End Pump Laser Marking Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431354 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

End Pump Laser Marking Machine Market Size

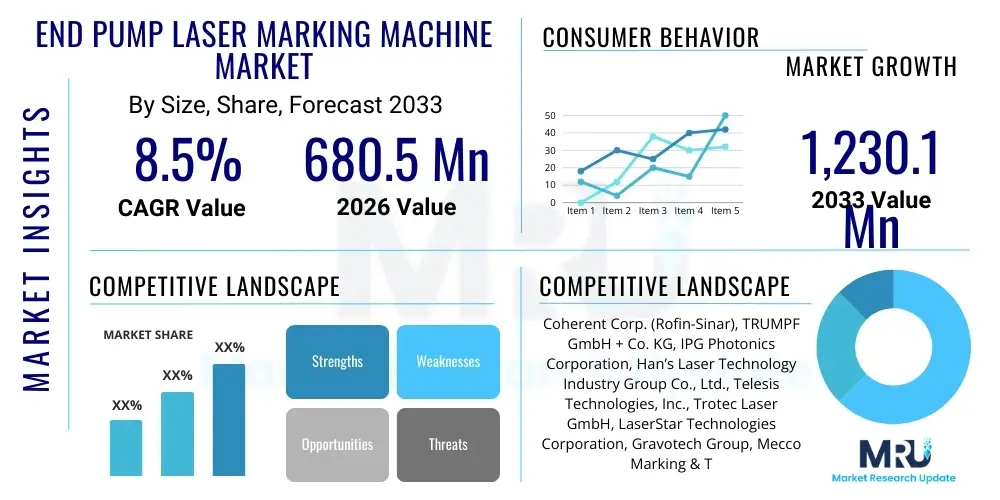

The End Pump Laser Marking Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 680.5 Million in 2026 and is projected to reach USD 1,230.1 Million by the end of the forecast period in 2033.

End Pump Laser Marking Machine Market introduction

The End Pump Laser Marking Machine Market encompasses high-precision industrial systems utilizing diode-pumped solid-state (DPSS) laser technology where the pump source, typically a laser diode, is coupled to the end face of the gain medium (like Nd:YAG or Nd:YVO4). This configuration offers superior beam quality, higher conversion efficiency, and a more compact footprint compared to traditional lamp-pumped systems, making end-pumped lasers ideal for intricate and demanding marking applications across various industrial sectors. These machines are essential tools for permanent, high-contrast, and fast marking on materials ranging from metals and plastics to ceramics and composites. Key applications include unique identification marking, serialization, branding, data matrix codes, and complex graphics, particularly in fields requiring durability and traceability such as automotive components, medical instruments, and advanced electronic substrates.

The core benefit driving the adoption of end-pump laser marking machines is their ability to deliver exceptional reliability and long service life with minimal maintenance requirements. Unlike other marking technologies that require consumables or contact, laser marking is a non-contact process, eliminating tool wear and ensuring consistent marking quality across millions of cycles. The high peak power and short pulse duration capabilities of these systems allow for precise material ablation or color change without causing significant heat-affected zones (HAZ), which is crucial for sensitive materials used in semiconductor and medical device manufacturing. Furthermore, the inherent stability and high beam quality translate directly into finer resolutions and faster processing speeds, thereby enhancing overall manufacturing efficiency and throughput in high-volume production environments.

Major driving factors fueling market expansion include the global trend toward industrial automation (Industry 4.0), the escalating demand for product traceability and anti-counterfeiting measures across regulated industries, and continuous technological advancements improving laser efficiency and reducing cost-of-ownership. Specifically, the miniaturization of electronic components necessitates highly precise marking solutions that end-pumped lasers inherently provide. Moreover, emerging applications in additive manufacturing (3D printing) and specialized material processing, where material identification must withstand harsh environmental conditions, further solidify the critical role of end-pump laser marking systems in the modern manufacturing landscape, pushing vendors to innovate on faster scanning heads and smarter control software.

End Pump Laser Marking Machine Market Executive Summary

The End Pump Laser Marking Machine Market is undergoing robust expansion driven primarily by the escalating demand for high-resolution, permanent identification across critical sectors like automotive, aerospace, and advanced electronics. Business trends indicate a strong move towards integrated solutions, where marking systems are seamlessly incorporated into fully automated production lines, often utilizing robotic loading and unloading mechanisms. Key manufacturers are focusing their investment on developing systems capable of handling a wider array of materials and complex geometries, including 3D contoured surfaces, necessitating advancements in galvanometer scanning technologies and dynamic focusing systems. The competitive landscape is characterized by strategic mergers and acquisitions aimed at consolidating technological capabilities and expanding regional service networks, particularly in the rapidly industrializing Asia Pacific region, emphasizing efficiency, uptime, and minimal footprint as core value propositions for end-users seeking operational excellence.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by the massive concentration of electronics manufacturing, automotive production, and a rapidly expanding medical device industry in countries such as China, South Korea, and Japan. North America and Europe maintain significant market shares, characterized by demand for high-end, customized solutions compliant with stringent regulatory standards, especially for traceability requirements in aerospace and medical implants. These mature markets focus heavily on adopting the latest generation of ultra-short pulse (USP) end-pumped lasers, which offer exceptional quality and minimal material stress, demanding higher initial capital expenditure but promising superior long-term performance. Emerging markets in Latin America and the Middle East and Africa (MEA) are showing increasing adoption rates as local industries modernize their manufacturing infrastructure and seek cost-effective, durable marking solutions for export-oriented goods.

Segmentation trends highlight the increasing dominance of higher power end-pumped systems (30W and above) driven by the need for faster deep engraving and high-speed superficial marking on metallic parts in the automotive sector. Concurrently, the medical segment is seeing strong demand for low-power, high beam quality systems optimized for delicate materials and stringent cleanliness standards required for sterilization processes, focusing particularly on systems optimized for UDI (Unique Device Identification) compliance. Technology-wise, the shift from traditional lamp-pumped to diode-pumped systems is nearly complete, with current innovation focusing on enhancing software integration, predictive maintenance capabilities, and improving energy efficiency to lower operational costs for end-users facing increasing utility costs and sustainability pressures globally. The convergence of marking capabilities with machine vision systems for automated quality verification represents a critical segment trend.

AI Impact Analysis on End Pump Laser Marking Machine Market

User queries regarding the impact of Artificial Intelligence (AI) on End Pump Laser Marking Machines frequently revolve around themes of automation, quality control assurance, and predictive maintenance capabilities. Users are keen to understand how AI algorithms can enhance the existing precision of laser marking systems, particularly concerning dynamic material recognition and automated parameter adjustment for mixed batch production runs. A major concern is the complexity and cost associated with integrating deep learning models into existing legacy marking infrastructure, balanced against the expectation that AI should drastically reduce waste through real-time defect detection and compensate for slight shifts in material surface conditions or ambient temperature fluctuations. Furthermore, there is significant interest in using AI-driven predictive analytics to monitor laser diode health, optics contamination, and galvanometer performance, thereby minimizing unplanned downtime and optimizing maintenance schedules, transforming reactive service models into proactive operational strategies.

The primary area of AI influence centers on optimizing the marking process itself. AI-powered machine vision systems are increasingly being deployed to confirm the quality, placement, and readability of marked codes (such as QR or Data Matrix) instantly after application, surpassing traditional human visual inspection methods in speed and reliability. These systems use sophisticated convolutional neural networks (CNNs) trained on vast datasets of acceptable and unacceptable marks to achieve near-perfect quality assurance. This integration allows manufacturers operating in highly regulated fields, such as aerospace and medical device manufacturing, to maintain exceptionally high traceability standards while significantly increasing throughput, mitigating the risks associated with non-compliant product marking that can lead to costly recalls or regulatory fines.

Beyond quality control, AI fundamentally alters the operational efficiency of large-scale marking deployments. AI algorithms analyze operational data streams, including power consumption, cooling efficiency, and component wear indicators, to predict potential component failures with high accuracy before they occur. This predictive capability allows maintenance teams to schedule interventions during planned downtime, ensuring maximum machine utilization. Moreover, advanced AI controllers can learn optimal power and speed settings for various materials and thicknesses based on historical success data, automatically adjusting laser parameters in real-time to maintain constant mark depth and contrast despite minor variations in input material or system component degradation over time, leading to consistent performance without manual operator intervention.

- AI-driven real-time quality verification of marked codes (AEO: Enhanced Traceability).

- Predictive maintenance analytics for laser diode and system component lifespan optimization (AEO: Maximized Uptime).

- Automated parameter optimization for dynamic material handling and mixed production batches.

- Integration with factory IoT networks for centralized data logging and process improvement feedback loops.

- Enhanced material recognition and adaptive beam focusing using deep learning algorithms.

DRO & Impact Forces Of End Pump Laser Marking Machine Market

The End Pump Laser Marking Machine Market is primarily driven by the compelling global requirement for stringent product traceability, mandated largely by regulatory bodies across the automotive, medical, and aerospace industries. The superior performance characteristics of end-pumped lasers, including high beam quality, energy efficiency, and low maintenance needs, align perfectly with the Industry 4.0 paradigm emphasizing automation and operational cost reduction. These drivers are supplemented by the continuous evolution of advanced materials (e.g., specialized polymers, high-strength alloys) which demand non-contact, high-precision marking solutions that minimize material stress. Simultaneously, the impact forces of rapid technological convergence, integrating marking systems with robotic arms and sophisticated machine vision for closed-loop quality control, are amplifying the market potential by enabling fully autonomous manufacturing cells.

However, market growth faces notable restraints, chiefly concerning the high initial capital investment required for high-quality end-pumped laser systems, which can be prohibitive for small and medium-sized enterprises (SMEs) in developing regions. Technical complexity and the requirement for specialized, highly trained operators and maintenance personnel also pose a significant barrier to entry, contrasting sharply with simpler, lower-cost marking alternatives. Furthermore, while the technology is versatile, certain highly reflective or extremely heat-sensitive materials still present challenges, sometimes requiring highly specialized wavelength configurations or ultra-short pulse technologies which further increase system cost and complexity, potentially slowing broader adoption rates in highly specialized niche applications.

Opportunities for exponential market growth lie predominantly in expanding applications within emerging economies, where rapid industrialization mandates quality assurance upgrades. The shift towards 3D marking capabilities, allowing precise marking on curved, irregular, or complex geometric surfaces prevalent in aerospace turbines and medical implants, represents a high-value opportunity segment. Additionally, the development of turnkey, modular laser systems that are easier to integrate and service, coupled with flexible financing and leasing models, provides a pathway to overcome the cost restraint challenge, making advanced laser marking accessible to a wider market demographic. The convergence with smart factory environments and the push towards sustainable manufacturing processes, favoring energy-efficient laser technology over chemical or mechanical methods, further defines the long-term growth trajectory and strategic opportunities for market participants.

Segmentation Analysis

The End Pump Laser Marking Machine Market segmentation provides a crucial framework for understanding diverse application requirements and technological preferences across various industrial verticals. The market is primarily categorized by laser type, output power, and the specific end-user application demanding high-precision, non-contact marking. Analysis reveals that the choice of segment largely depends on the required marking speed, depth, material compatibility, and the regulatory environment of the target industry. Technological advancements continually blur the lines between segments, particularly as higher-power systems become more energy-efficient and low-power systems gain in beam quality, addressing both high-speed serialization and microscopic component identification needs effectively.

- By Type:

- Diode-Pumped Solid-State (DPSS) Lasers (e.g., Nd:YAG, Nd:YVO4)

- Fiber Coupled Diode (FCD) Systems (utilized for pumping)

- Ultrafast End-Pumped Systems (Picosecond, Femtosecond)

- By Power Output:

- Low Power (10W - 20W)

- Medium Power (30W - 50W)

- High Power (>50W)

- By End-Use Application:

- Electronics and Semiconductor Manufacturing (Wafer marking, PCB labeling)

- Automotive and Transportation (Engine parts, VIN plates, safety components)

- Medical Devices and Pharmaceutical Packaging (Surgical instruments, UDI marking)

- Aerospace and Defense (Turbine blades, structural components traceability)

- Jewelry and Luxury Goods (Branding, serialization on precious metals)

- General Industrial Marking and Tooling

- By Geographical Region:

- North America (NA)

- Europe (EU)

- Asia Pacific (APAC)

- Latin America (LA)

- Middle East and Africa (MEA)

Value Chain Analysis For End Pump Laser Marking Machine Market

The value chain for the End Pump Laser Marking Machine Market begins with the upstream suppliers of critical high-technology components, primarily focusing on optical elements, high-power laser diodes (the pump source), and gain media (e.g., Nd:YVO4 crystals). This stage is characterized by high technical expertise and stringent quality control, as the performance and longevity of the final marking machine depend heavily on the quality of these core elements. Consolidation among specialized component providers often influences pricing and supply stability in the midstream manufacturing phase. Efficient sourcing and vertical integration capabilities, particularly for laser diode manufacturing and advanced optics fabrication, grant significant competitive advantages to machine manufacturers by enabling cost reduction and faster innovation cycles in developing next-generation pumping schemes and resonator designs.

The midstream segment involves the design, assembly, integration, and testing of the complete marking system. Key activities here include integrating the resonator with high-speed galvanometer scanning heads, sophisticated focusing optics, cooling systems, and proprietary control software. Manufacturers must ensure the final system delivers high beam quality and reliability under harsh industrial conditions. Distribution channels are varied: direct sales models are favored for large, custom installations involving deep client consultation (especially in aerospace or specialized medical applications), while indirect channels, utilizing regional distributors and system integrators, dominate sales to smaller industrial users and penetrate geographically dispersed markets like Southeast Asia and Latin America. These integrators provide localized technical support and customized fixture design, adding crucial value to the final deployment.

Downstream analysis focuses on end-user adoption, after-sales service, and consumables (though laser marking is largely consumable-free, optics and diodes have defined lifespans). Service contracts, technical training, and software updates are major recurring revenue streams, essential for maintaining long-term customer relationships and ensuring optimal system performance. The value chain concludes with end-users applying the marking technology across various materials, generating critical traceability data which often feeds back into their own manufacturing execution systems (MES). The direct distribution model facilitates quicker feedback regarding application challenges, allowing manufacturers to rapidly adapt product offerings and software features to address evolving industrial requirements, such as new material compositions or increasingly dense data matrix standards.

End Pump Laser Marking Machine Market Potential Customers

The primary potential customers for End Pump Laser Marking Machines are entities requiring permanent, high-contrast, non-contact serialization and identification marks, particularly where high throughput and precision are paramount. The largest customer segment encompasses manufacturers within the Electronics and Semiconductor industry, where marking micro-components, printed circuit boards (PCBs), and silicone wafers demands micrometer-level precision and minimal thermal stress—attributes intrinsically offered by DPSS end-pumped systems. These customers prioritize system integration capabilities with cleanroom standards and compatibility with automated production lines, frequently seeking suppliers offering seamless communication protocols with Manufacturing Execution Systems (MES).

A second crucial customer base resides within the regulated industries: Medical Devices and Aerospace. Medical device manufacturers require systems compliant with Unique Device Identification (UDI) regulations for surgical tools and implants, needing marks that withstand repeated sterilization cycles without corrosion or degradation. Aerospace customers demand extremely durable, verifiable marks for critical components (e.g., turbine blades, structural airframe parts) to ensure lifelong traceability under extreme environmental conditions. These buyers are generally less price-sensitive and prioritize reliability, validation documentation, and specialized marking configurations for complex 3D surfaces, often preferring direct sales models for custom engineering support.

The Automotive sector represents another massive customer segment, utilizing end-pump lasers for VIN marking, engine block serialization, component traceability for quality assurance (e.g., brake systems, fuel injectors), and branding on interior plastic components. These high-volume customers focus on speed, durability, and cost-per-mark efficiency, often purchasing medium to high-power (>30W) systems capable of deep engraving and high-speed superficial marking. Furthermore, specialized niches, including precision tooling manufacturers, luxury goods producers (jewelry, watches), and advanced packaging companies, form a growing customer base, seeking aesthetic quality combined with high-security features inherent in fine laser marking.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 680.5 Million |

| Market Forecast in 2033 | USD 1,230.1 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coherent Corp. (Rofin-Sinar), TRUMPF GmbH + Co. KG, IPG Photonics Corporation, Han’s Laser Technology Industry Group Co., Ltd., Telesis Technologies, Inc., Trotec Laser GmbH, LaserStar Technologies Corporation, Gravotech Group, Mecco Marking & Traceability, TYKMA Electrox, Inc., Electrox Laser, Universal Laser Systems, Inc., Videojet Technologies, Inc., Keyence Corporation, Cajo Technologies Oy, FOBA Laser Marking + Engraving, SIC Marking, Epilog Laser, HGTECH Co., Ltd., Maiman Laser Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

End Pump Laser Marking Machine Market Key Technology Landscape

The technology landscape of the End Pump Laser Marking Machine Market is primarily defined by continuous advancements in solid-state laser physics and material interaction dynamics. The core technology remains the Diode-Pumped Solid-State (DPSS) architecture, utilizing high-efficiency laser diodes to excite a gain medium (such as Neodymium-doped materials). Recent innovation focuses heavily on improving the efficiency of the diode-to-crystal coupling mechanism and the thermal management systems, which directly correlates to enhanced beam quality (low M2 value) and increased operational lifespan of the laser source. High beam quality is critical as it allows for smaller spot sizes and greater working distances, essential attributes for precision marking on complex geometries or for integrating systems onto large factory floors with limited space, reinforcing the technology’s dominance in high-precision, industrial applications.

A significant technological shift involves the increasing adoption of Ultra-Short Pulse (USP) lasers (picosecond and femtosecond systems) that leverage end-pumped architecture. While traditionally viewed as specialized, the falling cost and increasing reliability of these systems are making them viable for marking applications that require "cold ablation"—a process that removes material without generating a significant heat-affected zone. This capability is paramount for processing sensitive materials like polymers used in medical devices, specialized coatings, or certain semiconductor substrates where thermal damage is strictly prohibited. The superior precision and minimal impact of USP end-pumped lasers position them as the future standard for high-security and high-integrity marking needs, moving beyond mere surface discoloration to controlled material modification.

Furthermore, the key technology landscape is heavily influenced by ancillary systems, notably high-speed galvanometer scanners and sophisticated control software. Advanced galvanometers offer enhanced speed and precision, allowing for marking on the fly (MOTF) applications and increasing overall production speeds. Software development focuses on user accessibility, integration with industrial protocols (like Profinet or Ethernet/IP), and advanced features such as dynamic focusing algorithms for 3D marking. These software-driven capabilities ensure that the physical high-precision laser output can be optimally utilized across varied production environments and material types, simplifying the operational complexities traditionally associated with advanced laser systems and making them highly versatile tools for Industry 4.0 environments.

Regional Highlights

The global demand for End Pump Laser Marking Machines exhibits significant regional variation, driven by differing industrial maturity levels, regulatory landscapes, and manufacturing concentrations. Asia Pacific (APAC) represents the largest and fastest-growing market due to the high density of electronics, semiconductor, and automotive manufacturing bases, particularly in China, Japan, and South Korea. These regions are investing heavily in automated production lines, where the speed and reliability of end-pumped systems are highly valued. Government initiatives promoting high-tech manufacturing and robust domestic consumption further accelerate the adoption of advanced laser marking technologies across various supply chains.

North America and Europe constitute mature markets characterized by stringent quality standards and a high focus on highly customized, high-margin applications, such as aerospace components, certified medical instruments, and defense equipment. These regions often lead in adopting the latest, highest-cost USP end-pumped systems to ensure compliance with advanced traceability mandates (e.g., European MDR for medical devices). The focus here is not primarily on volume but on the exceptional precision, durability, and non-destructive nature of the mark, coupled with the need for long-term service agreements and robust technical support from local providers.

Latin America (LA) and the Middle East and Africa (MEA) are emerging markets showing gradual but consistent growth. LA’s growth is anchored by its expanding automotive assembly and consumer electronics industries in countries like Mexico and Brazil, while the MEA region sees demand stemming from large-scale infrastructure projects, oil and gas component identification, and jewelry manufacturing hubs. These regions prioritize systems offering a strong balance between performance and cost-effectiveness, favoring robust, lower-maintenance DPSS systems capable of operating reliably in often challenging industrial environments, often procured through established distribution networks.

- Asia Pacific (APAC): Dominant market share due to the concentration of global semiconductor and automotive manufacturing. High adoption driven by industrial automation policies and massive manufacturing output in China and Taiwan. Focus on high-speed, high-throughput systems.

- North America: High demand for advanced, specialized marking solutions for aerospace and FDA-regulated medical devices. Market characterized by early adoption of Ultra-Short Pulse technology and stringent regulatory compliance requirements (e.g., UDI).

- Europe: Strong growth influenced by strict traceability mandates in the German automotive sector and complex marking requirements for sophisticated industrial machinery. Emphasis on energy efficiency and seamless integration into factory automation systems (Industry 4.0).

- Latin America (LA): Emerging market potential driven by expanding local assembly operations and increasing infrastructure investment. Demand focused on durable marking solutions for automotive parts and general industrial goods.

- Middle East and Africa (MEA): Gradual expansion driven by investment in energy sector components (oil and gas) requiring permanent identification and growth in high-value goods (jewelry) marking for anti-counterfeiting measures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the End Pump Laser Marking Machine Market.- Coherent Corp. (Rofin-Sinar)

- TRUMPF GmbH + Co. KG

- IPG Photonics Corporation

- Han’s Laser Technology Industry Group Co., Ltd.

- Telesis Technologies, Inc.

- Trotec Laser GmbH

- LaserStar Technologies Corporation

- Gravotech Group

- Mecco Marking & Traceability

- TYKMA Electrox, Inc.

- Electrox Laser

- Universal Laser Systems, Inc.

- Videojet Technologies, Inc.

- Keyence Corporation

- Cajo Technologies Oy

- FOBA Laser Marking + Engraving

- SIC Marking

- Epilog Laser

- HGTECH Co., Ltd.

- Maiman Laser Systems

Frequently Asked Questions

What are the primary advantages of an End Pump Laser Marking Machine over traditional marking methods?

End Pump Laser Marking Machines offer superior beam quality, resulting in finer resolution and permanent, high-contrast marks without material contact. Key advantages include high energy efficiency, exceptional longevity of the diode pump source (reducing operational costs), minimal maintenance requirements, and the capability for high-speed serialization crucial for automated industrial processes, unlike traditional inkjet or mechanical engraving methods.

Which industries are the major consumers of high-power (>30W) End Pump Laser Marking Systems?

The major consumers of high-power systems are the Automotive and Aerospace sectors, requiring deep, durable marking for critical metal components like engine parts, chassis frames, and turbine blades. These high-power units enable faster material removal (engraving) and ensure mark integrity under extreme environmental and operational stresses, satisfying stringent traceability regulations.

How does the integration of AI enhance the performance of End Pump Laser Marking Machines?

AI integration significantly enhances performance by enabling real-time quality verification of marked codes using machine vision, automatically optimizing laser parameters for variations in materials or production speeds, and facilitating predictive maintenance schedules based on component wear analysis. This results in maximized uptime, reduced waste, and superior, consistent quality control necessary for regulated applications.

What is the main restraining factor affecting the widespread adoption of this technology?

The main restraining factor is the high initial capital investment required for purchasing advanced End Pump Laser Marking Systems, especially high-end DPSS or Ultra-Short Pulse models. While operational costs are low, the significant upfront expenditure can deter small and medium-sized enterprises (SMEs) from upgrading their marking infrastructure.

Is the Asia Pacific region the dominant market for End Pump Laser Marking Machines, and why?

Yes, the Asia Pacific (APAC) region is the dominant market, driven by its expansive and rapidly automating manufacturing base, particularly in electronics, semiconductors, and high-volume automotive production. The region’s aggressive adoption of Industry 4.0 standards and the high density of global supply chains create immense demand for high-speed, reliable, and efficient laser marking solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager