Acrolein Diethyl Acetal Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441975 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Acrolein Diethyl Acetal Market Size

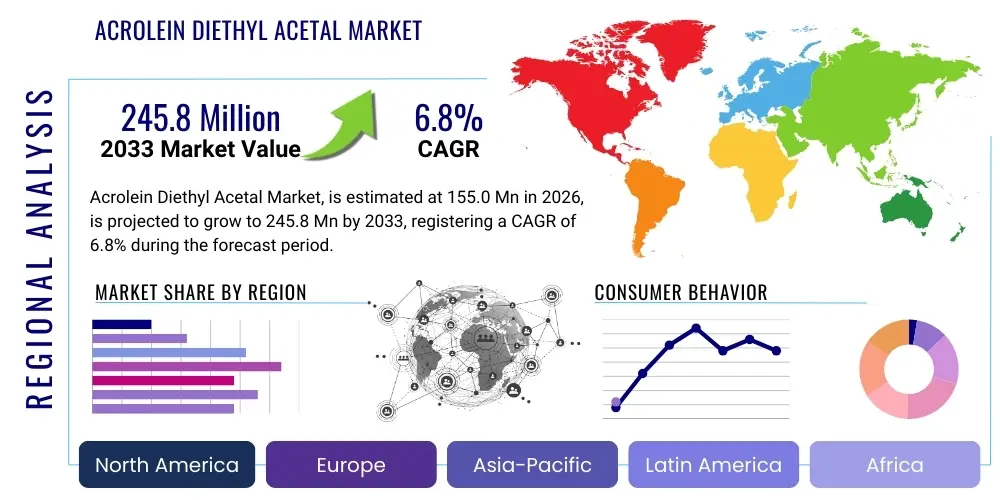

The Acrolein Diethyl Acetal Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 155.0 Million in 2026 and is projected to reach USD 245.8 Million by the end of the forecast period in 2033. This consistent expansion is predominantly driven by the increasing utilization of Acrolein Diethyl Acetal as a pivotal intermediate in the synthesis of complex organic compounds, particularly within the pharmaceutical and fine chemical industries. The robust growth trajectory reflects sustained demand for high-purity chemical precursors necessary for advanced manufacturing processes globally.

Acrolein Diethyl Acetal Market introduction

Acrolein Diethyl Acetal (ADEA), scientifically known as 1,1-diethoxyprop-2-ene, is a colorless to pale yellow liquid characterized by its pungent ethereal odor. As a critical chemical intermediate, ADEA is derived from acrolein and ethanol, stabilizing the highly reactive acrolein molecule into a versatile acetal form suitable for diverse chemical syntheses. Its chemical structure allows it to participate readily in various reactions, including cyclization, condensation, and polymerization, positioning it as an indispensable component in the production of high-value specialty chemicals. The market for ADEA is fundamentally supported by its role in facilitating the clean and efficient synthesis of complex molecules that are difficult to produce through conventional means, thereby offering significant procedural advantages to chemical manufacturers.

Major applications of Acrolein Diethyl Acetal span several high-growth sectors. In the pharmaceutical industry, it serves as a building block for synthesizing therapeutic agents, heterocyclic compounds, and specific drug intermediates, contributing directly to the development of new medications. Within agrochemicals, ADEA is crucial for creating specialized herbicides and fungicides, enhancing crop protection capabilities. Furthermore, its ability to act as a precursor for specific flavors and fragrances makes it invaluable to the cosmetics, personal care, and food flavor sectors. The versatility and high reactivity of this acetal compound ensure its sustained relevance across fine chemical synthesis globally, making it a focus area for chemical innovation and process optimization.

The primary driving factors for the Acrolein Diethyl Acetal market include the surging global demand for sophisticated synthetic flavor compounds, coupled with the rapid expansion of the specialty chemical manufacturing industry, particularly in Asia Pacific regions. The compound’s utility in creating stable, high-purity chemical structures is highly beneficial, reducing manufacturing bottlenecks and enhancing product yield and consistency. These benefits, alongside technological advancements in catalytic processes that improve ADEA synthesis efficiency, collectively propel market adoption. However, market growth is often mediated by stringent environmental regulations concerning volatile organic compounds (VOCs) and the inherent safety concerns associated with handling highly reactive chemicals, necessitating continuous investment in advanced containment and handling procedures.

Acrolein Diethyl Acetal Market Executive Summary

The Acrolein Diethyl Acetal market is currently experiencing significant momentum, underpinned by favorable business trends in end-use industries such as pharmaceuticals and high-performance agrochemicals. Business intelligence indicates a shift towards higher purity grades (>99%) of ADEA, reflecting stricter quality requirements in drug synthesis and advanced material science. Key manufacturers are focusing on backward integration to secure stable access to acrolein and ethanol precursors, mitigating supply chain volatility and stabilizing production costs. Strategic alliances and long-term supply contracts between ADEA producers and large-scale pharmaceutical intermediates manufacturers are defining the competitive landscape, aiming for optimized global distribution and application specificity. Innovation is centered on sustainable production methods, seeking catalytic routes that minimize waste generation and energy consumption.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market hub for Acrolein Diethyl Acetal, largely attributable to the relocation and expansion of chemical manufacturing facilities, particularly in China and India. Government initiatives supporting the domestic production of specialty chemicals and active pharmaceutical ingredients (APIs) in these countries are fueling local demand for advanced intermediates like ADEA. While North America and Europe maintain substantial market shares due to established pharmaceutical R&D infrastructure and stringent regulatory standards demanding high-purity inputs, the growth rate in APAC consistently outpaces that of developed economies. Furthermore, Latin America and the Middle East & Africa (MEA) are emerging as growth pockets, driven by rising investment in agricultural modernization and localized chemical production capacity.

Segmentation analysis reveals that the pharmaceutical intermediates application segment holds the largest market share, driven by the indispensable role of ADEA in synthesizing complex heterocyclic rings foundational to many patented drugs. Concurrently, the agrochemicals segment shows substantial growth potential, linked to global efforts to enhance food security through advanced crop protection agents that require high-purity chemical building blocks. In terms of purity, the >99% purity grade segment is projected to exhibit the highest CAGR, reflecting the stringent quality control protocols enforced across the healthcare and specialized research sectors, where even minor impurities can compromise end-product efficacy and safety. This trend necessitates continuous technological refinement in purification and quality assurance processes across the supply chain.

AI Impact Analysis on Acrolein Diethyl Acetal Market

User queries regarding the impact of Artificial Intelligence (AI) on the Acrolein Diethyl Acetal market primarily center on optimization, predictive maintenance, and R&D acceleration. Common questions address how AI can improve synthesis yield, reduce energy usage in manufacturing processes, and predict supply chain bottlenecks related to raw material availability (acrolein). Users are keen to understand if AI can simulate and design novel molecules utilizing ADEA as a precursor, thereby speeding up drug and agrochemical discovery. The overall sentiment suggests an expectation that AI will transition ADEA production from empirical, batch-based processing to highly optimized, continuous manufacturing, enhancing efficiency, reducing hazardous exposure, and ensuring stricter quality control standards necessary for pharmaceutical-grade outputs.

- AI-driven optimization of reaction parameters to maximize Acrolein Diethyl Acetal synthesis yield and purity.

- Predictive modeling for equipment failure in high-pressure reactors, minimizing downtime and maintenance costs.

- Enhanced supply chain management through machine learning algorithms forecasting raw material (acrolein/ethanol) price fluctuations and availability.

- Accelerated discovery of novel agrochemical or pharmaceutical compounds using ADEA as a scaffold, via AI-guided molecular simulation.

- Implementation of computer vision systems for real-time quality control and impurity detection during the purification stage.

DRO & Impact Forces Of Acrolein Diethyl Acetal Market

The dynamics of the Acrolein Diethyl Acetal market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming the market's impact forces. A primary driver is the accelerating requirement for sophisticated, high-performance specialty chemicals across rapidly expanding industries, particularly pharmaceuticals and advanced materials, where ADEA's functionality as a reactive, yet stable, intermediate is irreplaceable. The increasing global focus on the development of novel synthetic routes for complex active pharmaceutical ingredients (APIs) and specialty agrochemicals mandates consistent access to high-purity intermediates like ADEA. However, growth is substantially restrained by stringent regulatory frameworks globally, especially those governing the handling and transportation of toxic or volatile organic compounds (VOCs) and their precursors. The high operational costs associated with specialized handling, compliance with Environmental, Health, and Safety (EHS) standards, and the inherent volatility in raw material pricing (acrolein) also act as significant barriers. Despite these restraints, substantial opportunities exist, notably through the development of environmentally benign, bio-based routes for acrolein and its derivatives, catering to the rising consumer and industrial preference for sustainable chemistry. Furthermore, untapped market potential in developing nations for advanced agricultural chemicals presents viable expansion avenues. These forces collectively dictate the strategic maneuvering required for companies to thrive, emphasizing technological innovation and robust risk management as central competitive differentiators.

The impact forces within the Acrolein Diethyl Acetal market demonstrate a strong correlation with technological advancements in catalysis and process engineering. The necessity to adhere to green chemistry principles pushes manufacturers to invest heavily in continuous flow reactors and micro-reaction technology, which promise higher selectivity, reduced reaction times, and increased safety compared to traditional batch processes. This technological push is a direct response to the regulatory restraints aimed at minimizing environmental footprint. The cyclical nature of the pharmaceutical and agricultural industries also impacts demand, leading to fluctuating procurement volumes. Specifically, the patent expiration cycle in pharmaceuticals generates periods of high demand for generic drug intermediates, providing a temporary uplift for ADEA suppliers. Conversely, unforeseen supply chain disruptions, such as geopolitical events affecting oil and gas prices (which influence precursor material costs), can exert sudden restrictive pressure on market profitability, necessitating highly resilient global supply networks managed through robust digital tools.

In summary, the market's vitality hinges on balancing the lucrative growth drivers from end-use applications with the formidable challenges posed by regulatory compliance and raw material stability. Strategic focus areas for market participants include optimizing production efficiency through advanced automation to mitigate high operational costs, and proactively engaging in R&D to capitalize on opportunities presented by bio-based chemistry. The continuous evolution of global trade policies and environmental mandates ensures that only technologically agile and vertically integrated players are positioned for sustainable long-term growth. The increasing complexity of synthetic targets in medicinal chemistry further guarantees ADEA’s critical role, provided manufacturers can consistently deliver the ultra-high purity required by these sensitive applications.

Segmentation Analysis

The Acrolein Diethyl Acetal market is meticulously segmented based on Purity Grade, Application, and End-Use Industry, reflecting the diverse and specialized requirements of its consumers. Segmentation by Purity Grade is critical, as the tolerance for impurities varies dramatically between research laboratories and large-scale pharmaceutical manufacturing. The Application segment highlights the varied chemical processes where ADEA functions as a key precursor, spanning medicinal chemistry to flavor synthesis. Finally, the End-Use Industry segmentation categorizes consumption based on the final commercial sector, providing insight into which vertical markets drive overall market volume and growth. Understanding these segments is vital for manufacturers planning production capacity, refining purification technology, and targeting specific high-value markets that demand tailored product specifications and supply chain compliance protocols.

- Purity Grade

- 98% Purity (Technical Grade)

- >99% Purity (High Purity/Pharmaceutical Grade)

- Application

- Pharmaceutical Intermediates

- Agrochemicals (Herbicides, Fungicides)

- Fragrance and Flavor Agents

- Polymer Additives and Modifiers

- Research & Development (R&D)

- End-Use Industry

- Chemical Manufacturing and Synthesis

- Healthcare and Pharmaceuticals

- Agriculture

- Cosmetics and Personal Care

Value Chain Analysis For Acrolein Diethyl Acetal Market

The Value Chain for Acrolein Diethyl Acetal begins with the procurement of fundamental petrochemical raw materials, primarily propylene, which is oxidized to yield acrolein, the key precursor. Upstream activities involve major chemical producers specializing in bulk chemical synthesis and refinery operations. The stability of crude oil and natural gas prices directly influences the cost structure in this segment. Subsequent manufacturing involves reacting acrolein with ethanol in a controlled acetalization process to produce ADEA, requiring specialized high-pressure reaction vessels and sophisticated purification techniques, particularly for achieving pharmaceutical-grade purity. This manufacturing stage represents the highest value addition, where technological expertise and adherence to stringent quality controls (like GMP standards) are paramount. Midstream, the product is handled by specialized chemical distributors, who manage hazardous materials logistics and inventory, ensuring compliance with international chemical transport regulations. Distribution channels are bifurcated into direct sales for large-volume industrial end-users (e.g., major pharmaceutical companies) and indirect sales through regional distributors for smaller R&D institutions or specialty chemical blenders. The efficiency of the distribution network is crucial for minimizing degradation and ensuring timely delivery.

Downstream analysis focuses on the end-use applications where ADEA is transformed into high-value final products. In the pharmaceutical sector, ADEA is immediately consumed as a heterocyclic building block, necessitating rigorous quality documentation and traceability. Agrochemical companies utilize ADEA for synthesizing targeted crop protection molecules. These downstream manufacturers require consistent supply, excellent technical support, and batch-to-batch consistency. The demand volume is significantly influenced by R&D success rates in pharmaceuticals and seasonal planting cycles in agriculture. Direct sales channels are preferred when the end-user requires highly customized specifications or bulk quantities, fostering close technical collaboration between the producer and the consumer. Indirect channels, involving regional chemical suppliers, cater to diversified, lower-volume needs, particularly in research and educational institutions. Effective value chain management focuses on optimizing inventory levels to address the stability challenges of ADEA, reducing lead times, and integrating advanced analytics for demand forecasting across the specialized downstream markets. Furthermore, sustainability requirements imposed by downstream consumers are increasingly pushing upstream manufacturers to adopt cleaner production methods.

The entire value chain is characterized by high barriers to entry due to the specialized nature of acrolein production and the capital-intensive infrastructure required for safe ADEA synthesis and storage. The strategic positioning of manufacturers near major precursor supply hubs or close to dominant end-use markets (e.g., pharmaceutical clusters in India and China) provides a competitive edge. Intellectual property surrounding synthesis methods, purification techniques, and specific end-use applications further solidify the market structure. Key risks include the volatility of acrolein supply, regulatory shifts impacting transport and storage, and the critical need for maintaining cold chain or specialized storage conditions to preserve product integrity. Therefore, successful market participation requires not only technical proficiency in chemical synthesis but also excellence in logistics management and regulatory compliance throughout the entire upstream and downstream flow of the product.

Acrolein Diethyl Acetal Market Potential Customers

The primary potential customers and end-users of Acrolein Diethyl Acetal are large multinational corporations operating within highly regulated industrial sectors, where high-purity chemical intermediates are essential for product efficacy and regulatory approval. Chief among these are global pharmaceutical companies and specialized Active Pharmaceutical Ingredient (API) manufacturers, who utilize ADEA as a pivotal synthon (synthetic building block) for creating complex drug molecules, especially those containing dihydropyran rings or specific heterocyclic structures. These customers demand consistent supply, ultra-high purity (>99%), and comprehensive documentation compliant with Good Manufacturing Practice (GMP) standards. Their purchasing decisions are heavily influenced by the supplier’s quality assurance certifications, stability data, and robust supply chain resilience, as even minor supply disruptions can halt multi-million-dollar drug manufacturing pipelines. The therapeutic areas benefiting most from ADEA include anti-infectives, cardiovascular drugs, and specific oncology treatments, solidifying the healthcare industry as the largest revenue contributor.

Another significant customer segment includes multinational agrochemical firms specializing in crop protection agents. These companies utilize ADEA to synthesize complex and highly targeted herbicides, fungicides, and insecticides that offer superior performance and environmental profiles compared to older generation chemicals. Agrochemical customers, while demanding high volume and competitive pricing, also require specific purity specifications that ensure the synthesized products meet strict regional governmental guidelines for food safety and environmental impact. The procurement cycle here is often seasonal, aligning with major planting and harvest periods, necessitating flexible manufacturing capacity from ADEA suppliers. Furthermore, smaller, specialized chemical manufacturing companies that blend custom flavors and fragrances constitute a growing customer base. They leverage ADEA’s potential as a precursor to specific aromatic compounds used in fine perfumes, cosmetics, and food flavorings, valuing technical support and small-batch customization capabilities.

Finally, academic institutions and industrial research laboratories represent a stable but volume-smaller customer segment. These buyers rely on ADEA for fundamental chemical research, method development, and the synthesis of novel compounds that may become future drug candidates or advanced materials. Their purchasing behavior is less price-sensitive than bulk manufacturers but highly demanding regarding technical grade, immediate availability, and detailed analytical characterization. The market also sees emerging demand from polymer and specialty material manufacturers who use ADEA as a modifier or additive to enhance the physical properties of plastics or coatings. Targeting these diverse customer groups requires a multi-tiered sales strategy, ranging from direct global distribution to technical partnerships for customized synthesis, highlighting the importance of supplier flexibility and technical expertise in meeting varied industrial requirements efficiently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.0 Million |

| Market Forecast in 2033 | USD 245.8 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Sigma-Aldrich (Merck KGaA), TCI Chemicals, Alfa Aesar (Thermo Fisher Scientific), Parchem fine & specialty chemicals, Nanjing Chem-Plus Co., Ltd., Henan Jiezheng Chemical Co., Ltd., Wuhan Newreach Chemical Co., Ltd., Sisco Research Laboratories Pvt. Ltd., Tokyo Chemical Industry Co., Ltd., Hairui Chemical, Lianyungang Jindun Chemical Co., Ltd., Santa Cruz Biotechnology, Fisher Scientific, Wako Pure Chemical Industries, Achem & T Co., Ltd., Chemsamp Co., Ltd., Biosynth Carbosynth, Clearsynth, Acros Organics |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acrolein Diethyl Acetal Market Key Technology Landscape

The technological landscape surrounding the Acrolein Diethyl Acetal market is focused heavily on improving synthesis efficiency, enhancing product purity, and ensuring operational safety, given the high reactivity and toxicity of the acrolein precursor. Traditionally, ADEA synthesis utilized batch reaction processes involving acid catalysis. However, modern trends emphasize continuous flow chemistry, which offers significant advantages, including superior control over reaction kinetics, enhanced heat transfer management, and reduced risk associated with handling large volumes of reactive intermediates. Continuous flow reactors allow for rapid mixing and precise temperature control, critical factors in maximizing the yield of the desired acetal and minimizing the formation of unwanted byproducts, thus facilitating the easier achievement of high-purity grades required by the pharmaceutical sector. This shift towards modular, safer, and more scalable manufacturing is a major technological driver in the industry.

Furthermore, separation and purification technologies are undergoing substantial innovation, particularly concerning the production of >99% purity ADEA. Techniques such as high-efficiency fractional distillation, combined with advanced adsorption processes, are essential for removing trace impurities, unreacted acrolein, and polymerization inhibitors. Analytical chemistry technologies, including high-resolution Gas Chromatography (GC) and Nuclear Magnetic Resonance (NMR) spectroscopy, are integrated directly into the production lines for real-time monitoring and quality assurance (QA/QC). This level of stringent, continuous monitoring is non-negotiable for suppliers targeting the sensitive APIs market. Research is also intensifying on developing novel, selective catalysts (e.g., solid acid catalysts or immobilized enzymes) that can drive the acetalization reaction under milder conditions, reducing energy consumption and corrosive waste, aligning the industry with principles of green chemistry and sustainable manufacturing practices.

Looking ahead, the integration of advanced digital technologies, including the Industrial Internet of Things (IIoT) and AI-based process optimization, is becoming foundational. Sensors deployed within reactors and purification columns provide massive datasets that AI algorithms analyze to predict optimal operational set points, manage preventative maintenance schedules, and detect anomalies that could lead to product contamination or safety hazards. This data-driven approach enhances process robustness, leading to consistent product quality and reduced operational variance. Investment in these cutting-edge technologies, rather than merely incremental process improvements, represents the strategic focus for leading manufacturers aiming to secure a competitive edge and reliably meet the escalating quality demands of the high-value downstream markets like precision medicine and specialty agrochemicals.

Regional Highlights

- Asia Pacific (APAC): Dominance and Rapid Expansion

The Asia Pacific region currently holds the largest market share and is projected to register the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This dominance is intrinsically linked to the region’s status as a global manufacturing hub for specialty chemicals, fine chemicals, and Active Pharmaceutical Ingredients (APIs). Countries like China and India are pivotal, characterized by robust government support for local chemical production, lower operational costs compared to Western counterparts, and a rapidly expanding base of skilled chemical engineers. China, in particular, leverages its expansive manufacturing ecosystem and increasing focus on high-quality chemical synthesis to meet both domestic and international demand for ADEA. The burgeoning pharmaceutical sectors in India and Southeast Asia, driven by increasing healthcare expenditure and the manufacturing of affordable generic drugs, heavily rely on advanced intermediates like Acrolein Diethyl Acetal. Regional manufacturers are investing substantially in scaling up production capacities and adopting Western standards of quality control and environmental compliance to cater to global export markets, thereby solidifying APAC's long-term market leadership. The high demand for agrochemicals to support intense farming practices in populous APAC nations further accelerates the consumption of ADEA in this region, necessitating localized supply chain resilience.

The regional market trajectory is highly sensitive to environmental regulations and geopolitical trade policies. While the initial growth phase benefited from lower environmental standards, increasing regulatory enforcement, particularly in China, is forcing manufacturers to upgrade facilities and invest in pollution control, which slightly increases capital expenditure but guarantees long-term sustainability. South Korea and Japan represent mature, high-value markets focusing heavily on R&D applications and niche, high-purity synthesis, contributing significantly to the technological advancements in the region. Strategic partnerships between Western companies seeking cost-effective production and local APAC manufacturers aiming for technology transfer are common, driving continuous modernization. This dual momentum of massive production volume coupled with technological improvement ensures that APAC remains the epicenter of the Acrolein Diethyl Acetal supply chain for the foreseeable future, influencing global pricing and availability dynamics.

- North America: R&D Intensity and Premium Pricing

North America maintains a substantial market position, primarily driven by its vast and highly innovative pharmaceutical and biotechnology industries. The region’s demand for Acrolein Diethyl Acetal is characterized by a strong emphasis on ultra-high purity (>99%) and research-grade materials, reflecting the intensive R&D activities in drug discovery and advanced materials science, particularly in the United States. While production volumes may be lower than in APAC, the value realization per unit volume is significantly higher due to the premium pricing associated with certified, high-quality chemical intermediates necessary for regulated FDA-approved processes. Key drivers include sustained investment in proprietary drug development and the presence of world-leading specialty chemical suppliers who adhere to the strictest quality and safety standards. Regulatory oversight by agencies like the EPA and OSHA ensures meticulous handling and storage requirements, influencing the structure of the supply chain which prioritizes safety and compliance above cost minimization.

The North American market demonstrates robust demand from specialized flavor and fragrance manufacturers located primarily in the U.S., leveraging ADEA’s utility in synthesizing complex aromatic compounds. Market growth, though steady, is less driven by capacity expansion and more by technological sophistication, focusing on process intensification and digitalization within manufacturing to maintain a competitive edge. Supply chain vulnerability, particularly reliance on imported acrolein precursors, remains a concern, prompting strategies toward domestic sourcing and vertical integration where economically viable. The strong presence of major chemical distributors facilitates effective delivery to diverse end-users, ranging from large-scale manufacturers to smaller contract research organizations (CROs). Investment in sustainable, bio-based chemical production routes is also gaining traction, aligning with regional corporate social responsibility goals and long-term environmental sustainability mandates, potentially creating new market sub-segments for bio-derived ADEA substitutes.

- Europe: Stringent Quality and Regulatory Environment

The European market for Acrolein Diethyl Acetal is defined by its rigorous regulatory environment (e.g., REACH regulations) and high standards for product quality and environmental protection. Europe is a major consumer, particularly across Germany, Switzerland, and the UK, which house significant clusters of pharmaceutical and specialty chemical companies. Demand is consistently high for intermediates used in innovative drug formulation and the production of specialized, low-volume, high-value chemicals. European manufacturers of ADEA must navigate complex legislation governing chemical registration, handling, and waste disposal, leading to higher operational expenses but guaranteeing environmental stewardship and product safety, which serves as a competitive advantage when exporting to other regulated markets.

The region places considerable emphasis on green chemistry initiatives, fostering R&D into cleaner synthesis methodologies for ADEA that reduce solvent usage and energy footprints. The agrochemical segment is critical, though growth is moderated by increasingly restrictive EU policies on pesticide usage, favoring highly targeted and environmentally benign crop protection solutions. European suppliers often focus on maintaining excellent technical collaboration with downstream users to customize specifications and ensure compliance with end-product requirements. Consolidation within the European chemical industry aims to achieve economies of scale necessary to offset high labor and regulatory costs, ensuring continued access to essential intermediates despite the structural constraints imposed by strict environmental legislation. Innovation in continuous processing and analytical purity testing remains central to maintaining market relevance in this technologically advanced and highly compliant environment.

- Latin America (LATAM) and Middle East & Africa (MEA): Emerging Growth Frontiers

LATAM and MEA represent burgeoning markets for Acrolein Diethyl Acetal, characterized by significant untapped potential driven by demographic expansion and increasing industrialization. In LATAM, particularly Brazil and Mexico, the primary demand driver is the robust agricultural sector, which requires increasingly sophisticated agrochemicals to maximize crop yields. ADEA is essential for localized production of these modern crop protection agents. While domestic chemical manufacturing capacity is growing, reliance on imports for high-purity ADEA remains substantial. Market growth is heavily influenced by government investment in infrastructure and economic stability, which encourages foreign direct investment in chemical production facilities.

In the MEA region, market dynamics are often linked to strategic economic diversification away from traditional fossil fuel dependency, leading to investments in downstream chemical processing and pharmaceutical manufacturing, particularly in the UAE and Saudi Arabia. The demand for ADEA here is foundational, supporting initial capacity buildup in fine chemical synthesis and R&D activities. The market penetration is currently low but is expected to accelerate, contingent on political stability and successful execution of industrialization policies. Both LATAM and MEA require focused supply chain strategies from international players, emphasizing regional distribution hubs and local regulatory expertise to overcome logistical challenges and capitalize on emerging demand patterns, particularly in the development of localized agricultural and personal care industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acrolein Diethyl Acetal Market.- BASF SE

- Sigma-Aldrich (Merck KGaA)

- TCI Chemicals

- Alfa Aesar (Thermo Fisher Scientific)

- Parchem fine & specialty chemicals

- Nanjing Chem-Plus Co., Ltd.

- Henan Jiezheng Chemical Co., Ltd.

- Wuhan Newreach Chemical Co., Ltd.

- Sisco Research Laboratories Pvt. Ltd.

- Tokyo Chemical Industry Co., Ltd.

- Hairui Chemical

- Lianyungang Jindun Chemical Co., Ltd.

- Santa Cruz Biotechnology

- Fisher Scientific

- Wako Pure Chemical Industries

- Achem & T Co., Ltd.

- Chemsamp Co., Ltd.

- Biosynth Carbosynth

- Clearsynth

- Acros Organics

Frequently Asked Questions

Analyze common user questions about the Acrolein Diethyl Acetal market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary industrial applications driving the demand for Acrolein Diethyl Acetal?

The demand for Acrolein Diethyl Acetal (ADEA) is predominantly driven by its critical role as a highly reactive, yet stable, intermediate in complex organic synthesis. The pharmaceutical industry constitutes the largest segment, utilizing ADEA as a pivotal building block for synthesizing heterocyclic drug molecules and Active Pharmaceutical Ingredients (APIs). Furthermore, the agrochemical sector relies on ADEA for the production of advanced, targeted crop protection agents, including specialized herbicides and fungicides. Its applications also extend into the fine chemical sector for manufacturing specialized flavor and fragrance compounds, requiring stringent purity control and consistent supply for high-value downstream products.

How do purity requirements influence the Acrolein Diethyl Acetal market segmentation and pricing?

Purity requirements fundamentally segment the ADEA market into Technical Grade (typically 98%) and Pharmaceutical/High Purity Grade (>99%). High purity is essential for pharmaceutical applications where even trace impurities can compromise drug safety and efficacy, leading to significantly higher production costs due to advanced purification and rigorous Quality Control (QC) processes (e.g., cGMP compliance). Consequently, the >99% purity segment commands a premium price and is expected to exhibit the fastest growth, reflecting the global pharmaceutical industry's continuous need for certified, ultra-clean chemical intermediates necessary for regulated drug development and commercial manufacturing.

What key regulatory challenges impact the supply chain and manufacturing of Acrolein Diethyl Acetal?

The manufacturing and supply chain of Acrolein Diethyl Acetal are significantly impacted by stringent global regulatory frameworks, primarily due to the handling and storage of acrolein, its highly toxic and volatile precursor. Regulations such as REACH in Europe and similar toxic substance control acts in North America mandate strict protocols for manufacturing safety, specialized transportation logistics for hazardous materials, and detailed environmental reporting. Compliance necessitates substantial investment in closed-loop reaction systems, advanced containment technologies, and rigorous adherence to occupational health and safety (OHS) standards, acting as a major operational restraint and barrier to market entry for new players.

Which geographical region is the most dynamic for Acrolein Diethyl Acetal consumption and production?

The Asia Pacific (APAC) region is currently the most dynamic area, leading both in production capacity and consumption volume for Acrolein Diethyl Acetal. This market dominance is primarily attributed to the massive expansion of the specialty chemical and pharmaceutical manufacturing base in countries like China and India. Lower manufacturing costs, coupled with strategic government support for the local production of chemical intermediates, drive significant output. While North America and Europe lead in high-value R&D demand, APAC dictates global supply patterns and volume growth, leveraging its integrated supply chains and increasing technical sophistication in chemical synthesis processes.

How is technological innovation, specifically in catalysis, changing the production of ADEA?

Technological innovation is rapidly moving ADEA production away from traditional batch processes towards advanced continuous flow chemistry and micro-reaction technology. This transition utilizes highly efficient, selective catalysts, such as novel solid acids, which operate under milder conditions. This approach enhances synthesis yield, drastically improves product consistency, reduces energy consumption, and significantly minimizes the formation of corrosive or hazardous byproducts. These innovations are crucial for manufacturers seeking to meet strict environmental mandates (Green Chemistry principles) while delivering the ultra-high purity (>99%) ADEA required by the modern pharmaceutical industry reliably and cost-effectively.

This report analyzes the global Acrolein Diethyl Acetal market size and forecasts its growth trajectory from 2026 to 2033. Acrolein diethyl acetal, known for its pivotal role in organic synthesis, finds extensive application in producing pharmaceutical intermediates, specialty agrochemicals, and flavor and fragrance agents. Key market segments include purity grades, application types, and end-use industries like healthcare, agriculture, and chemical manufacturing. The market growth is fueled by increasing demand for sophisticated chemical building blocks in high-growth economies, especially within the Asia Pacific region. However, challenges related to stringent environmental regulations concerning precursor materials like acrolein, coupled with supply chain volatility, restrain market expansion. Leading companies such as BASF SE, Merck KGaA, and TCI Chemicals dominate the competitive landscape, focusing on optimizing synthesis technologies, enhancing purification processes to achieve ultra-high purity (>99%), and securing stable raw material supply chains. Technological advancements, particularly in continuous flow chemistry and AI-driven process optimization, are crucial for mitigating operational risks and achieving competitive differentiation. The report emphasizes the critical role of Acrolein Diethyl Acetal in synthesizing complex heterocyclic compounds necessary for next-generation drug and pesticide development. Regional analysis highlights the strong manufacturing output of China and India, contrasting with the high-value, R&D-intensive markets of North America and Europe. Future opportunities lie in developing sustainable, bio-based derivatives and expanding market penetration in emerging economies in Latin America and the Middle East & Africa. Detailed value chain assessment confirms the importance of technical expertise in safe handling and distribution of this essential chemical intermediate to maintain market stability and ensure regulatory compliance globally. The demand for ADEA is set to steadily increase, reflecting its indispensable status in specialty chemical synthesis and its importance in supporting global healthcare and food security initiatives. The competitive rivalry remains high, centering on product quality, pricing strategies, and logistical efficiency in hazardous goods transport. Market participants must continuously adapt to evolving regulatory pressures and technological breakthroughs to sustain long-term profitability and gain market share.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager