Ethylene Scrubber Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432815 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Ethylene Scrubber Market Size

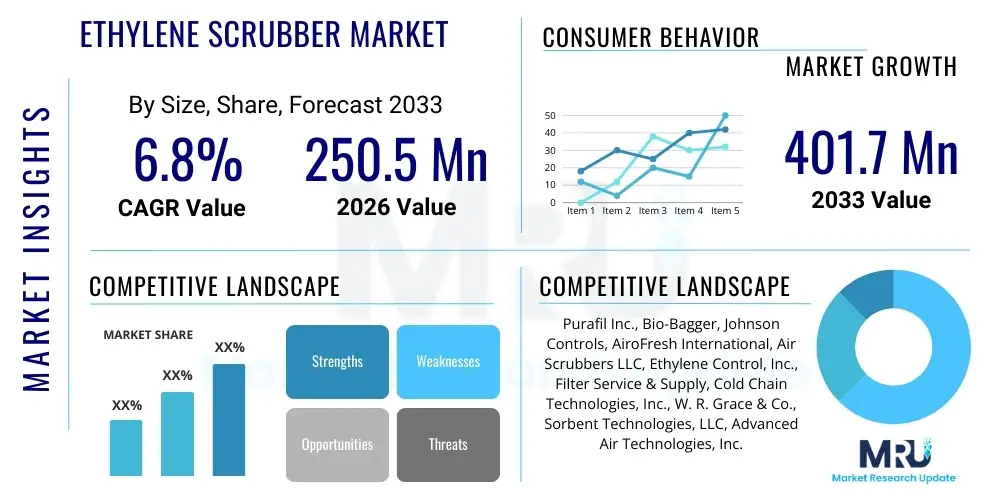

The Ethylene Scrubber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 250.5 Million in 2026 and is projected to reach USD 401.7 Million by the end of the forecast period in 2033. This consistent expansion is driven primarily by the escalating global focus on reducing post-harvest losses, ensuring the quality and longevity of perishable goods, and optimizing complex international fresh produce supply chains.

The core function of ethylene scrubbers, which is the removal of the gaseous plant hormone ethylene, is becoming increasingly critical across various sectors, including large-scale cold storage facilities, refrigerated shipping containers (reefers), and specialized ripening rooms. Market growth is underpinned by stringent regulatory standards concerning food waste and quality control, particularly in developed economies. Furthermore, the rising consumer demand for exotic and out-of-season produce necessitates advanced preservation technologies that maintain peak freshness during transit, thereby bolstering the adoption rates of sophisticated scrubbing systems.

Technological advancements, particularly in integrating smart monitoring systems and utilizing highly efficient adsorption media, are creating new avenues for market penetration. While initial capital expenditure for advanced systems poses a minor restraint, the significant return on investment derived from minimizing spoilage and extending marketable shelf life compels major logistics providers and agricultural businesses to adopt these solutions proactively. The Asia Pacific region, characterized by extensive agricultural output and rapidly developing cold chain infrastructure, is anticipated to be a major growth engine for the market during the forecast period.

Ethylene Scrubber Market introduction

Ethylene scrubbers are essential post-harvest treatment devices designed to eliminate ethylene gas (C2H4) from controlled environments, thereby extending the freshness and marketable lifespan of climacteric fruits, vegetables, and floricultural products. Ethylene, a naturally occurring plant hormone, acts as a signaling molecule that accelerates ripening and senescence (aging), leading to rapid quality degradation and significant financial losses if not effectively managed. These scrubbers operate through various mechanisms, predominantly chemical oxidation (using potassium permanganate (KMnO4) impregnated media), catalytic destruction, or physical adsorption using activated carbon or specialized molecular sieves. The primary applications span across cold storage warehouses, refrigerated transport containers (reefer ships and trucks), distribution centers, and highly specialized controlled atmosphere (CA) storage facilities used for long-term preservation of apples, bananas, and delicate flowers.

The inherent benefit of deploying ethylene scrubbing technology lies in its capacity to drastically minimize food spoilage and waste, which is a major global economic and sustainability concern. By maintaining ultra-low concentrations of ethylene in storage environments, quality attributes such as firmness, color, and nutritional value are retained for extended periods, facilitating greater flexibility in supply chain logistics and market timing. This technology is vital for producers engaging in international trade, where goods may endure lengthy transit times. Driving factors include the increasing global population demanding continuous access to high-quality fresh produce, the expansion of organized retail chains requiring centralized, long-duration storage, and global regulatory mandates pushing for greater efficiency and reduction in food loss throughout the entire value chain.

Beyond the agricultural sector, ethylene scrubbers also find application in the floriculture industry, where maintaining the freshness of cut flowers during shipping is paramount to market viability. The continuous evolution toward more sustainable and energy-efficient scrubbing methods, such as those utilizing UV-C light or advanced filtration, further supports market growth. This introduction sets the stage for analyzing how technological integration, especially smart sensor arrays and IoT platforms, is transforming these essential preservation tools into sophisticated components of modern cold chain management systems, ensuring the viability and quality of perishable goods from farm to consumer.

Ethylene Scrubber Market Executive Summary

The Ethylene Scrubber Market is defined by robust growth, propelled by macro-level business trends focused on supply chain optimization and sustainability mandates aimed at reducing global food waste. Key business trends include the shift toward integrated cold chain solutions, where ethylene scrubbing is not a standalone product but a networked component providing real-time atmospheric data. The necessity for longer-distance transit, supported by globalized trade, ensures sustained demand for high-performance scrubbers, particularly in the refrigerated shipping sector. Furthermore, companies are increasingly investing in next-generation adsorption media and catalysts that offer higher efficiency and longer service life, thereby reducing operational expenditure and maintenance downtime for end-users like large agricultural cooperatives and third-party logistics (3PL) providers specialized in perishable goods transport.

Regionally, Asia Pacific is emerging as the fastest-growing market, driven by massive investments in modernizing cold chain infrastructure across populous nations like China and India, coupled with significant fresh produce export volumes. North America and Europe currently represent the largest market share in terms of value, characterized by the early adoption of advanced, high-precision scrubbing technologies and strict enforcement of quality standards. Segment trends reveal that the chemical oxidation segment, largely relying on potassium permanganate, currently dominates the market due to its cost-effectiveness and proven efficacy, though the catalytic oxidation segment is projected to exhibit the highest CAGR as regulatory pressures favor reusable and non-chemical methods. The application segment growth is primarily concentrated within cold storage facilities and refrigerated shipping containers, reflecting the critical need for atmospheric control during both stationary holding and dynamic transportation phases.

Overall, the market is positioned for steady expansion, capitalizing on the convergence of technological refinement, global trade expansion, and increasing environmental consciousness regarding food security and waste reduction. The executive landscape is competitive, featuring specialized providers focusing on media formulation alongside large HVAC and refrigeration equipment manufacturers integrating scrubbing capabilities into their broader cold chain offerings. Strategic alliances focused on developing IoT-enabled predictive maintenance features and optimizing scrubber placement within complex storage layouts will be pivotal in capturing future market share and dictating the direction of technological advancement throughout the forecast period.

AI Impact Analysis on Ethylene Scrubber Market

Common user questions regarding the impact of AI on the Ethylene Scrubber Market center around themes of predictive maintenance, optimization of scrubbing cycles, and integration with broader cold chain management systems. Users are keen to understand how AI algorithms can leverage data from temperature, humidity, and atmospheric gas sensors (CO2, O2, and C2H4) to predict ethylene spikes before they occur, thereby optimizing the scrubber activation profile and extending the life of the filtration media. Key concerns revolve around the cost of implementing AI-enabled sensors and software platforms, data security in networked cold storage environments, and the reliability of machine learning models in predicting spoilage across diverse produce types with varying ethylene production rates. Expectations are high regarding the ability of AI to create fully autonomous storage environments that minimize manual intervention and ensure consistent quality, especially during dynamic conditions encountered in international shipping.

The integration of Artificial Intelligence transforms ethylene scrubbing from a passive air purification process into an active, responsive component of the cold chain. AI systems analyze historical environmental data alongside current sensor readings to establish baseline ethylene production rates for specific batches of produce. If the system detects deviations suggesting imminent spoilage or high respiration rates, AI can automatically trigger the scrubber system at the optimal level required, contrasting sharply with traditional systems that operate on fixed schedules or merely respond after a threshold is breached. This optimization minimizes energy consumption and significantly prolongs the efficiency of costly scrubbing media, moving toward truly smart, energy-efficient post-harvest management.

Furthermore, AI facilitates integration with enterprise resource planning (ERP) systems and logistics platforms. By providing highly accurate real-time data on the atmospheric conditions and predicted quality retention of the stored produce, AI assists supply chain managers in making dynamic routing and inventory decisions. For instance, a system might recommend accelerating the shipment of a particular container if its AI model predicts a shorter remaining shelf life due to unexpected ethylene stress, thereby prioritizing the freshest goods for market delivery. This level of predictive insight enhances transparency, reduces economic loss associated with unpredicted spoilage, and elevates the overall quality and reliability of the global fresh produce supply chain, solidifying AI’s role as a critical enabler of next-generation cold storage technology.

- AI-driven Predictive Maintenance: Forecasts media saturation and required replacement cycles, minimizing downtime and ensuring continuous operation.

- Optimized Scrubber Activation: Machine learning algorithms dynamically adjust scrubber intensity based on real-time fruit respiration and ethylene concentration data, conserving energy and extending media life.

- Integrated Quality Monitoring: AI correlates environmental data (temperature, humidity, C2H4 levels) with quality retention models to provide an estimated remaining shelf life for specific batches of produce.

- Anomaly Detection: Identifies unusual spikes in ethylene production indicative of potential storage issues or equipment malfunction faster than human operators.

- Resource Allocation Optimization: Enhances cold chain logistics by providing quality-related intelligence to inventory management and routing software.

DRO & Impact Forces Of Ethylene Scrubber Market

The Ethylene Scrubber Market is influenced by a dynamic interplay of factors encompassing strong regulatory pushes, technological innovation, and significant supply chain constraints. Key drivers include the overwhelming global imperative to minimize food waste, which accounts for substantial economic and environmental costs, compelling fresh produce stakeholders to invest in proven preservation technologies. The opportunities lie primarily in developing highly energy-efficient and reusable media, catering to the growing demand for sustainable cold chain solutions, and integrating these systems with advanced IoT monitoring platforms. Restraints primarily involve the high initial capital investment required for installing high-capacity scrubbing systems and the operational costs associated with frequently replacing chemical oxidation media, particularly in smaller operational settings. The overall impact forces center on sustainability mandates and consumer preference for quality, driving continuous technological evolution in filtration and atmospheric control.

Specific drivers include the globalization of the perishable goods trade, necessitating extended transit times and reliable atmospheric control within refrigerated containers and ships. As consumer expectations for year-round availability of high-quality, diverse produce rise, the reliance on effective ethylene removal systems intensifies. The growth of organized retail and large-scale centralized storage facilities further fuels demand for industrial-grade scrubbing solutions capable of managing voluminous storage spaces. Concurrently, technological advancement in sensor technology, allowing for precise measurement and control of ethylene concentrations in parts per billion (ppb), facilitates the deployment of more targeted and effective scrubbing strategies, reducing operational waste.

Opportunities are significant within emerging economies, particularly in the rapid expansion of their cold chain infrastructure, providing a large, untapped market for scrubber deployment in new storage and distribution centers. Furthermore, there is a strong market opportunity in retrofitting older cold storage facilities with modern, high-efficiency scrubbing units that meet current sustainability criteria. However, restraints such as the volatility in raw material costs for chemical media (e.g., potassium permanganate) and the competitive pressure from alternative preservation methods, such as specialized controlled atmosphere storage (CA), require manufacturers to continually innovate to maintain a competitive advantage. The impact forces overwhelmingly favor market expansion, as the societal and economic costs associated with food spoilage far outweigh the costs of advanced preservation technology, cementing the essential nature of ethylene scrubbing in modern food logistics.

Segmentation Analysis

The Ethylene Scrubber Market is primarily segmented based on the mechanism of ethylene removal (Type), the specific environment where the scrubbers are deployed (Application), and the primary users of the technology (End-User). Segmentation provides a granular view of market dynamics, revealing varying growth rates and adoption patterns across different technological approaches and user requirements. The dominant segmentation by type involves chemical adsorption/oxidation, which uses media like potassium permanganate impregnated alumina to chemically neutralize ethylene, and physical adsorption methods, often utilizing activated carbon or molecular sieves. The ongoing push for non-chemical, regenerative solutions is driving accelerated growth in the catalytic and advanced filtration segments.

Segmentation by application highlights the diverse operational needs of the supply chain. Cold storage warehouses and distribution centers demand large-scale, fixed scrubbing units designed for continuous operation in massive volumes. Conversely, refrigerated shipping containers (reefers) require compact, robust, and highly efficient units capable of enduring turbulent maritime environments for weeks on end. The end-user segment reveals that fresh produce farmers, exporters, and dedicated 3PL providers specializing in perishable logistics represent the largest consumers of ethylene scrubbing technology, closely followed by the high-value floriculture industry where quality retention is critical to commercial success.

Understanding these segments is crucial for manufacturers to tailor product development, focusing either on cost-effective, high-capacity chemical solutions for stationary storage or sophisticated, regenerative catalytic systems preferred by high-end logistics and long-distance transport operators. The shift toward integrated smart systems is increasingly blurring the lines between these segments, as end-users demand scrubbers that can seamlessly interface with existing environmental control infrastructure, irrespective of the underlying removal mechanism employed.

- By Type:

- Chemical Oxidation (e.g., Potassium Permanganate-based)

- Catalytic Oxidation (Thermal or UV-C based)

- Physical Adsorption (e.g., Activated Carbon, Zeolite)

- Hybrid/Membrane Technology

- By Application:

- Cold Storage Warehouses and Facilities

- Refrigerated Shipping Containers (Reefers)

- Transportation Vehicles (Trucks, Rail Cars)

- Ripening Rooms and Controlled Atmosphere (CA) Storage

- Floriculture Cold Rooms

- By End-User:

- Fresh Produce (Fruits, Vegetables, Grains)

- Floriculture and Horticulture

- Food Processing and Packaging Industry

- Third-Party Logistics (3PL) Providers

Value Chain Analysis For Ethylene Scrubber Market

The value chain of the Ethylene Scrubber Market commences with the upstream supply of raw materials and specialized components. This stage involves sourcing high-purity chemical compounds such as potassium permanganate for chemical media, activated alumina, zeolites, and specialized catalytic elements (e.g., platinum or palladium used in thermal catalytic scrubbers). Suppliers of advanced sensors (ethylene, temperature, CO2) and high-efficiency filtration housing materials also form a critical part of this segment. Manufacturing, the subsequent stage, involves engineering and assembling the scrubbing units, which includes media impregnation, housing fabrication, and integration of airflow management and control electronics. Efficiency and durability are key focuses at this stage, requiring adherence to stringent industrial refrigeration standards and food safety protocols.

The midstream segment involves the distribution channels, categorized into direct and indirect routes. Direct distribution often involves Original Equipment Manufacturers (OEMs) of cold storage facilities and refrigerated transport (reefer manufacturers) who integrate the scrubbers directly into their products. Indirect distribution relies on specialized industrial distributors, HVAC specialists, and agricultural equipment dealers who cater to existing cold storage operators and farms looking to upgrade or retrofit their facilities. Strong distribution networks are vital, especially for serving the global shipping market where rapid deployment and reliable maintenance services are non-negotiable requirements for logistics providers.

The downstream analysis focuses on the end-users and the after-sales service requirements. Major end-users, including large-scale fresh produce wholesalers, multinational food retailers, and specialized floriculture companies, drive demand for high-capacity, low-maintenance systems. Critical downstream services include media replacement and regeneration, technical support for atmospheric control systems, and predictive maintenance contracts, often managed by the manufacturers or certified 3PL service providers. The efficiency and reliability of the after-sales support significantly impact customer satisfaction and repeat business, particularly given the perishable nature of the goods being protected by these systems.

Ethylene Scrubber Market Potential Customers

Potential customers for ethylene scrubbers are overwhelmingly concentrated in sectors where the quality and shelf life of perishable goods are paramount to business success, specifically encompassing large-scale food production, logistics, and retail operations. The primary end-users are agricultural producers and exporters specializing in climacteric fruits (like bananas, apples, avocados) and vegetables that are highly sensitive to ethylene exposure. These producers rely on scrubbers to ensure their harvest maintains optimal quality through the crucial post-harvest processing and initial storage phases before being transferred to distribution channels. Their procurement decisions are heavily influenced by the system’s capacity, energy efficiency, and total cost of ownership over a typical harvest cycle.

A second major customer category includes third-party logistics (3PL) providers and large shipping companies operating refrigerated sea containers (reefers). These customers demand industrial-grade, highly durable scrubbers that can function reliably under dynamic conditions, ensuring cargo protection during long-haul international transit, which can span several weeks. For these logistics giants, the economic benefit of preventing cargo rejection due to spoilage far outweighs the investment in advanced scrubbing technology. Their purchasing requirements focus on compact design, robust construction, minimal need for maintenance during transit, and IoT compatibility for remote monitoring and control.

Finally, major retail chains and wholesale distribution centers constitute significant potential customers. As these entities manage vast inventories of diverse produce, they require large, centralized cold storage facilities equipped with powerful air purification and atmospheric control systems. Supermarket chains prioritize systems that facilitate inventory flexibility, allowing them to hold produce longer to respond effectively to market demand fluctuations. The floriculture industry also remains a high-value customer segment, utilizing smaller, high-precision scrubbers to maintain the vibrancy and longevity of delicate cut flowers and potted plants during distribution and display.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 250.5 Million |

| Market Forecast in 2033 | USD 401.7 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Purafil Inc., Bio-Bagger, Johnson Controls, AiroFresh International, Air Scrubbers LLC, Ethylene Control, Inc., Filter Service & Supply, Cold Chain Technologies, Inc., W. R. Grace & Co., Sorbent Technologies, LLC, Advanced Air Technologies, Inc., BGN International, Linde plc, Arkema S.A., Donaldson Company, Inc., Carrier Global Corporation, Daikin Industries, Ltd., Mitsubishi Heavy Industries, Thermo King Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ethylene Scrubber Market Key Technology Landscape

The technology landscape of the Ethylene Scrubber Market is dominated by three main technical approaches: chemical oxidation, catalytic decomposition, and physical adsorption, each with distinct benefits and constraints. Chemical oxidation, predominantly utilizing media impregnated with potassium permanganate (KMnO4) on a porous substrate like activated alumina, remains the most widely adopted and cost-effective method. KMnO4 acts as a powerful oxidizing agent, irreversibly converting ethylene into carbon dioxide and water. The key technological focus in this segment is developing higher-capacity, longer-lasting media that indicate saturation clearly, maximizing operational efficiency and minimizing replacement frequency. Suppliers are focused on improving the porosity and surface area of the carrier material to enhance reaction kinetics and media lifespan under varying humidity levels typical of cold storage.

Catalytic decomposition technologies represent the leading edge of innovation, addressing the sustainability concerns associated with consumable chemical media. This approach involves passing air over a catalyst bed (often containing precious metals like platinum or palladium) which, when heated (thermal catalysis) or exposed to UV light (photo-catalysis), accelerates the breakdown of ethylene into harmless byproducts. While catalytic scrubbers require higher initial capital investment and energy input for heating or specialized lighting, they offer the significant advantage of regeneration and reusable media, leading to a much lower environmental footprint and reduced long-term operational costs, making them highly attractive for premium, fixed installations and continuous operation environments.

Physical adsorption, relying on highly porous materials such as activated carbon or specialized zeolites, captures ethylene through weak intermolecular forces. This method is often employed in combination with chemical or catalytic stages (hybrid systems) to maximize overall air purification efficiency, particularly to remove other volatile organic compounds (VOCs) that can interfere with produce quality. The future technological trajectory is heavily leaning toward advanced hybrid systems integrating Internet of Things (IoT) sensors and Artificial Intelligence (AI) algorithms for real-time monitoring and predictive control. These smart systems optimize airflow, manage humidity, and dynamically adjust scrubbing intensity based on precise atmospheric data, significantly improving the efficacy and energy profile of post-harvest preservation operations.

Regional Highlights

The global Ethylene Scrubber Market exhibits significant regional disparities in terms of technological adoption, market maturity, and growth trajectory, largely reflective of the sophistication of local cold chain infrastructure and the scale of fresh produce export operations.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing regional market, fueled by massive investments in modernizing and expanding cold storage facilities and refrigerated transportation networks, particularly in major agricultural hubs like China, India, and Southeast Asia. The region’s large population, coupled with increasing disposable incomes and demand for imported fruits and high-value vegetables, drives the need for reliable long-term storage solutions. The prevalence of lengthy inland and inter-regional shipping routes necessitates robust, durable ethylene control solutions, establishing APAC as a prime target for high-capacity, economically viable scrubbing systems. Government initiatives focused on reducing post-harvest losses and improving food security further accelerate market penetration in this region.

- North America: North America holds a dominant market share in terms of value, characterized by the early adoption of advanced, integrated cold chain technologies and stringent quality control regulations. The region primarily demands high-precision, low-maintenance catalytic and AI-enabled hybrid scrubbers that integrate seamlessly with sophisticated Controlled Atmosphere (CA) storage systems. The market is mature, focused less on infrastructure expansion and more on technological refinement, energy efficiency, and predictive maintenance capabilities, driven by the presence of major global food processing and retail giants.

- Europe: Europe represents a highly competitive and mature market, marked by a strong emphasis on sustainability and environmental regulations. European end-users show a pronounced preference for reusable, regenerative catalytic scrubbers over chemical alternatives to minimize environmental impact and waste disposal issues. Western European countries, with established export links for high-value goods like cut flowers and specialized fruits, exhibit high demand for premium, customized scrubbing solutions tailored to specific commodity requirements. Regulatory push for waste reduction strongly underpins continuous demand and innovation here.

- Latin America: This region is crucial due to its status as a major global exporter of fruits (e.g., bananas, avocados, grapes). Market growth is steady, concentrated in segments related to refrigerated container shipping and export logistics. The focus is often on cost-effective, high-reliability chemical oxidation systems that can withstand the rigors of long-distance oceanic travel, securing the quality of exports destined for North American and European markets. Investment in modern infrastructure, though accelerating, still presents opportunities for entry-level and mid-range industrial scrubber solutions.

- Middle East and Africa (MEA): Growth in MEA is driven by the necessity to import a significant portion of fresh produce, requiring advanced atmospheric control for long-term storage in high-temperature climates. Investments in cold storage infrastructure, particularly within the Gulf Cooperation Council (GCC) countries, are creating new demand. The market here is growing rapidly, targeting essential food security goals through reducing spoilage in large-scale strategic reserves and handling centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ethylene Scrubber Market.- Purafil Inc.

- Bio-Bagger

- Johnson Controls

- AiroFresh International

- Air Scrubbers LLC

- Ethylene Control, Inc.

- Filter Service & Supply

- Cold Chain Technologies, Inc.

- W. R. Grace & Co.

- Sorbent Technologies, LLC

- Advanced Air Technologies, Inc.

- BGN International

- Linde plc

- Arkema S.A.

- Donaldson Company, Inc.

- Carrier Global Corporation

- Daikin Industries, Ltd.

- Mitsubishi Heavy Industries

- Thermo King Corporation

- Klinge Corporation

Frequently Asked Questions

Analyze common user questions about the Ethylene Scrubber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an ethylene scrubber in the cold chain?

The primary function of an ethylene scrubber is to remove ethylene gas (C2H4), a plant hormone that accelerates ripening and decay, from refrigerated environments, thereby extending the shelf life and maintaining the quality of fresh produce and cut flowers during storage and transit.

Which type of ethylene scrubber technology is considered the most cost-effective for large-scale cold storage?

Chemical oxidation scrubbers, primarily utilizing potassium permanganate (KMnO4) impregnated media, are generally considered the most cost-effective solution for large-scale, high-capacity cold storage facilities due to their proven efficacy, lower initial capital cost, and high absorption capacity per unit weight.

How does the integration of IoT and AI benefit ethylene scrubber efficiency?

IoT and AI integration allows for real-time monitoring of atmospheric gas concentrations and provides predictive analytics. This data enables dynamic adjustment of scrubber operations, ensuring activation only when necessary, which reduces energy consumption and maximizes the lifespan of the scrubbing media.

What are the key drivers propelling market growth in the Asia Pacific region?

Market growth in the Asia Pacific is primarily driven by massive infrastructure investments in modernizing the cold chain, significant reduction goals related to post-harvest food loss, and the rapidly increasing demand for high-quality, safe fresh produce across major economies like China and India.

Are catalytic ethylene scrubbers more sustainable than chemical scrubbers?

Yes, catalytic ethylene scrubbers are generally considered more sustainable because they utilize reusable or regenerative media and chemically break down ethylene without relying on consumable chemicals like potassium permanganate, leading to less operational waste and lower environmental impact over the long term.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager