Anti Static Air Blowers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442451 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Anti Static Air Blowers Market Size

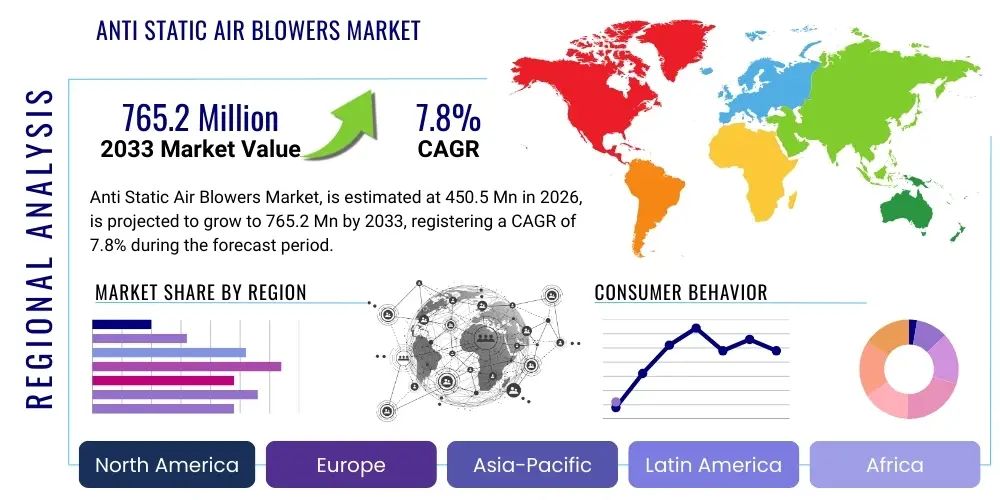

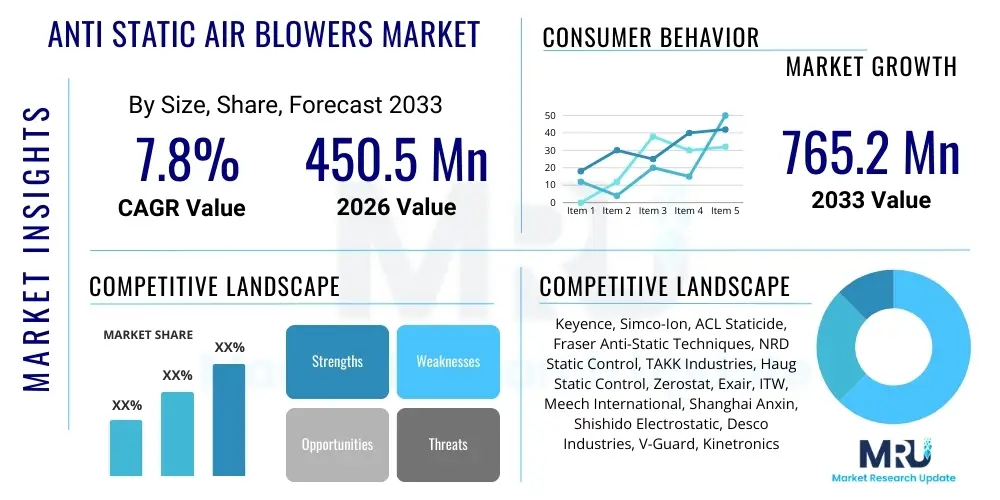

The Anti Static Air Blowers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450.5 million in 2026 and is projected to reach USD 765.2 million by the end of the forecast period in 2033.

Anti Static Air Blowers Market introduction

The Anti Static Air Blowers Market encompasses specialized equipment designed to neutralize static electricity charges on non-conductive materials, products, and equipment, primarily within controlled manufacturing and assembly environments. These devices function by generating a balanced stream of positive and negative ions, which are then carried via forced air across a target surface or area, effectively discharging accumulated static potential. This process is crucial in sectors where electrostatic discharge (ESD) or particulate attraction caused by static charges can lead to catastrophic component failure, product contamination, or operational hazards.

Anti Static Air Blowers, commonly known as ionizing air blowers or static eliminators, are indispensable tools in industries requiring stringent ESD control. Their core function is to maintain product integrity and ensure manufacturing efficiency by preventing damages inherent in static-sensitive operations, such as microchip handling, precision assembly, and coating processes. The product portfolio includes various designs, such as benchtop units for localized workstation protection, overhead ionizers for broader area coverage in cleanrooms, and ionizing air guns for targeted spot cleaning and neutralization, catering to diverse operational scales and environmental requirements.

The market is predominantly driven by the relentless miniaturization trend within the semiconductor and electronics industries, where smaller component geometries increase susceptibility to ESD damage. Furthermore, the expansion of regulated environments, particularly in pharmaceutical manufacturing (to prevent dust attraction and cross-contamination) and in advanced manufacturing like electric vehicle (EV) battery production, necessitates advanced static control measures. Key benefits derived from the adoption of these blowers include improved product yield rates, reduced rework and scrap costs, enhanced operator safety, and compliance with international quality standards like ANSI/ESD S20.20, thereby cementing their position as critical capital equipment.

Anti Static Air Blowers Market Executive Summary

The Anti Static Air Blowers Market demonstrates robust growth propelled by significant technological advancements in ionization efficiency and integration capabilities. Business trends highlight a strong shift towards intelligent ionizers equipped with real-time monitoring and feedback systems, addressing the stringent quality requirements of high-volume manufacturing sectors. Manufacturers are focusing on developing compact, high-performance blowers with faster discharge times to meet the demands of automated production lines and smaller footprint cleanrooms. Mergers and acquisitions, alongside strategic partnerships, are concentrated in strengthening distribution networks and expanding product portfolios to cover niche applications, particularly in advanced material handling and specialized medical device manufacturing.

Regionally, the Asia Pacific (APAC) region dominates the market share due to the concentration of global semiconductor foundries, electronics assembly hubs, and robust investment in consumer electronics manufacturing across countries like China, Taiwan, South Korea, and Japan. North America and Europe, while mature, exhibit high growth rates in the adoption of premium, fully automated ionizers driven by strict regulatory standards and high labor costs necessitating automated ESD solutions. Emerging markets in Latin America and the Middle East & Africa are displaying accelerating growth, primarily supported by increasing foreign direct investment in localized assembly and automotive production facilities that require basic to intermediate static control measures.

Segment trends reveal that the Benchtop Ionizers segment maintains the largest market share due to their widespread utility in individual workstations and repair facilities, offering a highly localized and cost-effective solution. However, the Overhead Ionizers segment is anticipated to witness the fastest growth, largely driven by the increasing construction and expansion of large-scale, high-classification cleanroom facilities in the semiconductor and pharmaceutical sectors. In terms of end-use, the Semiconductor & Electronics sector remains the primary revenue generator, although the Pharmaceutical & Medical Devices segment is quickly expanding its adoption of air blowers to maintain sterile environments and prevent contamination during critical handling processes.

AI Impact Analysis on Anti Static Air Blowers Market

Common user questions regarding AI’s impact on the Anti Static Air Blowers Market center around system optimization, predictive maintenance, and data integration with broader cleanroom management systems. Users frequently inquire about how AI can enhance the precision of static neutralization, specifically asking if algorithms can dynamically adjust ion balance and airflow based on real-time environmental factors such as humidity, temperature, and specific process steps being executed. A core concern is the transition from reactive maintenance schedules to predictive models, leveraging AI to forecast component failure or drift in ionization performance before it impacts product yield. Furthermore, there is strong expectation for AI-driven analytics to correlate ionization performance data directly with ESD event logs and production quality metrics, providing actionable insights for process improvement and validation documentation.

- AI enables predictive maintenance by analyzing sensor data (ion levels, fan speed, airflow) to anticipate component degradation and schedule proactive servicing, minimizing downtime.

- Integration of machine learning algorithms allows for dynamic optimization of ion balance and discharge rates based on real-time environmental condition changes, improving neutralization efficiency.

- AI facilitates enhanced quality control by correlating static elimination performance data directly with manufacturing yield rates, identifying weak points in the ESD control chain.

- Implementation of smart diagnostics and remote monitoring powered by AI reduces the need for manual checks, lowering operational costs and ensuring continuous compliance in automated facilities.

- AI systems can analyze large datasets from multiple ionizers across a facility, optimizing the configuration and placement of blowers for comprehensive static coverage in complex layouts.

DRO & Impact Forces Of Anti Static Air Blowers Market

The dynamics of the Anti Static Air Blowers Market are significantly shaped by strong underlying drivers, tempered by specific market restraints, while offering substantial avenues for future growth through strategic opportunities. The primary market driver is the critical need for electrostatic discharge (ESD) control in advanced manufacturing, particularly given the extremely high sensitivity of modern electronic components to static damage. This demand is reinforced by mandatory industry standards and regulatory compliance requirements, especially in high-reliability sectors such as aerospace and medical device production, where product failure carries severe consequences. Concurrently, the increasing adoption of highly automated production lines requires reliable, non-contact static neutralization methods that seamlessly integrate with robotic systems, further boosting the demand for advanced ionizers.

However, the market faces restraints, chiefly concerning the relatively high initial capital expenditure required for sophisticated ionizing systems, particularly for large overhead installations in expansive cleanrooms. Furthermore, the operational challenge of maintaining these devices acts as a restraint; ionizers require periodic cleaning of emitter points and recalibration to ensure optimal ion balance and discharge effectiveness, adding to operational overheads. The market also contends with the existence of alternative static control solutions, such as topical anti-static sprays, conductive flooring, and specialized wrist straps, which, while less effective in neutralizing airborne static fields, can be perceived as lower-cost alternatives in less critical applications.

Opportunities for market expansion are abundant, particularly through technological convergence, such as the integration of Internet of Things (IoT) capabilities for centralized monitoring and control, moving the industry towards 'Smart ESD' systems. The rapid growth of emerging manufacturing sectors, including the production of advanced composite materials, electric vehicle batteries, and flexible displays, presents new, large-scale applications for anti-static blowers. These factors exert significant impact forces, dictating that market participants must continuously innovate towards efficiency and connectivity while navigating the rigorous compliance environment and the competitive landscape defined by technological differentiation and service reliability.

Segmentation Analysis

The Anti Static Air Blowers Market segmentation provides a granular view of product utilization and market penetration across various industrial requirements, categorized primarily by Product Type and End-Use Industry. Analyzing these segments is crucial for understanding specific growth vectors, identifying high-potential market niches, and tailoring product development strategies. The distinctions in product type reflect variations in coverage area, portability, and installation methods, ranging from localized protection at a single bench to wide-area coverage across massive production floors. The end-use segmentation demonstrates the critical reliance of technologically advanced and highly regulated industries on effective static control solutions, illustrating distinct demand patterns based on compliance mandates and sensitivity levels.

The segmentation structure highlights the duality of market demand: high-volume, cost-sensitive demands from general electronics assembly requiring robust benchtop units, versus high-specification, compliance-driven demands from semiconductor fabrication and pharmaceutical processing requiring overhead ionizers with precise, verifiable performance characteristics. Geographical segmentation further intersects with these categories, showing that APAC drives demand for both volume and specialized types, while North America and Europe lead in the adoption of IoT-enabled, high-precision overhead systems. This structural analysis guides strategic investments in manufacturing capacity and targeted marketing efforts within the complex global market landscape.

- By Product Type:

- Benchtop Ionizers

- Overhead Ionizers

- Ionizing Air Guns/Nozzles

- Portable Ionizers

- By End-Use Industry:

- Semiconductor & Electronics

- Pharmaceutical & Medical Devices

- Automotive

- Aerospace & Defense

- Industrial Manufacturing (Plastics, Packaging, Optics)

- By Technology:

- AC (Alternating Current) Ionizers

- DC (Direct Current) Ionizers

- Pulsed DC Ionizers

Value Chain Analysis For Anti Static Air Blowers Market

The Value Chain for the Anti Static Air Blowers Market begins with the Upstream Analysis, which focuses on the sourcing and processing of core raw materials and sophisticated components. Key upstream elements include precision electronics for high-voltage power supplies, emitter materials (often tungsten or specialized alloys), fan components for air propulsion, and durable plastics or metals for housing and structural integrity. Critical suppliers in this stage include specialized electronic component manufacturers and material science companies. The quality and stability of these inputs, particularly the high-voltage power components and emitter points, directly influence the performance metrics (e.g., ion balance and discharge time) and lifespan of the final blower product.

The Midstream activities involve the design, manufacturing, and assembly processes, characterized by high-precision engineering and assembly line integration. Manufacturers invest heavily in proprietary ionization technologies (e.g., pulsed DC vs. steady-state DC) and aerodynamic design to optimize airflow and ion distribution uniformity. Quality control and testing—specifically focusing on ion balance verification using charged plate monitors—are paramount during this stage to ensure the devices meet stringent ESD standards like IEC 61340 and ANSI/ESD S20.20. Value addition here is driven by technological differentiation, product miniaturization, and the integration of smart monitoring features.

The Downstream Analysis involves distribution channels and reaching the end-users. Distribution is multifaceted, utilizing both Direct and Indirect channels. Direct sales often handle large-volume orders to major semiconductor fabs or global pharmaceutical companies, offering customized integration services and direct technical support. Indirect channels utilize specialized industrial distributors, ESD control retailers, and regional value-added resellers (VARs) who provide localized sales, maintenance, and training services, particularly important for reaching smaller industrial manufacturing clients and repair facilities. Effective distribution requires a highly technical sales force capable of consulting on optimal ESD control layouts and compliance requirements.

Anti Static Air Blowers Market Potential Customers

The primary End-Users/Buyers of Anti Static Air Blowers are organizations operating within sensitive manufacturing environments where static electricity poses a significant threat to product quality, performance, or operational safety. These customers require highly reliable and verifiable ESD control measures to prevent component failure and yield loss. The Semiconductor & Electronics industry forms the bedrock of demand, encompassing chip manufacturers, PCB assemblers, hard drive producers, and consumer electronics assemblers, all of whom handle components extremely vulnerable to static damage (often below 100V). These buyers prioritize rapid discharge times, excellent ion balance stability, and IoT connectivity for data logging and compliance auditing.

A second major customer group is the Pharmaceutical & Medical Devices sector, including manufacturers of diagnostic equipment, precision implants, and high-purity APIs. For these users, static blowers prevent dust and particulate attraction to products or packaging surfaces, crucial for maintaining sterile conditions and regulatory compliance (e.g., FDA requirements). Their procurement decisions focus less on speed and more on cleanliness (non-shedding materials) and verifiable ion output that minimizes turbulence, ensuring process stability within cleanroom conditions, typically ISO Class 5 or better. These buyers often require overhead units integrated into ceiling grids.

Further potential customers are found in Automotive manufacturing, particularly in the expanding electric vehicle (EV) battery and electronics control unit (ECU) production lines, and in the Aerospace & Defense industry, where zero-tolerance for failure in critical systems mandates the highest standards of static control. These buyers require robust, high-durability ionizers suitable for industrial environments, often procured through large-scale capital equipment purchasing cycles that favor established global suppliers who can provide extensive support and validation documentation across multiple manufacturing sites globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 765.2 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Keyence, Simco-Ion, ACL Staticide, Fraser Anti-Static Techniques, NRD Static Control, TAKK Industries, Haug Static Control, Zerostat, Exair, ITW, Meech International, Shanghai Anxin, Shishido Electrostatic, Desco Industries, V-Guard, Kinetronics, Alpha Systems, Static Clean International, Ion Industrial, TDK. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Anti Static Air Blowers Market Key Technology Landscape

The technological landscape of the Anti Static Air Blowers Market is defined by continuous innovation aimed at achieving higher ion balance accuracy, faster discharge times, and enhanced energy efficiency. The core technologies utilized are centered around ionization methods, predominantly categorized into Alternating Current (AC), Direct Current (DC), and Pulsed DC systems. AC ionizers utilize a single electrode to generate both positive and negative ions as the voltage alternates, offering a cost-effective solution but often resulting in slower neutralization speeds and less optimal ion balance. DC systems, conversely, use separate electrodes for positive and negative ions, providing faster discharge and superior ion balance, which is critical for highly sensitive semiconductor processes, though they require more complex high-voltage power supplies and monitoring.

The most advanced technology currently gaining traction is Pulsed DC (PDC) ionization, which applies high voltage to the emitter pins in short, controlled bursts or pulses. This method allows the ions to be generated at lower current levels, extending emitter life and significantly improving the efficiency of static neutralization over large areas, making them the preferred choice for sophisticated overhead ionizers in expansive cleanrooms. PDC systems minimize the phenomenon of ion recombination and can achieve exceptionally stable ion balance, often measurable within ±5 volts, meeting the most rigorous industry standards. Furthermore, recent technological integration focuses on incorporating closed-loop feedback mechanisms, where sensors continuously monitor the static potential and automatically adjust the blower's output to maintain the target neutralization level.

Beyond the core ionization methodology, the market is leveraging smart technologies, including microprocessors and IoT connectivity, to transform traditional blowers into smart static management tools. These integrated solutions allow for remote configuration, performance logging, and centralized data reporting, which is essential for compliance documentation and predictive maintenance protocols. Fan technology is also evolving, moving towards highly efficient, low-turbulence fans to minimize particulate generation—a mandatory feature for ISO Class 1 to Class 3 cleanroom applications. The continuous drive toward miniaturization of these ionizing systems, while maintaining high output, is allowing for easier integration into robotic cells and tight assembly workstations, further defining the competitive edge in the key technology landscape.

Regional Highlights

The Anti Static Air Blowers Market exhibits significant regional disparities in terms of maturity, adoption rate, and technological preference, primarily dictated by the local concentration of high-tech manufacturing and regional regulatory frameworks concerning ESD control. Asia Pacific (APAC) stands out as the global manufacturing powerhouse, driving both volume and innovation. North America and Europe are characterized by mature markets emphasizing high-specification, technologically advanced products tailored for stringent quality control and automation.

North America maintains a strong position, particularly due to the presence of large aerospace, defense, and advanced semiconductor research facilities. Demand here is focused on high-performance, verifiable ionization systems (predominantly Pulsed DC and networked IoT-enabled units) that integrate seamlessly into highly automated cleanrooms. The regulatory environment and high labor costs necessitate investment in reliable, low-maintenance equipment, driving preference for premium solutions. The United States, in particular, leads in the adoption of anti static blowers in medical device manufacturing due to strict FDA requirements for contamination control.

Europe represents a technologically sophisticated market, characterized by stringent environmental and safety regulations. The market here is driven by the robust automotive electronics sector (especially electric vehicle components) and high-end pharmaceutical manufacturing in countries like Germany, Switzerland, and Ireland. European users place a high value on energy efficiency, long-term reliability, and compliance documentation. The adoption curve for sophisticated, monitored overhead ionizers is steep, supporting growth for manufacturers offering integrated control systems that link static elimination data with overall factory automation platforms.

Asia Pacific (APAC) is the largest and fastest-growing region, dominated by manufacturing hubs in China, South Korea, Taiwan, and Japan. This region dictates global pricing and volume demands. The enormous scale of semiconductor fabrication (e.g., TSMC, Samsung) and consumer electronics assembly requires vast numbers of anti static air blowers. While cost remains a factor for general assembly, the demand for high-end, ultra-stable ionizers in advanced wafer fabrication facilities is exceptionally high, pushing regional manufacturers to rapidly close the technological gap with Western counterparts, leading to intense competition and rapid product cycles.

Latin America and the Middle East & Africa (MEA) represent emerging markets characterized by moderate but accelerating growth. Demand in Latin America is primarily tied to automotive assembly, localized electronics manufacturing, and packaging industries. These regions often favor reliable, entry-to-mid-level benchtop ionizers for localized protection. Growth in the MEA region is buoyed by investments in industrial diversification, including nascent technology parks and pharmaceutical facilities, particularly in the Gulf Cooperation Council (GCC) countries, requiring foundational static control measures as these industries scale up their complex manufacturing processes.

- Asia Pacific (APAC): Dominates the market, driven by high-volume semiconductor fabrication and consumer electronics assembly in China, Taiwan, and South Korea, leading the growth of both volume and specialized ionizers.

- North America: Focuses on high-reliability applications in Aerospace, Defense, and advanced Medical Device manufacturing, demanding premium, IoT-enabled Pulsed DC systems.

- Europe: Characterized by stringent quality control in Automotive electronics (EV) and Pharmaceuticals, driving the adoption of energy-efficient and highly documented integrated ionizer systems.

- Latin America: Emerging market focused on automotive manufacturing and localized industrial assembly, with increasing demand for reliable, mid-range benchtop static blowers.

- Middle East & Africa (MEA): Growth influenced by industrial diversification and expansion of localized pharmaceutical and technology infrastructure, favoring foundational ESD control equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Anti Static Air Blowers Market.- Keyence

- Simco-Ion (A division of ITW)

- ACL Staticide

- Fraser Anti-Static Techniques

- NRD Static Control

- TAKK Industries

- Haug Static Control

- Zerostat

- Exair

- ITW (Illinois Tool Works)

- Meech International

- Shanghai Anxin Static Control

- Shishido Electrostatic

- Desco Industries

- V-Guard (A brand offering static solutions)

- Kinetronics

- Alpha Systems

- Static Clean International

- Ion Industrial

- TDK

Frequently Asked Questions

Analyze common user questions about the Anti Static Air Blowers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an Anti Static Air Blower and where are they essential?

The primary function is to neutralize electrostatic charges on materials and surfaces by emitting a balanced stream of positive and negative ions via forced air. They are essential in ESD-sensitive environments, particularly semiconductor fabrication, electronics assembly, and pharmaceutical cleanrooms, to prevent component damage and particle attraction.

What is the difference between AC, DC, and Pulsed DC ionization technologies?

AC ionizers use one emitter for alternating positive/negative ions, offering simple, cost-effective static control. DC ionizers use separate emitters for consistent positive and negative output, providing faster discharge. Pulsed DC (PDC) systems pulse the ion output, achieving the fastest discharge and best ion balance stability over large distances, making them optimal for advanced cleanrooms.

How frequently do Anti Static Air Blowers require maintenance and calibration?

Anti Static Air Blowers typically require maintenance—cleaning the emitter points—weekly or monthly depending on the environment’s cleanliness level, and mandatory annual or semi-annual calibration using a charged plate monitor (CPM) to verify ion balance (offset voltage) and discharge time compliance with ESD standards.

Which end-use industry segment exhibits the highest growth potential for Anti Static Air Blowers?

While the Semiconductor & Electronics segment is the largest revenue driver, the Pharmaceutical & Medical Devices segment, followed closely by advanced Automotive (EV battery manufacturing), exhibits the fastest growth potential due to increasing regulatory stringency regarding particle contamination and the expanding global investment in certified cleanroom facilities.

How is IoT and AI influencing the performance of static control blowers?

IoT enables centralized monitoring, remote configuration, and data logging of multiple blowers across a facility, ensuring continuous compliance. AI integration is leading to predictive maintenance scheduling and dynamic adjustments of ion output based on real-time environmental data (humidity, temperature), optimizing neutralization efficiency and reducing manual oversight.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager