Anti-Fog Paint Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441857 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Anti-Fog Paint Market Size

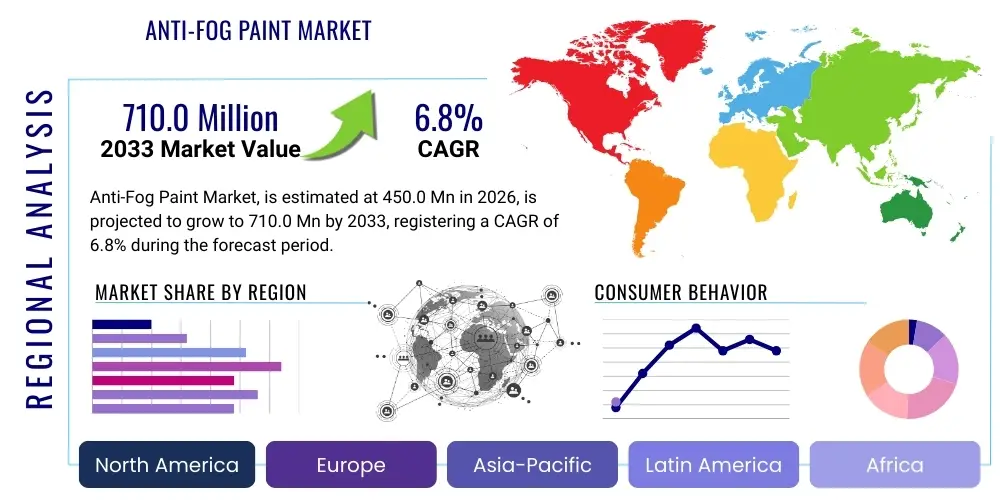

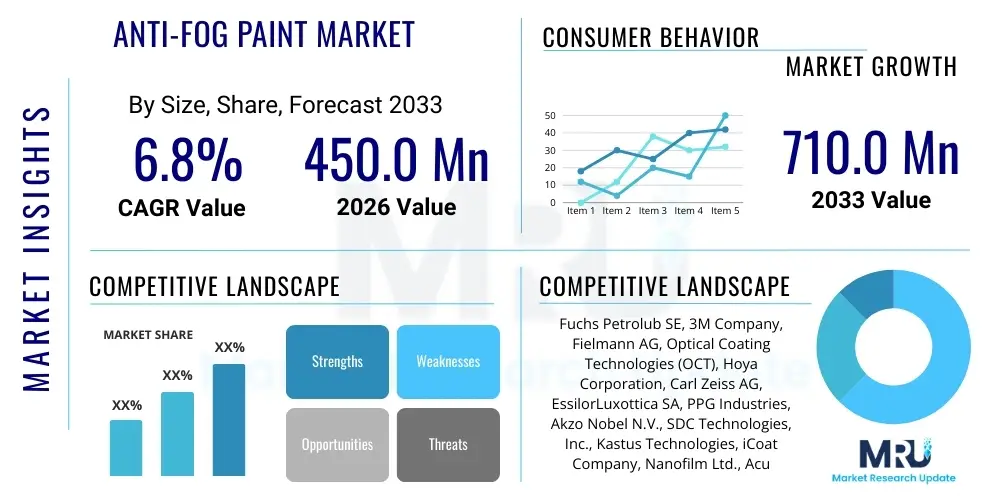

The Anti-Fog Paint Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.0 Million in 2026 and is projected to reach USD 710.0 Million by the end of the forecast period in 2033.

Anti-Fog Paint Market introduction

The Anti-Fog Paint Market encompasses specialized coating solutions designed to prevent the condensation of water vapor on surfaces, maintaining clarity and visibility in high-humidity or rapidly changing temperature environments. These coatings utilize hydrophilic or super-hydrophilic materials, often based on nanotechnology and surface science, which spread condensed moisture into a thin, transparent film rather than forming opaque droplets. The primary product goal is enhancing safety, operational efficiency, and product longevity across various sectors where fogging poses a significant operational hazard or visual impairment, such as automotive, healthcare, aerospace, and consumer electronics.

Major applications of anti-fog paints include automotive windshields, rear-view mirrors, safety goggles, optical lenses, display screens, and refrigerated display cases. The paints are formulated to be durable, abrasion-resistant, and optically clear, often applied through dipping, spraying, or spin-coating processes depending on the substrate material, which commonly includes polycarbonate, glass, and various plastics. Key benefits derived from these coatings involve reduced maintenance downtime, improved safety standards, especially in industrial settings, and enhanced user experience for optical devices and instrumentation.

Driving factors for this market are intrinsically linked to stringent safety regulations requiring clear visibility in protective equipment and vehicles, coupled with the rapid expansion of the healthcare sector, particularly involving advanced surgical equipment and diagnostic instruments. Furthermore, increasing consumer demand for high-performance optics in sports and electronics drives innovation in transparent, long-lasting anti-fog formulations. Technological advancements, such as hybrid polymer systems and UV-cured coatings, continue to improve the efficacy and longevity of these protective surfaces, further solidifying market growth prospects globally.

Anti-Fog Paint Market Executive Summary

The Anti-Fog Paint Market is undergoing significant transformation driven by increasing regulatory focus on safety in the industrial and automotive sectors, creating robust demand for high-performance anti-fog solutions. Business trends indicate a shift towards sustainable and bio-based anti-fog formulations to address growing environmental concerns, alongside intensified R&D efforts in developing multifunctional coatings that offer anti-fog properties combined with anti-glare, anti-scratch, or antimicrobial functionalities. Regional trends highlight Asia Pacific as the fastest-growing market, largely fueled by booming automotive production, rapid industrialization, and substantial investments in medical device manufacturing in countries like China and India, while North America and Europe maintain leading positions due to stringent industrial safety standards and high adoption rates of advanced protective equipment.

Segment trends emphasize the dominance of the Polycarbonate segment due to its widespread use in protective eyewear and helmet visors, materials that inherently benefit significantly from anti-fog treatments. In terms of application, the Automotive sector remains a cornerstone, crucial for enhancing driving safety through treated windows and mirrors, followed closely by the fast-expanding Medical and Healthcare segment, critical for maintaining the clarity of surgical scopes and diagnostic lenses during operation. The technology landscape is moving towards solvent-free, water-based, and nanostructured coatings, reflecting both environmental compliance needs and the pursuit of superior optical clarity and durability, ensuring that the market trajectory remains highly positive throughout the forecast period.

The competitive landscape is characterized by strategic collaborations between raw material suppliers and end-product manufacturers, aiming to optimize coating application processes and reduce production costs. Key players are heavily investing in expanding their production capacities and global distribution networks to capitalize on emerging opportunities in developing economies. Furthermore, the market structure is evolving as niche players specializing in advanced nanotechnology-enabled coatings gain traction, challenging established chemical giants through superior product performance, particularly in highly sensitive areas like precision optics and augmented reality (AR) devices.

AI Impact Analysis on Anti-Fog Paint Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Anti-Fog Paint Market often revolve around optimizing material composition, predicting coating performance under variable climate conditions, and automating quality control during the manufacturing process. Users are keen to understand how AI-driven predictive modeling can accelerate the development cycle of novel hydrophilic polymers and reduce the reliance on extensive physical testing. Key concerns include the computational cost of simulating complex surface tension dynamics and the need for standardized, high-quality data sets derived from real-world application environments. Expectations are high that AI will significantly shorten the time-to-market for high-durability, next-generation anti-fog solutions tailored specifically for niche applications, such as high-altitude aerospace optics or deep-sea instrumentation, requiring precise functional stability.

- AI-driven Material Informatics: Utilizing machine learning algorithms to screen and predict the functional properties of thousands of potential hydrophilic compounds, dramatically accelerating the discovery of novel anti-fog formulations with enhanced durability and optical clarity.

- Optimized Manufacturing Parameters: Implementing AI and IoT (Internet of Things) systems within coating lines to dynamically adjust parameters like temperature, humidity, curing time, and spray thickness, ensuring consistent quality and minimizing material waste.

- Predictive Performance Modeling: Employing AI to simulate the long-term degradation and anti-fog effectiveness of coatings under various environmental stressors (e.g., UV exposure, chemical abrasion, extreme temperature fluctuations) before commercial deployment.

- Enhanced Quality Control (QC): Integrating computer vision and deep learning models for automated, non-destructive inspection of coated surfaces, identifying microscopic defects or inconsistencies in film thickness far more rapidly and accurately than manual inspection.

- Personalized Formulation Development: Using customer usage data and application requirements (e.g., specific lens curvature, expected humidity levels) analyzed by AI to develop bespoke coating solutions for high-value industrial or military contracts.

- Supply Chain Resilience: Leveraging AI for demand forecasting and inventory management of specialized raw materials (e.g., specific nanoparticles or rare polymers), ensuring a stable supply chain despite geopolitical or logistical volatility.

DRO & Impact Forces Of Anti-Fog Paint Market

The Anti-Fog Paint Market is primarily driven by the escalating demand for safety-critical visibility solutions across industries, particularly mandated by evolving governmental regulations concerning protective personal equipment (PPE) and vehicular safety standards. However, the market faces significant restraints related to the high initial investment required for sophisticated coating equipment, the complexity of ensuring long-term adhesion on diverse substrates (especially plastics), and the continuous challenge of balancing anti-fog performance with anti-scratch resistance and overall film durability. Opportunities abound in the burgeoning fields of virtual reality (VR) and augmented reality (AR) headsets, advanced medical imaging, and solar energy systems, all requiring specialized, high-performance transparent coatings. These market forces, combined with intense competitive pressure and rapid technological cycles, create a dynamic environment where innovation in nanotechnology and material science dictates market success and penetration.

Segmentation Analysis

The Anti-Fog Paint Market is comprehensively segmented based on material, substrate, application, and end-use industry, providing granular insights into demand patterns and growth drivers across diverse functional needs. The primary segmentation by material distinguishes between hydrophilic polymer-based coatings, which absorb moisture, and nano-silica or surfactant-based coatings, which facilitate water spreading. Substrate segmentation is critical as the coating performance is highly dependent on the underlying material, spanning glass, polycarbonate, acrylic, and other specialized plastics. Application categories highlight the usage on various products such as lenses, mirrors, and displays, while the end-use industry classification (Automotive, Medical, Industrial Safety, etc.) defines the regulatory and performance requirements.

- By Material Type:

- Hydrophilic Polymers (e.g., Polyurethane, Acrylics)

- Silica-based Nanocoatings

- Surfactant-based Coatings

- Hybrid Formulations

- By Substrate:

- Glass

- Polycarbonate (PC)

- Acrylic (PMMA)

- Other Plastics (e.g., PET, PVC)

- By Application:

- Lenses (Eyewear, Camera Lenses)

- Mirrors (Automotive, Bathroom)

- Displays and Screens (Consumer Electronics, Industrial Monitors)

- Visors and Shields (Helmets, Protective Gear)

- By End-Use Industry:

- Automotive and Transportation

- Medical and Healthcare (Surgical Scopes, Diagnostic Equipment)

- Industrial Safety (Goggles, Face Shields)

- Consumer Goods and Optics

- Aerospace and Defense

- Sports and Leisure

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Anti-Fog Paint Market

The value chain for the Anti-Fog Paint Market begins with the upstream sourcing of specialized chemical raw materials, including advanced polymers, nanoparticles (such as silica and titanium dioxide), surfactants, and high-purity solvents. This stage is characterized by high technical expertise and stringent quality control, as the performance characteristics of the final anti-fog coating are heavily dependent on the purity and functionalization of these base components. Key players in this upstream segment include specialized chemical manufacturers and polymer science firms. Innovation at this stage, particularly in developing stable, environmentally friendly, and highly effective hydrophilic components, dictates the cost structure and performance potential of the final product.

The middle segment involves formulation, manufacturing, and coating application. Manufacturers convert raw materials into functional paint formulations, often requiring sophisticated mixing and dispersion technologies, especially for nanocoatings, to ensure uniform distribution and long-term stability. The distribution channel is bifurcated: direct distribution is common for large OEM contracts in the automotive or medical sectors, involving direct application lines, while indirect distribution utilizes chemical distributors and specialized resellers for smaller volume customers or specialized retail products like anti-fog sprays. Effective inventory management and tailored logistics are essential due to the sometimes short shelf life or specific storage requirements of certain chemical formulations.

The downstream analysis focuses on the end-users and application systems. Direct sales channels dominate in large-scale industrial segments where specialized application processes, such as UV curing lines or plasma deposition, are integrated into the client's manufacturing setup (e.g., auto assembly plants, medical device fabrication). Indirect channels serve the aftermarket, retail, and smaller industrial buyers through distributors, wholesale chemical suppliers, and e-commerce platforms, offering ready-to-use coatings or sprays. The efficiency of the distribution network directly influences market penetration, particularly in geographically diverse regions where prompt technical support and consistent supply are critical for maintaining continuous industrial operations.

- Upstream Activities: Sourcing of specialized monomers, hydrophilic polymers, nano-silica, specialized surfactants, and high-purity solvents from chemical producers. Focus on material synthesis and quality assurance.

- Midstream Activities: Research and Development (R&D), formulation, mixing, dispersion technology (especially for nanosuspensions), manufacturing of the final coating product, and packaging.

- Downstream Activities (Distribution):

- Direct Channel: OEM supply to automotive manufacturers, large medical device firms, and defense contractors requiring bulk specialized coatings and application technology consultation.

- Indirect Channel: Chemical distributors, regional agents, wholesale suppliers, and retail channels for smaller volume, aftermarket, and consumer products (sprays, wipes).

- End-User Application: Surface preparation, application (spray coating, spin coating, dip coating), curing processes (UV, thermal), quality control, and post-sales technical support.

Anti-Fog Paint Market Potential Customers

Potential customers for the Anti-Fog Paint Market span a broad spectrum of industries where visual clarity and safety are paramount operational concerns. The core customer base includes Original Equipment Manufacturers (OEMs) in the transportation sector, specifically automotive, rail, and marine manufacturers, who require durable anti-fog treatment for windows, headlights, and internal gauges to comply with safety standards. Another crucial segment is the medical device industry, where surgeons and diagnostic professionals rely heavily on clear vision provided by treated surgical scopes, endoscopes, and protective face shields, making hospitals, clinics, and medical device manufacturers primary targets.

Beyond transportation and healthcare, the industrial safety sector constitutes a robust demand segment. Companies operating in manufacturing, construction, chemical processing, and oil and gas require anti-fog coatings for protective eyewear (safety goggles, face shields) to safeguard employees and maintain continuous workflow in humid or harsh environments. Furthermore, consumer electronics and optics manufacturers represent a rapidly growing customer base, integrating anti-fog properties into high-end products such as camera lenses, smartphone covers, virtual and augmented reality (VR/AR) headsets, and sports optics, catering to the growing demand for high-performance and reliable optical performance.

The increasing complexity and regulatory oversight in all these industries mean that customers are increasingly demanding specialized, multi-functional coatings that not only prevent fogging but also offer resistance to abrasion, chemicals, and UV degradation. This drives the potential customer profile towards those seeking long-term, high-durability solutions integrated early in their product design cycle, moving away from temporary, consumable anti-fog treatments towards permanent, engineered coating systems applied during manufacturing.

- Automotive OEMs (Windshields, Mirrors, Headlights)

- Medical Device Manufacturers (Surgical Scopes, Diagnostic Lenses, Face Shields)

- Industrial Safety Equipment Manufacturers (Goggles, Respirators, Helmets)

- Aerospace and Defense Contractors (Cockpit Displays, Visors)

- Consumer Electronics and Optics Companies (Camera Lenses, Display Screens, VR/AR Headsets)

- Solar Panel Manufacturers (Protective Coatings for efficiency maintenance)

- Cold Storage and Refrigeration Equipment Producers (Display Cases, Freezer Windows)

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.0 Million |

| Market Forecast in 2033 | USD 710.0 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fuchs Petrolub SE, 3M Company, Fielmann AG, Optical Coating Technologies (OCT), Hoya Corporation, Carl Zeiss AG, EssilorLuxottica SA, PPG Industries, Akzo Nobel N.V., SDC Technologies, Inc., Kastus Technologies, iCoat Company, Nanofilm Ltd., Aculon, Inc., Mist-Away Technologies, Inc., Corning Incorporated, Nippon Paint Holdings Co., Ltd., Axalta Coating Systems, The Sherwin-Williams Company, Clariant AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Anti-Fog Paint Market Key Technology Landscape

The technological landscape of the Anti-Fog Paint Market is rapidly evolving, moving primarily towards advanced material science centered on maximizing surface hydrophilicity and mechanical durability. The fundamental technologies rely on two main mechanisms: the hydrophilic approach, utilizing specialized polymers or inorganic materials (like TiO2 or SiO2 nanoparticles) to create a surface energy low enough to allow water to sheet rather than bead; and the anti-static/anti-fog combination, which prevents dust accumulation that often acts as nucleation sites for water droplets. Recent advancements focus on developing permanent, UV-curable, and thermally stable coatings that can withstand repeated cleaning cycles and harsh chemical exposure, essential requirements in medical and automotive applications.

Nanotechnology plays a pivotal role, enabling the construction of nanostructured surfaces with tailored roughness and porosity, significantly improving the efficacy of the anti-fog layer. Sol-gel technology is increasingly adopted for manufacturing durable, inorganic-organic hybrid coatings, offering superior adhesion and resistance properties compared to traditional polymer-only systems. Furthermore, there is a distinct technological trend toward developing sustainable and eco-friendly formulations, specifically replacing volatile organic compounds (VOCs) with water-based or solvent-free systems, driven by stricter environmental regulations in North America and Europe. This shift requires sophisticated chemical engineering to maintain performance characteristics using greener alternatives.

Another area of intense R&D focuses on combining anti-fog capabilities with other high-demand functionalities, creating 'smart' or multi-functional coatings. Examples include combining anti-fogging with anti-microbial properties (crucial for medical devices), anti-glare coatings (for high-end display panels), or self-healing properties that maintain visual clarity even after minor surface damage. The application techniques are also advancing, with vapor deposition and highly automated robotic spray systems ensuring ultra-thin, uniform film application, which is crucial for maintaining the optical integrity of complex geometries like progressive lenses and curved displays.

- Hydrophilic Polymer Systems: Utilizing water-absorbing materials such as highly cross-linked polyurethanes and specialized acrylics to rapidly absorb moisture vapor, maintaining transparency.

- Nanotechnology-Enabled Coatings: Incorporation of functionalized nanoparticles (e.g., TiO2, SiO2) to create permanent super-hydrophilic surface textures via sol-gel or plasma-enhanced chemical vapor deposition (PECVD).

- UV-Curable Formulations: Rapid-curing systems utilized in high-throughput manufacturing environments, offering superior hardness, abrasion resistance, and reduced production cycle times.

- Hybrid Inorganic-Organic Coatings: Combining the durability and chemical resistance of inorganic matrices with the flexibility and adhesion properties of organic polymers, commonly used for high-stress applications like automotive exterior lenses.

- Water-Based and VOC-Free Systems: Development of eco-friendly formulations to comply with stringent environmental standards, requiring highly sophisticated stabilizing agents and film-forming processes.

Regional Highlights

Geographically, the Anti-Fog Paint Market exhibits diverse growth characteristics influenced by regional safety standards, industrial output, and climate conditions. North America and Europe traditionally hold significant market shares, characterized by mature automotive and aerospace industries, coupled with some of the world's most rigorous occupational safety regulations, which mandate the use of high-quality anti-fog protective equipment. The high healthcare expenditure and advanced medical device manufacturing infrastructure in these regions further solidify demand for premium, durable anti-fog solutions for surgical and diagnostic equipment. Technological early adoption, particularly in integrating anti-fog properties into specialized optics and military applications, drives value growth in these markets.

Asia Pacific (APAC) is projected to be the fastest-growing market during the forecast period. This rapid expansion is primarily attributed to explosive growth in the regional automotive manufacturing hubs, particularly in China, Japan, and South Korea, alongside massive investments in industrialization across Southeast Asia, which necessitates greater compliance with industrial safety mandates. Furthermore, the immense scale of consumer electronics manufacturing and the expanding presence of global medical device companies establishing production facilities in APAC countries significantly contribute to the surging demand for anti-fog coatings for lenses, displays, and medical instruments. The region also faces widespread challenges with high ambient humidity, naturally increasing the baseline demand for effective anti-fog solutions.

Latin America (LATAM) and the Middle East & Africa (MEA) represent emerging markets characterized by increasing urbanization, infrastructure development, and growing public awareness regarding occupational safety. While currently possessing smaller market shares, these regions offer substantial long-term opportunities due to expanding local manufacturing capabilities and rising import volumes of vehicles and industrial machinery, all requiring clarity-enhancing coatings. Investment in oil and gas exploration and petrochemical processing in the MEA region specifically drives the demand for heavy-duty, chemically resistant anti-fog safety gear. Local manufacturers are increasingly focused on adapting formulations suitable for extreme regional climatic conditions, ranging from high desert heat to tropical humidity.

- North America: Market leader driven by strict OSHA regulations, advanced medical device R&D, and substantial demand from the defense and aerospace sectors for specialized optical coatings.

- Europe: High market penetration due to stringent EU regulations (e.g., REACH compliance), strong automotive aftermarket demand, and continuous innovation in optical lenses and premium consumer goods.

- Asia Pacific (APAC): Fastest growth expected, fueled by rapid expansion of the automotive and electronics manufacturing sectors in China, India, and ASEAN nations, coupled with high humidity levels driving necessity.

- Latin America (LATAM): Growth spurred by infrastructure investment and increasing automotive production, creating steady demand for industrial and transportation safety coatings.

- Middle East and Africa (MEA): Emerging market driven by expansion in oil and gas industries, construction, and rising urbanization requiring improved industrial safety standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Anti-Fog Paint Market.- Fuchs Petrolub SE

- 3M Company

- Fielmann AG

- Optical Coating Technologies (OCT)

- Hoya Corporation

- Carl Zeiss AG

- EssilorLuxottica SA

- PPG Industries

- Akzo Nobel N.V.

- SDC Technologies, Inc.

- Kastus Technologies

- iCoat Company

- Nanofilm Ltd.

- Aculon, Inc.

- Mist-Away Technologies, Inc.

- Corning Incorporated

- Nippon Paint Holdings Co., Ltd.

- Axalta Coating Systems

- The Sherwin-Williams Company

- Clariant AG

Frequently Asked Questions

Analyze common user questions about the Anti-Fog Paint market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary mechanism of action for modern Anti-Fog Paints?

Modern anti-fog paints typically employ a hydrophilic mechanism where the coating surface possesses high surface energy, causing condensed water vapor to spread out immediately into a thin, uniform, transparent sheet rather than forming light-scattering micro-droplets (fog). This sheeting action maintains visual clarity.

Which end-use industry is the largest consumer of Anti-Fog Coatings?

The Automotive and Transportation industry traditionally stands as the largest consumer of anti-fog coatings, utilized extensively for interior windshields, side mirrors, and lighting components to ensure driving safety and compliance with visibility regulations.

Are anti-fog coatings permanent, or do they require reapplication?

The permanence of anti-fog coatings varies by type. Permanent, high-durability coatings, often utilizing nano-technology or UV-cured polymers, are integrated during manufacturing for applications like safety goggles or automotive glass. Temporary, surfactant-based sprays or wipes require periodic reapplication.

What technological trends are currently driving innovation in anti-fog formulations?

Key technological innovations include the development of solvent-free, water-based coatings to enhance sustainability, integration of inorganic nanoparticles (like silica) via sol-gel processes for superior durability, and the creation of multi-functional coatings offering anti-fog alongside anti-scratch or anti-microbial properties.

What challenges exist regarding the durability of anti-fog paints?

The main challenges relate to maintaining the critical hydrophilic surface properties over time against environmental degradation, such as UV exposure, chemical cleaners, and mechanical abrasion. Ensuring long-term adhesion to various plastic substrates, especially polycarbonate, also remains a significant technical hurdle for sustained performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager