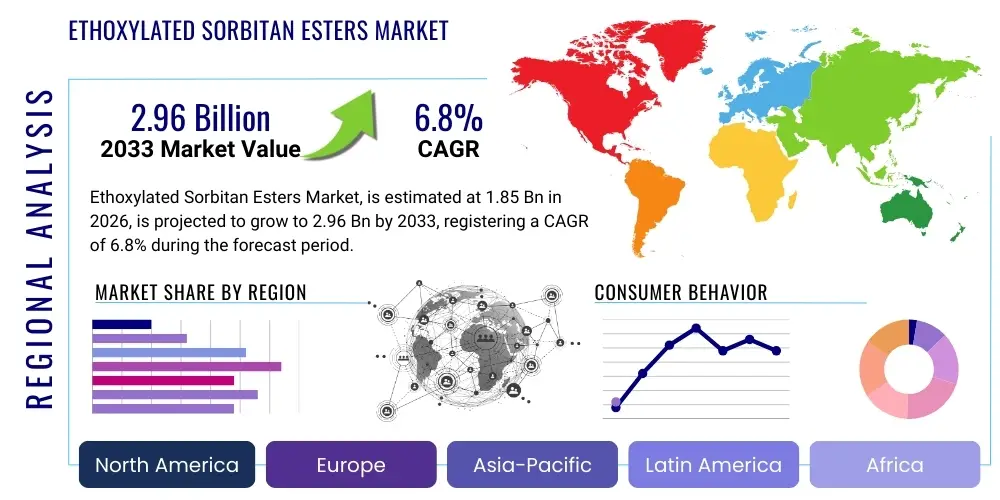

Ethoxylated Sorbitan Esters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439687 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Ethoxylated Sorbitan Esters Market Size

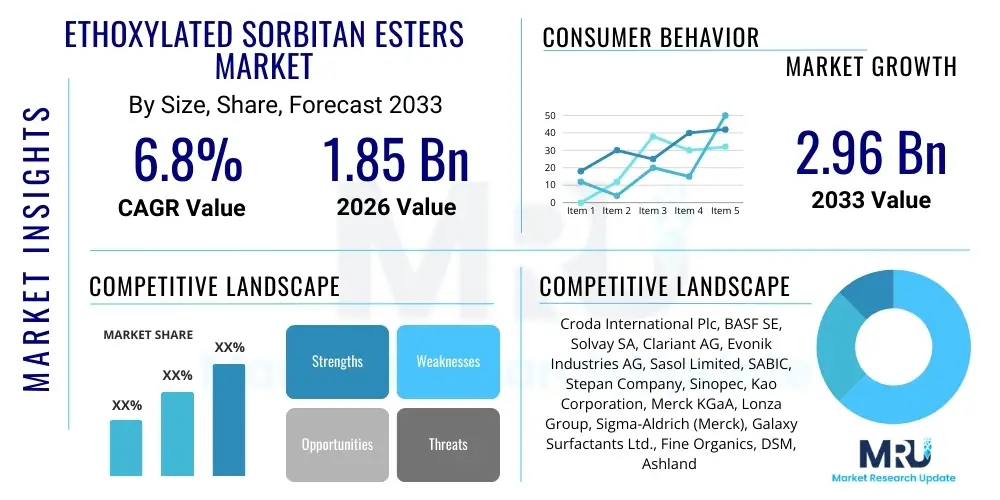

The Ethoxylated Sorbitan Esters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.96 Billion by the end of the forecast period in 2033.

Ethoxylated Sorbitan Esters Market introduction

Ethoxylated Sorbitan Esters, commonly known as Polysorbates, represent a crucial class of non-ionic surfactants derived from the ethoxylation of sorbitan esters. These versatile compounds are synthesized through the esterification of sorbitol with fatty acids, followed by the addition of ethylene oxide. This process yields molecules with both hydrophilic (polyoxyethylene chains) and lipophilic (fatty acid esters) characteristics, making them exceptionally effective emulsifiers, solubilizing agents, and dispersants. Their amphiphilic nature allows them to reduce interfacial tension between immiscible phases, thereby stabilizing emulsions and facilitating the homogeneous distribution of various ingredients in complex formulations. This unique chemical structure contributes significantly to their widespread applicability across diverse industries, addressing critical formulation challenges.

The primary applications of Ethoxylated Sorbitan Esters span across a multitude of sectors, including food and beverages, pharmaceuticals, cosmetics and personal care, and various industrial processes. In the food industry, they function as emulsifiers in baked goods, ice creams, and dairy alternatives, preventing fat separation and improving texture. Pharmaceutical formulations utilize them as solubilizers for poorly water-soluble drugs, enhancing bioavailability and ensuring uniform drug delivery in oral, topical, and injectable preparations. Within cosmetics and personal care, they are indispensable for creating stable emulsions in creams, lotions, shampoos, and conditioners, while also solubilizing fragrances and essential oils. Industrially, they find use in textile processing, agricultural formulations, and as dispersants in paints and coatings, demonstrating their broad utility.

The market for Ethoxylated Sorbitan Esters is driven by several pivotal factors, including the continuous expansion of end-use industries, particularly in emerging economies. The increasing demand for processed and convenience foods, coupled with the growing consumer expenditure on personal care and pharmaceutical products, fuels their consumption. Furthermore, the inherent benefits these esters offer, such as their low toxicity, broad pH stability, and compatibility with a wide range of ingredients, make them a preferred choice for formulators. Technological advancements in synthesis and purification methods are also contributing to the availability of higher-quality and specialized grades, further cementing their position as indispensable ingredients in modern formulations. The versatility and performance attributes of these compounds underpin their sustained market growth and strategic importance.

Ethoxylated Sorbitan Esters Market Executive Summary

The Ethoxylated Sorbitan Esters market is characterized by robust growth, propelled by sustained demand from key end-use industries and continuous innovation in product applications. Current business trends indicate a strong emphasis on developing specialized grades tailored for specific functionalities, such as enhanced stability for sensitive active pharmaceutical ingredients (APIs) or improved sensory profiles for cosmetic formulations. Manufacturers are increasingly investing in research and development to optimize ethoxylation processes, aiming for higher purity, reduced impurity profiles, and more sustainable production methods. Strategic collaborations between raw material suppliers and end-product manufacturers are becoming common, ensuring a stable supply chain and facilitating the development of novel applications. Furthermore, market players are focusing on expanding their global footprint, particularly in rapidly industrializing regions, through mergers, acquisitions, and strategic partnerships, solidifying their competitive advantage and market share.

Regionally, the Asia Pacific continues to emerge as the dominant and fastest-growing market for Ethoxylated Sorbitan Esters, primarily due to the rapid expansion of the food and beverage, pharmaceutical, and personal care industries in countries like China, India, and Southeast Asian nations. Increasing disposable incomes, urbanization, and a burgeoning middle class in these regions are driving consumer demand for products that utilize these esters. North America and Europe, while representing mature markets, exhibit stable demand driven by stringent regulatory frameworks that favor high-quality, compliant ingredients and a sustained focus on innovation in high-value applications. Latin America and the Middle East & Africa are showing significant potential, spurred by increasing industrialization and growing consumer bases, attracting investment from global manufacturers seeking new growth avenues and diversified markets.

Segment-wise, the market sees significant dynamism. The Polysorbate 80 segment holds the largest share, attributed to its broad utility as an emulsifier and solubilizer in both pharmaceutical and food applications. Polysorbate 20 also demonstrates substantial growth, particularly within the cosmetics and personal care sector due to its mildness and effective solubilizing properties for fragrances and essential oils. Application-wise, the food and beverage industry remains a cornerstone, driven by the need for texture enhancement, stability, and shelf-life extension in a wide array of products. The pharmaceutical sector is poised for accelerated growth, fueled by the increasing complexity of drug formulations and the critical role these esters play in drug delivery systems and stability. The personal care segment benefits from evolving consumer preferences for sophisticated and effective cosmetic products, where these esters are vital for formulation integrity and performance, underscoring their irreplaceable role across multiple economic pillars.

AI Impact Analysis on Ethoxylated Sorbitan Esters Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Ethoxylated Sorbitan Esters market frequently revolve around its potential to revolutionize production efficiency, supply chain resilience, and the speed of new product development. Users are keen to understand how AI can optimize complex chemical synthesis processes, leading to higher yields and reduced waste. Furthermore, questions often arise about AI's role in predicting market demand fluctuations, enabling more strategic inventory management and mitigating risks associated with raw material price volatility. There is also significant interest in AI's capacity to accelerate the discovery and formulation of novel ethoxylated sorbitan esters with enhanced functional properties or improved sustainability profiles, ultimately driving innovation within the sector. Essentially, users expect AI to be a transformative force, enhancing operational intelligence and fostering advanced material science.

- AI-driven optimization of ethoxylation reaction parameters, leading to improved yield and reduced energy consumption.

- Predictive maintenance analytics for manufacturing equipment, minimizing downtime and extending asset lifespan.

- Enhanced supply chain visibility and risk management through AI-powered forecasting of raw material availability and pricing.

- Accelerated discovery and design of novel ethoxylated sorbitan ester derivatives with tailored properties using machine learning algorithms.

- AI-assisted formulation development in end-use industries, optimizing ingredient ratios for desired stability and performance.

- Improved quality control and impurity detection in real-time through AI-powered spectroscopy and image analysis.

- Market demand forecasting and trend analysis, enabling proactive production planning and inventory optimization.

- Robotics and automation in handling and packaging, increasing efficiency and reducing human error in production facilities.

DRO & Impact Forces Of Ethoxylated Sorbitan Esters Market

The Ethoxylated Sorbitan Esters market is dynamically influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces, collectively shaping its trajectory. Key drivers include the consistent growth across diverse end-use industries such as food and beverages, pharmaceuticals, and cosmetics, where these esters are indispensable for formulation stability and performance. The escalating demand for processed foods, functional ingredients, and sophisticated personal care products, particularly in emerging economies, further propels market expansion. Moreover, their low toxicity, broad compatibility, and versatility in various applications make them a preferred choice over alternative emulsifiers, reinforcing their market position. Continuous research and development efforts aimed at enhancing their functional properties and exploring new application areas also serve as significant growth catalysts.

However, the market also faces considerable restraints that temper its growth potential. Volatility in the prices of key raw materials, namely sorbitol, fatty acids, and especially ethylene oxide (a petrochemical derivative), can significantly impact production costs and profit margins for manufacturers. The increasingly stringent regulatory landscape, particularly concerning residues of ethylene oxide (EO) and 1,4-dioxane in end products, necessitates costly purification processes and compliance measures, adding to operational complexities. The availability of substitute emulsifiers and surfactants, including plant-based or synthetic alternatives, presents a competitive challenge, requiring manufacturers to continuously innovate and differentiate their offerings. Furthermore, environmental concerns regarding the ethoxylation process and the sustainability of certain raw material sources also pose challenges, pushing for greener production methods.

Despite these restraints, significant opportunities exist for market players to capitalize on. The growing trend towards bio-based and sustainable chemistry offers avenues for developing ethoxylated sorbitan esters from renewable raw materials, aligning with consumer preferences for eco-friendly products. Expansion into untapped and emerging markets, particularly in Latin America, the Middle East, and Africa, where industrialization and consumer spending are on the rise, presents substantial growth potential. Developing specialized, high-performance grades tailored for niche applications, such as advanced drug delivery systems or highly stable cosmetic emulsions, can command premium pricing and open new revenue streams. Moreover, leveraging technological advancements in process optimization and AI-driven formulation can enhance efficiency and accelerate innovation, creating a competitive edge. These strategic opportunities, coupled with ongoing demand, paint a promising future for the Ethoxylated Sorbitan Esters market, provided challenges are effectively navigated.

Segmentation Analysis

The Ethoxylated Sorbitan Esters market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics, consumption patterns, and growth opportunities. These segments are primarily defined by the type of Polysorbate, the specific application areas, and the end-use industries they serve, alongside geographical considerations. Each segment reflects unique demand characteristics driven by varying functional requirements, regulatory landscapes, and consumer preferences, underpinning a complex yet highly structured market. The segmentation analysis highlights the versatility of these compounds and their critical role across a wide array of products and processes, ensuring their sustained relevance in both established and emerging markets.

- By Type:

- Polysorbate 20 (Polyoxyethylene (20) Sorbitan Monolaurate)

- Polysorbate 40 (Polyoxyethylene (20) Sorbitan Monopalmitate)

- Polysorbate 60 (Polyoxyethylene (20) Sorbitan Monostearate)

- Polysorbate 80 (Polyoxyethylene (20) Sorbitan Monooleate)

- Others (e.g., Polysorbate 65, Polysorbate 85)

- By Application:

- Emulsifiers

- Solubilizers

- Dispersants

- Wetting Agents

- Stabilizers

- Thickeners

- Others

- By End-Use Industry:

- Food & Beverages

- Bakery & Confectionery

- Dairy & Frozen Desserts

- Meat & Poultry Products

- Beverages

- Processed Foods

- Pharmaceuticals

- Oral Formulations

- Topical Formulations

- Injectable Formulations

- Vaccines

- Cosmetics & Personal Care

- Skincare

- Haircare

- Oral Care

- Fragrances

- Makeup

- Industrial

- Textile Auxiliaries

- Agricultural Chemicals (Pesticides, Herbicides)

- Paints & Coatings

- Lubricants & Metalworking Fluids

- Household Cleaners

- Others (e.g., Polymers, Adhesives, Specialty Chemicals)

- Food & Beverages

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Australia, Rest of Asia Pacific)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Value Chain Analysis For Ethoxylated Sorbitan Esters Market

The value chain for Ethoxylated Sorbitan Esters encompasses a series of interconnected stages, beginning with the sourcing of raw materials and extending through manufacturing, distribution, and final application by various end-use industries. The upstream segment of this value chain involves the procurement of key building blocks: sorbitol, fatty acids, and ethylene oxide. Sorbitol is typically derived from glucose, often from corn or other starchy crops, while fatty acids originate from natural oils and fats (e.g., palm oil, coconut oil, soy oil) or petrochemical sources. Ethylene oxide, a crucial component for the ethoxylation process, is predominantly a petrochemical derivative. Reliable access to these raw materials at stable prices is fundamental to the industry's profitability and consistent production, making strong supplier relationships and diversified sourcing strategies critical for manufacturers.

The core manufacturing process involves the esterification of sorbitol with a specific fatty acid to produce sorbitan esters, followed by their ethoxylation with ethylene oxide to achieve the desired degree of ethoxylation and specific Polysorbate type (e.g., Polysorbate 20, 80). This stage requires specialized chemical expertise, robust process control, and adherence to stringent quality and safety standards. After synthesis, further purification, filtration, and quality assurance steps ensure the final product meets regulatory requirements and specific customer specifications for purity, color, and functional properties. Innovations in catalyst technology, continuous processing, and solvent-free ethoxylation methods are continuously being explored to enhance efficiency, reduce environmental impact, and lower production costs, signifying a dynamic and evolving manufacturing landscape driven by both economic and sustainability imperatives.

The downstream analysis of the value chain focuses on the distribution and end-use of Ethoxylated Sorbitan Esters. Distribution channels are varied, ranging from direct sales by major manufacturers to large-scale industrial customers, to indirect channels involving a network of specialized chemical distributors and agents. These intermediaries play a vital role in reaching smaller customers, managing inventory, providing technical support, and navigating regional logistics and regulatory requirements. The final stage involves the incorporation of these esters into finished products across the food and beverage, pharmaceutical, cosmetics and personal care, and industrial sectors. The effectiveness and compliance of the esters in these diverse applications are paramount, driven by the specific formulation needs and the performance criteria set by the end-users. The close collaboration between manufacturers and end-users, often facilitated by distributors, is essential for identifying new application opportunities and optimizing product performance, ensuring a steady flow of innovation and market responsiveness.

Ethoxylated Sorbitan Esters Market Potential Customers

The primary potential customers for Ethoxylated Sorbitan Esters are diverse and span a wide array of industries, each leveraging the unique surfactant properties of these compounds for their specific product formulations and manufacturing processes. At the forefront are manufacturers within the food and beverage sector, who utilize these esters extensively as emulsifiers in dairy products, baked goods, confectionery, and processed foods to improve texture, stability, and shelf life. Pharmaceutical companies represent another critical customer segment, relying on ethoxylated sorbitan esters as solubilizers for active pharmaceutical ingredients, as emulsifiers in creams and ointments, and as stabilizers in suspensions and vaccines, ensuring consistent drug delivery and formulation integrity. The versatility and safety profile of these excipients make them indispensable in modern drug development and production, addressing complex solubility and stability challenges in a wide range of therapeutic applications.

Furthermore, the cosmetics and personal care industry is a significant consumer, where these esters are crucial for creating stable emulsions in a vast array of products, including lotions, creams, shampoos, conditioners, and sunscreens. They also serve as effective solubilizers for fragrances, essential oils, and other lipophilic ingredients, allowing formulators to achieve desired aesthetic and functional properties in their products. Industrial sectors also constitute a substantial customer base, with applications ranging from textile auxiliaries, where they act as wetting and dispersing agents, to agricultural formulations, where they enhance the efficacy of pesticides and herbicides by improving their spread and penetration. Additionally, their use in paints, coatings, lubricants, and metalworking fluids highlights their broad industrial applicability, demonstrating their value proposition across a multitude of manufacturing environments that require sophisticated surfactant chemistry for optimal performance and product quality.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.96 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Croda International Plc, BASF SE, Solvay SA, Clariant AG, Evonik Industries AG, Sasol Limited, SABIC, Stepan Company, Sinopec, Kao Corporation, Merck KGaA, Lonza Group, Sigma-Aldrich (Merck), Galaxy Surfactants Ltd., Fine Organics, DSM, Ashland Global Holdings Inc., Seppic (Air Liquide Healthcare), SPI Pharma, Inc., Nippon Oil & Fats Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ethoxylated Sorbitan Esters Market Key Technology Landscape

The technology landscape for the Ethoxylated Sorbitan Esters market is continuously evolving, driven by the need for enhanced efficiency, improved product purity, and greater sustainability. The core production process involves two main steps: esterification and ethoxylation. Esterification technology focuses on optimizing the reaction between sorbitol and fatty acids, often utilizing various catalysts (e.g., acid or enzyme catalysts) and reaction conditions to achieve high selectivity and yield of sorbitan esters. Innovations in this area include continuous processing techniques that allow for higher throughput and more consistent product quality compared to traditional batch reactors. Furthermore, advancements in enzymatic esterification offer a milder, more environmentally friendly alternative, reducing energy consumption and minimizing unwanted by-products, which aligns with green chemistry principles.

The subsequent ethoxylation step, involving the reaction of sorbitan esters with ethylene oxide, is critical for defining the specific Polysorbate type and its functional properties. Key technological advancements here include the development of highly selective catalysts that control the degree of ethoxylation with greater precision, minimizing the formation of unreacted ethylene oxide or polyethylene glycols. Modern ethoxylation plants often incorporate advanced process control systems, leveraging real-time monitoring and automation to ensure optimal reaction conditions, improve safety, and reduce the overall energy footprint. Techniques for safer handling and delivery of ethylene oxide, such as on-site generation or specialized storage, are also gaining traction to mitigate safety risks associated with this highly reactive chemical. The design of novel reactor technologies, such as loop reactors or specialized multi-stage reactors, aims to improve heat transfer and mixing efficiency, thereby enhancing reaction kinetics and product uniformity.

Beyond the primary synthesis, purification technologies play a crucial role in delivering high-quality Ethoxylated Sorbitan Esters, especially given stringent regulatory requirements for residues like ethylene oxide and 1,4-dioxane. Advanced distillation techniques, membrane filtration, and chromatographic purification methods are increasingly being employed to achieve ultra-high purity grades required for sensitive pharmaceutical and cosmetic applications. Furthermore, the burgeoning field of bio-based chemistry is exploring sustainable alternatives for ethylene oxide, such as bio-derived ethylene or its precursors, which could fundamentally transform the raw material sourcing and environmental profile of ethoxylated products. The integration of digital technologies, including process modeling, simulation, and data analytics, is also enhancing R&D capabilities, allowing for faster development of new products and optimization of existing processes, thereby propelling the market towards more efficient, safer, and environmentally responsible manufacturing practices.

Regional Highlights

- Asia Pacific: The Asia Pacific region stands as the largest and fastest-growing market for Ethoxylated Sorbitan Esters, primarily driven by the rapid industrialization and urbanization across countries such as China, India, Japan, South Korea, and Southeast Asian nations. The burgeoning food and beverage industry, fueled by a large and growing population with increasing disposable incomes, significantly contributes to demand for emulsifiers and stabilizers. Simultaneously, the expanding pharmaceutical sector in these economies, coupled with a robust cosmetics and personal care manufacturing base, creates substantial uptake for high-purity ethoxylated sorbitan esters. Favorable government policies promoting manufacturing and an increasing focus on R&D also support market growth, positioning APAC as a global manufacturing hub and a crucial consumer market.

- North America: North America represents a mature yet highly innovative market for Ethoxylated Sorbitan Esters, characterized by stable demand from well-established end-use industries, particularly pharmaceuticals and cosmetics. The United States leads the region, driven by its advanced healthcare infrastructure, strong pharmaceutical R&D, and a sophisticated personal care market that demands premium, high-performance ingredients. Strict regulatory standards for product safety and quality, particularly by the FDA, compel manufacturers to invest in high-purity grades and advanced production technologies. There is a growing trend towards natural and sustainable ingredients, prompting innovation in bio-based ethoxylation and more environmentally friendly production methods to cater to evolving consumer preferences.

- Europe: The European market for Ethoxylated Sorbitan Esters is driven by a strong emphasis on sustainability, stringent regulatory frameworks (such as REACH), and a robust cosmetics and pharmaceutical industry, especially in countries like Germany, France, and the UK. While market growth is steady, the focus is heavily on product quality, safety, and traceability, leading to a preference for high-grade, compliant materials. Innovation in green chemistry and the development of ethoxylated products with reduced environmental footprints are key trends. The demand for clean label ingredients in food and beverages also influences product development, pushing manufacturers to offer solutions that meet the region's high standards for consumer safety and environmental responsibility.

- Latin America & Middle East and Africa (MEA): These regions are emerging as significant growth markets for Ethoxylated Sorbitan Esters, propelled by increasing industrialization, economic development, and a rising middle class. In Latin America, countries like Brazil and Mexico are witnessing rapid expansion in their food processing, pharmaceutical, and personal care sectors, leading to higher consumption of these surfactants. The MEA region, particularly the UAE and Saudi Arabia, benefits from diversified economies and substantial investments in manufacturing capabilities, translating into growing demand across various industrial applications. While nascent compared to mature markets, these regions offer substantial untapped potential and attract global manufacturers looking to expand their market reach and capitalize on new growth opportunities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ethoxylated Sorbitan Esters Market.- Croda International Plc

- BASF SE

- Solvay SA

- Clariant AG

- Evonik Industries AG

- Sasol Limited

- SABIC

- Stepan Company

- Sinopec

- Kao Corporation

- Merck KGaA

- Lonza Group

- Sigma-Aldrich (part of Merck)

- Galaxy Surfactants Ltd.

- Fine Organics

- DSM

- Ashland Global Holdings Inc.

- Seppic (Air Liquide Healthcare)

- SPI Pharma, Inc.

- Nippon Oil & Fats Co., Ltd.

Frequently Asked Questions

What are Ethoxylated Sorbitan Esters and their primary function?

Ethoxylated Sorbitan Esters, commonly known as Polysorbates, are non-ionic surfactants derived from sorbitol and fatty acids, subsequently ethoxylated with ethylene oxide. Their primary function is to act as emulsifiers, solubilizers, and dispersants, reducing interfacial tension between immiscible substances to create stable emulsions and homogeneous mixtures in various formulations. This amphiphilic nature makes them indispensable across a broad spectrum of industries, enabling the stable combination of oil and water phases in products ranging from food to pharmaceuticals, thereby enhancing texture, stability, and drug delivery.

What are the main end-use industries for Ethoxylated Sorbitan Esters?

The main end-use industries for Ethoxylated Sorbitan Esters include food and beverages, pharmaceuticals, cosmetics and personal care, and various industrial applications. In food, they stabilize emulsions in products like ice cream and baked goods. Pharmaceuticals utilize them for drug solubilization and formulation stability. The cosmetics sector employs them as emulsifiers and solubilizers in creams, lotions, and fragrances. Industrially, they are found in textiles, agriculture, and paints, highlighting their versatile utility as critical formulation components across diverse manufacturing sectors.

What factors are driving the growth of the Ethoxylated Sorbitan Esters Market?

The Ethoxylated Sorbitan Esters market growth is primarily driven by the expanding demand from end-use industries, particularly the thriving food and beverage, pharmaceutical, and personal care sectors, especially in emerging economies. Increasing consumer preference for processed foods and advanced cosmetic and pharmaceutical products significantly contributes to their consumption. Furthermore, their inherent benefits such as high efficiency, broad compatibility, and low toxicity, coupled with continuous innovation in product development and sustainable production methods, also act as key growth drivers, ensuring their sustained relevance and adoption in modern formulations.

What are the key challenges or restraints in the Ethoxylated Sorbitan Esters market?

Key challenges in the Ethoxylated Sorbitan Esters market include the volatility of raw material prices (sorbitol, fatty acids, ethylene oxide), which can impact production costs and profit margins. Stringent regulatory guidelines regarding residual levels of ethylene oxide and 1,4-dioxane in end products necessitate costly purification processes. The availability of alternative emulsifiers and surfactants also poses a competitive threat, requiring constant innovation from manufacturers. Additionally, increasing environmental concerns and the push for more sustainable production methods present both challenges and opportunities for technological advancement in the sector.

How is AI impacting the Ethoxylated Sorbitan Esters market?

Artificial Intelligence is set to significantly impact the Ethoxylated Sorbitan Esters market by optimizing production processes, enhancing supply chain efficiency, and accelerating new product development. AI can be used for real-time process control to improve reaction yields and reduce waste, predictive maintenance of machinery to minimize downtime, and forecasting market demand to optimize inventory. Furthermore, AI-powered algorithms can aid in the discovery of novel ester formulations with enhanced properties and assist in quality control, ultimately driving operational excellence and fostering innovation within the industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager