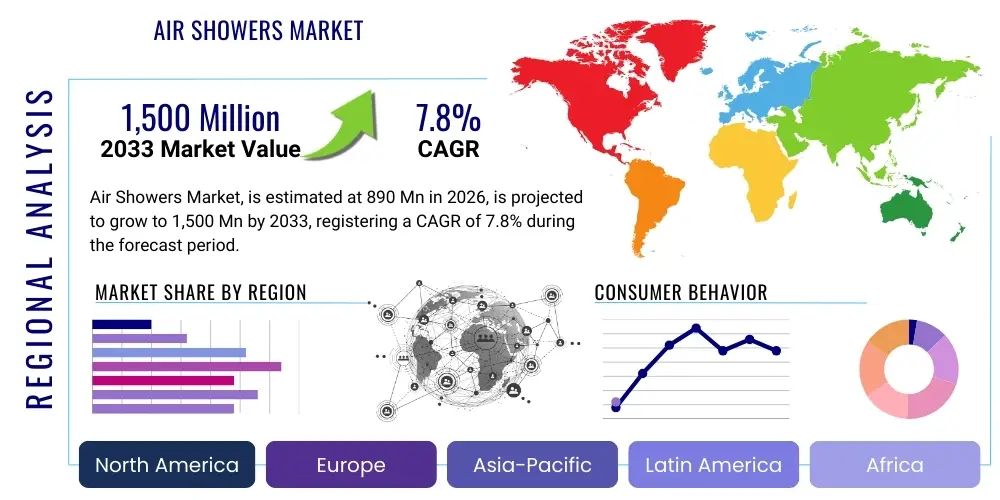

Air Showers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440967 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Air Showers Market Size

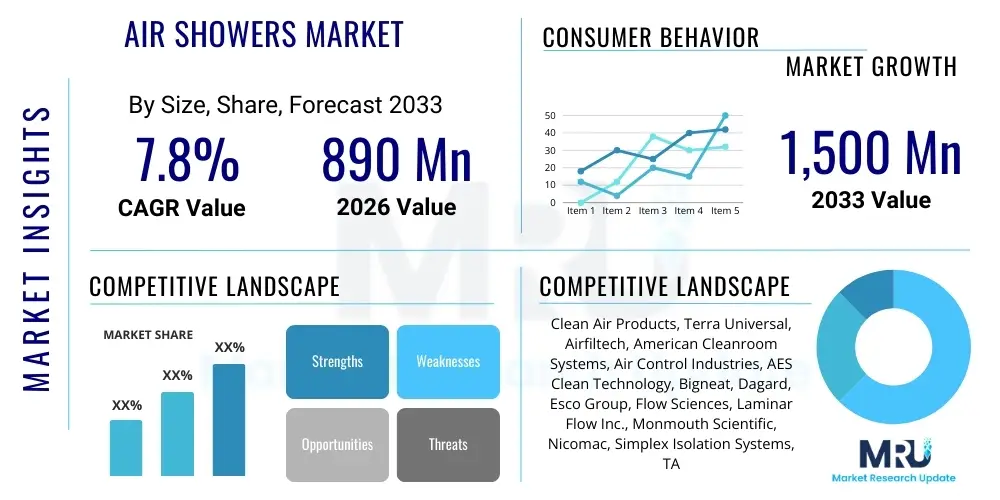

The Air Showers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $890 Million in 2026 and is projected to reach $1,500 Million by the end of the forecast period in 2033. This robust growth trajectory is underpinned by escalating demands for highly controlled environments across critical industries such as pharmaceuticals, microelectronics, and advanced biotechnology. The strict enforcement of ISO 14644 standards and increasing governmental emphasis on product quality and sterility significantly contribute to the continuous adoption of air shower systems globally.

Air Showers Market introduction

The Air Showers Market encompasses the manufacturing, distribution, and maintenance of specialized pre-clean zones designed to minimize particulate matter contamination upon personnel and material entry into controlled environments or cleanrooms. An air shower is essentially a contained chamber that utilizes high-velocity jets of HEPA-filtered or ULPA-filtered air to dislodge and remove surface-borne contaminants (such as dust, lint, and fibers) from individuals or objects before they proceed into a clean space. These systems are fundamental components of contamination control strategy, providing a critical barrier between non-controlled and controlled areas.

The core functionality of an air shower relies on high-pressure air nozzles operating at velocities typically exceeding 6,000 feet per minute (FPM), ensuring effective scrubbing action on all surfaces. Applications span a wide spectrum of sensitive manufacturing and research fields, including semiconductor fabrication plants where minuscule particulate contamination can destroy microprocessors, pharmaceutical production facilities requiring aseptic conditions for drug safety, and medical device manufacturing. Key benefits include enhanced product yield, compliance with stringent regulatory requirements, and prolonged operational integrity of cleanroom filters and infrastructure. Driving factors are predominantly the exponential growth in global biopharma manufacturing, the relentless miniaturization trend in electronics necessitating increasingly cleaner production spaces, and global investments in specialized research laboratories focused on emerging technologies.

Air Showers Market Executive Summary

The Air Showers Market exhibits strong growth, propelled by mandatory quality control standards and technological advancements integrating smart monitoring capabilities. Business trends highlight a shift towards modular and customizable air shower designs that cater specifically to varying cleanroom sizes and classification requirements, such as ISO Class 7 or Class 5 environments. Furthermore, key players are focusing on energy efficiency and reduced operational noise levels to improve sustainability and user acceptance in high-throughput facilities. Strategic partnerships between air shower manufacturers and cleanroom builders are becoming prevalent, streamlining installation and validation processes for end-users seeking complete contamination control solutions.

Regional trends indicate that the Asia Pacific (APAC) region is dominating market expansion, primarily due to the massive scale-up of semiconductor fabrication facilities in countries like China, Taiwan, and South Korea, coupled with rapidly expanding generic drug manufacturing bases in India and Southeast Asia. North America and Europe remain mature markets, characterized by high regulatory adherence and robust demand from advanced biotechnology and specialty chemical sectors, focusing heavily on upgrading existing infrastructure with automated, high-efficiency systems. Segment trends show that the Tunnels/Modular Air Showers segment is gaining traction, especially in large-scale logistics operations within regulated environments, offering superior throughput and flexible configuration options compared to traditional single-unit systems.

AI Impact Analysis on Air Showers Market

User inquiries regarding AI's impact on the Air Showers Market frequently center on themes of predictive maintenance, operational efficiency improvements, and smart contamination tracking. Users are particularly interested in how Artificial Intelligence can move air showers beyond simple mechanical functions towards being proactive components of a contamination control network. Key concerns involve integrating disparate sensor data—such as particle counts, air velocity, and door cycles—to predict potential failures or optimize showering duration based on real-time environmental factors. Expectations include AI-driven self-diagnosis, automated regulatory compliance reporting, and the capability to adjust operational parameters dynamically to maintain stringent ISO standards while minimizing energy consumption. The market anticipates AI will transform air showers from static barriers into intelligent, self-managing environmental control points.

- AI integration enables predictive maintenance scheduling for critical components like HEPA filters and fan blowers, reducing unplanned downtime.

- Machine learning algorithms optimize showering cycle times based on personnel traffic flow and measured particulate contamination levels for maximum efficiency.

- Real-time data analytics provided by AI enhances compliance reporting and audit readiness by monitoring adherence to specified velocity profiles and air changes per hour.

- AI systems can detect anomalies in air pressure differentials or nozzle performance instantly, triggering alerts before contamination events occur.

- Enhanced user authentication and access control systems utilizing AI (e.g., facial recognition combined with contamination data) ensure only properly decontaminated personnel proceed.

DRO & Impact Forces Of Air Showers Market

The dynamics of the Air Showers Market are fundamentally shaped by the confluence of stringent global regulatory mandates and rapid technological progress in sensitive manufacturing sectors. Drivers include the ever-increasing need for contamination control in aseptic environments, particularly within personalized medicine and complex biological drug manufacturing, necessitating higher standards of air cleanliness. Restraints primarily involve the substantial initial capital investment required for high-grade air shower installations and the ongoing operational costs associated with frequent filter replacement and specialized maintenance. Opportunities are emerging through the development of energy-efficient designs, integration with Building Management Systems (BMS), and the growing demand for customized, modular solutions that can be rapidly deployed or relocated, especially in temporary research setups or expanding facilities.

Impact forces, analyzed through a Porter’s framework lens, reveal moderate to high buyer power, especially from large pharmaceutical and semiconductor corporations that procure systems in bulk and demand customization and integration services. The threat of new entrants remains low due to high technological barriers, rigorous regulatory approval processes, and the necessity of establishing a trusted track record in critical contamination control. Supplier power is also moderate, driven by the specialized nature of HEPA/ULPA filtration media and high-velocity blower technology. The primary competitive rivalry is centered on efficiency, customization capability, post-sales support, and compliance certification, rather than solely on pricing, reflecting the mission-critical nature of the equipment in preventing catastrophic product losses.

Segmentation Analysis

The Air Showers Market is extensively segmented across several dimensions, reflecting the diverse application requirements and technological configurations necessary for effective contamination control across various industries. Primary segmentation focuses on the type of air shower unit, defining its operational structure and throughput capacity, followed by the direction of air flow which dictates the efficiency of particle removal. Further crucial differentiation occurs based on the end-use industry, as pharmaceutical, electronic, and healthcare sectors each possess unique regulatory frameworks and specific cleanliness thresholds (e.g., ISO Class requirements) that mandate tailored air shower specifications, ranging from standard entry units to large, fully automated material transfer tunnels.

- By Type:

- Standard Air Showers (Single/Double Door)

- Tunnels/Modular Air Showers (High-throughput systems)

- High-Velocity Air Showers (Optimized for stubborn particulate removal)

- Pass-Through Chambers (For material transfer)

- By Flow Direction:

- Single-sided Flow

- Double-sided Flow

- Three-sided Flow (Maximizing coverage)

- Top Flow/Vertical Flow

- By End-Use Industry:

- Pharmaceutical & Biotechnology (Aseptic manufacturing)

- Semiconductors & Electronics (Micro/Nano-fabrication)

- Healthcare (Operating Rooms, Isolation Wards, Sterile Processing)

- Food & Beverage Processing (Minimizing microbial contamination)

- Industrial Manufacturing (Aerospace, Automotive specialized coating)

- By Technology:

- Microprocessor-Controlled Systems

- Manual/Timer-Based Systems

Value Chain Analysis For Air Showers Market

The value chain for the Air Showers Market begins with the upstream raw material suppliers, predominantly focusing on high-grade stainless steel (for construction requiring corrosion resistance and ease of cleaning), specialized filtration media providers (HEPA and ULPA filters), and advanced blower motor manufacturers crucial for achieving the necessary air velocity. Air shower manufacturers then engage in complex system design, fabrication, and integration, requiring precision engineering to ensure airtight seals, uniform air distribution, and compliance with structural and electrical safety standards. This upstream analysis highlights the dependency on specialized component quality, where minor variations in filter efficiency or motor performance can significantly compromise the final system’s effectiveness and regulatory compliance.

Downstream analysis involves the distribution channels and the ultimate end-users. Distribution is often handled directly for large, complex projects requiring custom integration, or through specialized cleanroom equipment distributors and system integrators who provide installation, qualification (IQ/OQ), and validation services. Direct sales channels are preferred for high-value contracts in the pharmaceutical and semiconductor sectors where technical consultation and post-installation service contracts are critical. Indirect channels serve smaller laboratories and industrial applications requiring standard units. The profitability throughout the chain is often maximized at the integration and after-sales service stages, including calibration and mandated periodic filter changes, representing essential recurring revenue streams.

Air Showers Market Potential Customers

Potential customers for air shower systems are organizations operating mission-critical environments where control over airborne particulate and microbial contamination is paramount to product integrity, public safety, or regulatory adherence. The pharmaceutical and biotechnology sectors represent the largest and most demanding customer base, encompassing companies involved in sterile drug production, vaccine manufacturing, cell and gene therapy development, and quality control laboratories. These buyers require systems validated to strict cGMP (current Good Manufacturing Practice) standards and often necessitate specialized features like explosion-proof motors or specific material finishes suitable for harsh chemical cleaning agents.

The second major cohort consists of semiconductor and electronics manufacturers, especially those involved in producing microchips, advanced displays, and sensitive optical equipment where even sub-micron particles can cause significant defects, leading to massive yield losses. These end-users typically demand ULPA filtration and robust, high-throughput tunnel systems to process large volumes of materials or personnel efficiently. Other significant buyers include hospitals (especially surgical suites and sterile compounding pharmacies), research institutions, aerospace and defense contractors handling sensitive materials, and specialized food processing plants aiming for enhanced hygiene and extended shelf life for their products. Their purchasing decisions are driven by compliance, operational efficiency, and total cost of ownership over the system's lifespan.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $890 Million |

| Market Forecast in 2033 | $1,500 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Clean Air Products, Terra Universal, Airfiltech, American Cleanroom Systems, Air Control Industries, AES Clean Technology, Bigneat, Dagard, Esco Group, Flow Sciences, Laminar Flow Inc., Monmouth Scientific, Nicomac, Simplex Isolation Systems, TAIKisha Ltd., Kwang-Jin Tech, Fan-S Division, Camfil, Shenzhen Jinyi Clean Equipment, Guangzhou Haobang Clean Technology |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Air Showers Market Key Technology Landscape

The contemporary Air Showers Market is characterized by a drive towards enhanced operational efficiency, better contamination capture, and improved user experience, all facilitated by sophisticated technological integration. Fundamental technology centers on high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filtration systems, which are mandatory for achieving ISO 5 (Class 100) or higher cleanliness levels. The core innovation lies in the blower and nozzle design, with manufacturers increasingly employing high-static pressure centrifugal blowers coupled with adjustable stainless steel nozzles engineered for optimal air shearing and scrubbing effectiveness. Velocity control, often governed by sophisticated variable frequency drives (VFDs), ensures consistent air speed regardless of pressure loading on the filters, maximizing particulate removal efficacy while managing energy consumption.

Recent technological advancements emphasize smart control systems and connectivity. Modern air showers utilize microprocessor-based controls that allow for precise programming of cycle times, door interlocking sequences (crucial for maintaining pressure differentials), and error diagnostics. Integration with Internet of Things (IoT) sensors is rapidly becoming standard, enabling real-time monitoring of critical parameters such as internal air velocity, differential pressure across filters, and particle count levels. This data is often relayed to a central Building Management System (BMS) or cloud platform, facilitating remote monitoring, data logging for regulatory audits, and predictive alerts for filter replacements, thus reducing manual oversight and ensuring continuous compliance.

Furthermore, attention is being paid to material science and ergonomics. Antimicrobial coatings on internal surfaces are utilized in healthcare and pharmaceutical settings to minimize microbial colonization. Advanced door interlocking mechanisms, sometimes employing magnetic levitation technology for smooth operation and minimal particle generation, enhance reliability. The future technology landscape is moving towards customizable air stream profiles, perhaps employing advanced computational fluid dynamics (CFD) modeling during the design phase, to ensure comprehensive coverage and minimized re-entrainment of particles, thereby guaranteeing the highest level of cleanliness before entry into the most critical zones.

Regional Highlights

The global Air Showers Market exhibits significant regional disparities driven by industrial output and regulatory maturity. The Asia Pacific (APAC) region currently holds the largest market share and is projected to demonstrate the fastest growth rate throughout the forecast period. This dominance is primarily fueled by massive government and private sector investments in high-tech manufacturing, including the rapid expansion of semiconductor foundries in Taiwan, South Korea, and mainland China, which demand extremely high-class cleanrooms. Furthermore, the burgeoning pharmaceutical and generic drug manufacturing industry in India and Southeast Asia significantly contributes to the demand for certified air showers necessary for GMP compliance.

North America, particularly the United States, represents a highly mature market characterized by demand for high-specification, customized air showers, driven by the cutting-edge biotechnology, aerospace, and specialized defense sectors. Demand here is less about initial infrastructure build-out and more focused on upgrading existing facilities, implementing advanced automation, and integrating systems with sophisticated centralized monitoring platforms. Europe follows a similar trend, with strict European Medicines Agency (EMA) regulations driving demand in countries like Germany, Switzerland, and Ireland (key pharmaceutical manufacturing hubs). European users prioritize energy efficiency (VFDs and optimized cycle times) and robust documentation to meet rigorous environmental and quality standards.

The Latin America and Middle East & Africa (MEA) regions currently represent emerging markets. Growth in MEA is being driven by localized investment in pharmaceutical production capacity, aiming for self-sufficiency in drug supply chains, particularly in the Gulf Cooperation Council (GCC) nations. Latin American growth is steady, stimulated by foreign direct investment in basic electronics assembly and the modernization of healthcare infrastructure. However, these regions often face challenges related to initial capital costs and the availability of specialized maintenance expertise, making standardized and easy-to-maintain models highly attractive.

- Asia Pacific (APAC): Market leader and fastest growth; dominated by semiconductor fabrication and pharmaceutical scale-up (China, Taiwan, South Korea, India).

- North America: Mature market focusing on high-specification, automated systems for biotechnology, aerospace, and advanced R&D.

- Europe: High demand driven by EMA compliance; strong focus on energy efficiency and validated systems in core pharmaceutical manufacturing countries (Germany, Ireland).

- Latin America: Steady, gradual growth driven by healthcare infrastructure modernization and localized industrial development.

- Middle East & Africa (MEA): Emerging market primarily driven by pharmaceutical production self-sufficiency initiatives and infrastructure projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Air Showers Market.- Clean Air Products

- Terra Universal

- Airfiltech

- American Cleanroom Systems

- Air Control Industries

- AES Clean Technology

- Bigneat

- Dagard

- Esco Group

- Flow Sciences

- Laminar Flow Inc.

- Monmouth Scientific

- Nicomac

- Simplex Isolation Systems

- TAIKisha Ltd.

- Kwang-Jin Tech

- Fan-S Division

- Camfil

- Shenzhen Jinyi Clean Equipment

- Guangzhou Haobang Clean Technology

Frequently Asked Questions

Analyze common user questions about the Air Showers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an air shower in a cleanroom environment?

The primary function of an air shower is to minimize particulate contamination on personnel and materials entering a cleanroom. It achieves this by utilizing high-velocity, filtered air jets (typically 6,000 FPM or more) to dislodge and remove surface particles before entry, thereby maintaining the cleanroom’s specific ISO classification.

Which industries are the major consumers of air shower systems?

The major consumer industries are Pharmaceutical and Biotechnology (for aseptic processing and compliance with cGMP), Semiconductors and Electronics (for micro-fabrication requiring ultra-low particle counts), and Healthcare (for sterile operating theaters and compounding pharmacies).

How often should HEPA filters in air showers be replaced?

HEPA filter replacement frequency depends heavily on operational hours, environment cleanliness, and differential pressure readings. Typically, filters are monitored via pressure gauges; replacement is necessary when the pressure drop exceeds the manufacturer’s specified limit, indicating high particulate loading, often ranging from 12 to 36 months under normal use.

What is the difference between a standard air shower and a modular air shower tunnel?

A standard air shower is a single, contained unit designed for low-to-moderate throughput (1-2 persons/cycle). A modular air shower tunnel consists of interconnected segments, allowing for customization and significantly higher throughput rates, often used for large groups of personnel or high volumes of materials via conveyor systems.

How does the implementation of air showers affect operational cost efficiency?

While air showers represent a significant initial investment, they dramatically improve operational cost efficiency by reducing product reject rates (improving yield) due to contamination, minimizing the frequency of high-cost filter changes in the main cleanroom HVAC system, and ensuring continuous regulatory compliance, avoiding costly shutdowns or recalls.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager