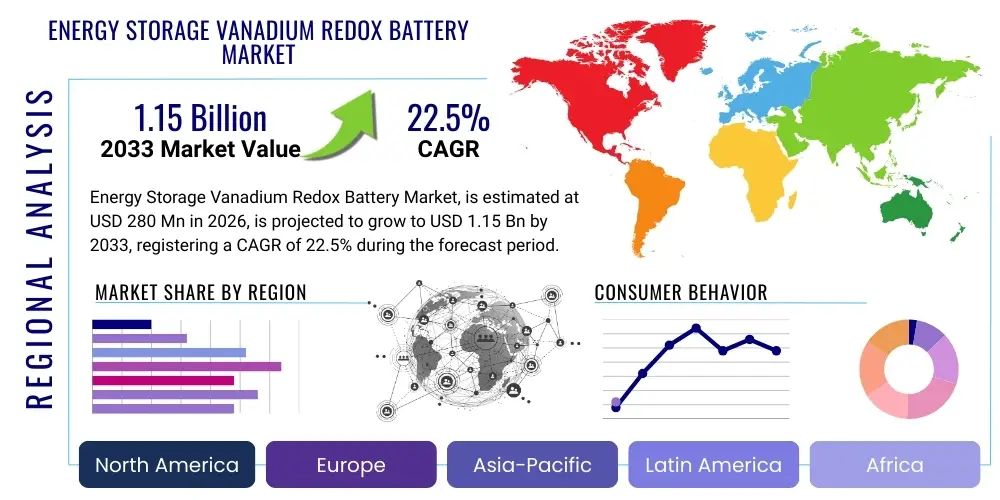

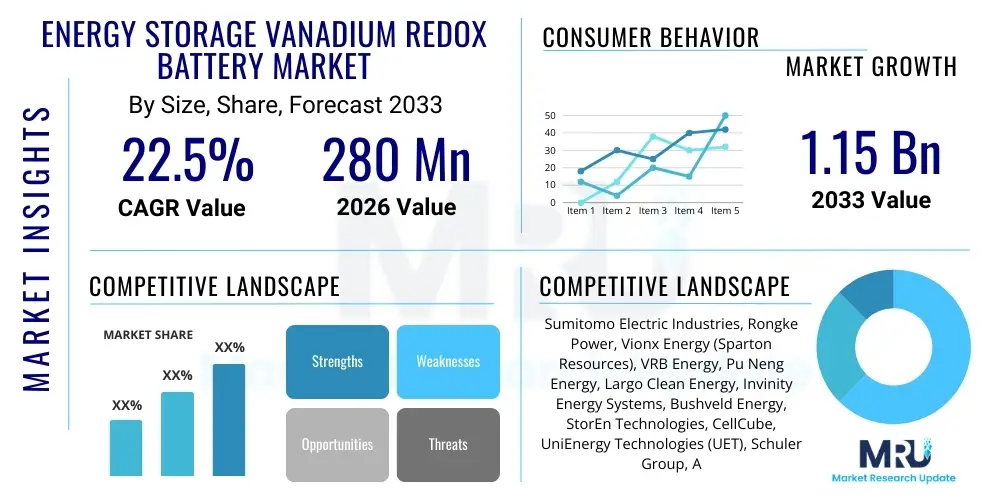

Energy Storage Vanadium Redox Battery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439156 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Energy Storage Vanadium Redox Battery Market Size

The Energy Storage Vanadium Redox Battery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 22.5% between 2026 and 2033. The market is estimated at USD 280 million in 2026 and is projected to reach USD 1.15 billion by the end of the forecast period in 2033. This substantial growth is fundamentally driven by the escalating global requirement for long-duration energy storage solutions necessary to integrate intermittent renewable energy sources, such as solar and wind power, effectively into existing grid infrastructure. Vanadium redox flow batteries (VRFBs) offer unique characteristics, particularly their non-flammability and capacity for decoupling power and energy, which make them highly suitable for utility-scale applications requiring 4 to 10 hours of discharge capacity.

The increasing emphasis on grid resilience and modernization across developed and rapidly industrializing economies further catalyzes market expansion. Governments worldwide are implementing supportive policies, tax credits, and mandates for energy storage deployment, recognizing its crucial role in managing peak load demands and stabilizing transmission systems. As manufacturing processes for VRFB components, including membranes and electrolytes, mature and achieve economies of scale, the initial high capital expenditure (CAPEX) associated with these systems is expected to decrease, thereby accelerating adoption rates, particularly in regions with ambitious decarbonization goals like Europe and North America.

Moreover, the inherent longevity and deep cycle capabilities of VRFBs, often exceeding 20 years with minimal degradation, present a strong value proposition compared to conventional lithium-ion technologies in specific long-duration applications. Investment in research and development focuses intensely on improving energy density through electrolyte modifications and enhancing system efficiency via advanced thermal management and stacking designs. This technological progression, coupled with the growing necessity for reliable, safe, and scalable energy storage to support distributed generation and microgrids, firmly establishes the VRFB market as a critical component of the future sustainable energy landscape.

Energy Storage Vanadium Redox Battery Market introduction

The Vanadium Redox Battery (VRFB) market centers around large-scale electrochemical energy storage systems utilizing the unique redox properties of vanadium ions in different oxidation states dissolved in an acidic electrolyte. These batteries operate by storing energy in external tanks, where liquid electrolytes are pumped through an electrochemical cell stack, allowing for the independent scaling of power (determined by the cell stack size) and energy (determined by the electrolyte volume). This inherent flexibility and modularity position VRFBs as a superior choice for applications requiring several hours of continuous discharge, contrasting sharply with the energy density constraints of solid-state battery alternatives. The underlying principle involves the reversible reduction and oxidation of V(II)/V(III) and V(IV)/V(V) couples across a membrane, ensuring extremely long cycle life and negligible capacity fading over decades of operation.

Major applications for VRFBs span across utility-scale grid infrastructure, including peak shaving, load leveling, frequency regulation, and, critically, smoothing the output variability of large wind and solar farms. Beyond grid services, these systems are increasingly deployed in commercial and industrial (C&I) settings to optimize energy usage, participate in demand charge reduction programs, and provide reliable backup power for essential services. The primary benefits driving market penetration include unparalleled safety due to the use of non-flammable aqueous electrolytes, the capability for deep cycling without degradation, and the potential for 100% depth of discharge. Furthermore, the electrolyte is fully reusable at the end of the system's life, significantly lowering the long-term environmental footprint and ensuring a circular economy approach to resource utilization.

The market is fundamentally driven by robust governmental mandates promoting renewable energy integration and global efforts toward achieving carbon neutrality by mid-century. Supportive regulatory environments, alongside technological advancements focused on reducing component costs, particularly for expensive materials like ion exchange membranes, are accelerating commercialization. Investment in manufacturing capacity expansion, particularly in Asia Pacific and North America, is aimed at reducing supply chain bottlenecks and achieving necessary scale. These driving factors coalesce to support the rapid transition away from fossil fuel peaking plants, positioning VRFBs as a core enabler of stable, resilient, and fully decarbonized power grids worldwide.

Energy Storage Vanadium Redox Battery Market Executive Summary

The global Energy Storage Vanadium Redox Battery market is undergoing a period of accelerated commercialization, transitioning from demonstration projects to widespread utility-scale deployment, primarily fueled by the imperative for long-duration storage. Business trends emphasize strategic vertical integration, where key players are securing vanadium supply agreements or investing directly in electrolyte manufacturing to stabilize costs and ensure material security, mitigating the volatility inherent in the vanadium commodity market. Furthermore, the market is characterized by increasing cross-sector partnerships between established battery manufacturers, EPC contractors, and renewable energy developers to deliver fully integrated storage solutions. These collaborations are crucial for optimizing system design, accelerating project deployment timelines, and achieving competitive pricing against established storage technologies, particularly in the multi-megawatt (MW) and multi-megawatt-hour (MWh) segments.

Regionally, the market exhibits strong dynamism, with Asia Pacific (APAC), particularly China and Australia, leading in terms of deployed capacity and manufacturing scale due to substantial governmental support and large-scale renewable energy targets. North America and Europe, driven by ambitious decarbonization policies like the U.S. Inflation Reduction Act (IRA) and the European Green Deal, represent high-growth potential regions, focusing on utility grid stabilization and enhancing energy independence. These regions are prioritizing long-duration, non-flammable solutions for densely populated areas and critical infrastructure. The emphasis in regional development is moving beyond mere technological demonstration towards proving financial viability and achieving bankability for large-scale infrastructure financing, underscoring the market's maturation.

Segmentation trends indicate a clear dominance of the utility-scale application segment, which accounts for the largest share of market revenue, necessitating high-capacity systems often exceeding 10 MWh. Within technology segments, flow battery architecture standardization and system efficiency improvements are key areas of focus. Demand is increasingly shifting toward third-generation VRFBs featuring enhanced energy density electrolytes (e.g., high-concentration or mixed acid solutions) and advanced, lower-cost membrane technologies, aiming to reduce the overall system footprint and improve volumetric energy output. This segmented focus ensures that VRFBs remain highly relevant for the specific challenge of integrating high penetrations of intermittent solar and wind generation.

AI Impact Analysis on Energy Storage Vanadium Redox Battery Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the VRFB market frequently revolve around how AI can mitigate operational complexity, optimize system lifetime, and lower deployment costs. Key themes include the use of machine learning for predictive maintenance to prevent premature cell stack failures, optimizing charging and discharging schedules based on real-time grid conditions and renewable forecasts, and enhancing the efficiency of electrolyte management systems. Users are deeply interested in how AI algorithms can model complex electrochemical processes within the battery to predict degradation accurately, thereby maximizing the utilization window and ensuring system stability. Furthermore, there is significant inquiry into AI’s role in optimizing the supply chain, specifically forecasting vanadium demand and managing inventory efficiently to buffer against commodity price volatility and supply disruptions.

AI’s most transformative application in the VRFB sector lies in operational optimization and predictive analytics. By analyzing vast datasets generated by battery management systems (BMS), including flow rates, temperature profiles, state-of-charge, and historical performance metrics, AI models can detect subtle anomalies far earlier than traditional threshold-based monitoring. This capability enables predictive maintenance, shifting maintenance strategies from reactive to proactive, which significantly reduces downtime and extends the operational lifespan of the expensive cell stack and peripheral equipment. Furthermore, sophisticated reinforcement learning models are being developed to optimize dispatch strategies, deciding precisely when to charge or discharge based on marginal electricity costs, weather forecasts, and grid congestion indices, thereby maximizing the financial return on investment (ROI) for asset owners.

Beyond operational performance, AI is playing a growing role in the initial design and manufacturing phases. Generative design tools leveraging AI are used to optimize the geometry of flow plates and manifolds within the cell stack to minimize pumping losses and ensure uniform electrolyte distribution, directly improving round-trip efficiency. In manufacturing, machine vision systems powered by AI are enhancing quality control for critical components like membranes and bipolar plates, leading to higher manufacturing yields and reduced defect rates. This holistic application of AI—from material selection and design optimization to real-time dispatch and end-of-life predictions—is essential for making VRFBs competitive in the rapidly evolving landscape of long-duration energy storage.

- AI algorithms enable precise, real-time dispatch optimization based on predictive grid modeling and energy price volatility.

- Machine learning improves predictive maintenance by forecasting component failure, specifically membrane and stack degradation, enhancing system reliability.

- AI enhances electrolyte management by optimizing concentration levels and flow rates, maximizing volumetric energy density and efficiency.

- Generative AI tools accelerate stack design, minimizing hydraulic losses and reducing system parasitic energy consumption.

- AI-driven supply chain analytics improve vanadium procurement and inventory management, stabilizing raw material costs for manufacturers.

DRO & Impact Forces Of Energy Storage Vanadium Redox Battery Market

The VRFB market growth is shaped by a strong interplay of drivers, restraints, and opportunities. The primary driver is the accelerating global integration of intermittent renewable energy, which necessitates safe, scalable, and long-duration storage solutions to maintain grid stability and reliability when solar or wind resources are low. The inherent safety profile (non-flammability) of VRFBs provides a compelling advantage, especially for deployments in urban areas or sensitive infrastructure, directly addressing major concerns associated with thermal runaway in lithium-ion batteries. Opportunities primarily arise from continuous technological innovation focused on improving electrolyte formulations, developing lower-cost membranes, and optimizing system integration, which collectively drive down the levelized cost of storage (LCOS). These advancements make VRFBs increasingly competitive against alternative storage technologies for multi-hour applications.

However, the market faces significant restraints, most notably the high initial capital expenditure (CAPEX) associated with manufacturing and installation, which is often higher than current lithium-ion solutions, hindering widespread commercial adoption without subsidy support. Another crucial restraint is the supply chain volatility and price fluctuation of vanadium, a critical raw material often sourced from a limited number of geographical regions, introducing economic uncertainty for large projects. Impact forces, which dictate the speed and direction of market evolution, include regulatory shifts, such as stricter fire safety codes for energy storage installations that inherently favor VRFBs, and the maturity of recycling infrastructure for vanadium electrolytes, which, when established, significantly reduces the lifetime cost and environmental impact of the battery.

Furthermore, the competitive landscape is intensely driven by continuous breakthroughs in alternative flow battery chemistries (e.g., zinc-bromine or iron-air) and next-generation long-duration technologies (e.g., mechanical or thermal storage). This intense competition forces VRFB developers to rapidly enhance their technology's energy density and round-trip efficiency (RTE) to maintain market relevance. The ultimate success of the market is heavily influenced by the ability of manufacturers to transition from bespoke, project-specific systems to standardized, mass-produced modular units, achieving the necessary economies of scale. Regulatory environments that offer clear, long-term policy signals supporting grid modernization and long-duration storage procurement are the most powerful external force driving successful VRFB deployment.

Segmentation Analysis

The Energy Storage Vanadium Redox Battery market is broadly segmented based on Application, Type (by Power Capacity), and End-User, reflecting the diverse needs of the energy sector for long-duration storage. Analyzing these segments provides critical insights into deployment patterns and investment priorities globally. By Application, the Utility Grid segment dominates, encompassing large-scale installations used for grid leveling, ancillary services, and renewable energy firming. This segment requires high-capacity, multi-megawatt-hour systems capable of extended discharge periods. The Commercial & Industrial (C&I) segment, while smaller, represents a significant growth area, focusing on demand charge reduction and microgrid development. Understanding this split is crucial for manufacturers tailoring product specifications and marketing strategies.

Segmentation by Type or power capacity differentiates between large-scale storage systems (typically >1 MW and >4 MWh) and smaller modular systems designed for distributed generation or integration with smaller renewable assets. Large-scale systems are optimized for lowest LCOS and highest operational lifespan, catering primarily to utility and Independent Power Producer (IPP) requirements. Smaller modular systems emphasize ease of installation, scalability, and integration complexity, often targeting remote applications or specific industrial processes. This capacity-based segmentation helps in forecasting the demand for specific component sizes, such as stack dimensions and electrolyte volumes, influencing manufacturing investment strategies.

The End-User segmentation further refines market targeting, identifying key buyers such as Utilities and Independent Power Producers (IPPs) as the major purchasers, followed by commercial entities, remote infrastructure operators (e.g., telecommunications towers), and defense installations requiring high reliability and low maintenance. Utilities focus on long-term performance guarantees and system bankability, whereas C&I users prioritize fast ROI via energy arbitrage and demand control. The structural complexity and safety advantages of VRFBs make them particularly appealing to infrastructure owners where reliability and fire safety are paramount considerations, driving specialized product development for these niche, high-value end-user groups.

- By Application:

- Utility Grid Storage (Grid-scale, Ancillary Services, Renewable Firming)

- Commercial & Industrial (C&I) Storage (Peak Shaving, Demand Charge Reduction)

- Microgrids and Off-Grid Systems

- By Type (Power Capacity):

- Large Scale Systems (MW/MWh Class)

- Small/Modular Scale Systems (kW/kWh Class)

- By End-User:

- Utilities and IPPs (Independent Power Producers)

- Commercial Energy Consumers

- Industrial Facilities

- Residential (Emerging/Niche)

Value Chain Analysis For Energy Storage Vanadium Redox Battery Market

The VRFB value chain begins with the critical upstream activities centered on raw material procurement and processing. This stage involves the extraction and refinement of vanadium resources, typically sourced globally from major mining regions such as China, Russia, South Africa, and Brazil. The refined vanadium pentoxide (V2O5) is then chemically processed into the vanadium electrolyte solution (typically sulfuric acid based), which constitutes the single largest cost component of the overall battery system. Efficient, high-volume, and cost-effective electrolyte manufacturing is paramount for competitive pricing, leading many key players to form strategic partnerships or undertake backward integration into electrolyte production to mitigate material cost volatility and ensure quality control, as the purity and stability of the electrolyte directly impact battery performance and longevity.

The midstream phase focuses on manufacturing the core battery components and integrating them into a functional system. Component manufacturing includes the production of the electrochemical cell stack (involving bipolar plates, ion-exchange membranes, and electrode materials), storage tanks, and balance-of-plant (BOP) components like pumps, piping, and the sophisticated battery management system (BMS). System integrators play a vital role here, assembling these components into containerized, modular units suitable for deployment. Standardization of stack design and the adoption of more advanced membrane technologies (e.g., cheaper, high-performance porous membranes) are key areas where midstream actors seek to achieve manufacturing efficiencies and lower production costs, facilitating large-scale deployment.

The downstream segment encompasses the distribution, installation, operation, and maintenance, as well as the eventual decommissioning and recycling of the systems. Distribution channels are typically direct for utility-scale projects, involving direct contracting between the system integrator and the utility or IPP, often utilizing specialized EPC (Engineering, Procurement, and Construction) firms. Indirect channels involve regional distributors or energy service companies (ESCOs) for smaller C&I or microgrid installations. A crucial aspect of the downstream value chain is the long-term operational services, including remote monitoring, performance guarantees, and, most importantly, the end-of-life recycling and reconstitution of the vanadium electrolyte, ensuring that the high-value material is recovered and reused, which significantly enhances the system's long-term economic and environmental viability.

Energy Storage Vanadium Redox Battery Market Potential Customers

The primary consumers and buyers of Vanadium Redox Flow Battery technology are large energy infrastructure operators who require reliable, long-duration storage capacity to manage system-wide variability and enhance grid stability. Utility companies and Independent Power Producers (IPPs) represent the most significant customer segment, as they invest in massive, multi-megawatt installations to store excess renewable energy generated during peak production times (e.g., midday solar peaks) for use during peak demand periods or periods of low generation. These buyers demand systems with proven high cycle life, robust safety features, and a guaranteed performance longevity of 20+ years, necessitating systems that can meet stringent operational requirements and bankability standards for multi-billion dollar infrastructure projects. Their purchasing decisions are heavily influenced by the Levelized Cost of Storage (LCOS) and regulatory compliance requirements related to grid interconnection and safety.

Another crucial customer segment consists of large industrial and commercial enterprises, particularly those with high, fluctuating power consumption profiles, such as manufacturing plants, data centers, and major logistics hubs. These end-users utilize VRFBs primarily for demand charge management (peak shaving), ensuring power quality, and providing reliable backup power, particularly where uninterrupted operation is mission-critical. For these customers, the inherent non-flammability of VRFBs is a major deciding factor, especially when installing systems within or adjacent to existing corporate infrastructure where fire safety risks must be minimized. The economic rationale for C&I deployment is highly dependent on local electricity tariff structures and the availability of incentives for distributed energy resource deployment.

Emerging but rapidly growing customer groups include Microgrid Developers and providers of critical infrastructure solutions, such as telecommunication network operators, military bases, and remote island utilities. In these applications, VRFBs offer distinct advantages due to their ability to provide reliable, long-term energy security without reliance on fluctuating fuel supplies or concerns related to environmental contamination. The modularity and relatively simple scalability of flow battery systems allow them to be tailored precisely to the unique power and energy requirements of off-grid or remote community power systems. This flexibility, combined with the low maintenance requirements over long operational periods, makes VRFBs ideal for locations where access and service are challenging or expensive.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 280 Million |

| Market Forecast in 2033 | USD 1.15 Billion |

| Growth Rate | 22.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sumitomo Electric Industries, Rongke Power, Vionx Energy (Sparton Resources), VRB Energy, Pu Neng Energy, Largo Clean Energy, Invinity Energy Systems, Bushveld Energy, StorEn Technologies, CellCube, UniEnergy Technologies (UET), Schuler Group, Australian Vanadium Limited, RedFlow Limited, Gildemeister Energy Storage, Shanghai Electric, Dalian Bingshan Group, VoltStorage, H2 Inc., Enerox GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Energy Storage Vanadium Redox Battery Market Key Technology Landscape

The core technology landscape of the VRFB market is characterized by intense efforts aimed at improving energy density, enhancing system efficiency, and significantly reducing manufacturing costs, primarily through materials innovation. A major focus area is the development of next-generation vanadium electrolytes. This includes moving beyond traditional sulfate electrolytes to high-concentration or mixed-acid electrolytes (e.g., sulfate-chloride or sulfate-bromide systems). These advancements allow for higher vanadium ion solubility, enabling a greater amount of energy to be stored per unit volume, which ultimately decreases the size and cost of the required storage tanks and the system footprint. Successful implementation of these enhanced electrolytes is paramount for making VRFBs economically viable for space-constrained urban deployments and maximizing their performance metrics.

Membrane technology represents the second critical technological frontier, as the membrane separating the positive and negative electrolyte streams is often the most expensive component in the cell stack after the electrolyte itself. Traditional perfluorinated ion exchange membranes (like Nafion) are highly effective but prohibitively expensive. Technological efforts are concentrated on developing lower-cost alternatives, such as non-fluorinated hydrocarbon-based membranes or specialized porous separators. These new membranes aim to maintain high ion conductivity and chemical stability while significantly reducing material cost, thereby driving down the overall system CAPEX. Furthermore, advancements in bipolar plate materials, specifically moving towards composite or graphite felt electrodes with enhanced surface area and optimized flow channels, are boosting the electro-chemical reaction kinetics and round-trip efficiency (RTE).

System integration and management technologies also form a vital part of the technical landscape. Continuous refinement of the Battery Management System (BMS) is essential, incorporating sophisticated algorithms for state-of-charge (SOC) estimation, fault detection, and precise flow control to minimize parasitic losses from pumping and cooling systems. The design of modular, containerized VRFB units simplifies transportation, installation, and scalability, making deployment faster and less dependent on custom engineering for each site. Future technological trends are also exploring hybrid VRFB systems, potentially integrating small lithium-ion buffers or coupling VRFBs with green hydrogen production/storage systems, maximizing their versatility in complex, dynamic renewable energy environments.

Regional Highlights

The global VRFB market demonstrates significant regional disparities in terms of deployment maturity, regulatory support, and manufacturing dominance, influenced heavily by local energy policies and grid modernization initiatives. Asia Pacific (APAC) currently dominates the market, primarily driven by massive utility-scale deployment programs in China, which has heavily subsidized flow battery research, manufacturing, and commercial projects, establishing itself as a global leader in installed capacity. South Korea and Australia also represent strong growth hubs within APAC, fueled by ambitious targets for integrating high levels of solar and wind generation, where the need for long-duration storage is critical for network stability. This region benefits from established supply chains and governmental emphasis on renewable energy infrastructure build-out, accelerating the commercialization timeline.

North America, particularly the United States, is poised for explosive growth, stimulated by favorable federal legislation, such as the Investment Tax Credit (ITC) offered through the Inflation Reduction Act (IRA), which significantly improves the financial viability of long-duration storage projects. Key states like California and New York have mandated energy storage targets and prioritize non-flammable solutions, creating a strong market pull for VRFBs in utility and C&I applications. Deployment in this region often emphasizes grid reliability, particularly in areas prone to natural disasters or high congestion, and technological focus is placed on domestic manufacturing and supply chain security to meet 'Buy American' requirements.

Europe is another high-potential market, driven by the ambitious targets of the European Green Deal and the necessity to balance increasingly fragmented and interconnected national grids utilizing diverse renewable sources. Germany, the UK, and Italy are leading the adoption curve, often integrating VRFBs into commercial microgrids, regional utility systems, and virtual power plants (VPPs). While still slower than APAC in utility-scale deployment volume, Europe focuses heavily on standardization, safety protocols, and circular economy principles, leveraging the recycling advantages of vanadium electrolyte. The Middle East and Africa (MEA) and Latin America (LATAM) represent emerging markets, with deployment focused on enhancing grid resilience, supporting remote electrification projects, and addressing power quality issues in resource-rich areas that are adopting large-scale solar power projects.

- Asia Pacific (APAC): Dominates the market share due to large-scale deployments in China and Australia, supported by aggressive governmental renewable energy mandates and substantial manufacturing capabilities.

- North America: Fastest-growing region, accelerated by federal incentives (IRA) and state mandates prioritizing long-duration, safe storage solutions for grid modernization and resilience.

- Europe: Focuses on system integration, high-safety standards, and technological innovation driven by the European Green Deal; deployment targets C&I and microgrid applications as well as utility services.

- Latin America (LATAM): Emerging market driven by decentralized power generation needs and improving grid infrastructure in countries like Brazil and Chile, often linked to large mining operations.

- Middle East & Africa (MEA): Growth driven by remote electrification projects and the coupling of VRFBs with vast solar projects in the GCC region to ensure stable energy supply in harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Energy Storage Vanadium Redox Battery Market.- Sumitomo Electric Industries

- Rongke Power

- Vionx Energy (Sparton Resources)

- VRB Energy

- Pu Neng Energy

- Largo Clean Energy

- Invinity Energy Systems

- Bushveld Energy

- StorEn Technologies

- CellCube

- UniEnergy Technologies (UET)

- Schuler Group

- Australian Vanadium Limited

- RedFlow Limited

- Gildemeister Energy Storage

- Shanghai Electric

- Dalian Bingshan Group

- VoltStorage

- H2 Inc.

- Enerox GmbH

Frequently Asked Questions

Analyze common user questions about the Energy Storage Vanadium Redox Battery market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of Vanadium Redox Batteries (VRFBs) over Lithium-ion batteries for grid storage?

VRFBs offer superior advantages in long-duration applications (typically 4-10+ hours) due to their decoupled power and energy capacities, non-flammability, extremely long cycle life (20+ years), and minimal capacity degradation over time, making them inherently safer and more economical for massive, utility-scale deployments.

What is the biggest restraint impacting the commercial adoption of VRFBs?

The principal restraint is the high upfront Capital Expenditure (CAPEX), largely attributable to the cost of the vanadium electrolyte and the ion exchange membrane. Furthermore, market sensitivity to the volatile price and supply chain of vanadium metal poses a commercial challenge that technology developers are working to mitigate through supply contracts and advanced recycling techniques.

How is the Levelized Cost of Storage (LCOS) for VRFBs being reduced?

LCOS is primarily reduced through technological advancements such as developing high-concentration, energy-dense electrolytes, utilizing cheaper, more efficient membrane materials, optimizing stack design to minimize pumping losses, and achieving economies of scale in automated manufacturing processes, ultimately extending the system lifespan and reducing operational expenditure.

Which geographic region currently leads the market in VRFB deployments?

Asia Pacific (APAC), particularly China, leads the global market in terms of deployed VRFB capacity, driven by substantial national investment, clear renewable energy integration mandates, and established domestic supply chains and manufacturing capabilities supporting large-scale utility projects.

What role does the electrolyte play in the long-term sustainability of VRFB systems?

The electrolyte, which holds the majority of the stored energy, is key to sustainability because it does not degrade chemically and is fully recoverable and reusable at the end of the battery’s operational life, enabling a highly efficient closed-loop recycling process that minimizes resource depletion and enhances the system's overall lifecycle economics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager