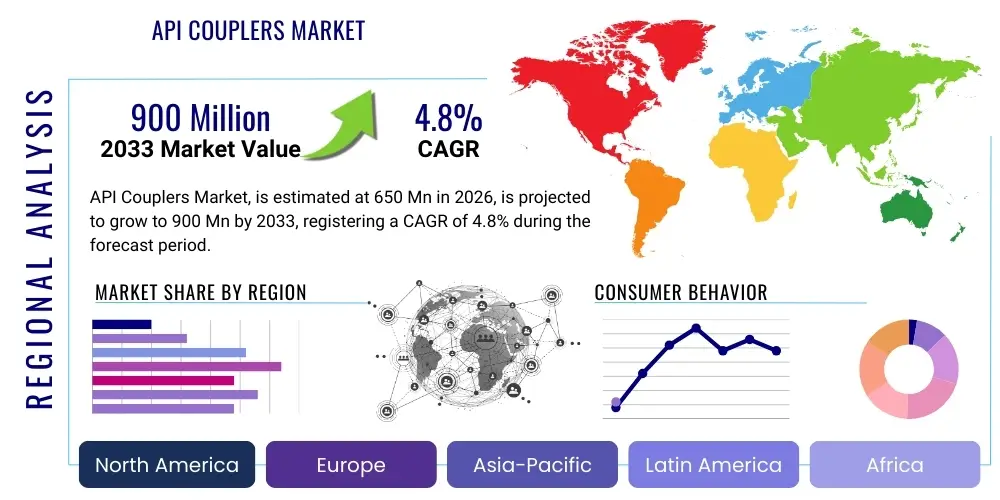

API Couplers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442938 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

API Couplers Market Size

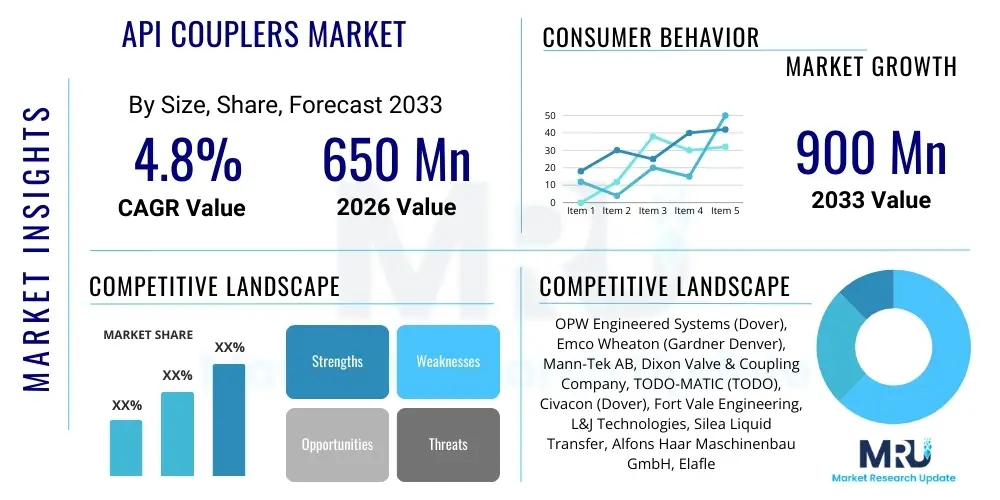

The API Couplers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 900 Million by the end of the forecast period in 2033.

API Couplers Market introduction

The API Couplers Market encompasses the specialized equipment designed for the safe, efficient, and standardized transfer of petroleum products and other hazardous liquids, primarily utilizing connection systems compliant with API Recommended Practice 1004. These couplers are crucial components in the bulk liquid transfer infrastructure, serving as the interface between transport vehicles (tank trucks, railcars) and fixed storage terminals or dispensing systems. Their primary function is to minimize spills, prevent product cross-contamination, and ensure operator safety during loading and unloading operations, which are often characterized by high flow rates and flammable materials.

API Couplers are precision-engineered devices that feature dry-break technology, meaning they minimize fluid loss upon disconnection, a critical requirement for both environmental compliance and economic efficiency in the petroleum industry. Key applications span across petroleum distribution networks, including fuel terminals, refineries, bulk storage depots, and specialized chemical transport logistics. The rigorous standards set by organizations like the American Petroleum Institute (API) drive continuous innovation in design, focusing on material compatibility, ergonomic operation, and enhanced sealing mechanisms to handle diverse hydrocarbon types from gasoline and diesel to aviation fuels.

The core benefits derived from the widespread adoption of API Couplers include significantly reduced environmental risk due to minimized spillage, improved operational speed and turnaround times at loading racks, and compliance with increasingly stringent global safety and occupational health regulations. Market growth is principally driven by large-scale infrastructure investments in emerging economies, the mandatory replacement of outdated transfer systems in mature markets, and the persistent regulatory pressure emphasizing spill prevention and emissions control across the entire fuel supply chain.

API Couplers Market Executive Summary

The global API Couplers Market is experiencing robust growth driven by mandatory safety upgrades and the expansion of oil and gas distribution infrastructure, particularly in the Asia Pacific region. Current business trends indicate a strong move toward lightweight materials, such as specialized aluminum alloys, and the integration of advanced safety features, including optical sensing and pneumatic interlocks, to ensure foolproof connection sequences. Manufacturers are focusing on standardizing components to simplify maintenance while also addressing niche requirements related to handling biofuels and specialized chemical agents, which demand higher levels of chemical compatibility and corrosion resistance.

Regionally, North America and Europe continue to dominate in terms of technology adoption and the enforcement of the highest safety standards, necessitating frequent upgrades to comply with environmental laws (e.g., ATEX directives in Europe). However, the most significant growth impetus originates from the Asia Pacific region, fueled by rapid industrialization, massive investments in refinery capacity, and the development of modern logistics networks in countries like China, India, and Southeast Asian nations. Latin America and the Middle East also present substantial opportunities as they modernize their oil infrastructure to support increasing domestic consumption and export activities.

Segmentation analysis highlights the dominance of bottom-loading couplers due to their inherent safety advantages over traditional top-loading methods, minimizing static electricity build-up and reducing vapor emissions. Furthermore, the stainless steel segment is projected to exhibit a higher CAGR, driven by demand from chemical and corrosive fluid transfer applications where standard aluminum couplers are insufficient. The operational efficiency gains offered by modern API couplers, coupled with the regulatory mandate for dry-break capabilities, solidify the market's trajectory toward consistent expansion over the forecast period.

AI Impact Analysis on API Couplers Market

Users frequently inquire about how Artificial Intelligence (AI) and associated technologies like IoT and predictive maintenance systems affect physical components such as API couplers. Common user questions revolve around optimizing the maintenance schedules for these critical components, determining the remaining useful life of sealing mechanisms, and improving the overall safety protocols at loading terminals using intelligent monitoring. The key themes summarized from user concerns focus on leveraging AI not for the direct design of the coupler itself, but for managing the infrastructure in which the coupler operates. Users expect AI to reduce operational downtime, predict catastrophic failures related to worn seals or improper connections, and automate compliance reporting by tracking usage cycles and maintenance logs associated with each coupling unit.

The primary influence of AI in the API Couplers domain is the enhancement of predictive maintenance strategies. By integrating sensors (pressure, temperature, flow rate, vibration) into the surrounding transfer system or even the coupler assembly itself, AI algorithms can analyze real-time operational data to identify subtle deviations indicative of potential wear or imminent failure. This shift from time-based or reactive maintenance to condition-based maintenance significantly improves safety margins, extends component lifespan, and optimizes inventory management for spare parts, directly influencing the total cost of ownership for terminal operators.

Furthermore, AI plays a pivotal role in optimizing logistics and loading rack utilization. Machine learning models analyze throughput data, weather conditions, and scheduling information to optimize the sequencing of tank truck movements, minimizing idle time and maximizing terminal efficiency. While the physical coupler remains a mechanical standard, the intelligent management system surrounding it, powered by AI, ensures that the coupler is utilized optimally and safely, thereby boosting terminal productivity and maintaining rigorous environmental and safety standards compliance.

- Implementation of predictive analytics models to forecast seal degradation and required maintenance intervals for couplers.

- Integration of IoT sensors within loading systems to monitor connection integrity and operational parameters in real-time, feeding data to AI platforms.

- Optimization of loading rack scheduling and throughput efficiency using machine learning algorithms based on historical coupling cycles.

- Automated anomaly detection in coupling sequences, alerting operators to potential human error or mechanical malfunction before spills occur.

- Enhanced inventory management for spare parts (seals, locking mechanisms) driven by AI forecasts of component usage and failure rates.

DRO & Impact Forces Of API Couplers Market

The API Couplers Market landscape is shaped by a powerful confluence of stringent regulatory mandates (Drivers), technological complexity and high initial investment costs (Restraints), and emerging opportunities in new energy transfer systems (Opportunities). The overarching impact force is the non-negotiable requirement for operational safety and environmental protection in the handling of volatile and hazardous substances. This force necessitates continuous investment in high-quality, certified dry-break coupling technology, driving market stability and demanding compliance from all industry participants.

Key market drivers include global harmonization efforts favoring API 1004 standards, large-scale infrastructure replacement cycles in mature economies, and regulatory pressure from environmental agencies (like the EPA and EU directives) to minimize Volatile Organic Compound (VOC) emissions during loading and unloading. Conversely, significant restraints involve the high initial capital outlay required for adopting new bottom-loading systems compared to legacy top-loading methods, resistance to change in established distribution networks, and the prevalence of lower-cost, non-certified alternatives in developing regions, which pose safety risks and dilute market quality.

Opportunities for market expansion are substantial, particularly in the development of smart couplers equipped with RFID for asset tracking, integrated sensors for connection verification, and specialized variants for emerging fuels like liquid hydrogen, renewable diesel, and Sustainable Aviation Fuel (SAF). The demand for couplers designed to handle the corrosive properties and specific temperature requirements of these next-generation fuels presents a lucrative avenue for specialized manufacturers, ensuring long-term technological relevance for the market sector.

Segmentation Analysis

The API Couplers Market is highly diversified, segmented primarily by type, material, application, and size, reflecting the varied operational environments and fluid characteristics encountered across the petroleum and chemical logistics sectors. Understanding these segments is critical for manufacturers aiming to align their product development strategies with specific end-user requirements concerning fluid compatibility, pressure ratings, and operational longevity. The dominance of bottom-loading systems emphasizes the industry's shift towards inherently safer and more efficient bulk transfer protocols, reducing worker exposure and environmental contamination risks.

Material segmentation reveals a critical division based on corrosion resistance and weight. Aluminum couplers are the industry standard for light petroleum products like gasoline and diesel due to their excellent balance of light weight and durability, which minimizes operator strain during frequent connections. Conversely, stainless steel and specialized alloy couplers cater to more aggressive applications, including aviation fuels, certain chemicals, and high-purity applications, where superior chemical resistance and structural integrity against corrosive media are paramount.

Application analysis segments demand based on the transfer point: refineries, bulk storage terminals, and transport vehicles (tank trucks and railcars). The terminal and depot segment represents the largest market share due to the high volume of installed loading bays and the continuous need for robust, high-throughput systems. Furthermore, size segmentation (e.g., 3-inch and 4-inch) reflects standard flow capacity requirements, where 4-inch couplers dominate high-volume loading operations, ensuring rapid turnaround times for transport logistics providers.

- By Type:

- Standard Couplers (API 1004)

- Emergency Breakaway Couplers

- High-Flow Couplers

- Dry-Break Couplers

- By Material:

- Aluminum (Standard)

- Stainless Steel (Corrosion Resistant)

- Specialized Alloys

- By Application:

- Fuel Terminals and Depots

- Tank Trucks and Road Tankers

- Rail Tank Cars

- Refineries and Chemical Plants

- Military and Aviation Fueling

- By Size:

- 3-inch Couplers

- 4-inch Couplers

- Other Sizes (e.g., specialized smaller couplings)

Value Chain Analysis For API Couplers Market

The value chain for the API Couplers Market begins with the upstream sourcing of high-grade raw materials, primarily specialized aluminum billets, stainless steel alloys (304 and 316), and precision components like specialized polymer seals and gaskets. Manufacturers rely on established, certified suppliers to ensure the metallurgy meets stringent standards required for handling hazardous, pressurized fluids. Critical upstream activities involve specialized casting, forging, and CNC machining processes that determine the dimensional accuracy and structural integrity of the coupler body, which is foundational to its dry-break functionality and long-term reliability.

Midstream activities center on precision manufacturing, assembly, and rigorous testing. This phase involves assembling intricate internal mechanisms, installing sophisticated sealing systems, and performing hydrostatic and functional testing to comply with API and international safety standards. Intellectual property often resides in the patented internal valve designs and locking mechanisms that prevent accidental decoupling under pressure. Distribution channels are highly specialized; direct sales often target large refinery operators and major logistics companies that require technical support and customized loading rack solutions, while indirect channels utilize specialized industrial distributors and regional agents who provide local inventory and maintenance services to smaller fleets and independent terminals.

Downstream activities involve the final installation and integration of the couplers into loading rack infrastructure, fleet maintenance, and aftermarket services. Potential customers, such as major oil companies and bulk chemical distributors, prioritize reliability and rapid access to spare parts, making the quality of the service network a critical differentiator. The efficiency of the distribution channel—whether direct through specialized engineering firms or indirect via dedicated fluid handling distributors—is crucial for minimizing downtime associated with maintenance or mandatory safety upgrades across global fuel networks.

API Couplers Market Potential Customers

The primary consumers and end-users of API couplers are organizations heavily involved in the storage, transportation, and distribution of refined petroleum products, specialized chemicals, and petrochemical feedstocks. These entities require equipment that guarantees compliance with severe safety regulations while maximizing operational throughput at high-volume transfer points. This demanding operational environment defines the need for durable, certified, and technologically advanced coupling solutions.

Key potential customers include integrated oil and gas majors (e.g., ExxonMobil, Shell), independent refinery operators, and large-scale bulk fuel storage and distribution companies that own and operate extensive networks of fuel terminals and loading racks globally. Furthermore, independent logistics providers specializing in hazardous materials transport, who operate large fleets of tank trucks and railcars, constitute a significant portion of the market, driven by the need to equip their fleets with standardized, reliable components to interface seamlessly with various terminal infrastructures.

Niche customer segments include military logistics commands, which require robust and often custom-designed couplers for rapid field fueling operations, and aviation fuel suppliers, who adhere to exceptionally high standards of cleanliness and material compatibility to prevent fuel contamination. The procurement decisions in these customer segments are driven predominantly by safety certifications, total cost of ownership (TCO) factoring in minimal maintenance, and adherence to specific national and international standards (e.g., ATEX, US DOT, API).

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 900 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | OPW Engineered Systems (Dover), Emco Wheaton (Gardner Denver), Mann-Tek AB, Dixon Valve & Coupling Company, TODO-MATIC (TODO), Civacon (Dover), Fort Vale Engineering, L&J Technologies, Silea Liquid Transfer, Alfons Haar Maschinenbau GmbH, Elaflex Hiby GmbH, Kanon Loading Equipment, Willcox & Gibbs, Gutteling B.V., Liquip International, Betts Industries, J&M Tankers, Wiese Systems, Sure Seal Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

API Couplers Market Key Technology Landscape

The API Couplers Market relies heavily on precision fluid dynamics and mechanical engineering to achieve safe and efficient dry-break connections. The central technological focus is the development of robust sealing technologies, such as advanced polymer and PTFE materials, that can maintain integrity under high pressure and temperature variations while remaining chemically inert to aggressive fuels and additives. Furthermore, the incorporation of dual-sealing systems and shear-pin mechanisms is standard practice to prevent leaks during connection and accidental disconnection, ensuring adherence to zero-spill mandates. The evolution of materials science, particularly in specialized aluminum casting techniques, is essential for producing lightweight yet high-strength coupler bodies capable of extended operational lifetimes in harsh industrial environments.

A crucial technological advancement driving the current market is the integration of electronic and pneumatic interlocks. These systems ensure that coupling cannot be engaged or disengaged unless pre-defined safety conditions (e.g., zero flow, proper alignment, and grounding) are met. Pneumatic validation systems, often tied into the terminal’s central control unit, confirm positive engagement before allowing fluid transfer to commence. This integration moves the coupler beyond a simple mechanical device into a smart component of a sophisticated safety system, thereby mitigating the risk of human error, which is a leading cause of spills at loading racks.

Future technology focuses on the development of smart couplers incorporating Industrial Internet of Things (IIoT) components. This includes embedding RFID chips for accurate asset management and tracking the maintenance history of individual units, as well as integrating magnetic or optical proximity sensors to provide digital confirmation of the fully closed and sealed position to the terminal automation system. These innovations enhance accountability, streamline regulatory compliance reporting, and facilitate the implementation of AI-driven predictive maintenance programs, optimizing the operational efficiency and safety performance of the entire fluid transfer network.

Regional Highlights

- North America: North America represents a mature yet technologically leading market for API couplers, characterized by extremely strict safety regulations mandated by organizations such as the EPA, OSHA, and DOT. The demand is driven primarily by infrastructure replacement and upgrades, with a strong focus on adopting sensor-equipped smart couplers and high-flow variants to maximize throughput. Manufacturers here benefit from high certification barriers, ensuring premium product pricing. The shift towards sustainable fuels, particularly ethanol blends and renewable diesel, necessitates material compatibility upgrades in existing coupler fleets, providing sustained aftermarket opportunities.

- Europe: The European market is highly regulated, notably influenced by ATEX directives concerning explosive atmospheres and stringent environmental legislation regarding vapor recovery and spill containment. The region shows strong preference for high-quality, corrosion-resistant stainless steel couplers, especially in chemical logistics. Germany, the UK, and the Netherlands are key markets due to their high concentration of chemical plants and major fuel distribution hubs. Growth is steady, focused heavily on compliance-driven investments and the modernization of older facilities to meet stringent pan-European standards.

- Asia Pacific (APAC): APAC is the fastest-growing region, driven by explosive industrial growth, massive investments in new refinery capacity, and the rapid expansion of fuel distribution networks across China, India, and Southeast Asia. While price sensitivity remains a factor, the increasing awareness of safety and the adoption of international best practices in emerging markets are driving demand for API-compliant couplers. This region provides the greatest opportunity for volume sales, particularly for reliable, cost-effective aluminum couplers suitable for standard petroleum products.

- Middle East and Africa (MEA): This region is crucial due to the concentration of global oil production and export terminals. Demand is robust, linked directly to capital spending on upstream and downstream oil infrastructure projects. Investment cycles focus on large-scale, heavy-duty couplers suitable for high-volume transfer operations at export terminals. Key growth markets include Saudi Arabia, the UAE, and Nigeria, where national oil companies prioritize operational reliability and standardized equipment purchasing.

- Latin America: The market is characterized by fluctuating demand driven by nationalized oil companies and varying regulatory standards across countries. Brazil and Mexico are the largest markets, currently undergoing modernization programs. The focus is on replacing legacy equipment with API 1004 compliant systems to improve safety and reduce cargo loss, often involving significant government-backed infrastructure projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the API Couplers Market.- OPW Engineered Systems (Dover Corporation)

- Emco Wheaton (Gardner Denver)

- Mann-Tek AB

- Dixon Valve & Coupling Company

- TODO-MATIC (TODO)

- Civacon (Dover Corporation)

- Fort Vale Engineering

- L&J Technologies

- Silea Liquid Transfer

- Alfons Haar Maschinenbau GmbH

- Elaflex Hiby GmbH

- Kanon Loading Equipment

- Willcox & Gibbs

- Gutteling B.V.

- Liquip International

- Betts Industries

- J&M Tankers

- Wiese Systems

- Sure Seal Inc.

- Parker Hannifin Corporation

Frequently Asked Questions

Analyze common user questions about the API Couplers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an API Coupler and why is API 1004 compliance critical?

API Couplers are standardized dry-break connection devices used for the safe and spill-free transfer of petroleum liquids between storage terminals and transport vehicles. API Recommended Practice 1004 compliance is critical as it mandates uniform dimensional standards and safety features, ensuring interoperability across different terminals globally and minimizing environmental risk and product loss.

What are the main advantages of bottom loading over traditional top loading systems?

Bottom loading, facilitated by API couplers, significantly enhances safety by minimizing operator exposure to hazardous vapors, reducing static electricity buildup, and decreasing the potential for catastrophic spills. It also improves terminal efficiency by allowing for simultaneous multi-compartment loading and faster truck turnaround times compared to labor-intensive top-loading methods.

How does the material choice (Aluminum vs. Stainless Steel) impact the use of API Couplers?

Aluminum couplers are lightweight and cost-effective, commonly used for standard petroleum products like gasoline and diesel. Stainless steel couplers offer superior chemical resistance and structural integrity, making them necessary for handling corrosive materials, specialized chemicals, and high-purity fluids such as aviation fuel (Jet A) where material contamination must be strictly avoided.

What technological trends are expected to drive innovation in the API Couplers Market?

Key technological advancements include the integration of IoT sensors and RFID for smart asset tracking and predictive maintenance. Manufacturers are focusing on incorporating advanced pneumatic and electronic interlocks to automate safety verification and the development of specialized polymer seals compatible with next-generation biofuels and hydrogen.

Which geographic region exhibits the highest growth potential for API Couplers?

The Asia Pacific (APAC) region is projected to demonstrate the highest growth rate due to extensive investments in new oil and gas infrastructure, rapid expansion of modern logistics networks, and the increasing adoption of international safety and environmental standards across emerging economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager