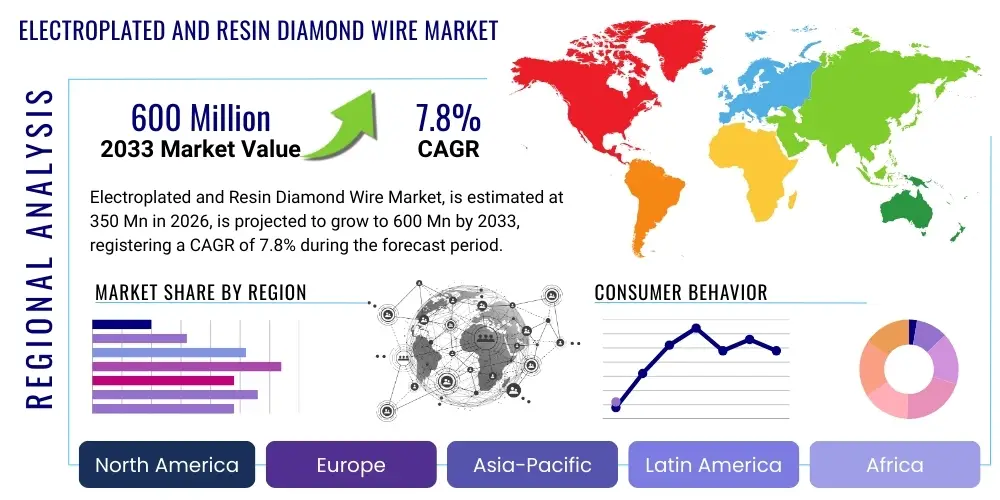

Electroplated and Resin Diamond Wire Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439847 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Electroplated and Resin Diamond Wire Market Size

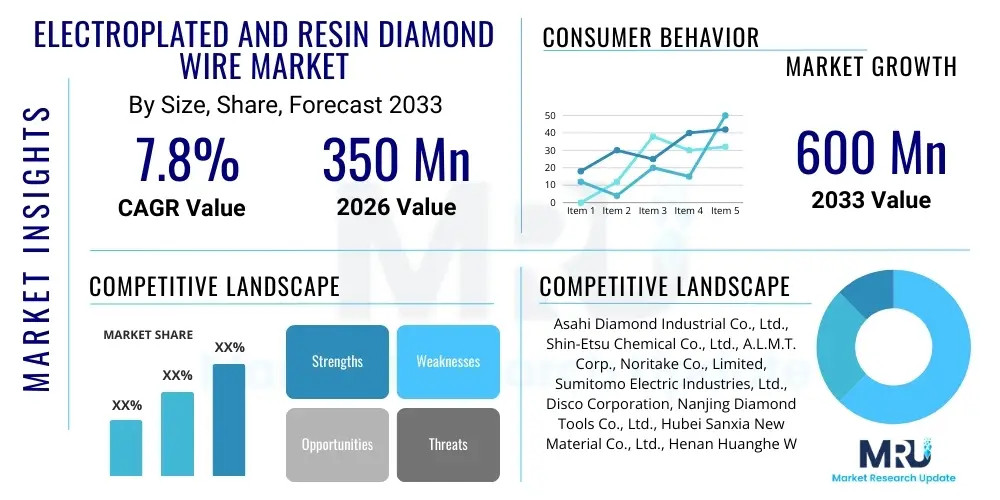

The Electroplated and Resin Diamond Wire Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 600 Million by the end of the forecast period in 2033.

Electroplated and Resin Diamond Wire Market introduction

The Electroplated and Resin Diamond Wire Market encompasses advanced cutting tools critical for precision slicing across a myriad of hard and brittle materials. These wires, distinguished by their diamond grit bonding methods, offer superior efficiency, minimal material waste, and exceptional surface finishes compared to conventional cutting technologies. Electroplated diamond wires feature a single layer of diamonds chemically bonded to the wire surface, providing aggressive cutting for robust materials. In contrast, resin diamond wires embed diamonds within a flexible resin matrix, offering a smoother cut and longer lifespan, particularly suitable for softer yet still challenging materials like silicon ingots and ceramics. This market serves as a cornerstone for industries demanding high-precision material processing, enabling the miniaturization and enhanced performance of various components.

The primary applications of electroplated and resin diamond wires span across the semiconductor industry for silicon wafer slicing, photovoltaic sector for solar cell production, sapphire and gemstone processing, and the advanced ceramics and optical glass industries. These wires are instrumental in manufacturing microelectronics, LED components, high-performance lenses, and structural ceramics, where material integrity and cut quality are paramount. Their ability to cut hard materials with reduced kerf loss, meaning less material waste, makes them economically attractive and environmentally conscious. The continuous advancements in material science and increasing demand for precision components are consistently expanding the utility and scope of these specialized cutting wires.

Key benefits of utilizing diamond wire technology include unparalleled cutting accuracy, reduced energy consumption due to efficient material removal, and enhanced safety profile compared to abrasive slurry-based cutting systems. The inherent hardness of diamonds allows for precise, clean cuts without inducing thermal stress or micro-cracks, which are common issues with alternative methods. This technology significantly improves throughput and yield rates, especially in high-volume manufacturing environments. Driving factors for market growth include the burgeoning demand for solar energy, exponential expansion of the electronics and semiconductor industries, and the increasing adoption of advanced materials like composites and technical ceramics in automotive, aerospace, and medical sectors. Furthermore, stringent quality requirements for finished products and the ongoing pursuit of manufacturing cost reductions are compelling industries to invest in more efficient cutting solutions.

Electroplated and Resin Diamond Wire Market Executive Summary

The Electroplated and Resin Diamond Wire Market is currently experiencing robust growth, propelled by significant advancements in material science and an escalating global demand for high-precision cutting solutions. Business trends within this sector are characterized by intense innovation, with manufacturers continually developing new wire designs and diamond bonding technologies to enhance cutting speed, accuracy, and wire lifespan. Strategic partnerships between wire manufacturers and equipment providers are becoming more prevalent, aimed at offering integrated cutting solutions that optimize performance and efficiency for end-users. Consolidation activities, including mergers and acquisitions, are also observed as companies seek to expand their technological portfolios, market reach, and competitive edge. Furthermore, there is a growing emphasis on sustainable manufacturing practices, driving the development of wires with reduced environmental impact and improved recyclability.

Regional trends indicate that Asia Pacific, particularly countries like China, Japan, South Korea, and Taiwan, dominates the market due to its robust semiconductor, solar, and electronics manufacturing bases. The region benefits from substantial investments in R&D and advanced manufacturing infrastructure, making it a pivotal hub for both production and consumption of diamond wires. North America and Europe are also significant markets, driven by their strong aerospace, medical device, and high-tech industries, which require precision cutting of advanced materials. These regions are witnessing increased adoption of automation and smart manufacturing techniques, further fueling the demand for high-performance diamond wires. Emerging economies in Latin America and the Middle East are showing potential for growth as industrialization and technological adoption accelerate, creating new opportunities for market expansion.

Segmentation trends reveal that the market is diversifying in terms of wire types, applications, and end-use industries. While silicon wafer slicing remains a dominant application, the demand for cutting sapphire, advanced ceramics, and specialized alloys is rapidly expanding. By type, resin diamond wires are gaining traction for their finer surface finish and longer tool life, complementing the aggressive cutting capabilities of electroplated wires. The semiconductor and photovoltaic industries continue to be the largest end-users, but the medical devices and optical industries are showing significant growth potential, driven by the increasing complexity and precision requirements of their products. This granular segmentation allows manufacturers to tailor products and marketing strategies to specific industry needs, optimizing market penetration and fostering specialized innovation.

AI Impact Analysis on Electroplated and Resin Diamond Wire Market

The Electroplated and Resin Diamond Wire Market stands on the cusp of transformative changes driven by Artificial Intelligence (AI) integration, addressing common user questions related to optimizing cutting processes, predicting maintenance, and enhancing material utilization. Users are keen to understand how AI can improve the precision and speed of diamond wire cutting operations, minimize kerf loss, and reduce overall manufacturing costs. There is a strong expectation that AI will provide predictive analytics for equipment failure, wire wear, and process deviations, thereby preventing costly downtime and improving operational efficiency. Furthermore, inquiries often revolve around AI's capability to automate complex cutting paths, handle diverse material properties, and provide real-time process adjustments for optimal performance. The overarching theme is a desire for smarter, more efficient, and more reliable diamond wire cutting solutions that leverage data-driven insights to achieve unprecedented levels of productivity and quality.

Stakeholders in the market are particularly interested in AI's role in advancing quality control and material yield. Users frequently ask about AI algorithms for defect detection, real-time monitoring of cut surfaces, and optimizing wire tension and feed rates based on material characteristics. The potential for AI to simulate cutting scenarios and predict outcomes before physical execution is also a significant area of inquiry, promising to accelerate R&D cycles and reduce trial-and-error costs. Moreover, the integration of AI into machine vision systems for precise material positioning and post-cut inspection is highly anticipated, as it can significantly reduce human error and ensure consistent product quality. These AI-powered solutions are expected to lead to a substantial reduction in scrap rates and a maximization of usable material, which are critical concerns in high-value material processing industries.

Beyond operational enhancements, the market anticipates AI's contribution to supply chain optimization and personalized manufacturing. Questions arise regarding AI's ability to forecast demand for specific diamond wire types, manage inventory levels efficiently, and optimize logistics. Users are also exploring how AI can facilitate mass customization, enabling tailored wire specifications for unique cutting challenges or specialized materials, which would previously be cost-prohibitive. The market envisions AI as a key enabler for adaptive manufacturing environments where cutting parameters dynamically adjust to changing conditions, material batches, or desired output specifications without extensive manual intervention. This holistic integration of AI across the entire value chain is expected to redefine industry standards for efficiency, adaptability, and profitability in the electroplated and resin diamond wire market.

- AI-driven predictive maintenance for cutting machines and wire wear, reducing downtime.

- Optimization of cutting parameters (speed, tension, feed rate) through machine learning algorithms for enhanced efficiency and yield.

- Real-time quality control and defect detection on cut surfaces using AI-powered vision systems.

- Automated path planning and complex geometry cutting for improved precision and material utilization.

- Data analytics for process optimization, leading to reduced kerf loss and increased material recovery.

- Smart inventory management and supply chain forecasting for diamond wire consumption.

- Enhanced R&D through AI simulations of cutting processes and material interactions.

- Personalized cutting solutions and adaptive manufacturing based on AI-driven insights for specific customer needs.

DRO & Impact Forces Of Electroplated and Resin Diamond Wire Market

The Electroplated and Resin Diamond Wire Market is significantly shaped by a complex interplay of drivers, restraints, and opportunities, all influenced by various impact forces. The primary drivers fueling market expansion include the exponential growth of the semiconductor industry, driven by increasing demand for electronic devices, AI, and IoT, which necessitates ultra-precise silicon wafer slicing. Similarly, the burgeoning solar energy sector's continuous need for efficient and cost-effective solar cell production is a major catalyst. Furthermore, the growing adoption of advanced materials in diverse industries such as aerospace, automotive, and medical, which require specialized cutting solutions for hard and brittle substances like sapphire, ceramics, and composites, consistently pushes market demand. Technological advancements in diamond wire manufacturing, leading to improved wire performance, longer lifespan, and finer cut quality, also serve as a crucial market driver, making these tools more attractive and economically viable for a wider range of applications.

However, the market also faces considerable restraints that can impede its growth trajectory. The high initial capital investment required for diamond wire cutting equipment and the associated operational costs, including the wires themselves, can be prohibitive for smaller enterprises or those in developing regions. Intense competition from alternative cutting technologies, though often less efficient for specific applications, can present a challenge, particularly in segments where precision is not the absolute top priority. Moreover, the highly specialized nature of the manufacturing process for diamond wires, requiring specific technical expertise and quality control, creates barriers to entry and limits the number of global suppliers. Economic downturns and geopolitical uncertainties can also impact end-user industries, leading to reduced investment in new equipment and slower adoption of advanced cutting solutions, thereby acting as a short-to-medium term restraint on market expansion.

Despite these challenges, the Electroplated and Resin Diamond Wire Market is rich with opportunities. The increasing global focus on sustainable manufacturing and reducing material waste presents a significant opening, as diamond wire cutting offers superior kerf loss reduction compared to traditional methods. The development of next-generation materials and components across various high-tech industries will continually create new applications and demand for specialized diamond wires capable of handling novel substrates. Opportunities also arise from the growing trend towards automation and Industry 4.0 integration in manufacturing, where precision cutting tools are critical components of smart factories. Furthermore, market penetration into emerging economies through strategic partnerships and localized production offers substantial growth potential, tapping into new industrialization waves. The continuous innovation in diamond bonding techniques and wire substrate materials promises to unlock even greater efficiency and application versatility, paving the way for sustained market expansion and technological leadership.

Segmentation Analysis

The Electroplated and Resin Diamond Wire Market is segmented to provide a granular understanding of its diverse applications, material types, and end-user industries, enabling targeted market strategies and product development. This comprehensive segmentation allows for a detailed analysis of market dynamics across various dimensions, revealing key growth areas and competitive landscapes. The market is primarily categorized based on the type of diamond wire, the material it is designed to cut, and the industrial sectors that utilize these cutting solutions, reflecting the specialized nature and broad applicability of this technology. Understanding these segments is crucial for stakeholders to identify lucrative niches, anticipate demand shifts, and optimize their product portfolios to meet evolving industry needs, ensuring sustained market relevance and profitability.

- By Type:

- Electroplated Diamond Wire

- Resin Diamond Wire

- Hybrid Diamond Wire

- By Material Cut:

- Silicon

- Sapphire

- Ceramics (e.g., Alumina, Zirconia, Silicon Carbide)

- Quartz

- Glass (e.g., Optical Glass, Special Glass)

- Crystals (e.g., Germanium, GaAs)

- Hard Metals and Composites

- By Application:

- Wafer Slicing (Semiconductor, Photovoltaic)

- Block Cutting

- Profiling

- Dicing

- Precision Grinding

- By End-Use Industry:

- Semiconductor

- Photovoltaic (Solar Energy)

- Optics and Photonics

- Consumer Electronics

- Aerospace and Defense

- Medical Devices

- Automotive

- Gemstone Processing

- Research and Development

Value Chain Analysis For Electroplated and Resin Diamond Wire Market

The value chain for the Electroplated and Resin Diamond Wire Market is intricate, involving several distinct stages from raw material sourcing to end-user application, highlighting the interdependencies among various stakeholders. Upstream analysis typically begins with the procurement of high-quality industrial diamonds, which are either natural or synthetic, and high-strength wire cores, often made from steel, tungsten, or special alloys. These core materials are crucial for the wire's durability and cutting performance. Manufacturers of industrial diamonds and wire core materials form the foundational layer of the value chain, supplying specialized components that dictate the ultimate quality and effectiveness of the diamond wire. Strict quality control at this stage is paramount, as the purity and consistency of raw materials directly impact the wire's cutting efficiency and lifespan.

Midstream activities primarily involve the manufacturing process of the diamond wire itself. This includes advanced electroplating techniques for bonding diamonds to the wire surface, or sophisticated resin application processes for embedding diamonds within a polymer matrix. This stage requires significant technological expertise, proprietary bonding methods, and precision engineering to ensure uniform diamond distribution, optimal grit size, and robust adhesion. Manufacturers also focus on developing innovative wire designs, such as specific patterns for diamond placement or varying wire diameters, to cater to diverse cutting requirements. Quality assurance, including testing for tensile strength, diamond retention, and cutting performance, is a critical component of this stage to guarantee product reliability and consistency before reaching the market.

Downstream analysis focuses on the distribution channels and the end-users. Direct distribution channels are common for large industrial clients, where manufacturers engage directly with semiconductor fabs, solar panel producers, or advanced material processors to offer tailored solutions, technical support, and after-sales service. This direct approach allows for closer relationships and quicker feedback loops. Indirect distribution involves working with specialized distributors, agents, and system integrators who have established networks within specific regional markets or industries. These intermediaries play a vital role in market penetration, especially for smaller manufacturers or in regions where direct presence is challenging. End-users, ranging from major electronics corporations to research institutions, then utilize these wires in their cutting equipment, generating the final product and completing the value chain. The effectiveness of both direct and indirect channels is critical for timely product delivery and extensive market reach, ensuring that the precision cutting tools reach the demanding applications efficiently.

Electroplated and Resin Diamond Wire Market Potential Customers

The potential customer base for the Electroplated and Resin Diamond Wire Market is incredibly diverse, encompassing a wide array of industries that rely on high-precision cutting of hard, brittle, or expensive materials. Foremost among these are the semiconductor manufacturers, who represent a foundational segment. These companies require diamond wires for slicing silicon ingots into wafers with extreme thinness and minimal kerf loss, which is essential for microchip production. The increasing demand for advanced processors, memory chips, and sensor technologies, driven by AI, IoT, and 5G, directly translates into a continuous and growing need for these specialized cutting tools. Their emphasis on yield optimization and surface quality makes diamond wire an indispensable component in their fabrication processes, continually driving innovation and adoption within this critical end-user segment.

Another significant customer segment is the photovoltaic industry, particularly manufacturers of solar cells and panels. Diamond wire technology is crucial for slicing silicon ingots into thin wafers used in solar cells, contributing directly to the efficiency and cost-effectiveness of solar energy production. As global energy demands shift towards renewable sources, the solar industry experiences sustained growth, making it a robust and expanding market for diamond wire suppliers. Furthermore, industries involved in processing advanced materials, such as sapphire for LED substrates and smartphone screens, technical ceramics for aerospace and medical applications, and optical glass for high-performance lenses, represent a substantial and growing customer base. These sectors demand precision, minimal material damage, and superior surface finish, which are inherent advantages of diamond wire cutting, ensuring their continued reliance on this technology.

Beyond these major industrial players, other notable potential customers include manufacturers of medical devices, where precision cutting of biocompatible ceramics and advanced composites is critical for implants and surgical instruments. The gemstone and jewelry industry also utilizes diamond wires for cutting and shaping precious stones with high accuracy and minimal waste. Research and development institutions, universities, and specialized prototyping firms also form a niche but important customer segment, often requiring customized diamond wire solutions for material science experiments and new product development. The common thread among all these diverse customers is their imperative for unparalleled precision, material integrity, and operational efficiency in cutting challenging materials, positioning electroplated and resin diamond wires as an indispensable enabling technology across high-tech manufacturing landscapes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 600 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Asahi Diamond Industrial Co., Ltd., Shin-Etsu Chemical Co., Ltd., A.L.M.T. Corp., Noritake Co., Limited, Sumitomo Electric Industries, Ltd., Disco Corporation, Nanjing Diamond Tools Co., Ltd., Hubei Sanxia New Material Co., Ltd., Henan Huanghe Whirlwind Co., Ltd., Saint-Gobain Abrasives, Zhejiang Ruixin Diamond Tools Co., Ltd., Hunan Sinosun Technology Co., Ltd., NTC Nano Technology Co., Ltd., Diamond Wiretec Co., Ltd., DIATEX S.p.A., Dr. Fritsch GmbH, SCHMID Group, Meyer Burger Technology AG, M. E. R. Ltd., Okazaki Manufacturing Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electroplated and Resin Diamond Wire Market Key Technology Landscape

The Electroplated and Resin Diamond Wire Market is characterized by a dynamic and evolving technology landscape, continuously driven by the pursuit of enhanced cutting performance, extended wire lifespan, and improved cost-efficiency. A foundational technology involves the sophisticated manufacturing processes for creating the diamond wires themselves. For electroplated wires, this encompasses advanced electrodeposition techniques that ensure uniform embedding of diamond particles onto a high-strength wire substrate, typically steel or tungsten, with precise control over diamond concentration, size, and exposure. Innovations in this area focus on achieving stronger bond strength between the diamonds and the core, which prevents premature diamond shedding and extends the wire's cutting efficiency and overall durability, crucial for demanding industrial applications requiring aggressive and consistent material removal.

For resin diamond wires, the key technological advancements revolve around the development of advanced polymer matrix materials and specialized embedding processes. These resins must possess optimal elasticity, thermal stability, and diamond retention capabilities to securely hold the diamond grit while allowing for a smoother, more controlled cutting action. Researchers are exploring novel resin formulations, including thermosets and thermoplastics with specialized additives, to enhance wear resistance, reduce friction, and improve coolant compatibility. Furthermore, the techniques for uniformly dispersing diamonds within the resin and applying this matrix to the wire core are critical, impacting the wire's cutting characteristics, such as surface finish, kerf width, and lifespan, particularly vital for high-precision applications like silicon wafer slicing in the semiconductor and photovoltaic industries, where material waste must be minimized.

Beyond the core manufacturing of the wires, the broader technology landscape also includes innovations in the associated cutting equipment and process optimization. This involves advancements in multi-wire sawing machines that utilize these wires, incorporating features such as highly precise tension control systems, advanced feed mechanisms, and sophisticated coolant delivery systems. These integrated technologies work in tandem with the diamond wires to maximize cutting speed, accuracy, and efficiency. The adoption of sensors and automation for real-time monitoring of cutting parameters, predictive maintenance, and quality control represents another significant technological thrust. Furthermore, ongoing research into new diamond synthesis methods, alternative wire core materials offering superior strength-to-weight ratios or corrosion resistance, and environmentally friendly manufacturing processes are continually pushing the boundaries of what is possible in diamond wire cutting technology, promising even greater performance and versatility in future applications across various high-tech sectors.

Regional Highlights

- Asia Pacific: This region stands as the dominant market for electroplated and resin diamond wires, primarily driven by its robust and rapidly expanding electronics, semiconductor, and solar power industries. Countries like China, Japan, South Korea, and Taiwan are global leaders in manufacturing silicon wafers, solar cells, and consumer electronics, necessitating extensive use of precision diamond wire cutting. Significant government investments in manufacturing infrastructure and R&D further solidify its leading position, with a strong focus on high-volume production and continuous technological advancements.

- North America: Characterized by a strong presence of aerospace, medical device, and advanced materials industries, North America represents a significant market. The demand here is largely for high-performance and customized diamond wires for cutting specialized alloys, composites, and high-purity crystals for demanding applications. The region also boasts a robust research and development ecosystem, driving innovation in cutting technologies and adoption of advanced manufacturing processes, contributing to sustained growth in high-value segments.

- Europe: Similar to North America, Europe's market is propelled by its advanced manufacturing sectors, including automotive, industrial machinery, and precision optics. Germany, France, and Italy are key contributors, emphasizing quality, efficiency, and environmental sustainability in their production processes. The region shows a growing interest in resin diamond wires for their superior surface finish and longer lifespan, particularly in applications requiring delicate material processing and stringent quality control.

- Latin America: This region is an emerging market for diamond wire technology, with growth driven by increasing industrialization and foreign direct investment in manufacturing sectors, particularly automotive and electronics assembly. Brazil and Mexico are leading the adoption of modern cutting solutions to enhance their production capabilities and competitiveness. While currently a smaller share, the region offers substantial growth potential as its industrial base continues to develop and integrate advanced processing technologies.

- Middle East and Africa (MEA): The MEA region's market is nascent but shows promising growth, primarily influenced by investments in infrastructure, energy, and nascent manufacturing industries. The construction and mining sectors, alongside burgeoning solar energy projects, present opportunities for specialized diamond wire applications. As the region diversifies its economies and invests in high-tech manufacturing, the demand for precision cutting tools is expected to steadily increase, albeit from a smaller base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electroplated and Resin Diamond Wire Market.- Asahi Diamond Industrial Co., Ltd.

- Shin-Etsu Chemical Co., Ltd.

- A.L.M.T. Corp.

- Noritake Co., Limited

- Sumitomo Electric Industries, Ltd.

- Disco Corporation

- Nanjing Diamond Tools Co., Ltd.

- Hubei Sanxia New Material Co., Ltd.

- Henan Huanghe Whirlwind Co., Ltd.

- Saint-Gobain Abrasives

- Zhejiang Ruixin Diamond Tools Co., Ltd.

- Hunan Sinosun Technology Co., Ltd.

- NTC Nano Technology Co., Ltd.

- Diamond Wiretec Co., Ltd.

- DIATEX S.p.A.

- Dr. Fritsch GmbH

- SCHMID Group

- Meyer Burger Technology AG

- M. E. R. Ltd.

- Okazaki Manufacturing Company

Frequently Asked Questions

What are the primary differences between electroplated and resin diamond wires?

Electroplated diamond wires feature a single layer of industrial diamonds chemically bonded to the wire core, offering aggressive cutting and high material removal rates, ideal for robust materials. Resin diamond wires, conversely, embed diamonds within a flexible resin matrix, providing a smoother cut, finer surface finish, and generally longer lifespan, making them suitable for delicate materials like silicon wafers where minimal damage is crucial.

Which industries are the major end-users of electroplated and resin diamond wires?

The semiconductor and photovoltaic industries are the largest end-users, relying heavily on these wires for precise wafer slicing from silicon ingots. Other significant sectors include optics and photonics for cutting glass and sapphire, aerospace and defense for advanced composites, medical devices for biocompatible materials, and gemstone processing, all requiring high precision and minimal material waste.

How does diamond wire cutting contribute to sustainable manufacturing?

Diamond wire cutting significantly contributes to sustainability by reducing kerf loss, which is the amount of material lost during cutting, leading to higher material utilization and less waste. This efficiency is particularly vital for expensive materials like silicon and sapphire. Additionally, it often involves a cleaner cutting process compared to slurry-based methods, reducing the environmental impact associated with abrasive waste disposal and energy consumption.

What are the key technological advancements expected in the diamond wire market?

Key technological advancements include improved diamond bonding techniques for enhanced wire durability and cutting efficiency, development of novel resin formulations for smoother cuts and extended lifespan, and innovations in wire core materials for superior strength. Furthermore, integration of AI and automation in cutting machines for real-time parameter optimization, predictive maintenance, and quality control are significant trends shaping the future of the market.

What impact does the growth of the semiconductor industry have on the diamond wire market?

The growth of the semiconductor industry has a profound impact, as it is a primary driver for the diamond wire market. The increasing global demand for microchips, fueled by AI, IoT, 5G, and consumer electronics, necessitates higher volumes of ultra-thin, high-quality silicon wafers. This directly translates to an escalating demand for electroplated and resin diamond wires capable of precision slicing with minimal kerf loss and superior surface integrity, underpinning significant market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager