Abort Gate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443203 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Abort Gate Market Size

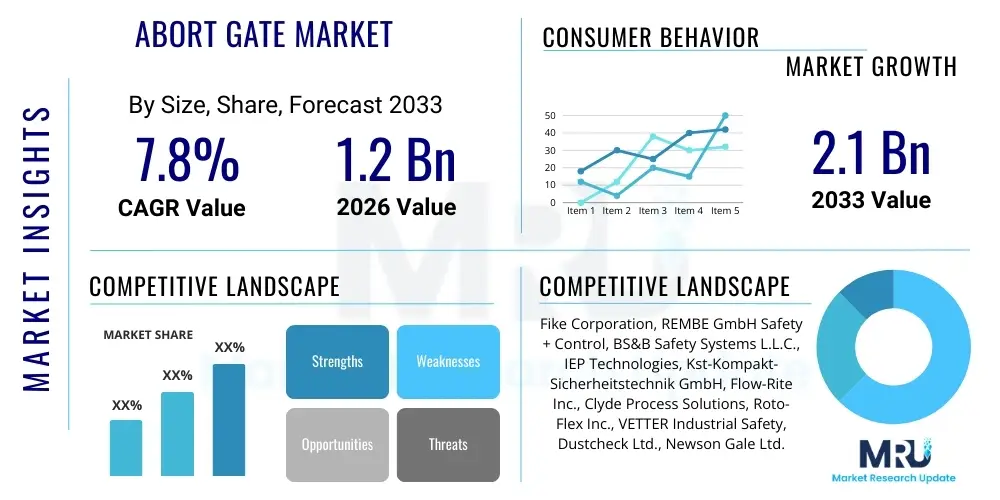

The Abort Gate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2033. This growth trajectory is primarily underpinned by escalating global emphasis on industrial safety standards and regulatory mandates across high-risk sectors such as mining, bulk material handling, and chemical processing. The inherent necessity of reliable emergency diversion systems to mitigate catastrophic equipment failure and operational downtime positions the Abort Gate sector as a critical component of modern industrial infrastructure investment, ensuring robust expansion over the next decade.

Abort Gate Market introduction

The Abort Gate Market encompasses the manufacturing, distribution, and implementation of specialized mechanical and automated diversion devices crucial for rapidly interrupting the flow of bulk materials, powders, or gases in industrial conveyance systems. These devices are predominantly employed in processes involving potentially explosive, hazardous, or high-temperature materials, serving as a vital safety barrier to prevent the spread of fire, explosion, or cross-contamination. Functionally, an abort gate is designed for instantaneous deployment upon detection of an aberrant condition—such as spark detection in dust collectors or pressure anomalies in pneumatic transport—thereby diverting the material stream into a safe containment area or stopping the flow entirely. This rapid response capability is central to protecting upstream and downstream equipment, safeguarding personnel, and ensuring compliance with strict industrial safety regulations like NFPA standards in North America and ATEX directives in Europe.

Major applications of abort gates span diverse heavy industries, including grain processing, woodworking, pharmaceuticals, power generation (coal handling), and chemical manufacturing. In material handling systems, particularly those utilizing pneumatic conveyors or chutes, these gates act as critical control points. The primary benefits derived from the adoption of high-performance abort gates include significantly reduced insurance liabilities, minimized operational downtime following an incident, and the preservation of capital-intensive production machinery. Moreover, advancements in gate technology, such as the integration of smart sensors and high-speed actuation systems, are driving factors that enhance the reliability and responsiveness of these essential safety components. The increasing complexity of automated production lines globally necessitates integrated safety solutions, thereby providing sustained momentum for market expansion.

Abort Gate Market Executive Summary

The Abort Gate Market is characterized by robust growth, driven primarily by tightening global regulatory frameworks pertaining to dust explosion prevention and industrial operational safety. Current business trends indicate a strong move toward highly customized, integrated safety systems that incorporate high-speed abort gates directly linked to sophisticated detection technologies, moving beyond standalone mechanical solutions. Geographically, the Asia Pacific region is expected to exhibit the fastest growth, propelled by massive infrastructure projects, burgeoning manufacturing capabilities, and the subsequent adoption of advanced safety protocols in emerging economies like China and India. Conversely, North America and Europe maintain dominance in terms of technology adoption, driven by stringent adherence to established safety guidelines and a readiness to invest in premium, high-reliability components.

Segment trends reveal a significant shift toward electronically actuated and pneumatically operated gates, favored over traditional gravity-fed or manually operated systems due to their superior speed and reliability in emergency scenarios. Furthermore, the market is segmented based on the type of material handled—with specialized gates for abrasive solids, granular materials, and volatile powders demanding unique design specifications, material compositions, and sealing capabilities. The competitive landscape remains moderately fragmented, featuring global specialized safety equipment manufacturers alongside regional players catering to specific industrial niches. Key strategies employed by market leaders include intensive R&D focused on increasing gate closure speed, enhancing seal integrity under extreme conditions, and developing IIoT-enabled diagnostic features for predictive maintenance and compliance auditing.

AI Impact Analysis on Abort Gate Market

User queries regarding the impact of Artificial Intelligence on the Abort Gate Market center around themes of predictive failure, optimized maintenance schedules, real-time threat assessment, and enhanced decision-making speed far exceeding traditional PLC-based systems. Users frequently ask: "How can AI predict a need for an abort sequence before a sensor trips?" and "Will AI integration reduce false positive shutdowns?" The core concern is leveraging AI to transform reactive safety mechanisms into proactive, intelligent safety architectures. Key expectations involve AI analyzing vast datasets from integrated sensors (vibration, temperature, flow rates, dust concentration) to identify subtle anomalies or deteriorating operational health patterns that could lead to catastrophic failure, thereby initiating a preventative abort sequence rather than relying solely on immediate hazard detection (like a sudden spark).

The integration of AI into abort gate systems is transitioning these components from simple mechanical barriers into critical nodes within a comprehensive, intelligent plant safety network. AI algorithms enable sophisticated pattern recognition that traditional threshold-based systems cannot match. For instance, by correlating minor fluctuations in conveyor motor load with ambient humidity and material density, AI can predict the impending risk of static charge buildup or material clogging, initiating a controlled slowdown or abort sequence to prevent a potentially hazardous situation like a dust explosion. This proactive capability significantly reduces unwarranted operational stoppages, addressing a key historical pain point—the economic cost of false positive aborts—by ensuring the system only triggers when statistically necessary, dramatically improving overall equipment effectiveness (OEE) and operational efficiency.

- AI-driven Predictive Maintenance: Analyzing gate actuation cycles, seal wear, and pneumatic system health to schedule maintenance before failure, ensuring 100% operational readiness for emergency deployment.

- Real-Time Anomaly Detection: Utilizing machine learning models to process multisensory input (thermal, optical, acoustic) to identify nascent hazard conditions (e.g., micro-sparks or unusual vibration patterns) milliseconds faster than conventional detection systems, initiating rapid abort procedures.

- Optimized Response Calibration: Dynamically adjusting gate closure speed and diversion path selection based on real-time material flow dynamics and predicted trajectory, maximizing containment efficiency.

- Reduction of False Positives: AI contextual awareness minimizes unnecessary shutdowns caused by transient environmental noise or minor, non-critical fluctuations, improving system uptime and reducing revenue loss.

- Compliance Reporting and Auditing: Automated generation of time-stamped, AI-verified safety logs detailing conditions leading to an abort, greatly simplifying regulatory compliance and post-incident analysis.

DRO & Impact Forces Of Abort Gate Market

The Abort Gate Market is fundamentally shaped by powerful synergistic forces: market expansion is driven by globally mandated safety regulations and the rapid modernization of industrial infrastructure, while restraining factors include the high initial capital investment required and the complexity of integrating advanced gate systems into legacy facilities. Opportunities are abundant in the development of smart, IIoT-enabled gates offering remote diagnostics and predictive capabilities, particularly within emerging markets that are establishing modern, high-standard industrial zones. These driving, restraining, and opportunity forces collectively dictate the market’s pace, influencing investment decisions, technological development cycles, and competitive strategies among key players, making regulatory changes a primary impact force that mandates continuous product evolution and rigorous certification standards for system components.

Drivers: The most potent driver is the increasingly stringent regulatory landscape, particularly in explosion-prone environments like milling, grain silos, and certain chemical processing plants. Standards such as NFPA 652/654 in the US and ATEX/IECEx in Europe require proven, high-integrity isolation devices to protect against deflagration propagation. Furthermore, the massive investment in industrial automation across high-growth regions like APAC necessitates reliable and rapid safety cut-offs that can integrate seamlessly with complex automated lines, thus fueling demand for advanced pneumatic and electromechanical abort gates. The rising awareness regarding employee safety and the corresponding reduction in operational liability achieved through superior safety systems also strongly incentivize the adoption of certified abort gates across all industrial sectors.

Restraints: Significant barriers to market growth include the high cost associated with certified, explosion-proof abort gate systems and their corresponding detection apparatus. Small and medium-sized enterprises (SMEs) often face capital constraints preventing the replacement of older, non-compliant systems. Additionally, integrating high-speed abort gates into existing, heterogeneous legacy plant infrastructure presents considerable engineering challenges, often requiring extensive system modification, which translates into prolonged installation periods and operational disruption. The requirement for specialized expertise for both installation and ongoing maintenance of these complex safety systems, particularly in remote industrial locations, further acts as a constraining factor on widespread adoption.

Opportunities: Major opportunities reside in the advancement of smart safety components capable of proactive maintenance and remote monitoring. Developing specialized abort gates tailored for emerging applications, such as large-scale battery manufacturing or recycling facilities dealing with volatile lithium-ion powders, presents a high-growth niche. There is a burgeoning market for retrofitting existing facilities with high-speed, compact abort gates that minimize installation footprint and maximize regulatory compliance without necessitating a complete overhaul of the material handling system. Furthermore, expanding distribution and service networks in industrializing regions, coupled with localized manufacturing partnerships, offer substantial pathways for market penetration.

Segmentation Analysis

The Abort Gate Market is intricately segmented based on core functional characteristics, operational mechanisms, and the specific application environments they serve, ensuring tailored safety solutions meet diverse industrial demands. Segmentation by mechanism—pneumatic, electric, and mechanical—reflects varying needs for response speed and power availability, with pneumatic gates typically dominating high-speed material diversion applications due to their inherent rapid actuation capabilities. Further market distinction is drawn based on the type of material flow: granular solids, fine powders, gases, or slurries, as each material dictates specific gate design (e.g., blade shape, sealing material, anti-abrasion coatings) to ensure reliable sealing and prevent jamming or excessive wear. This granular segmentation allows manufacturers to target niche industrial requirements, optimizing product performance for demanding environments such as those handling highly corrosive chemicals or abrasive mineral dust.

Application-based segmentation highlights key end-use industries, including the critical sectors of wood processing (where fire and dust explosion risks are high), food and beverage processing (demanding high sanitation standards and non-contaminating materials), and heavy industrial sectors like mining and power generation. The material construction segment is vital, differentiating between standard carbon steel components and highly specialized stainless steel alloys (e.g., 304 or 316L) required for corrosive or pharmaceutical-grade environments where contamination control is paramount. The increasing complexity of industrial processes and the regulatory push for enhanced process safety drives the demand for highly specialized and certified components, thus strengthening the importance of focused, application-specific segmentation strategies within the competitive landscape. Understanding these segmentation nuances is crucial for strategic market positioning and product development alignment.

- By Mechanism Type:

- Pneumatically Actuated Abort Gates (High speed, reliable in hazardous zones)

- Electrically Actuated Abort Gates (Precise control, ideal for smaller streams)

- Mechanically Actuated Abort Gates (Simple, low-maintenance)

- By Material Handled:

- Granular Solids (e.g., pellets, grains)

- Fine Powders and Dust (Explosion isolation applications)

- Gases and Vapors (High-pressure diversion systems)

- Slurries and Liquids (Chemical processing containment)

- By End-Use Industry:

- Food and Beverage Processing (Hygienic design)

- Mining and Minerals (Abrasive handling)

- Woodworking and Furniture Manufacturing (Dust explosion mitigation)

- Chemical and Pharmaceutical (Corrosion resistance, purity control)

- Power Generation (Coal/biomass handling)

- By Gate Design:

- Slide Gates

- Flap Gates

- Diverter Gates

Value Chain Analysis For Abort Gate Market

The value chain for the Abort Gate Market commences with the upstream supply of specialized raw materials, primarily high-grade steels (stainless steel for corrosive resistance or high-tensile carbon steel for structural integrity), specialized elastomers for sealing components, and complex electronic components such as sensors, PLC units, and high-speed solenoid valves required for actuation systems. Key upstream dynamics include managing the volatility in steel prices and securing reliable suppliers for high-precision, certified components that must meet explosion-proof standards (e.g., intrinsically safe circuitry). Manufacturers then engage in precision engineering, welding, and rigorous testing, culminating in the certification of the finished abort gate system by bodies like NFPA or TÜV, a critical step that significantly adds intellectual property and quality value to the product.

The midstream phase involves the core manufacturing process, where integration expertise is vital, combining mechanical precision with complex controls. Downstream analysis reveals a distribution channel heavily reliant on specialized industrial safety system integrators and authorized distributors who possess the necessary technical competence to install and calibrate these critical safety devices according to local codes and specific process requirements. Direct sales often characterize large, customized projects for multinational corporations, while smaller, standardized gates are sold through industrial supply catalogs and specialized component distributors. The primary value addition downstream is through installation, calibration, and long-term service contracts, ensuring the gate remains fully operational and compliant throughout its lifespan, often involving comprehensive technical support and mandatory periodic re-certification services.

Abort Gate Market Potential Customers

Potential customers, or end-users/buyers, in the Abort Gate Market are defined by their engagement in industrial processes that handle combustible dusts, hazardous materials, or operate high-speed conveyance systems where rapid material flow interruption is necessary to prevent catastrophic events. These customers typically operate environments where regulatory compliance is non-negotiable and the cost of downtime or a safety incident is prohibitively high. The primary buying motivators include achieving insurance compliance, mitigating legal liability, protecting high-value capital equipment (like filter systems or silos), and ensuring worker safety. Procurement decisions are often centralized within plant safety engineering departments or corporate risk management teams, prioritizing certified reliability, proven response time specifications, and long-term technical support over initial purchase price.

Key segments of potential customers include large-scale bulk material handlers such as agricultural cooperatives operating massive grain storage and processing facilities, mineral processing and cement plants dealing with abrasive and sometimes explosive fine powders, and pharmaceutical or fine chemical producers requiring absolute purity and explosion isolation across segregated processing lines. Other crucial buyers are original equipment manufacturers (OEMs) of dust collection and pneumatic conveying systems who integrate abort gates as essential, non-optional safety features within their larger machinery offerings. The decision-making process for these customers is characterized by detailed specification matching, extensive vendor qualification based on component certifications (e.g., ATEX, FM Approvals), and a requirement for integration capabilities with existing plant control and fire detection systems, emphasizing the need for highly technical sales engagement.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 2.1 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fike Corporation, REMBE GmbH Safety + Control, BS&B Safety Systems L.L.C., IEP Technologies, Kst-Kompakt-Sicherheitstechnik GmbH, Flow-Rite Inc., Clyde Process Solutions, Roto-Flex Inc., VETTER Industrial Safety, Dustcheck Ltd., Newson Gale Ltd., Boss Products, Vortex Valves, S&S Air Compressor Services, Hamer-Schlauchtechnik, Coperion K-Tron, Schenck Process Holding GmbH, Donaldson Company, Inc., A.C.S. Air Components Systems, and Explosion Protection Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Abort Gate Market Key Technology Landscape

The technological landscape of the Abort Gate Market is rapidly evolving, moving beyond simple mechanical diversion toward integrated, high-speed electromechanical and pneumatic systems supported by advanced sensor technology and sophisticated control logic. Central to this evolution is the imperative to achieve closure speeds in milliseconds to effectively halt the propagation of explosions or fires in dust collection systems. Modern abort gates rely heavily on high-pressure pneumatic actuators coupled with specialized solenoid valves engineered for extremely rapid response times and high cycles. Material science advancements, particularly in abrasion-resistant coatings (such as ceramics or specialized polymers) and sealing materials capable of withstanding extreme temperatures and chemical exposure, are crucial for extending the operational life and integrity of the gate in harsh industrial environments, ensuring reliable closure under emergency conditions.

A key trend is the integration of Smart Gate technology, utilizing the Industrial Internet of Things (IIoT). This involves embedding multiple diagnostic sensors—including proximity switches, pressure transducers, and vibration monitors—directly into the gate mechanism. These sensors feed continuous operational data back to a central PLC or cloud platform, allowing for real-time performance monitoring and sophisticated predictive maintenance algorithms to assess component wear and system health. This shift from simple passive safety component to an active, connected safety node enhances compliance documentation and significantly reduces the probability of a gate failure during a critical event. Furthermore, advancements in control panel technology allow for integrated system architecture, where the abort gate communicates seamlessly with spark detection, flame sensors, and pressure monitoring systems, enabling a coordinated and optimized emergency response across multiple plant areas.

The adoption of standardized communication protocols, such as OPC UA or industrial Ethernet, is making the integration process simpler and more robust, allowing gate status and diagnostic information to be monitored globally. This technological convergence ensures that the abort gate is not only fast and reliable mechanically but also intelligent and fully traceable digitally. The continuous pressure from regulatory bodies to prove the functional safety integrity level (SIL) of these systems mandates the use of certified components and rigorous design verification processes, pushing manufacturers towards continuous innovation in fail-safe mechanism design and self-testing capabilities, ensuring the gate's readiness remains verifiable at all times.

Regional Highlights

- North America: This region holds a significant market share, primarily due to the established and strictly enforced safety standards, particularly those mandated by the Occupational Safety and Health Administration (OSHA) and the comprehensive dust explosion standards developed by the NFPA. The market is characterized by high investment in advanced, certified safety equipment and a strong preference for domestically manufactured, high-reliability components. Key demand generators include the robust grain handling sector, major petrochemical industries, and large-scale industrial manufacturing facilities undergoing modernization. The U.S. remains the core market, driven by the replacement cycle of older safety systems and proactive adoption of AI-enabled diagnostic features.

- Europe: Europe exhibits strong growth, heavily influenced by the ATEX (Appareils destinés à être utilisés en Atmosphères Explosibles) directives and the machinery directive, which mandate the use of certified explosion protection systems. Germany, the UK, and Scandinavia are key markets, showing a strong demand for sophisticated, high-end abort gate systems used in pharmaceutical production and advanced manufacturing. The focus here is on achieving high Safety Integrity Levels (SIL) and ensuring environmental compliance. Strict regulations regarding material traceability in the food and beverage sector further contribute to the steady uptake of stainless steel, hygienic-design abort gates across the continent.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by massive investment in industrial infrastructure, rapid urbanization, and the relocation of global manufacturing operations to countries like China, India, and Southeast Asian nations. Although regulatory enforcement is historically varied, the trend is moving toward adopting international safety standards, particularly in new industrial parks and export-focused facilities. The sheer volume of material handled in construction, power generation (coal), and manufacturing sectors creates massive demand. Price sensitivity remains a factor, but the shift towards higher-quality, compliant components is accelerating, offering significant expansion opportunities for international vendors.

- Latin America: This region presents a market with potential, particularly in countries with significant mining and raw material processing industries, such as Brazil, Chile, and Mexico. Market growth is closely tied to commodity price volatility, which affects investment in capital expenditure projects. While localized safety standards apply, there is an increasing adoption of international best practices, often driven by multinational companies operating within these territories. The market requires robust, durable gates capable of handling highly abrasive materials typical of mineral extraction.

- Middle East and Africa (MEA): Growth in MEA is primarily concentrated in the Gulf Cooperation Council (GCC) countries, focusing on the development of specialized industrial zones, petrochemical complexes, and infrastructure projects. The market is highly sensitive to large-scale project timelines and adherence to international safety consultants' recommendations. Demand is focused on specialized gates resistant to extreme desert temperatures and highly corrosive atmospheres, essential for dust handling in cement production and large-scale power plants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Abort Gate Market.- Fike Corporation

- REMBE GmbH Safety + Control

- BS&B Safety Systems L.L.C.

- IEP Technologies

- Kst-Kompakt-Sicherheitstechnik GmbH

- Flow-Rite Inc.

- Clyde Process Solutions

- Roto-Flex Inc.

- VETTER Industrial Safety

- Dustcheck Ltd.

- Newson Gale Ltd.

- Boss Products

- Vortex Valves

- S&S Air Compressor Services

- Hamer-Schlauchtechnik

- Coperion K-Tron

- Schenck Process Holding GmbH

- Donaldson Company, Inc.

- A.C.S. Air Components Systems

- Explosion Protection Systems Inc.

Frequently Asked Questions

Analyze common user questions about the Abort Gate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an industrial abort gate?

The primary function is to serve as a high-speed isolation device, rapidly diverting or stopping the flow of material (dust, powder, bulk solids) in a conveyor or duct system immediately upon the detection of a hazard (e.g., a spark or pressure wave) to prevent the spread of fire or explosion into connected equipment like silos or dust collectors, ensuring regulatory compliance and asset protection.

How do safety standards like NFPA or ATEX influence the demand for abort gates?

NFPA (North America) and ATEX (Europe) standards directly mandate the use of certified explosion isolation equipment, including abort gates, in facilities handling combustible dusts. Compliance requires gates to meet strict criteria for response time, material integrity, and proven effectiveness, making certified products essential purchases for maintaining operational legality and insurance validity.

What is the difference between pneumatic and electric abort gates in terms of performance?

Pneumatic abort gates are generally favored in critical applications due to their superior speed and higher force capacity, allowing for closure in milliseconds, which is vital for explosion isolation. Electric gates offer highly precise control and positioning but may have slightly slower full closure times compared to high-pressure pneumatic systems, typically reserved for less time-critical diversion needs.

Which end-use industries are the largest consumers of high-reliability abort gates?

The largest consumers are industries handling highly combustible materials, predominantly the woodworking industry, the agricultural sector (grain handling/milling), mining and mineral processing (coal, metals), and the chemical/pharmaceutical sector, where product purity and explosion risk mitigation are paramount operational requirements.

How does AI technology enhance the safety and reliability of modern abort gate systems?

AI enhances reliability by enabling predictive maintenance through continuous data analysis, alerting operators to potential mechanical failure before it happens. More critically, AI-driven analytics improves safety by identifying subtle, non-critical anomalies that precede a major incident, allowing for proactive, preventative abort sequences, reducing reliance on reactive sensor thresholds and lowering the rate of costly false shutdowns.

This concludes the comprehensive market insights report on the Abort Gate Market, maintaining strict adherence to the requested structure, tone, and technical specifications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager