opportunities are particularly robust in the electric vehicle market, requiring durable gap fillers for battery thermal management systems, and the global deployment of 5G and 6G infrastructure, which demands robust cooling for densely packed base station amplifiers and components.

The most profound impact force shaping this market is the synergistic requirement for both extreme performance and stringent reliability. As chips become smaller and hotter, the thermal resistance contribution of the TIM layer becomes proportionally more significant to the overall system thermal budget. This forces manufacturers to invest heavily in R&D to push the thermal conductivity limits while simultaneously ensuring the materials maintain mechanical integrity and consistency over 10-20 years of operation, crucial for automotive and enterprise hardware life cycles. The interplay between thermal performance and mechanical properties is complex; highly filled materials often achieve excellent thermal conductivity but may lack the requisite softness or compliance required to fill large, non-uniform gaps found in power module assemblies. This creates a segmentation challenge where different applications necessitate vastly different material chemistries and mechanical specifications.

Furthermore, global supply chain dynamics exert considerable influence, particularly regarding the sourcing and pricing of high-purity ceramic and metallic fillers. Geopolitical factors and trade policies can impact the availability and cost of key components like aluminum oxide, boron nitride, and high-purity silver used in premium TIM products. The environmental impact and regulatory landscape are also emerging impact forces; manufacturers are increasingly expected to develop halogen-free, RoHS-compliant, and environmentally sustainable TIM solutions. This regulatory push, combined with the escalating performance requirements from key end-user markets (such as defense and aerospace), mandates continuous technological evolution, making the market highly sensitive to material science breakthroughs and manufacturing efficiencies that can reduce costs while enhancing performance parameters.

Segmentation Analysis

The Electronic Thermal Interface Materials market is intricately segmented based on material type, product form, application, and end-user, reflecting the diverse and specialized thermal requirements across the electronics industry. Material types primarily differentiate between polymer matrices (silicone, epoxy, polyurethane) and the high-conductivity filler content (ceramic, metal, carbon), which determines the ultimate thermal performance. The product form segmentation is critical for application engineering, separating highly flowable greases and gels from structured pads, tapes, and phase change materials. Application segmentation focuses on where the heat is generated and managed, covering core areas like ICs/Processors, power semiconductors, LEDs, and memory modules. Finally, end-user segmentation clearly distinguishes between sectors with unique reliability and volume demands, notably Automotive, Consumer Electronics, Telecommunications, and High-Performance Computing, providing clarity on market priorities and growth vectors within each category.

- By Type:

- Greases and Pastes (Non-curing compounds)

- Thermal Pads and Tapes (Elastomers and films)

- Gap Fillers (Putty, Dispensable Gel)

- Phase Change Materials (PCMs)

- Thermal Adhesives and Potting Compounds (Curing compounds)

- Liquid Metal TIMs

- By Material Chemistry:

- Silicone-based TIMs

- Non-Silicone based TIMs (Acrylic, Epoxy, Urethane)

- Carbon-based TIMs (Graphite, Diamond)

- Metallic Fillers (Aluminum, Silver)

- Ceramic Fillers (Alumina, Boron Nitride, Aluminum Nitride)

- By Application:

- Integrated Circuits (CPUs, GPUs, ASICs)

- Power Electronics (IGBT modules, MOSFETs, Diodes)

- LED Lighting

- Memory and Storage Devices

- Battery Thermal Management Systems (BTMS)

- By End-User:

- Consumer Electronics (Smartphones, Laptops)

- Automotive (EV/HEV, Infotainment, ADAS)

- Telecommunications (5G Base Stations, Network Equipment)

- Industrial & Commercial (Factory Automation, Power Supplies)

- Aerospace & Defense

- Healthcare and Medical Devices

- High-Performance Computing & Data Centers

Value Chain Analysis For Electronic Thermal Interface Materials Market

The value chain for Electronic Thermal Interface Materials begins with the sophisticated sourcing and refinement of specialized raw materials, primarily focusing on high-purity polymer resins and highly conductive filler particles. Upstream analysis highlights the critical role of chemical suppliers providing specialized silicone polymers, acrylics, and epoxy resins, alongside material processors specializing in creating sub-micron powders of materials like boron nitride, alumina, zinc oxide, and synthetic graphite. The quality and uniformity of these filler particles directly dictate the thermal performance and cost of the final TIM product. Tight control over particle size distribution and surface treatment is essential, meaning dependency rests heavily on a few specialized material science companies capable of producing high-grade thermal fillers. Disruptions in the supply of these specialty chemicals or fillers can significantly impact the pricing and availability of high-end TIM solutions globally.

The midstream segment involves the core manufacturing process where TIM formulators blend the polymer matrix with the conductive fillers, additives, and curing agents to create the finished product forms (greases, pads, or phase change sheets). This stage involves proprietary mixing techniques, dispersion technologies, and precise quality control to ensure uniform thermal conductivity and desired physical properties like viscosity and hardness. Distribution channels are bifurcated: direct sales typically handle high-volume, custom orders to Tier 1 OEMs in the automotive and data center industries, requiring technical support and precise material calibration. Indirect channels utilize distributors and value-added resellers (VARs) to serve smaller customers, aftermarket needs, and a wider geographical area, often handling standardized thermal pad stock or general-purpose thermal greases. The shift towards automated manufacturing of electronics has intensified the need for TIM suppliers to provide materials optimized for automated dispensing and assembly lines, particularly for high-volume applications like automotive battery packs.

Downstream analysis focuses on the integration and adoption by various end-users. The ultimate buyers—electronic device manufacturers—are highly sensitive to factors beyond simple thermal conductivity, prioritizing ease of application, long-term reliability against environmental stresses (humidity, vibration, temperature cycling), and overall cost of ownership. The value chain is heavily influenced by the semiconductor industry's roadmap; as new chip architectures are developed, TIM suppliers must simultaneously develop compliant materials. Technical support and collaborative design are paramount in the downstream segment, requiring TIM manufacturers to work closely with OEM thermal engineers to optimize bond line thickness (BLT) and application methodology. The high dependency on technical service makes the downstream channel a significant differentiator, often leveraging specialized application equipment and testing labs to ensure product quality and integration success for complex high-power assemblies.

Electronic Thermal Interface Materials Market Potential Customers

Potential customers for Electronic Thermal Interface Materials span the entire spectrum of high-technology manufacturing where efficient heat dissipation is a non-negotiable requirement for performance and safety. The primary and fastest-growing customer segment includes manufacturers of Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs), which require massive volumes of durable, high-compliance gap fillers for their battery thermal management systems (BTMS), power control units (PCUs), and traction inverters. These automotive buyers prioritize long-term reliability (often 15+ years), resistance to harsh environmental factors, and materials that facilitate automated assembly processes. The second crucial customer base is the Data Center and Cloud Infrastructure providers, who are constantly scaling up server density and adopting advanced AI accelerators, demanding ultra-high performance greases, liquid metal TIMs, and specialized pads for direct-to-chip cooling solutions.

Beyond these high-growth sectors, traditional but critical end-users include manufacturers of high-end Consumer Electronics, such as premium smartphones, gaming consoles, and high-performance laptops, which rely on thin-film TIMs and graphite sheets to manage heat in confined spaces. The Telecommunications sector, particularly companies deploying 5G and future 6G infrastructure, represents significant clientele. 5G base stations, being densely packed with high-power radio frequency (RF) components and processors, require robust thermal management solutions that can withstand outdoor environments and continuous operation. These customers seek materials with excellent dielectric strength and environmental stability, favoring thermal pads and rugged gap fillers.

Furthermore, specialized industrial and medical device manufacturers constitute a vital customer segment. Industrial automation relies on power modules, programmable logic controllers (PLCs), and motor drives that demand reliable thermal pads and adhesives to maintain operational uptime in harsh factory conditions. Medical imaging equipment (MRI, CT scanners) and high-power laser systems also require high-reliability, often custom-formulated TIMs to ensure consistent performance for safety-critical applications. These diverse customer needs underscore the fragmentation of the TIM market, where a one-size-fits-all solution is ineffective, forcing suppliers to maintain a broad portfolio catering to precise thermal, mechanical, and electrical specifications across various industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.8 Billion |

| Market Forecast in 2033 | $3.4 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Laird Performance Materials, Henkel AG & Co. KGaA, 3M Company, Dow Corning Corporation, Parker Hannifin Corporation, Honeywell International Inc., Shin-Etsu Chemical Co., Ltd., Wacker Chemie AG, Fujipoly, Momentive Performance Materials Inc., Bergquist (Henkel), KCC Corporation, Chomerics (Parker), Aavid Thermalloy, AI Technology Inc., Boyd Corporation, Master Bond Inc., Timtronics, Denka Company Limited, SEMIKRON. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electronic Thermal Interface Materials Market Key Technology Landscape

The technology landscape for Electronic Thermal Interface Materials is characterized by continuous material science breakthroughs aimed at maximizing thermal conductivity while maintaining critical physical properties such as compliance and low dielectric constant. A major technological focus is the optimization of filler morphology and loading levels. Researchers are moving beyond basic spherical fillers towards highly aligned structures, such as vertically oriented carbon fibers, carbon nanotubes (CNTs), and hexagonal boron nitride (h-BN) sheets, which facilitate anisotropic heat flow directly through the bond line. This focus on structured materials is essential for high-end applications, yielding thermal conductivities significantly higher than those achievable with randomly dispersed fillers. Furthermore, advancements in specialized phase change materials (PCMs) are crucial, offering high flowability during the initial thermal cycle to eliminate air voids, followed by solidification to prevent pump-out or migration during long-term operation, thus ensuring robust long-term performance.

Another rapidly evolving area is the development and adoption of exotic and ultra-high-performance TIMs, particularly Liquid Metal TIMs (LMTIMs). Composed typically of gallium alloys, LMTIMs offer exceptionally high thermal conductivity (often exceeding 50 W/mK) and are gaining traction in extreme high-power applications, especially in dedicated supercomputing and high-end gaming processors where the heat flux is localized and intense. However, the commercial application of LMTIMs requires specialized containment and barrier layers due to their corrosive nature toward common heat sink materials like aluminum, driving parallel innovation in encapsulation and surface treatment technologies. Concurrently, the rise of advanced manufacturing techniques like additive manufacturing (3D printing) is being explored to create custom, intricately structured thermal pads and complex gap filler geometries that optimize thermal paths in highly constrained electronic assemblies, reducing material waste and improving design flexibility.

The application technology aspect is equally critical. The shift towards large-format power modules and battery packs necessitates the use of automated dispensing systems for gap fillers, requiring TIM suppliers to formulate materials with highly controlled thixotropy and viscosity stability to ensure perfect, consistent bond line thickness across expansive surfaces. Sensor integration into thermal management systems (Smart TIMs) is an emerging technology, where materials are being developed to incorporate micro-sensors or temperature-sensitive elements that can report on their state and thermal performance in real-time. This level of monitoring is becoming essential in safety-critical applications like autonomous driving systems and high-voltage power electronics, allowing for predictive maintenance and real-time adjustment of cooling strategies, thereby enhancing overall system reliability and accelerating the adoption rate of specialized, high-cost TIM solutions.

Regional Highlights

- Asia Pacific (APAC): Dominance and Manufacturing Hub The APAC region commands the largest market share globally due to its established dominance in semiconductor manufacturing, consumer electronics production, and the exponential growth of its domestic automotive and data center industries. Countries such as China, South Korea, and Taiwan are central hubs for advanced component fabrication, creating an immense, continuous demand for all forms of TIMs, particularly thermal pads and greases for high-volume consumer goods. The rapid expansion of electric vehicle manufacturing, especially in China, is fueling unprecedented demand for large-volume, highly reliable gap fillers essential for battery thermal management systems. This region remains the engine of volume growth, driven by aggressive infrastructural investment in 5G and AI-related computing hardware.

- North America: Innovation and High-Performance Computing North America is characterized by high demand for cutting-edge, high-performance TIMs, primarily driven by investments in hyperscale data centers, advanced military/aerospace electronics, and leading-edge AI research infrastructure. The market here prioritizes performance over cost, leading to higher adoption rates of premium solutions like Phase Change Materials and specialized Liquid Metal TIMs for high-end server processors and GPUs. The U.S. market is significantly influenced by defense spending and the rapid development of autonomous vehicle technology, demanding extreme reliability and adherence to stringent quality standards for mission-critical electronic control units.

- Europe: Automotive Electrification and Industrial Automation The European market is heavily influenced by the stringent regulatory push toward vehicle electrification, making the automotive sector the primary growth catalyst for TIMs, particularly in Germany and Scandinavian countries. There is robust demand for reliable, high-compliance, and durable thermal gap fillers used in European electric vehicle battery packs and power electronics (inverters/converters). Furthermore, Europe's strong industrial base necessitates high-reliability TIMs for factory automation equipment, renewable energy systems (solar inverters, wind turbine controls), and railway applications, focusing on long lifespan and robust performance under variable environmental conditions.

- Latin America (LATAM) and Middle East & Africa (MEA): Emerging Infrastructure These regions currently hold smaller market shares but are poised for accelerated growth, largely driven by improving telecommunication infrastructure (4G/5G rollout) and increasing data localization requirements leading to new data center construction. In the Middle East, high ambient operating temperatures necessitate robust, high-temperature resistant TIMs for network equipment and solar power installations. While volume is lower, the growth potential is concentrated in smart city projects, energy sector upgrades, and initial manufacturing investments, requiring functional thermal management solutions to maintain infrastructure reliability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electronic Thermal Interface Materials Market.- Laird Performance Materials (A DuPont Business)

- Henkel AG & Co. KGaA (Including Bergquist)

- 3M Company

- Dow Corning Corporation

- Parker Hannifin Corporation (Including Chomerics)

- Honeywell International Inc.

- Shin-Etsu Chemical Co., Ltd.

- Wacker Chemie AG

- Fujipoly

- Momentive Performance Materials Inc.

- KCC Corporation

- Boyd Corporation

- AI Technology Inc.

- Master Bond Inc.

- Timtronics

- Denka Company Limited

- SEMIKRON

- Indium Corporation

- GrafTech International

- Heraeus Group

Frequently Asked Questions

Analyze common user questions about the Electronic Thermal Interface Materials market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between thermal grease and thermal pads, and when should each be used?

Thermal grease offers superior thermal conductivity and fills microscopic gaps more effectively due to its liquid/paste nature, resulting in lower thermal resistance; it is ideal for high-power, high-performance processors where minimizing temperature is critical. Thermal pads are solid, pre-formed materials providing easier application, higher conformability for uneven surfaces, and better electrical isolation; they are preferred for large area applications like battery modules, power semiconductors, and automated assembly processes where long-term stability against pump-out is required.

How does the shift towards electric vehicles (EVs) specifically impact the demand for Electronic TIMs?

EVs dramatically increase the demand for high-volume, highly reliable thermal gap fillers, primarily utilized in Battery Thermal Management Systems (BTMS) to dissipate heat from lithium-ion battery cells. EV applications demand thicker, highly compliant gap fillers with exceptional durability and long-term chemical stability to ensure battery safety and performance over the vehicle’s lifespan, making the automotive sector the fastest-growing application segment for high-performance TIMs.

What role does boron nitride play in modern high-performance Thermal Interface Materials?

Boron Nitride (BN) is one of the most widely used high-conductivity ceramic fillers in premium TIMs. Its critical role stems from its excellent thermal conductivity combined with high electrical insulation (dielectric strength), making it ideal for high-power electronic devices where both efficient heat transfer and electrical isolation are required, particularly in power modules and IGBTs, offering a superior performance balance compared to metal oxide fillers.

What are the main thermal failure modes associated with TIMs, and how are manufacturers addressing them?

The main failure modes include pump-out (migration of grease away from the interface under thermal cycling), dry-out (loss of volatile components), and material degradation leading to increased thermal impedance over time. Manufacturers are addressing these through R&D focused on proprietary high-stability polymer matrices, using advanced thixotropic additives to resist flow, and developing Phase Change Materials (PCMs) that solidify at operating temperatures to eliminate migration risks and enhance long-term reliability.

Which regional market shows the greatest potential for future growth in terms of technological adoption and value?

While Asia Pacific leads in volume, North America is expected to show the greatest growth potential in terms of value and technological adoption. This growth is driven by massive investment in next-generation AI accelerators and High-Performance Computing (HPC) infrastructure, requiring ultra-premium, high-cost TIMs like Liquid Metal and advanced structured gap fillers necessary for managing extreme heat loads (often exceeding 500W per chip) found in cutting-edge data center hardware.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager