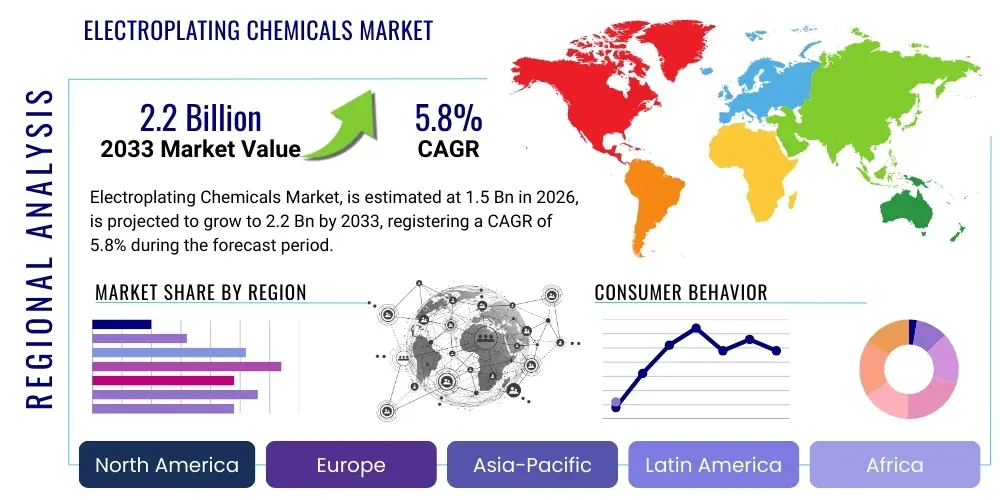

Electroplating Chemicals Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440351 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Electroplating Chemicals Market Size

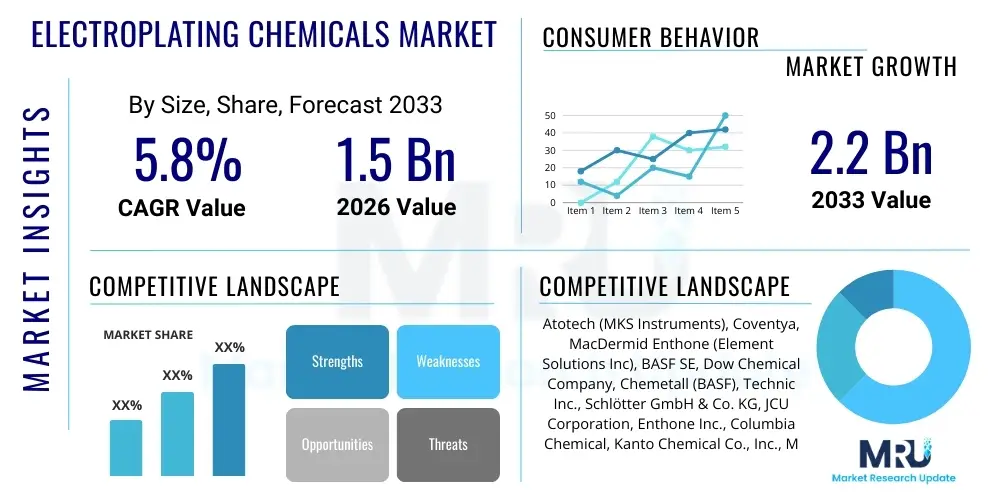

The Electroplating Chemicals Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.2 Billion by the end of the forecast period in 2033.

Electroplating Chemicals Market introduction

Electroplating is a surface finishing technique that involves depositing a thin layer of metal onto a conductive substrate using an electric current. This process utilizes a diverse range of electroplating chemicals, which are crucial for preparing the substrate, facilitating the metal deposition, and refining the final finish. These chemicals include various acids, bases, salts of the plating metals, and a host of organic and inorganic additives designed to enhance plating efficiency, improve coating properties, and ensure consistency.

The primary objective of electroplating is to impart specific functional and aesthetic properties to base materials. Functionally, electroplating enhances corrosion resistance, improves wear resistance, increases hardness, boosts electrical conductivity, and provides superior solderability. Aesthetically, it offers decorative finishes, varying in luster, color, and texture, often used in consumer goods and luxury items. The chemicals involved are meticulously formulated to achieve these precise outcomes, ensuring strong adhesion, uniform thickness, and desired surface characteristics.

Major applications for electroplating chemicals span across numerous industries, including automotive for corrosion protection and decorative trim, electronics for circuit boards and connectors, aerospace for high-performance components, jewelry for aesthetic appeal, and general manufacturing for tools and hardware. The market is significantly driven by continuous industrial growth, the escalating demand for high-performance and durable goods, and technological advancements that necessitate enhanced surface properties. These factors collectively underscore the indispensable role of electroplating chemicals in modern manufacturing.

Electroplating Chemicals Market Executive Summary

The Electroplating Chemicals Market is experiencing dynamic shifts, characterized by evolving business trends, distinct regional growth patterns, and specialized segmental demands. A notable business trend involves increasing consolidation among key players, driven by the need for economies of scale and comprehensive product portfolios, alongside a pronounced focus on sustainable and environmentally compliant chemical formulations. Companies are heavily investing in research and development to introduce safer, more efficient, and greener plating solutions, responding to stringent global environmental regulations and consumer demand for eco-friendly products. Furthermore, the market is witnessing an acceleration in the adoption of advanced process control and automation technologies to optimize plating operations, reduce waste, and improve overall product quality, fostering innovation in chemical delivery systems and waste treatment.

Regional trends highlight the Asia Pacific (APAC) as the leading growth engine for the electroplating chemicals market, fueled by robust industrialization, rapid expansion in the automotive and electronics manufacturing sectors, particularly in China, India, and Southeast Asian countries. North America and Europe, while being mature markets, continue to contribute significantly due to their strong presence in high-tech industries such as aerospace, medical devices, and advanced electronics, coupled with a focus on high-performance and specialty plating applications. These regions are also at the forefront of implementing strict environmental regulations, driving demand for advanced and sustainable plating chemistries. Emerging economies in Latin America and the Middle East & Africa are showing promising growth potential, supported by ongoing infrastructure development and increasing manufacturing activities.

Segment-wise, the market is primarily bifurcated into decorative and functional plating, with functional applications, particularly in electronics and automotive, demonstrating robust growth due to the escalating demand for enhanced material properties like superior corrosion resistance, wear protection, and electrical conductivity. Within metal types, nickel, copper, and zinc plating chemicals retain significant market shares, while precious metals like gold, silver, and platinum witness steady demand in high-value applications such as jewelry, connectors, and medical devices. The industry is also observing a shift towards more specialized plating processes and chemistries that cater to specific performance requirements, such as electroless plating for intricate geometries and pulse plating for improved deposit characteristics. This nuanced evolution across segments underscores the market's adaptability to diverse industrial needs and technological advancements.

AI Impact Analysis on Electroplating Chemicals Market

The integration of Artificial Intelligence (AI) into the electroplating chemicals market is poised to revolutionize several critical facets, from process optimization to product development and environmental compliance. Common user questions often revolve around how AI can enhance efficiency, reduce costs, improve quality consistency, and mitigate environmental risks within complex plating operations. Users are keen to understand AI's capability to analyze vast datasets generated by plating lines, predict process deviations, and recommend optimal chemical compositions or operating parameters. There is significant interest in leveraging AI for predictive maintenance of plating equipment, real-time quality control to minimize defects, and accelerating the discovery and formulation of new, more sustainable electroplating chemicals. The overarching theme is the expectation that AI will drive smarter, more precise, and environmentally friendly electroplating practices.

- AI can optimize plating bath parameters in real-time, leading to reduced chemical consumption and energy costs.

- Predictive analytics powered by AI enables proactive maintenance of plating equipment, minimizing downtime and increasing operational efficiency.

- Enhanced quality control through AI-driven defect detection and classification ensures higher product consistency and fewer rejections.

- AI accelerates the R&D process for new electroplating chemical formulations by simulating experiments and predicting material properties.

- Improved waste management and effluent treatment optimization using AI algorithms to comply with stringent environmental regulations.

- AI facilitates supply chain optimization for raw materials, predicting demand fluctuations and ensuring timely procurement.

- Process automation and robotics, guided by AI, can lead to increased precision and safety in plating operations.

- Data-driven insights from AI help in identifying root causes of plating issues, leading to rapid troubleshooting and process improvements.

- Development of smart plating systems that can self-regulate and adapt to changing conditions for consistent performance.

DRO & Impact Forces Of Electroplating Chemicals Market

The Electroplating Chemicals Market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory and competitive landscape. Key drivers propelling market expansion include the continuous growth of industrial sectors such as automotive, electronics, and aerospace, which increasingly demand enhanced surface properties for their components. The rising global production of vehicles, consumer electronics, and machinery necessitates reliable and high-performance electroplated finishes for corrosion resistance, wear protection, and aesthetic appeal. Furthermore, advancements in electroplating technology and the development of specialized chemicals that cater to intricate applications and stringent performance specifications also act as powerful market stimulants, pushing innovation and adoption across various end-use industries.

Conversely, the market faces several formidable restraints that temper its growth. Stringent environmental regulations, exemplified by directives like RoHS and REACH, impose significant challenges on manufacturers, particularly regarding the use and disposal of certain hazardous chemicals, leading to increased compliance costs and a need for continuous reformulation. The volatile pricing of raw materials, many of which are commodity chemicals or precious metals, introduces supply chain complexities and impacts profit margins for chemical producers. Additionally, the high capital investment required for setting up advanced electroplating facilities and effective waste treatment systems, coupled with health and safety concerns associated with chemical handling, can deter new entrants and limit expansion for smaller players in the industry.

Despite these restraints, numerous opportunities are emerging that promise to unlock new growth avenues for the electroplating chemicals market. The burgeoning demand for green electroplating solutions, including chrome alternatives and cyanide-free processes, presents a substantial opportunity for companies investing in sustainable innovation and eco-friendly product development. The expanding applications of nanotechnology in surface finishing, offering superior coating properties at nanoscale, also represents a lucrative growth area. Moreover, the rapid industrialization and infrastructure development in emerging economies, particularly in Asia Pacific and Latin America, are creating new demand centers for electroplating services and chemicals. The ongoing trend towards automation and digitalization in manufacturing also provides an opportunity for integrating smart plating solutions and advanced process controls, enhancing efficiency and product quality.

Segmentation Analysis

The Electroplating Chemicals Market is comprehensively segmented to provide granular insights into its diverse applications, material types, and industrial end-uses. This detailed segmentation allows for a precise understanding of market dynamics, growth drivers, and specific opportunities within each category, catering to the specialized needs of various industries. The market is primarily divided by chemical type, application focus, the specific metal being plated, the end-use industry, and the plating process employed, reflecting the multifaceted nature of electroplating technologies and demands across the global industrial landscape.

- By Type

- Acidic Electroplating Chemicals

- Alkaline Electroplating Chemicals

- Neutral Electroplating Chemicals

- Others (e.g., Cyanide-based, Non-cyanide alkaline)

- By Application

- Decorative Electroplating (e.g., jewelry, automotive trim, sanitary fittings)

- Functional Electroplating (e.g., corrosion resistance, wear resistance, electrical conductivity, EMI shielding)

- By End-Use Industry

- Automotive (e.g., bumpers, engine parts, interior components)

- Electronics (e.g., PCBs, connectors, semiconductor components)

- Aerospace & Defense (e.g., aircraft components, missile systems)

- Jewelry (e.g., gold, silver, rhodium plating)

- Heavy Equipment & Machinery (e.g., hydraulic components, industrial tools)

- Building & Construction (e.g., fasteners, hardware)

- Medical Devices (e.g., surgical instruments, implants)

- Others (e.g., marine, consumer goods, printing)

- By Metal Type

- Nickel Electroplating Chemicals

- Copper Electroplating Chemicals

- Zinc Electroplating Chemicals

- Chromium Electroplating Chemicals

- Gold Electroplating Chemicals

- Silver Electroplating Chemicals

- Tin Electroplating Chemicals

- Palladium Electroplating Chemicals

- Rhodium Electroplating Chemicals

- Platinum Electroplating Chemicals

- Lead Electroplating Chemicals

- Others (e.g., Cadmium, Indium, Brass)

- By Process

- Rack Plating

- Barrel Plating

- Continuous Plating (Reel-to-Reel)

- Electroless Plating

- Pulse Plating

- Brush Plating

Value Chain Analysis For Electroplating Chemicals Market

The value chain for the electroplating chemicals market is a complex network that begins with the extraction and processing of raw materials, moves through chemical manufacturing and formulation, and culminates in the application by end-use industries. At the upstream segment, the value chain involves the procurement of basic chemicals, metal salts, and additives from various chemical producers and mining operations. These raw materials, such as nickel sulfates, copper cyanides, chromic acids, and a wide array of organic brighteners and stabilizers, are sourced globally. The quality and availability of these foundational components significantly influence the cost and performance of the final electroplating chemical formulations, making raw material supplier relationships crucial.

Midstream in the value chain, specialized electroplating chemical manufacturers take these raw materials and formulate them into proprietary plating solutions, pre-treatment chemicals, post-treatment chemicals, and waste treatment products. This stage involves significant research and development to create high-performance, environmentally compliant, and application-specific chemical systems. These manufacturers often work closely with end-users and plating service providers to tailor solutions that meet specific technical requirements and regulatory standards. Their expertise lies in blending various components to achieve optimal plating bath stability, deposition efficiency, and desired coating properties for a wide range of substrates and applications.

The downstream segment primarily involves the distribution channels and the end-users of electroplating chemicals. Distribution can be direct, where large chemical manufacturers sell directly to major industrial customers with in-house plating facilities, or indirect, through a network of specialized distributors and agents. These distributors play a vital role in providing local stock, technical support, and logistical services to a fragmented customer base, especially small and medium-sized plating shops. End-users, including automotive OEMs, electronics manufacturers, aerospace companies, and jewelry makers, either operate their own plating lines or outsource to third-party electroplating service providers. The choice of direct or indirect channels often depends on the customer's size, geographic location, and the complexity of their plating requirements, with both models playing a critical role in market penetration and customer reach.

Electroplating Chemicals Market Potential Customers

The Electroplating Chemicals Market serves a diverse array of potential customers across various industrial sectors, each requiring specialized chemical formulations and processes tailored to their unique product specifications and performance demands. These end-users are primarily entities that seek to enhance the surface properties of their manufactured components, whether for functional benefits such as corrosion protection, wear resistance, or electrical conductivity, or for aesthetic purposes like decorative finishes. The broad applicability of electroplating makes its chemicals indispensable to a wide range of manufacturing processes, making the customer base highly fragmented yet interconnected by the need for superior surface treatment solutions.

Key segments of potential customers include the automotive industry, which utilizes electroplating extensively for both functional components (e.g., engine parts, brake calipers, connectors) requiring corrosion and wear resistance, and decorative elements (e.g., grille, emblems, interior trim) for aesthetic appeal. The electronics sector represents another significant customer base, relying on electroplating for printed circuit boards (PCBs), connectors, semiconductor packaging, and lead frames, where precise metal deposition is crucial for conductivity, solderability, and reliability. Aerospace and defense industries are also major consumers, demanding high-performance coatings for critical aircraft components, satellite parts, and weaponry that must withstand extreme conditions and provide superior durability.

Furthermore, the jewelry industry is a traditional and consistent customer, employing electroplating for gold, silver, rhodium, and other precious metal finishes to enhance the appearance and durability of ornaments. The general manufacturing and heavy equipment sectors use electroplating for tools, fasteners, hydraulic components, and various industrial machinery parts to improve their lifespan and performance under harsh operating conditions. Other significant customer segments include medical device manufacturers, construction hardware suppliers, and industries producing consumer goods, all of whom leverage electroplating chemicals to meet specific material performance and aesthetic requirements. This wide array of applications underscores the essential nature of electroplating chemicals to modern industrial production.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atotech (MKS Instruments), Coventya, MacDermid Enthone (Element Solutions Inc), BASF SE, Dow Chemical Company, Chemetall (BASF), Technic Inc., Schlötter GmbH & Co. KG, JCU Corporation, Enthone Inc., Columbia Chemical, Kanto Chemical Co., Inc., Meltex Inc., EPI Electrochemical Products Inc., Honeywell International Inc., Hubbard-Hall Inc., Okuno Chemical Industries Co., Ltd., Ronatec, C. Uyemura & Co., Ltd., Asterion LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electroplating Chemicals Market Key Technology Landscape

The electroplating chemicals market is continuously evolving, driven by significant advancements in plating technologies aimed at improving efficiency, performance, and environmental sustainability. A pivotal aspect of the current technological landscape involves the development of advanced plating processes that offer superior control over deposition characteristics and material properties. Technologies such as pulse plating, which uses pulsed current instead of continuous direct current, allow for finer grain structures, improved throwing power, and enhanced material properties like hardness and corrosion resistance. Similarly, composite plating, where fine insoluble particles are co-deposited with the metal matrix, creates novel materials with unique functional attributes, such as self-lubricating or highly wear-resistant surfaces. These innovations expand the scope of electroplating beyond traditional applications, enabling new material functionalities for demanding environments.

Another crucial area of technological innovation focuses on developing environmentally friendly and sustainable plating solutions. With increasing regulatory pressure and a global shift towards green manufacturing, there is intense research and development in chrome-free plating alternatives, particularly for decorative and hard chrome applications, to eliminate hexavalent chromium compounds which are highly toxic. The move towards cyanide-free alkaline zinc and copper baths is also gaining traction, replacing traditional cyanide-based formulations that pose significant environmental and health risks. Furthermore, advancements in electroless plating, a non-electric chemical deposition process, offer advantages for complex geometries and non-conductive substrates, while new nanocoating technologies are enabling ultra-thin, high-performance films with enhanced properties at the nanoscale, pushing the boundaries of material science and surface engineering.

Beyond the chemical formulations, the technological landscape also encompasses significant progress in automation, process control, and real-time monitoring systems for electroplating lines. The integration of robotics and automated material handling systems enhances efficiency, reduces labor costs, and improves consistency in plating operations. Advanced sensors, coupled with data analytics and IoT capabilities, enable real-time monitoring of bath parameters such as pH, temperature, and metal ion concentrations, allowing for immediate adjustments and predictive maintenance, thereby minimizing defects and optimizing chemical usage. These technological advancements collectively contribute to more precise, cost-effective, and environmentally responsible electroplating processes, making the industry more adaptive to modern manufacturing demands and sustainability objectives. The emphasis on smart manufacturing and industry 4.0 principles is fundamentally reshaping how electroplating chemicals are utilized and managed in industrial settings.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to rapid industrialization, burgeoning automotive and electronics manufacturing sectors in countries like China, India, Japan, and South Korea. The region benefits from lower labor costs and a large consumer base, driving significant demand for both decorative and functional electroplated products.

- Europe: A mature market characterized by stringent environmental regulations and a strong focus on high-performance and specialty chemicals. Germany, the UK, France, and Italy are key contributors, driven by advanced manufacturing, aerospace, and medical device industries, emphasizing sustainable and high-quality plating solutions.

- North America: A significant market driven by technological innovation in aerospace, defense, automotive, and medical device sectors. The United States and Canada are leading the adoption of advanced plating techniques and environmentally compliant chemicals, with a strong emphasis on research and development.

- Latin America: An emerging market with growing industrial activity, particularly in the automotive and general manufacturing sectors in Brazil and Mexico. Economic development and increasing foreign investment are contributing to the rising demand for electroplating chemicals for various applications.

- Middle East & Africa (MEA): Shows promising growth potential, fueled by infrastructure development, increasing manufacturing capabilities, and a growing automotive industry in countries like UAE, Saudi Arabia, and South Africa. The region is witnessing an increase in demand for protective coatings and decorative finishes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electroplating Chemicals Market.- Atotech (MKS Instruments)

- Coventya

- MacDermid Enthone (Element Solutions Inc)

- BASF SE

- Dow Chemical Company

- Chemetall (BASF)

- Technic Inc.

- Schlötter GmbH & Co. KG

- JCU Corporation

- EPI Electrochemical Products Inc.

- Columbia Chemical

- Kanto Chemical Co., Inc.

- Meltex Inc.

- Hubbard-Hall Inc.

- Okuno Chemical Industries Co., Ltd.

- Ronatec

- C. Uyemura & Co., Ltd.

- Asterion LLC

- Pricerite Corporation

- Lea Manufacturing Co.

Frequently Asked Questions

What is the Electroplating Chemicals Market size and projected growth rate?

The Electroplating Chemicals Market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.2 Billion by 2033, growing at a Compound Annual Growth Rate (CAGR) of 5.8% during the forecast period.

What are the primary applications of electroplating chemicals?

Electroplating chemicals are primarily used for decorative purposes, enhancing aesthetic appeal, and functional applications, providing properties like corrosion resistance, wear protection, hardness, and electrical conductivity in industries such as automotive, electronics, aerospace, and jewelry.

What are the key drivers for the Electroplating Chemicals Market?

The market is driven by consistent industrial growth, particularly in automotive and electronics manufacturing, rising demand for high-performance and durable goods, and continuous technological advancements in surface finishing techniques that require specialized chemical formulations.

What are the major challenges faced by the market?

Key challenges include stringent environmental regulations requiring eco-friendly chemical alternatives, volatility in raw material prices, high capital investment for advanced plating facilities, and health and safety concerns associated with chemical handling and waste management.

Which region dominates the Electroplating Chemicals Market, and why?

The Asia Pacific (APAC) region currently dominates the market due to rapid industrialization, significant expansion of the automotive and electronics manufacturing industries, and a large consumer base in countries like China, India, and other Southeast Asian nations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager