Environmental Control Room Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433509 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Environmental Control Room Market Size

The Environmental Control Room Market is experiencing robust growth driven by escalating demands for precision testing and manufacturing across highly regulated industries such as pharmaceuticals, aerospace, and electronics. These facilities are critical infrastructure necessary to ensure product reliability and regulatory compliance by simulating or maintaining specific atmospheric conditions. The increasing complexity of R&D protocols and the stringent quality control standards mandated globally contribute significantly to market expansion, particularly in emerging economies ramping up sophisticated manufacturing capabilities.

Regulatory bodies worldwide, including the FDA, EMA, and various national standards organizations, mandate rigorous testing under controlled environments, solidifying the necessity of environmental control rooms (ECRs). This regulatory push, combined with technological advancements in control systems and modular construction, allows ECRs to be deployed more efficiently and accurately than ever before. Furthermore, the growth in battery technology research and development, which often requires highly specific temperature and humidity ranges, presents a substantial market catalyst, ensuring sustained growth trajectory throughout the forecast period.

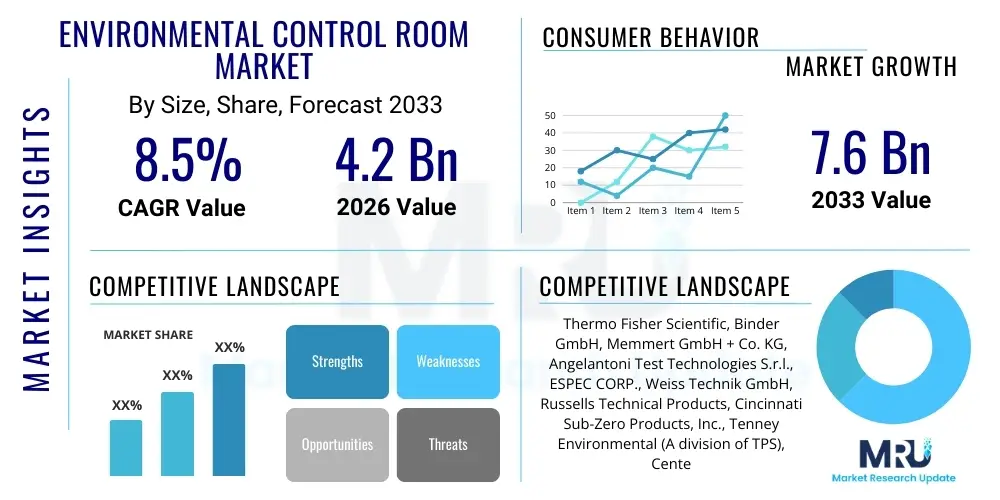

The Environmental Control Room Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 7.6 Billion by the end of the forecast period in 2033.

Environmental Control Room Market introduction

The Environmental Control Room Market encompasses the design, manufacture, installation, and maintenance of specialized facilities engineered to maintain precise, often extreme, atmospheric conditions, including control over temperature, humidity, air pressure, and particulate matter contamination. These specialized rooms, ranging from small test chambers to large production cleanrooms, are essential products utilized across critical sectors where product integrity, calibration, and safety depend on controlled environmental parameters. Major applications include stability testing in pharmaceuticals, material reliability testing in automotive and aerospace sectors, and sensitive manufacturing processes in the semiconductor industry, ensuring products meet stringent quality and performance specifications.

The primary benefits derived from the adoption of environmental control rooms include enhanced product quality and consistency, reduced risk of material degradation or contamination, validation of performance under various climatic stresses, and crucially, streamlined compliance with international regulatory standards (such as ISO, GMP, and GLP). Key driving factors propelling this market include the global expansion of biological and pharmaceutical R&D activities, the rapid evolution of complex microelectronics requiring ultraclean manufacturing environments, and increased investment in electric vehicle battery development, all of which necessitate specialized, highly controllable testing and production facilities.

Product sophistication within this market is characterized by integration of advanced HVAC systems, complex air filtration (HEPA/ULPA), sophisticated data logging and monitoring systems, and modular construction techniques that allow for flexibility and scalability. The convergence of these technological capabilities addresses the industry need for precision, energy efficiency, and operational agility in controlling environmental variables, making ECRs indispensable assets in modern high-tech industries.

Environmental Control Room Market Executive Summary

The Environmental Control Room Market is characterized by a strong convergence of business trends centered on automation, modular construction, and energy efficiency. Demand is increasingly shifting towards turnkey solutions that integrate advanced monitoring and data analytics capabilities, allowing users to achieve tighter tolerances and better regulatory traceability. Key vendors are focusing on developing scalable, prefabricated modular units that significantly reduce installation time and operational footprint, particularly appealing to industries requiring rapid scaling, such as biotechnology startups and semiconductor fabrication facilities. Furthermore, sustainability is becoming a core competitive factor, driving manufacturers to invest in high-efficiency cooling technologies and smart control algorithms to minimize energy consumption, addressing both operational cost concerns and environmental mandates.

Regionally, the market exhibits divergent maturity levels. North America and Europe maintain dominance due to established regulatory frameworks, extensive pharmaceutical manufacturing bases, and significant R&D spending, particularly in aerospace and defense. However, the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by massive government investments in electronics manufacturing (especially in China, South Korea, and Taiwan) and the rapid expansion of generic drug production in India. Latin America and the Middle East & Africa (MEA) represent emerging opportunities, driven primarily by investments in local healthcare infrastructure and petrochemical testing facilities, though these regions still face challenges related to infrastructure readiness and initial capital expenditure requirements.

Segment trends highlight strong growth in the application of environmental control rooms in Life Sciences, primarily for stability testing and vaccine storage, demanding high-reliability systems with redundancy. Technologically, the segment for advanced monitoring and data logging systems is expanding rapidly as industries move towards Industry 4.0 principles, demanding real-time validation and predictive maintenance capabilities. Modular ECRs are gaining traction over traditional fixed installations due to their adaptability, lower upfront costs, and quicker deployment schedules, reflecting a market preference for flexible capital investment strategies aligned with fluctuating R&D needs.

AI Impact Analysis on Environmental Control Room Market

User queries regarding the impact of Artificial Intelligence (AI) on the Environmental Control Room Market primarily center on optimizing energy use, automating climate stability, and enhancing predictive maintenance. Users frequently ask how AI can prevent system failures in critical environments, improve calibration accuracy without manual intervention, and process the vast amounts of environmental data generated for regulatory reporting. The key themes revolve around achieving tighter control tolerances (reducing operational variability), extending equipment lifespan through early anomaly detection, and minimizing the substantial energy costs associated with maintaining precise, controlled environments, transforming ECRs from reactive systems to proactive, self-optimizing assets.

- AI optimizes HVAC and cooling systems by analyzing real-time load demand, external weather fluctuations, and internal operational schedules, leading to significant energy savings and reduced utility costs.

- Predictive maintenance algorithms use sensor data to identify minute deviations or component wear, forecasting potential failures in compressors, fans, or filters, thereby increasing uptime and operational reliability.

- Automated environmental calibration and drift correction are managed by AI models, ensuring high-fidelity conditions are consistently maintained, reducing manual intervention and minimizing the risk of human error in critical processes.

- AI-driven data analysis simplifies complex compliance reporting by automatically identifying relevant environmental data points, flagging excursions, and generating audit trails required by regulatory bodies (e.g., cGMP, ISO).

- Integration of machine learning allows ECRs to learn ideal operational profiles based on specific test or manufacturing protocols, dynamically adjusting environmental parameters for optimal efficiency and product yield.

DRO & Impact Forces Of Environmental Control Room Market

The dynamics of the Environmental Control Room Market are shaped by a complex interplay of driving factors (D), restraints (R), and opportunities (O), which collectively constitute the critical impact forces influencing investment decisions and technological innovation. Key drivers include stringent regulatory demands for stability testing and quality assurance across pharmaceuticals and highly sensitive electronics, necessitating the use of certified controlled environments. Furthermore, the global surge in research and development activities, particularly in novel drug delivery systems and advanced materials science, continuously fuels the demand for high-precision environmental simulation capabilities.

However, the market faces significant restraints, primarily revolving around the extremely high initial capital expenditure required for designing, constructing, and validating advanced control rooms, especially those meeting cleanroom standards (ISO Class 5 and below). Operational complexity and high energy consumption associated with maintaining precise temperature and humidity over long periods also pose financial challenges. These high entry and maintenance costs often restrict market adoption among smaller enterprises or in regions with limited infrastructure investment capacity, slowing broader market penetration.

Opportunities for growth are abundant, particularly in the adoption of modular and customizable ECR solutions that offer better scalability and reduced construction timelines. The integration of IoT and advanced data analytics presents a major opportunity for vendors to enhance control precision, remote diagnostics, and energy efficiency, creating premium service offerings. Furthermore, the burgeoning demand from specialized sectors, such as battery testing for electric vehicles and data center cooling environments, provides lucrative new application segments for tailored environmental control solutions, offering pathways for diversification and sustained market expansion.

Segmentation Analysis

The Environmental Control Room Market is rigorously segmented based on crucial attributes including Type, Application, and End-User, allowing for detailed analysis of demand patterns and technological deployment specific to industry needs. The classification by Type often distinguishes between fixed/permanent installations and highly flexible modular/portable solutions, reflecting varied investment strategies and site requirements across different industries. Application segmentation differentiates between the primary use cases, such as R&D (involving stability testing and material science) versus high-volume Manufacturing and storage processes (including cleanroom production and warehousing), each demanding distinct levels of environmental fidelity and size. End-User segmentation provides insight into the primary consuming industries, dominated by the highly regulated Life Sciences sector but increasingly influenced by high-tech manufacturing segments like Electronics and Automotive, requiring specialized system design and validation.

Analyzing these segments provides strategic clarity for market participants. For instance, the demand from the Pharmaceutical segment is characterized by strict validation requirements (21 CFR Part 11 compliance) and long operational life cycles, favoring robust, fixed installations with certified redundancy. Conversely, the Academic Research segment often prefers modular, smaller-scale ECRs that can be reconfigured or relocated as research grants and projects evolve. Understanding the interplay between these segmentation variables is essential for manufacturers to tailor their product offerings, sales strategies, and service models to effectively capture diverse pockets of demand across the global landscape.

The future evolution of market segmentation will likely see a greater emphasis on solutions defined by specific control parameters (e.g., Ultra-Low Humidity Environments or Extreme Temperature Cycling Chambers), moving beyond simple type classifications to performance-based categories driven by highly specialized technological requirements in advanced materials testing and biomanufacturing.

- Type: Fixed Installations, Modular/Portable Control Rooms

- Application: Stability Testing, R&D and Material Science, Manufacturing and Production, Calibration and Metrology, Storage and Warehousing

- End-User: Pharmaceutical and Biotechnology, Electronics and Semiconductors, Automotive and Aerospace, Academic and Research Institutions, Food and Beverage, Chemical and Petrochemical

- Control Parameter: Temperature Control (High, Low, Cycling), Humidity Control (Standard, Dry/Ultra-Low), Pressure Control (Positive/Negative)

Value Chain Analysis For Environmental Control Room Market

The value chain for the Environmental Control Room Market commences with the Upstream Analysis, which focuses heavily on the procurement of critical, highly specialized components. This includes advanced HVAC systems, high-efficiency cooling and dehumidification units, sophisticated sensor technology (for monitoring temperature, humidity, pressure, and particulates), and premium construction materials, particularly insulated panels and air handling components suitable for cleanroom standards. Key upstream challenges involve maintaining a reliable supply chain for validated, high-precision control instrumentation and managing fluctuating commodity prices for construction materials, requiring strategic partnerships with specialized component manufacturers to ensure quality and compliance.

Midstream activities involve the core competencies of ECR manufacturers, focusing on design engineering, system integration, fabrication, and stringent factory acceptance testing (FAT). This stage is highly knowledge-intensive, requiring expertise in thermodynamics, air flow dynamics, and regulatory compliance (e.g., GMP guidelines). The efficiency of the manufacturing process, particularly for modular solutions, dictates project profitability and deployment speed. Distribution channels are typically a mix of Direct and Indirect sales. Direct sales are prevalent for large, highly customized, fixed installations involving major pharmaceutical or aerospace clients, requiring extensive collaboration during the design and validation phases. Indirect channels, involving specialized system integrators, engineering firms, and regional distributors, are utilized for smaller, standardized modular units and geographical market penetration, providing localized installation and after-sales support.

Downstream analysis centers on installation, validation, commissioning, and long-term maintenance and service contracts. Validation (IQ/OQ/PQ) is a crucial step, especially in regulated sectors, confirming the ECR performs precisely to specifications. Maintenance and service contracts represent a significant ongoing revenue stream, focusing on calibration, repair, and ensuring continuous regulatory compliance. The interaction between the manufacturer and the end-user extends well beyond initial sale, emphasizing the need for robust technical support and a global service network to address the critical nature of the environments being controlled.

Environmental Control Room Market Potential Customers

The primary end-users and buyers of Environmental Control Room solutions are entities operating in environments where the reliability, stability, and integrity of their products, research, or manufacturing processes are critically dependent on precise atmospheric control. The largest cohort of potential customers resides within the Pharmaceutical and Biotechnology industries, who utilize ECRs extensively for stability testing of drugs, storage of sensitive biological materials, and sterile manufacturing processes compliant with Good Manufacturing Practices (GMP). These customers prioritize reliability, redundancy, and seamless regulatory documentation capabilities, often requiring large, fixed, validated installations.

A second major customer segment includes high-tech manufacturing, specifically Electronics and Semiconductors. These industries require ultra-clean environments (cleanrooms) for the fabrication of microchips, optical components, and sensors, where even minute particulates or humidity variations can cause product defects. Their demands focus on particulate filtration (HEPA/ULPA), vibration control, and specialized anti-static features. Furthermore, the Automotive and Aerospace sectors are increasingly significant buyers, leveraging ECRs for material testing, component performance validation under extreme conditions (temperature cycling, high humidity), and battery testing for electric vehicle applications, requiring large-volume chambers capable of handling heavy equipment.

Additionally, smaller but rapidly growing customer groups include academic research institutions that require flexible, multi-functional chambers for material science and climate simulation studies, and the Food & Beverage industry, which uses ECRs for shelf-life testing and quality control processes. All potential customers share a fundamental requirement: the ability to generate verifiable, repeatable, and traceable environmental conditions, making ECRs a mission-critical purchase.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 7.6 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Binder GmbH, Memmert GmbH + Co. KG, Angelantoni Test Technologies S.r.l., ESPEC CORP., Weiss Technik GmbH, Russells Technical Products, Cincinnati Sub-Zero Products, Inc., Tenney Environmental (A division of TPS), Center for Drug Evaluation and Research (CDER), CSZ, Scientific Climate Systems, Test Equity LLC, Darwin Chambers Company, Komeg Technology, C.M.E. s.r.l., Atlas Material Testing Technology, Climats S.A., Hanse Environmental, Inc., Sensitech (A part of Carrier). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Environmental Control Room Market Key Technology Landscape

The technological landscape of the Environmental Control Room Market is centered on achieving unparalleled precision, maximizing energy efficiency, and ensuring data integrity for regulatory compliance. Core technology involves advanced HVAC and refrigeration systems, utilizing environmentally friendly refrigerants and variable speed drive (VSD) technology to dynamically manage cooling and heating loads, thereby minimizing operational costs and energy peaks. High-performance insulation and vapor barriers are crucial for maintaining interior stability regardless of external environmental fluctuations, minimizing thermal leakage and condensation risk in high-humidity or extreme-temperature applications. The shift towards modular construction utilizes advanced sandwich panel technology and standardized interfaces, accelerating deployment and improving scalability compared to traditional stick-built construction methods.

A second critical aspect is the control and monitoring infrastructure, which has evolved significantly with the integration of Industry 4.0 principles. Modern ECRs are equipped with sophisticated Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) that manage complex interplay between temperature, humidity, and airflow parameters. Integrated sensor networks, often employing IoT technology, provide continuous, highly accurate, real-time data logging and remote accessibility. This technological evolution facilitates seamless integration with Laboratory Information Management Systems (LIMS) and Building Management Systems (BMS), ensuring traceability and centralized data management, which is mandatory for GMP validation.

Furthermore, specialized technologies are becoming standard, particularly in pharmaceutical and semiconductor applications. This includes advanced air filtration systems (HEPA and ULPA filters) capable of achieving ISO Class 5 or better cleanliness levels, and specialized dehumidification technologies like desiccant dehumidifiers, essential for maintaining extremely low relative humidity required in lithium-ion battery production and certain electronics manufacturing processes. The continuous refinement of calibration standards and automation capabilities ensures that the controlled environment remains a certified and reliable resource throughout its operational lifecycle.

Regional Highlights

North America dominates the Environmental Control Room Market, driven by the presence of a vast and mature pharmaceutical and biotechnology industry, particularly in the United States, which adheres to extremely strict FDA regulatory standards for stability testing and drug manufacturing. The region benefits from substantial government and private sector investment in cutting-edge R&D, especially in genomics, specialized aerospace materials, and advanced defense technologies, all necessitating high-specification, validated control environments. The market growth here is characterized by high demand for custom, large-scale fixed installations and specialized ultra-low temperature storage solutions, emphasizing quality assurance and regulatory compliance over cost minimization. The high concentration of technology companies and electric vehicle R&D also ensures sustained demand for sophisticated battery testing chambers.

Europe represents a highly mature market, characterized by stringent environmental and operational regulations set by the European Medicines Agency (EMA) and various national bodies. Key demand drivers include a robust automotive sector focused on new material development and emissions testing, as well as a strong tradition of high-quality pharmaceutical and clinical research across countries like Germany, Switzerland, and the UK. The European market shows a strong preference for energy-efficient, sustainable ECR solutions, often leading in the adoption of advanced refrigeration techniques and smart optimization software to meet ambitious sustainability targets. Modular ECRs are also gaining acceptance, particularly within university research and smaller clinical trial facilities, seeking flexible capital deployment strategies while maintaining high control fidelity.

Asia Pacific (APAC) is projected to register the highest growth rate during the forecast period, transitioning rapidly from an emerging market to a global manufacturing hub. This growth is predominantly fueled by massive state and private sector investments in electronics and semiconductor manufacturing (especially in Taiwan, South Korea, and mainland China), driving unprecedented demand for ISO-certified cleanrooms and highly precise humidity control chambers. Simultaneously, the burgeoning generic pharmaceutical and medical device manufacturing industries in India and Southeast Asia are increasing their adoption of ECRs to meet international quality standards and export requirements. The APAC market is highly price-sensitive but increasingly values integrated service and validation support, necessitating that vendors offer competitive, scalable, and rapidly deployable solutions suitable for large-scale production facilities.

Latin America remains an developing market for ECRs, with demand primarily concentrated in major economies such as Brazil and Mexico, driven by localized pharmaceutical manufacturing and food processing industries focused on regional supply chains. The market size is currently smaller but exhibits strong potential, bolstered by government initiatives aimed at modernizing healthcare infrastructure and increasing domestic production capabilities. Challenges include reliance on imports for advanced technology and a fragmented regulatory landscape, leading to a focus on essential, reliable control room functionalities rather than highly customized, cutting-edge systems.

Middle East and Africa (MEA) growth is largely dependent on localized investments in petrochemical testing laboratories, strategic food storage facilities, and, increasingly, domestic vaccine and biopharma production (e.g., in Saudi Arabia and UAE). The environmental challenge of extreme heat necessitates highly durable and high-capacity cooling systems tailored for desert climates. While the overall market volume is lower, the focus is on high-specification control rooms for specialized oil and gas R&D and critical governmental infrastructure projects, prioritizing redundancy and resilience in harsh operating conditions.

- North America: Dominant market share due to stringent FDA regulation, established Pharma/Biotech industries, and significant investment in aerospace and defense R&D. Key emphasis on validation and redundancy.

- Europe: Strong demand driven by the automotive sector, advanced R&D, and regulatory compliance (EMA). High adoption of energy-efficient and sustainable ECR technologies.

- Asia Pacific (APAC): Fastest-growing region, powered by semiconductor, electronics manufacturing expansion, and rapid growth in generic pharmaceuticals, favoring scalable and modular solutions.

- Latin America: Emerging market driven by local pharmaceutical production and infrastructure modernization; primary focus on essential, reliable control capabilities.

- Middle East & Africa (MEA): Growth linked to petrochemical testing and emerging domestic biopharma manufacturing, requiring specialized, high-resilience systems for extreme climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Environmental Control Room Market.- Thermo Fisher Scientific

- Binder GmbH

- Memmert GmbH + Co. KG

- Angelantoni Test Technologies S.r.l.

- ESPEC CORP.

- Weiss Technik GmbH

- Russells Technical Products

- Cincinnati Sub-Zero Products, Inc. (CSZ)

- Tenney Environmental (A division of TPS)

- Darwin Chambers Company

- Scientific Climate Systems

- Test Equity LLC

- Komeg Technology

- C.M.E. s.r.l.

- Atlas Material Testing Technology

- Climats S.A.

- Hanse Environmental, Inc.

- Sensitech (A part of Carrier)

- Vötsch Industrietechnik GmbH

- Aralab S.L.

Frequently Asked Questions

Analyze common user questions about the Environmental Control Room market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving the Environmental Control Room Market growth?

The market is primarily driven by stability testing required by pharmaceutical and biotech companies for regulatory submission (e.g., ICH guidelines), along with material endurance testing in the automotive and aerospace sectors, and ultra-precise manufacturing needs in the semiconductor industry.

How does the integration of IoT and AI benefit Environmental Control Room operations?

IoT provides real-time data logging and remote monitoring crucial for compliance and traceability. AI benefits ECRs by optimizing energy usage, automating climate control adjustments for tighter tolerances, and enabling predictive maintenance to prevent costly system failures.

What is the difference between Fixed and Modular Environmental Control Rooms?

Fixed installations are permanent, highly customized structures typically used for large-scale manufacturing or long-term high-security testing. Modular ECRs are prefabricated, scalable, and portable units offering flexibility, faster deployment, and lower initial capital outlay, ideal for R&D or temporary projects.

Which End-User segment holds the largest market share for ECRs?

The Pharmaceutical and Biotechnology segment holds the largest market share due to mandatory regulatory requirements (GMP/GLP) for stability testing, product shelf-life determination, and controlled storage of sensitive biological materials and therapeutics.

What are the key regulatory standards governing the design and operation of Environmental Control Rooms?

Key governing standards include ICH Guidelines Q1A (R2) for stability testing conditions, FDA regulations (e.g., 21 CFR Part 11 for electronic records), ISO standards (e.g., ISO 14644 for cleanroom classification), and various national Good Manufacturing Practice (GMP) requirements ensuring product quality and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager