Advanced Commercial Laundry Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440984 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Advanced Commercial Laundry Market Size

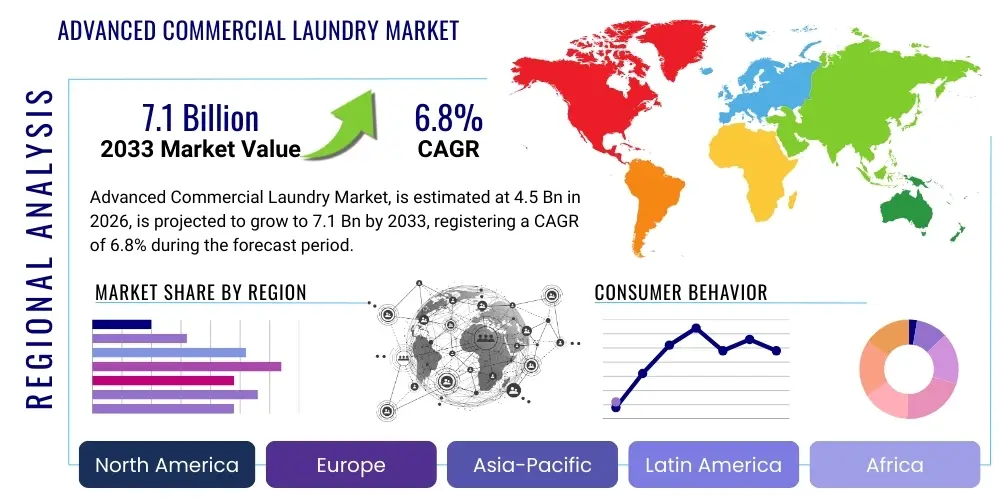

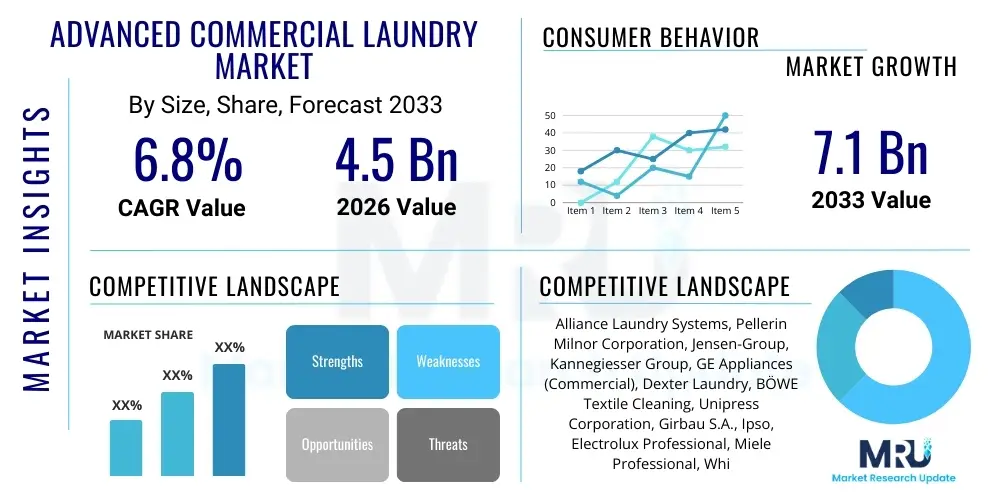

The Advanced Commercial Laundry Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.1 Billion by the end of the forecast period in 2033.

Advanced Commercial Laundry Market introduction

The Advanced Commercial Laundry Market encompasses sophisticated washing, drying, and finishing equipment and systems designed for high-volume, continuous operation environments such as hospitals, hotels, industrial laundries, and specialized textile care facilities. These systems integrate cutting-edge technologies like IoT connectivity, advanced heat recovery systems, precise chemical dosing mechanisms, and automated materials handling to maximize efficiency, reduce operational costs, and ensure superior textile longevity and hygiene standards. The core product offering includes industrial washers (barrier washers, continuous batch washers), energy-efficient tumble dryers, high-speed ironers, and specialized finishing equipment, all managed via centralized digital control interfaces, positioning them far beyond traditional commercial machinery.

Major applications of advanced commercial laundry solutions span critical sectors where hygiene and throughput are paramount. In the healthcare sector, sophisticated barrier washers and validated disinfection cycles are essential for preventing cross-contamination, adhering strictly to regulatory standards for medical linens and uniforms. The hospitality industry relies on high-capacity, gentle handling systems to maintain the quality and lifespan of high-value guest textiles, while maximizing water and energy savings due to high daily usage volumes. Driving factors include stringent regulatory requirements concerning environmental impact and hygiene (especially post-pandemic), coupled with continuous technological advancements aimed at improving utility consumption and labor productivity through automation and smart monitoring.

The primary benefits delivered by these advanced systems include substantial reductions in resource consumption, particularly water and energy, facilitated by innovative features like ozone laundry systems and closed-loop water recycling units. Furthermore, enhanced data analytics and predictive maintenance capabilities drastically minimize unplanned downtime, a crucial factor in high-throughput operations. The shift toward fully automated systems, from soiled linen intake to clean linen folding and sorting, addresses chronic labor shortages and increases operational consistency. This technological evolution transforms laundry operations from a necessity into a highly efficient, measurable, and sustainable utility management process, driving strong market adoption across developed and rapidly industrializing economies seeking operational excellence.

Advanced Commercial Laundry Market Executive Summary

The global Advanced Commercial Laundry Market is characterized by robust business trends driven primarily by the escalating demand for sustainable and highly automated textile processing solutions. Key business imperatives include developing modular systems adaptable to various space constraints and throughput requirements, alongside a strong focus on integration with enterprise resource planning (ERP) systems for seamless operational oversight. Strategic mergers and acquisitions are common as established players seek to absorb niche technology providers, particularly those specializing in AI-driven process optimization and complex robotics for sorting and folding. The transition towards subscription-based models (Laundry-as-a-Service, or LaaS) for maintenance and digital services is a burgeoning trend, shifting capital expenditure towards operational expenditure for end-users, thus broadening accessibility to advanced technologies.

Regionally, the market exhibits differential growth rates anchored by varying levels of industrial development and regulatory enforcement. North America and Europe maintain dominance due to high labor costs necessitating automation, stringent environmental regulations pushing the adoption of eco-friendly systems, and a large installed base of high-capacity healthcare and hospitality infrastructure requiring continuous upgrades. Conversely, the Asia Pacific (APAC) region is poised for the highest growth trajectory, fueled by rapid expansion in its tourism, healthcare, and manufacturing sectors, driving massive investment in new, large-scale industrial laundries. Latin America and the Middle East & Africa (MEA) present significant opportunities, especially in urban centers, linked to infrastructure projects and increased focus on public health standards, though market penetration rates remain lower, prioritizing basic commercial upgrades over full technological integration.

Segment trends highlight the dominance of the Continuous Batch Washer (CBW) segment under the Equipment type, driven by unparalleled water efficiency and high throughput capacities essential for institutional laundries. The Technology segment is overwhelmingly focused on Smart Connectivity (IoT and predictive maintenance solutions) and Water Recycling Systems, reflecting both operational necessity and compliance pressure. The End-User segment sees Healthcare maintaining a crucial position due to non-negotiable hygiene demands and continuous capital investment, while the Industrial/Linen Services segment shows the fastest expansion as commercial outsourcing of laundry operations becomes more prevalent across various industries, demanding large, interconnected fleet management systems capable of 24/7 operation.

AI Impact Analysis on Advanced Commercial Laundry Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Advanced Commercial Laundry Market frequently revolve around quantifying efficiency gains, understanding the reliability of autonomous operations, and assessing the required capital investment for integration. Common concerns focus on job displacement, the security of interconnected IoT-enabled machines, and the complexity of training AI models to handle diverse textile types and varying degrees of soiling accurately. Users are keenly interested in predictive maintenance accuracy, optimized chemical usage through real-time AI analysis, and the potential for fully autonomous end-to-end processing—from automated textile identification and sorting to quality control and inventory management, expecting AI to deliver labor cost savings and measurable reductions in resource waste across the entire laundry lifecycle.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze vibration, temperature, and cycle data to forecast equipment failures, dramatically reducing unplanned downtime and maintenance costs.

- Optimized Resource Consumption: AI systems continuously monitor water flow, energy use, and chemical dosage, adjusting parameters in real-time based on load size, fabric type, and soiling level for maximum efficiency.

- Automated Quality Control (AQC): Employing computer vision and AI to detect stains, tears, and quality issues post-wash and finish, reducing manual inspection errors and ensuring textiles meet defined quality standards before dispatch.

- Dynamic Load Balancing and Scheduling: AI optimizes the workload distribution across multiple machines, ensuring optimal machine utilization and energy tariff management based on predicted demand and operational costs.

- Robotics and Sorting Automation: Integrating AI with robotic arms for precise handling, sorting of incoming soiled linens, and highly accurate folding and stacking of clean textiles, minimizing human intervention.

- Enhanced Hygiene Validation: AI assists in validating disinfection cycles by correlating temperature, duration, and chemical parameters against regulatory standards, providing unalterable, automated audit trails for healthcare facilities.

- Supply Chain Integration: Using AI to forecast linen demand fluctuations in large institutions (e.g., hospitals, hotel chains) to optimize inventory levels and scheduling across large, geographically dispersed laundry service providers.

DRO & Impact Forces Of Advanced Commercial Laundry Market

The Advanced Commercial Laundry Market is shaped by a confluence of accelerating drivers, significant restraints, and clear long-term opportunities, which collectively define the impact forces governing market expansion. Key drivers include stringent regulatory demands for hygiene (particularly post-COVID-19 protocols in healthcare and hospitality), the pressing need to mitigate rapidly escalating labor costs through automation, and mandatory corporate sustainability initiatives requiring measurable reductions in water and energy consumption. Restraints primarily involve the high initial capital investment required for sophisticated automated systems, particularly hindering adoption among smaller, independent laundry businesses, alongside the complexity of integrating diverse, legacy machinery with modern IoT platforms and the requisite skilled labor gap for maintaining complex mechatronic systems.

Opportunities for growth are concentrated in the development and deployment of flexible, modular, and containerized laundry solutions suitable for remote or rapidly developing areas, catering to temporary housing or military operations. Furthermore, the expansion of the 'smart textile' market and specialized industrial applications (e.g., cleanroom garments, hazardous materials handling) necessitates bespoke, highly technical washing and decontamination processes, opening new niches for advanced system providers. The development of Laundry-as-a-Service (LaaS) models, which bundle equipment, maintenance, and digital oversight into a single operational expenditure contract, lowers the barrier to entry for smaller users, transforming the market structure and accelerating technology adoption globally, thereby creating a sustainable revenue stream for manufacturers.

The impact forces driving the market are substantial, dominated by technological leverage, regulatory pressure, and economic necessity. Technological innovation acts as the primary accelerator, constantly pushing the boundaries of efficiency and integration. Regulatory compliance, especially in Europe and North America regarding environmental discharge and textile hygiene (EN 14065, ISO standards), acts as a non-negotiable market driver. Economically, the continuous pressure to increase throughput and reduce operational expense (OpEx) while minimizing human error mandates the shift towards fully automated, data-driven laundry facilities. These forces ensure that only systems capable of providing quantifiable returns on investment (ROI) through sustainability and efficiency gains will sustain long-term market relevance.

Segmentation Analysis

The Advanced Commercial Laundry Market is fundamentally segmented based on Technology, End-User, Capacity, and Type of Equipment, reflecting the diverse needs across institutional and industrial applications. Understanding these segments is critical for manufacturers to tailor product development and market strategies. Technology segmentation, focused on innovations like IoT connectivity and advanced recycling, drives product differentiation and premium pricing, while the End-User segmentation dictates specific operational requirements, such as sterile barrier compliance in healthcare versus sheer volume processing in industrial settings. Capacity segmentation allows for catering to the scale of operations, ranging from localized hotel operations to centralized, hyper-scale linen service providers. The complex interplay between these segments defines the competitive landscape and regional investment priorities.

- By Technology:

- Smart Connectivity (IoT, Remote Diagnostics, Fleet Management)

- Water Recycling and Re-use Systems

- Energy Efficiency Technologies (Heat Recovery, Gas-fired Dryers, Ozone Systems)

- Chemical Dosing Automation

- By Equipment Type:

- Washers (Continuous Batch Washers (CBW), Barrier Washers, High-Speed Wash Extractors)

- Dryers and Finishers (Industrial Tumble Dryers, Chest Heated Ironers, Flatwork Finishers)

- Ancillary Systems (Folding Machines, Sorting Systems, Tunnel Finishers, Automated Conveyors)

- By End-User:

- Healthcare (Hospitals, Clinics, Long-Term Care Facilities)

- Hospitality (Hotels, Resorts, Cruise Lines)

- Industrial and Linen Service Providers (Rental Services, Uniform Companies)

- On-Premise Laundry (OPL) (Sports Clubs, Educational Institutions)

- By Capacity:

- Small Capacity (<100 kg/hr)

- Medium Capacity (100–500 kg/hr)

- Large/Industrial Capacity (>500 kg/hr)

Value Chain Analysis For Advanced Commercial Laundry Market

The value chain for the Advanced Commercial Laundry Market begins with sophisticated upstream activities focused heavily on R&D, material sourcing, and specialized component manufacturing. Upstream suppliers provide high-precision components such as industrial-grade motors, advanced microprocessors for control systems, high-durability stainless steel for drums, and specialized sensors for IoT integration. The ability to secure reliable supplies of customized automation and AI components is critical in maintaining manufacturing efficiency. Manufacturers invest heavily in proprietary intellectual property related to water conservation (e.g., reverse osmosis filtration) and heat management systems, creating barriers to entry and dictating cost structures for the final equipment assembly.

The midstream phase involves the core activities of equipment design, manufacturing, assembly, and rigorous quality assurance testing, often conducted in large, highly specialized global manufacturing centers. Distribution channels are complex, involving both direct sales models for major industrial projects (e.g., centralized linen processors) and indirect channels through certified dealers, regional distributors, and specialized installers who also provide crucial post-sales support and maintenance contracts. Direct sales ensure deep customization and long-term client relationships for large, complex installations, while indirect channels provide market penetration and localized service expertise across diverse geographies and smaller operational scales.

Downstream activities center on installation, commissioning, training, and long-term service provision, which is becoming increasingly vital. The shift towards connectivity means that revenue derived from digital services, predictive maintenance contracts, and specialized software updates now constitutes a growing and high-margin part of the downstream value proposition. End-users—hospitals, large hotels, and industrial laundries—are the final recipients, where the machinery’s effectiveness is measured against strict performance indicators (KPIs) related to energy consumption, throughput, and textile hygiene. Strong collaboration between the manufacturer and the end-user’s facility management team is essential for optimizing machine performance over its entire operational lifespan.

Advanced Commercial Laundry Market Potential Customers

Potential customers for advanced commercial laundry solutions are primarily large organizations and specialized service providers where textile processing volume, regulatory compliance, and operational efficiency are critical financial and logistical concerns. The largest segment remains the Healthcare sector, where hospitals and healthcare networks require equipment that meets stringent sanitary standards (e.g., barrier technology to separate clean and soiled linens) and provides validated disinfection cycles. These institutions prioritize reliability, traceability, and low risk of cross-contamination, often favoring premium-priced, customized solutions with comprehensive service agreements.

The Hospitality industry, including major hotel chains, resorts, and cruise operators, forms another significant customer base. Their purchasing decisions are driven by the need for high-quality finishing (to maintain guest satisfaction) and minimizing operational costs through energy and water conservation, due to the sheer volume of daily laundry. They often invest in high-efficiency ironers and finishing equipment that reduce labor intensity. Furthermore, specialized Industrial Linen Service Providers and uniform rental companies, which process vast quantities of diversified textiles for third parties (e.g., automotive, food processing, specialized manufacturing), represent the fastest-growing customer group, demanding the highest level of automation and centralized fleet management software.

Other substantial segments include educational campuses, military facilities, and increasingly, specialized high-tech industries requiring cleanroom laundry services. These customers seek machines capable of handling specific fabric types (e.g., anti-static or fire-retardant materials) with precise process control, often involving specialized chemical injections. The overall trend indicates that any entity aiming to reduce manual labor involvement, comply with environmental standards, and monetize detailed operational data through smart machinery represents a viable and expanding customer base for advanced commercial laundry system vendors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alliance Laundry Systems, Pellerin Milnor Corporation, Jensen-Group, Kannegiesser Group, GE Appliances (Commercial), Dexter Laundry, BÖWE Textile Cleaning, Unipress Corporation, Girbau S.A., Ipso, Electrolux Professional, Miele Professional, Whirlpool Corporation (Commercial Division), Danube International, Seitz GmbH, Schulthess Maschinen AG, Speed Queen Commercial, BMM Weston, Tingue, EPI. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Advanced Commercial Laundry Market Key Technology Landscape

The technology landscape of the Advanced Commercial Laundry Market is defined by the integration of digital sophistication with mechanical durability, pivoting heavily on the Industrial Internet of Things (IIoT). Modern commercial equipment is no longer purely mechanical; it functions as a data node within a centralized management ecosystem. Key technologies include proprietary Continuous Batch Washing (CBW) systems that optimize mechanical action and counter-flow water reuse, achieving unprecedented water consumption reduction. Energy efficiency is driven by thermal technologies such as highly effective heat recovery units (HRUs) that capture exhaust heat from dryers and repurpose it to preheat water, substantially reducing the energy load required for boiler operation. Furthermore, advanced microprocessor controllers manage variable speed drives (VSDs) on motors, matching energy consumption precisely to the load requirements, moving far beyond fixed-speed systems.

Smart connectivity, enabled by embedded sensors and communication modules (4G/5G, Wi-Fi), allows for real-time monitoring of all critical operational metrics, including chemical consumption, temperature profiles, and vibration analysis. This data feeds into cloud-based platforms, enabling manufacturers to offer sophisticated predictive maintenance services, often marketed under "digital uptime guarantees." The development of chemical dosing technology has evolved to include peristaltic pumps linked directly to the machine's control panel, allowing for highly accurate, dynamic injection of detergents, emulsifiers, and sanitizers based on textile load size and measured soil levels, minimizing chemical waste and ensuring textile longevity.

The future technology focus is strongly centered on automation and autonomy, particularly in the post-processing phase. Robotics integration, supported by AI vision systems, is essential for high-speed folding, sorting, and stacking of finished textiles, directly addressing high labor costs. Furthermore, specialized sanitization technologies like Ozone Laundry Systems (OLS) are gaining traction, using ozone gas dissolved in cold water to achieve microbial inactivation, reducing the reliance on high-temperature cycles and heavy bleach usage, offering significant advantages in operational expense reduction and environmental compliance. The ongoing R&D aims at creating truly closed-loop systems that approach zero net water discharge and minimal energy waste, requiring highly advanced filtration and sterilization technologies for water reuse.

Regional Highlights

- North America: Characterized by high labor costs, necessitating strong investments in advanced automation and robotics. The large healthcare sector is a primary demand driver, focusing on rigorous infection control and validated washing protocols. Regulations favor highly efficient, water-saving equipment. The region is a leader in adopting IoT and predictive maintenance service models.

- Europe: This region is globally recognized for the strictest environmental and hygiene standards, particularly demanding CE certification and compliance with directives regarding chemical discharge and energy consumption. Focus is heavily placed on Continuous Batch Washers (CBW) and advanced heat recovery systems. Germany, France, and the Nordics are technology hubs, driving innovation in sustainable laundry solutions and barrier technology for healthcare.

- Asia Pacific (APAC): Exhibits the highest growth potential, fueled by massive infrastructure development in hospitality (tourism boom) and expanding urban healthcare services, especially in China, India, and Southeast Asia. While initial pricing sensitivity is higher, the sheer scale of new facilities drives volume purchases of large-capacity industrial equipment. Increasing regulatory pressure regarding pollution in nations like China is accelerating the shift from outdated equipment to energy-efficient models.

- Latin America: Growth is primarily concentrated in Brazil and Mexico, driven by burgeoning urbanization and the expansion of the hospitality sector. Adoption is gradual, with a preference for durable, mid-range automation that offers a quick return on investment. The key challenge remains overcoming economic volatility and ensuring reliable infrastructure support for complex connected systems.

- Middle East and Africa (MEA): Marked by significant investment in large-scale hospitality and tourism projects (e.g., UAE, Saudi Arabia) and essential public health infrastructure. The crucial drivers here are the need for high-capacity systems capable of handling peak demand and the necessity for robust water conservation technologies due to regional water scarcity, leading to adoption of sophisticated water recycling and treatment systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Advanced Commercial Laundry Market.- Alliance Laundry Systems

- Pellerin Milnor Corporation

- Jensen-Group

- Kannegiesser Group

- GE Appliances (Commercial)

- Dexter Laundry

- BÖWE Textile Cleaning

- Unipress Corporation

- Girbau S.A.

- Ipso

- Electrolux Professional

- Miele Professional

- Whirlpool Corporation (Commercial Division)

- Danube International

- Seitz GmbH

- Schulthess Maschinen AG

- Speed Queen Commercial

- BMM Weston

- Tingue

- EPI (European Process Industries)

Frequently Asked Questions

Analyze common user questions about the Advanced Commercial Laundry market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth in the Advanced Commercial Laundry Market?

The primary growth drivers are the increasing global emphasis on rigorous hygiene standards (especially in healthcare post-pandemic), continuously rising industrial labor costs necessitating automation investments, and stringent governmental regulations enforcing energy and water conservation mandates.

How does AI contribute to operational efficiency in modern commercial laundries?

AI significantly enhances efficiency by enabling predictive maintenance to minimize downtime, optimizing resource consumption (water, energy, chemicals) in real-time based on load analysis, and powering robotic systems for automated sorting, folding, and quality control processes.

What is the significance of Continuous Batch Washers (CBW) in this market?

CBWs are critical for high-volume industrial and institutional operations because they offer superior water and energy efficiency compared to traditional wash extractors, utilizing counter-flow water reuse principles and providing high throughput essential for large-scale textile processing.

Which regions are leading in the adoption of sustainable laundry technologies?

Europe and North America are the leaders in sustainable technology adoption, driven by strict environmental discharge regulations and high energy costs, leading to widespread use of advanced heat recovery, closed-loop water recycling, and ozone laundry systems.

What are the main financial restraints affecting market expansion?

The primary financial restraint is the high initial capital investment required for purchasing and installing fully automated, IoT-enabled industrial laundry systems, making financing challenging for smaller businesses and requiring extended ROI periods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager