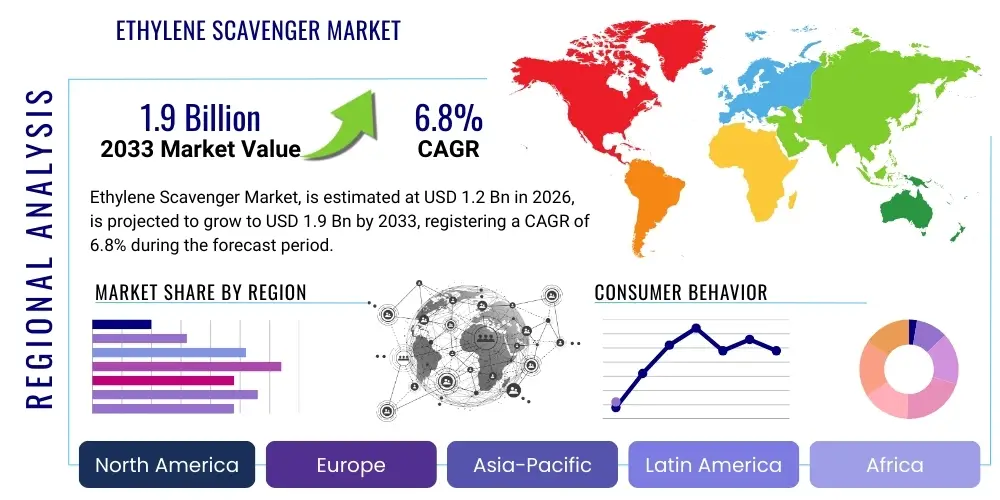

Ethylene Scavenger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436516 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Ethylene Scavenger Market Size

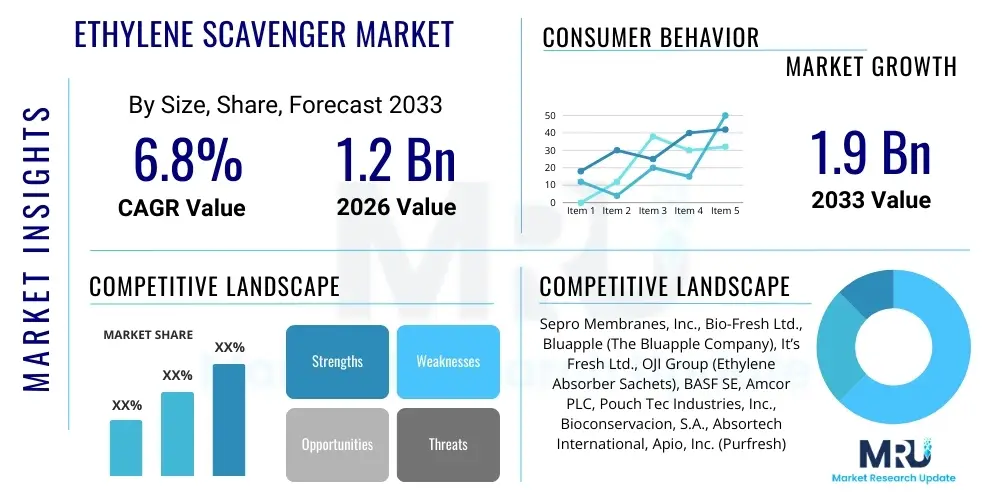

The Ethylene Scavenger Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2033.

Ethylene Scavenger Market introduction

The Ethylene Scavenger Market is defined by products and systems designed to absorb or neutralize ethylene gas, a plant hormone responsible for accelerating the ripening, senescence, and spoilage of fruits, vegetables, and flowers. Ethylene scavengers play a critical role in extending the shelf life of perishable agricultural products during post-harvest handling, storage, and transportation. These products typically utilize active ingredients such as potassium permanganate (KMnO4) embedded in inert carriers, specialized molecular sieves, or advanced absorbent polymers, effectively mitigating product loss and maintaining quality across the supply chain. The primary mechanism involves the oxidation of ethylene gas into inert compounds, ensuring a low-ethylene environment conducive to prolonged freshness.

Major applications of ethylene scavengers span the entire cold chain logistics spectrum, from packaging solutions used directly with fresh produce (e.g., sachets, pads, films) to large-scale air purification systems implemented in refrigerated containers, storage facilities, and ripening rooms. The integration of these solutions is crucial for mitigating the substantial economic losses associated with food waste, a global challenge amplified by increasingly long-distance global trade routes for fresh commodities. The effectiveness of ethylene scavengers is particularly valued in high-value horticulture segments, including exotic fruits, cut flowers, and organic produce, where maintaining pristine quality translates directly into higher market prices and consumer satisfaction.

Key driving factors propelling the growth of this market include the escalating global demand for high-quality, fresh, and minimally processed foods, coupled with stringent regulatory pressures worldwide aimed at reducing food waste and improving sustainable practices within the agricultural and logistics sectors. Furthermore, advancements in packaging technology, particularly the development of smart and active packaging solutions that seamlessly incorporate scavenging materials, are enhancing the accessibility and efficiency of these products, facilitating their broader adoption across developing and developed economies alike.

Ethylene Scavenger Market Executive Summary

The Ethylene Scavenger Market is characterized by robust growth, primarily fueled by the imperative to minimize post-harvest losses and satisfy rising consumer expectations for extended shelf life in fresh produce. Current business trends indicate a strong shift toward sustainable and biodegradable scavenging solutions, moving beyond traditional potassium permanganate toward advanced natural mineral zeolites and polymer-based systems that offer superior absorption capacity and environmental profiles. Strategic collaborations between ethylene scavenger manufacturers and large-scale logistics providers, particularly those focused on controlled atmosphere storage and intercontinental shipping, are defining competitive differentiation, prioritizing ease of integration and cost-effectiveness across complex supply chains. Investment is heavily concentrated in optimizing active packaging formats, aiming for maximum efficiency with minimal material usage.

Regionally, the Asia Pacific (APAC) market is witnessing the fastest expansion, driven by rapidly improving cold chain infrastructure in major economies like China and India, coupled with massive volumes of fresh produce exported to lucrative Western markets. North America and Europe remain mature markets, focusing less on infrastructure establishment and more on regulatory compliance and the adoption of high-performance, precision scavenging technologies integrated into smart packaging. The demand in Latin America and the Middle East & Africa (MEA) is accelerating, reflecting increasing urbanization, rising disposable incomes, and the consequent demand for a consistent supply of imported and locally sourced perishable goods, necessitating robust post-harvest management.

Segment trends reveal that the Potassium Permanganate (KMnO4) segment currently dominates based on its established cost-effectiveness and proven efficacy, though the market share of natural zeolites and specialized mineral-based scavengers is rapidly increasing due to environmental concerns and improved performance metrics. By application, the fruits and vegetables segment holds the largest market share, directly corresponding to the massive scale of global agricultural trade, while the cut flowers segment represents a highly profitable niche characterized by extreme sensitivity to ethylene exposure, thereby demanding premium scavenging solutions.

AI Impact Analysis on Ethylene Scavenger Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the application and effectiveness of ethylene scavenging technologies. Key questions center on AI’s role in predicting produce shelf life, optimizing scavenger deployment, and integrating scavenging systems within smart cold chain logistics. The primary concern is moving beyond passive scavenging toward a proactive, predictive approach. Users expect AI to analyze real-time environmental variables (temperature, humidity, ethylene concentration) alongside historical product data to precisely calculate the required scavenger dosage and placement, thereby maximizing efficiency and reducing operational costs. This integration promises to transform post-harvest management from a generalized prophylactic measure into a data-driven, highly individualized process tailored to specific commodity types and logistical routes, ensuring optimal quality preservation.

- AI-driven Predictive Analytics: Utilizing machine learning algorithms to forecast remaining shelf life based on temperature fluctuations and initial ethylene load, optimizing scavenging treatment duration.

- Smart Logistics Optimization: AI systems directing the precise placement and quantity of ethylene scavengers within refrigerated containers to ensure uniform atmospheric control across complex cargo arrangements.

- Automated Dosage Control: Integration of AI with environmental sensors to automatically adjust the rate of ethylene absorption or release in dynamic controlled atmosphere storage environments.

- Yield Loss Reduction Modeling: Using AI to simulate various storage scenarios and scavenger types to determine the most cost-effective solution for specific agricultural exports, minimizing waste.

- Real-time Monitoring and Alerting: Machine learning processes analyzing sensor data to flag deviations in ethylene levels immediately, allowing for preemptive intervention and enhanced product safety.

DRO & Impact Forces Of Ethylene Scavenger Market

The Ethylene Scavenger Market is fundamentally driven by the critical global need to curb post-harvest losses, which often exceed 30% of total harvest in certain segments, representing significant economic and sustainability challenges. Regulations mandating food safety standards and traceability, particularly in importing nations, further compel fresh produce handlers to adopt active preservation technologies. However, the market faces restraints such as the relatively high initial cost of integrating specialized scavenger systems into existing logistics infrastructures and the lack of comprehensive cold chain infrastructure in certain developing regions. Opportunities lie in the shift toward sustainable, non-chemical scavenging agents and the increasing proliferation of e-commerce for fresh groceries, necessitating robust preservation during last-mile delivery. The cumulative impact forces push the market toward innovation in biodegradable and highly efficient packaging inserts, positioning these technologies as indispensable components of the modern global food supply chain.

Segmentation Analysis

The Ethylene Scavenger Market is comprehensively segmented based on the active material used, the specific form in which the scavenger is applied, and the major end-use applications in the post-harvest sector. This multi-dimensional segmentation allows for a detailed analysis of market dynamics, revealing varying growth rates and adoption patterns influenced by cost constraints, regulatory approvals, and the unique preservation requirements of different perishable goods. Understanding these segments is vital for stakeholders to tailor product development and market entry strategies, focusing on high-growth segments such as biodegradable materials and integrated packaging solutions.

- By Type (Active Material): Potassium Permanganate, Activated Carbon, Natural Minerals (Zeolites, etc.), Others (e.g., Polymer-based).

- By Form: Sachets and Filters, Integrated Packaging Films (Active Packaging), Granules and Powders, Air Filtration Systems.

- By Application: Fruits and Vegetables (Sub-segmented: Climacteric Fruits, Non-climacteric Fruits, Leafy Greens), Cut Flowers, Ornamentals and Plants, Others (e.g., Seeds).

- By Region: North America, Europe, Asia Pacific (APAC), Latin America (LATAM), Middle East & Africa (MEA).

Value Chain Analysis For Ethylene Scavenger Market

The value chain for the Ethylene Scavenger Market begins with upstream activities involving the sourcing and processing of raw materials, primarily potassium permanganate, specialized mineral zeolites, and polymer resins used for carrier matrices. Key upstream challenges include maintaining consistent quality and securing stable supply chains for specialized chemicals, which directly influences the final product cost and performance characteristics. Manufacturers then engage in proprietary formulation and conversion processes, transforming raw materials into standardized products like sachets, filters, or masterbatch for active packaging films. Innovation at this stage is focused on enhancing absorption kinetics and extending the useful life of the scavenger products before saturation.

Midstream activities involve the production and integration of these scavengers into various formats, focusing heavily on efficient manufacturing and quality control specific to the intended application. Distribution channels are critical, distinguishing between direct sales to large agricultural exporters and cold storage operators, and indirect sales through specialized packaging converters and logistics partners who incorporate scavengers into their service offerings. Direct sales often involve customized bulk solutions, while indirect distribution leverages existing networks for standardized, retail-ready products.

Downstream activities center on the end-users—pack houses, fresh produce distributors, floriculture businesses, and logistics companies—who utilize these products to mitigate spoilage during storage and transit. The effectiveness of the scavenger is ultimately validated at this stage, depending on proper application and synergy with existing cold chain management systems. The trend shows increasing reliance on integrated, direct-to-packaging solutions, positioning the distribution channel as a high-value intermediary providing technical support and customized integration services.

Ethylene Scavenger Market Potential Customers

Potential customers for ethylene scavenger products are predominantly entities involved in the production, handling, and distribution of perishable goods across the global supply chain, where mitigating quality degradation is paramount to profitability. These end-users are characterized by their dependence on maintaining optimal freshness and extending shelf life to access distant markets and reduce financial losses associated with food spoilage. The adoption rate among these groups is highly sensitive to the economic value of the cargo being protected, leading to a strong demand from high-value segments like exotic fruit exporters and ornamental flower growers, who cannot tolerate even minimal quality deterioration.

The largest volume buyers include major fresh produce aggregators and multinational supermarket chains that manage complex supply lines spanning multiple continents. These buyers seek cost-effective, large-scale solutions, such as centralized air purification systems and bulk filter media. Conversely, smaller organic farms and specialized producers often opt for unit-level solutions like individual sachets and films tailored for premium, direct-to-consumer packaging, emphasizing aesthetics and environmental sustainability alongside preservation performance. Logistics and shipping companies, particularly those managing large fleets of refrigerated containers (reefers), represent another vital customer segment, seeking robust, certified, and compliant solutions for long-haul transportation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sepro Membranes, Inc., Bio-Fresh Ltd., Bluapple (The Bluapple Company), It’s Fresh Ltd., OJI Group (Ethylene Absorber Sachets), BASF SE, Amcor PLC, Pouch Tec Industries, Inc., Bioconservacion, S.A., Absortech International, Apio, Inc. (Purfresh), Mitsubishi Chemical Corporation, Adsorbents & Desiccants Corporation of America (ADCOA), Coperion GmbH, Kureha Corporation, AgroFresh Solutions, Inc., Sorbent Systems, Inc., XtraPlast, Inc., SANOVO TECHNOLOGY GROUP, SUEZ Water Technologies & Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ethylene Scavenger Market Key Technology Landscape

The technological landscape of the Ethylene Scavenger Market is rapidly evolving, driven by the need for enhanced efficiency, lower environmental impact, and seamless integration into modern packaging and logistics systems. The foundational technology remains the oxidation of ethylene using potassium permanganate (KMnO4) impregnated onto carriers like alumina or silica gel, offering reliable and cost-effective scavenging. However, significant research and development efforts are now concentrated on advanced material science, specifically leveraging natural mineral sorbents such as high-surface-area zeolites, which provide excellent absorption capabilities without the heavy reliance on traditional chemical oxidizers. These newer technologies are often branded as sustainable alternatives, resonating strongly with environmentally conscious consumers and regulated markets.

A crucial technological shift involves the rise of active and intelligent packaging incorporating ethylene scavenging functions directly into films or liners. This is achieved through masterbatch technology, where scavenger compounds are homogeneously dispersed within the polymer matrix of the packaging material, enabling controlled release and continuous protection throughout the product's life cycle. This integration eliminates the need for standalone sachets or filters, streamlining packaging processes and providing more uniform atmospheric control around the product. Furthermore, the convergence of scavenging technology with smart sensors is a key emerging trend, where cheap, disposable ethylene sensors can be integrated with the scavenger material to indicate saturation level and optimal replacement time, moving towards predictive maintenance rather than fixed schedules.

Innovations also include the utilization of photocatalytic degradation methods, where certain catalysts, often titanium dioxide-based, are activated by UV light (or ambient light) to break down ethylene molecules into harmless components like water and carbon dioxide. While still emerging for bulk cargo applications, this technology shows promise for enclosed storage environments requiring continuous, regenerative scavenging capabilities. The overall trajectory is toward composite systems that offer multi-functional benefits, combining ethylene scavenging with moisture absorption (desiccants) and antimicrobial properties, creating a holistic controlled environment for optimal preservation.

Regional Highlights

The dynamics of the Ethylene Scavenger Market vary significantly across major geographical regions, influenced by the maturity of cold chain infrastructure, regulatory frameworks concerning food safety, and the scale of horticultural exports.

- North America: Characterized by highly sophisticated cold chain logistics and high consumer demand for premium, long-shelf-life fresh produce. The region is a major adopter of advanced integrated packaging films and smart scavenging systems, driven by stringent food safety regulations and the large-scale distribution requirements of major retailers.

- Europe: Driven by strong sustainability mandates and a focus on reducing food waste, leading to high adoption rates of natural mineral-based and biodegradable scavenger solutions. Western Europe maintains a high demand for advanced filter systems in controlled atmosphere storage for imported fruits and vegetables.

- Asia Pacific (APAC): Represents the highest growth potential due to rapid investment in modernizing cold chain infrastructure, particularly in emerging economies like China, India, and Southeast Asian nations. APAC is both a massive producer and an increasingly significant consumer of perishable goods, driving substantial demand for cost-effective sachets and filters to manage vast volumes of internal and export traffic.

- Latin America (LATAM): A critical region due to its status as a major global exporter of fruits (e.g., bananas, avocados, grapes). Adoption is high in key export segments, where maintaining quality during long-haul sea freight is crucial, driving the use of high-capacity container-level scavengers.

- Middle East & Africa (MEA): Growth is fueled by increasing urbanization and reliance on imported perishable goods, particularly in the Gulf Cooperation Council (GCC) countries, necessitating robust post-harvest protection during transit and storage in hot climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ethylene Scavenger Market.- Sepro Membranes, Inc.

- Bio-Fresh Ltd.

- Bluapple (The Bluapple Company)

- It’s Fresh Ltd.

- OJI Group (Ethylene Absorber Sachets)

- BASF SE

- Amcor PLC

- Pouch Tec Industries, Inc.

- Bioconservacion, S.A.

- Absortech International

- Apio, Inc. (Purfresh)

- Mitsubishi Chemical Corporation

- Adsorbents & Desiccants Corporation of America (ADCOA)

- Coperion GmbH

- Kureha Corporation

- AgroFresh Solutions, Inc.

- Sorbent Systems, Inc.

- XtraPlast, Inc.

- SANOVO TECHNOLOGY GROUP

- SUEZ Water Technologies & Solutions

- Polymer Logistics

- SmartPac International

- Fresh-Ripe Products

- Delta Trak, Inc.

- Garratt-Callahan Company

Frequently Asked Questions

Analyze common user questions about the Ethylene Scavenger market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth in the Ethylene Scavenger Market?

The market is primarily driven by the imperative to minimize significant post-harvest food waste globally, coupled with escalating consumer demand for fresh produce with extended shelf life and the expansion of complex international cold chain logistics.

Which type of Ethylene Scavenger material dominates the current market?

Potassium Permanganate (KMnO4) based scavengers currently hold the largest market share due to their proven effectiveness, established manufacturing processes, and cost-efficiency, particularly for high-volume applications.

How is active packaging influencing the adoption of Ethylene Scavengers?

Active packaging, which integrates scavenging compounds directly into films and liners, is rapidly increasing in adoption as it offers superior, continuous, and homogeneous ethylene control, replacing the need for separate sachets and streamlining the overall packaging process.

What role does the Asia Pacific region play in the Ethylene Scavenger Market expansion?

APAC is the fastest-growing region, fueled by massive agricultural output, rapid development of sophisticated cold chain infrastructure, and the necessity to preserve quality for large-scale export and growing domestic consumer bases.

What is the key regulatory challenge affecting market penetration?

Regulatory challenges primarily involve navigating varying international standards regarding chemical additives in food packaging and ensuring that scavenging agents meet environmental safety requirements, driving the shift toward natural, biodegradable alternatives.

What is the key function of ethylene scavengers in the cold chain?

Ethylene scavengers actively absorb or chemically oxidize ethylene gas, which is a naturally occurring plant hormone that accelerates ripening and decay, thereby significantly extending the viable storage and transport duration of perishable goods like fruits, vegetables, and cut flowers.

Are natural mineral scavengers replacing chemical options?

While chemical options like potassium permanganate remain prevalent, there is a strong market trend toward natural minerals, particularly specialized zeolites, as they offer comparable performance, better sustainability credentials, and lower regulatory hurdles in environmentally sensitive regions.

Which application segment utilizes premium scavenging technology most frequently?

The cut flowers and ornamentals segment frequently utilizes the most advanced and premium scavenging technologies, as these products are extremely sensitive to minute concentrations of ethylene, where even slight exposure can lead to rapid wilting and catastrophic financial loss.

How does the shelf life extension benefit the global food trade?

Shelf life extension facilitates long-distance global food trade, allowing producers to access new international markets, stabilize supply, and significantly reduce logistics-related financial risk associated with time-sensitive high-value commodities.

What is the primary constraint limiting the market growth?

The lack of standardized, adequate cold chain infrastructure in many developing and high-growth markets remains the principal constraint, as the efficiency of ethylene scavengers is highly dependent on being utilized within a stable temperature and humidity controlled environment.

Explain the concept of Generative Engine Optimization (GEO) in the context of this report.

GEO refers to structuring the content with highly specific headings, detailed descriptive paragraphs, and clear bulleted lists that directly address likely user queries and topical deep dives, ensuring the report is easily digestible and highly rankable by advanced AI and large language models for synthesized answers.

How are AI and IoT technologies impacting the deployment of ethylene scavengers?

AI and IoT enable 'smart scavenging' by using sensors to monitor real-time ethylene levels, temperature, and humidity, allowing AI algorithms to optimize the precise dosage and replacement timing of scavengers, thereby moving toward predictive and hyper-efficient post-harvest management.

What are the main segments covered by product form?

The primary forms include sachets and filters (standalone applications), integrated packaging films (active packaging solutions), granules and powders (bulk system inputs), and dedicated air filtration systems (large-scale warehouse or container applications).

How does the value chain distinguish between upstream and downstream activities?

Upstream activities focus on sourcing and chemical processing of raw materials (potassium permanganate, zeolites). Downstream activities involve the final application, distribution, and utilization of the finalized scavenger products by logistics firms and fresh produce distributors.

Which specific fruit types are most sensitive to ethylene and require critical scavenging?

Climacteric fruits such as bananas, avocados, kiwifruit, and tomatoes are highly sensitive to ethylene, as this gas triggers their rapid ripening process, necessitating robust and immediate scavenging solutions post-harvest to prevent premature spoilage.

What is the significance of the 6.8% CAGR projected for the market?

The 6.8% CAGR signifies a robust expansion driven by increasing global trade, sustained investment in cold chain modernization, and the indispensable role of ethylene scavenging in supporting both high-value specialized produce and mass-market fresh goods.

Are Ethylene Scavengers considered a long-term storage solution?

Yes, while they are critical during transit, ethylene scavengers are also integral to long-term controlled atmosphere (CA) storage facilities, where they work alongside temperature and gas composition management systems to maintain the dormancy of produce for months.

What technological advancement is reducing the reliance on standalone sachets?

The development of polymeric masterbatches and integrated active packaging films is reducing the reliance on standalone sachets by embedding the scavenging capability directly into the plastic packaging structure, offering continuous protection across the entire surface area of the package.

How do environmental regulations affect material choices for scavengers?

Environmental regulations, particularly in Europe, favor the use of materials that are non-toxic, easily recyclable, or biodegradable, creating a strong market incentive and investment focus on natural mineral and advanced biodegradable polymer-based scavenging solutions.

What is the primary difference in demand between North America and Asia Pacific?

North America focuses on advanced, smart, and compliance-driven integrated systems within an already mature cold chain. APAC demand is primarily volume-driven, focusing on cost-effective, high-capacity bulk solutions to rapidly scale up post-harvest management alongside developing infrastructure.

What are 'impact forces' in the context of this market report?

Impact forces represent the synergistic or opposing effects of drivers, restraints, and opportunities on the market trajectory, summarizing the combined pressure points determining future market growth and competitive landscape.

How do ethylene scavengers compare to chemical ripening inhibitors?

Ethylene scavengers function proactively by removing the gas responsible for ripening, whereas chemical ripening inhibitors (like 1-MCP) work reactively by blocking the fruit's receptors for ethylene, offering two distinct yet sometimes complementary methods of preservation.

Which key technology uses photocatalytic degradation for ethylene removal?

Photocatalytic systems typically use titanium dioxide (TiO2) catalysts activated by light (UV or visible spectrum) to break down ethylene molecules, offering a regenerative, chemical-free method of air purification in enclosed storage spaces.

What criteria do logistics companies use when selecting a scavenging solution?

Logistics companies prioritize compliance with international shipping regulations, high absorption capacity capable of lasting long-haul transit times, ease of installation, and robust performance under varying temperature and humidity conditions typical of maritime transport.

How does the market address the challenge of scavenger material saturation?

Newer technologies address saturation through visual indicators (e.g., color change in KMnO4) or, increasingly, through integrated smart sensors linked to IoT platforms that provide real-time data on material exhaustion, prompting timely replacement.

What is the critical role of specialized zeolites in modern scavenging?

Specialized zeolites are microporous, high-surface-area natural minerals that serve as efficient, non-chemical adsorbents, capturing ethylene molecules within their structured framework, offering a stable and environmentally friendly alternative to traditional chemical oxidizers.

How does the market differentiate between products for climacteric and non-climacteric fruits?

Climacteric fruits (ethylene-producing) require high-capacity, immediate scavenging solutions. Non-climacteric fruits (low ethylene response) require less aggressive scavenging, often focusing more on antimicrobial and moisture control aspects of the active packaging.

In the Value Chain, why are packaging converters becoming key intermediaries?

Packaging converters are vital because they possess the technical expertise to seamlessly integrate granular scavenger materials (like masterbatch) into large-scale production of specialized active packaging films, transforming raw material into a final, user-ready product format.

What is meant by 'AEO-optimized answer' in the FAQ section?

An AEO-optimized answer is concise, direct, and specifically structured to provide the most relevant information immediately, ensuring it is easily extracted and presented by search engine Answer Boxes and generative AI models as a definitive response to a user query.

How critical is the floriculture industry to the Ethylene Scavenger Market?

The floriculture industry is critically important as cut flowers are exquisitely sensitive to ethylene, resulting in extremely low tolerance for exposure, driving the demand for highly effective, premium-priced, and specialized scavenging solutions.

Why is supply chain stability crucial for upstream scavenger material suppliers?

Supply chain stability is crucial because chemical and mineral sourcing must be consistent and high-quality to ensure the uniform performance and regulatory compliance of the final scavenger product, which is often used globally under highly variable transit conditions.

Which segment of the market provides the highest revenue volume?

The Fruits and Vegetables application segment, specifically within mass market climacteric produce (such as bananas, apples, and citrus), generates the highest revenue volume due to the sheer scale of global production and trade involving these commodities.

What market trend is pushing companies to invest in R&D for natural minerals?

The growing consumer and regulatory pressure for reduced chemical usage in food preservation, coupled with the pursuit of competitive advantage through superior environmental profiles, is driving heavy R&D investment into natural, high-performance sorbent materials like specialized zeolites.

How does the demand in LATAM differ from that in Europe?

LATAM demand is focused heavily on securing quality for export markets, requiring high-volume solutions for ocean freight. European demand is focused on sustainability, local distribution freshness, and compliance with strict EU environmental directives for packaging materials.

What is the main advantage of an air filtration system over sachets?

Air filtration systems are designed for large-scale, centralized control in warehouses or containers, providing powerful, dynamic atmospheric management that ensures uniform ethylene removal across large volumes, which sachets cannot achieve effectively in bulk storage.

What potential opportunity exists in the e-commerce sector for scavengers?

The booming e-commerce and last-mile grocery delivery sector presents a significant opportunity, requiring smaller, robust, high-performance scavenger inserts integrated into consumer-facing packaging to guarantee freshness during the final, often uncontrolled, delivery stages.

Describe the function of Activated Carbon in ethylene scavenging.

Activated carbon primarily functions as an adsorbent, physically trapping ethylene molecules due to its exceptionally high surface area and porous structure, often used synergistically with chemical oxidizers to enhance overall removal efficiency.

Why is the Base Year set as 2025 in the report table?

The Base Year (2025) represents the period for which comprehensive, actual market data is fully compiled and analyzed, serving as the benchmark for projecting the market's trajectory throughout the subsequent forecast period (2026-2033).

What is the economic consequence of high post-harvest loss rates?

High post-harvest loss rates lead to immense economic inefficiency, including direct financial losses for producers and distributors, wasted resources (water, land, labor), and increased inflationary pressure on consumer food prices.

How are companies using segmentation analysis in their strategy?

Companies use segmentation analysis to identify underserved niches (e.g., specific organic fruits or specialized cut flowers), allowing them to tailor R&D, pricing, and distribution efforts to maximize profitability within segments with high willingness-to-pay for guaranteed freshness.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager