Automated Print Quality Inspection System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440706 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Automated Print Quality Inspection System Market Size

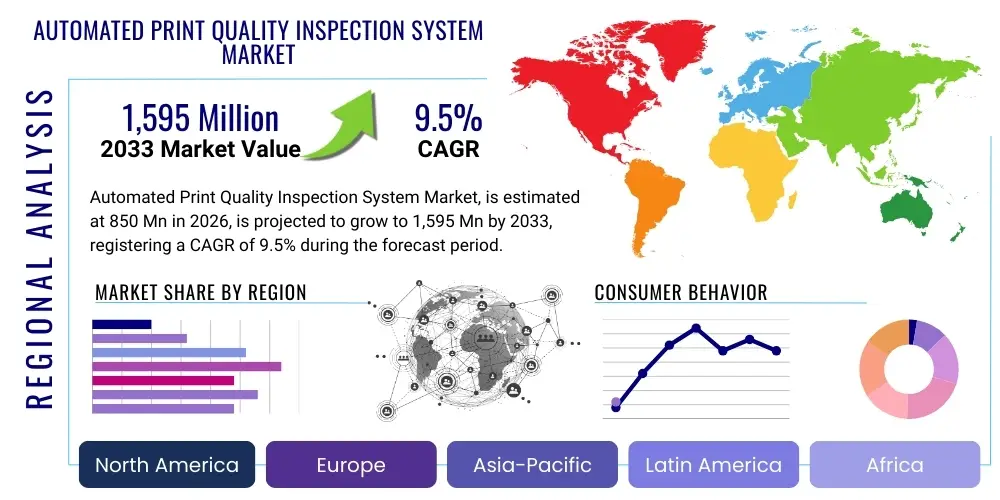

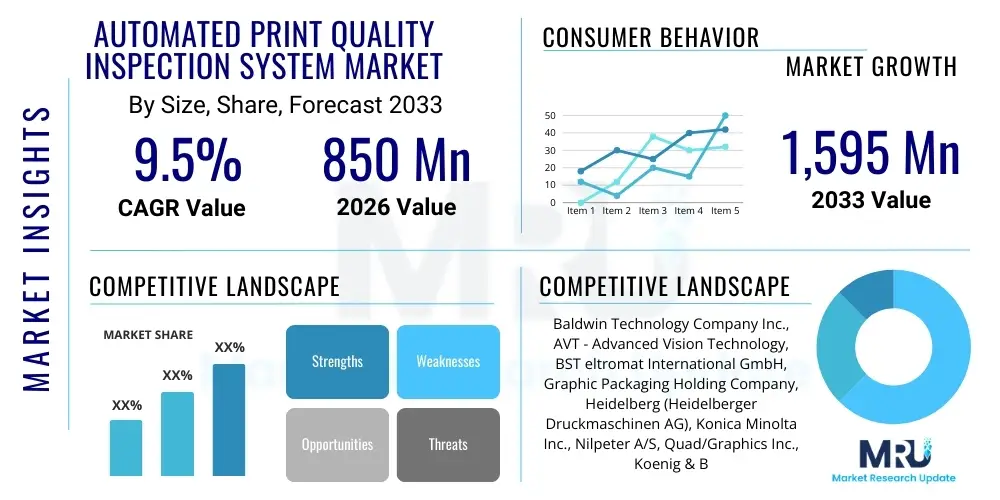

The Automated Print Quality Inspection System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,595 Million by the end of the forecast period in 2033.

Automated Print Quality Inspection System Market introduction

The Automated Print Quality Inspection System Market stands at the forefront of quality assurance within the global printing industry, driven by an escalating demand for flawless products and operational efficiency. These sophisticated systems leverage advanced vision technology, sensors, and often artificial intelligence to detect and analyze defects in printed materials across various stages of production. The primary objective is to identify imperfections such as color variations, misregistration, smudges, streaks, missing elements, and material flaws with unparalleled speed and accuracy, far surpassing the capabilities of manual inspection methods. This crucial technology ensures that printed goods meet stringent quality standards, thereby mitigating waste, reducing costly reprints, and upholding brand reputation across diverse sectors.

A typical Automated Print Quality Inspection System integrates high-resolution cameras, specialized lighting, and robust software algorithms to perform real-time analysis of printed surfaces. These systems are designed to operate at high production speeds, ensuring minimal disruption to manufacturing workflows while providing continuous monitoring. Key product types include inline systems, which are integrated directly into the printing press, and offline systems, used for post-production batch inspection. Their versatility makes them indispensable for industries where print quality is paramount, ranging from intricate pharmaceutical labels to large-scale packaging, commercial publications, and specialized electronic components.

The market is significantly propelled by several key factors. The pervasive trend towards Industry 4.0 and smart manufacturing initiatives drives the adoption of automation across production lines. Furthermore, increasing regulatory requirements for product traceability and quality, particularly in sectors like pharmaceuticals and food packaging, necessitate robust inspection solutions. The rising cost of labor, coupled with the inherent subjectivity and fatigue associated with manual inspection, makes automated systems an economically compelling alternative. Finally, the relentless pursuit of waste reduction and improved material utilization across global industries underscores the critical benefits of these systems, making them essential tools for modern printing and manufacturing operations seeking to maintain competitive edge and achieve sustainability goals.

Automated Print Quality Inspection System Market Executive Summary

The Automated Print Quality Inspection System Market is experiencing dynamic growth, characterized by significant business trends that reflect a broader industry shift towards advanced automation and data-driven quality control. A notable trend is the increasing integration of artificial intelligence and machine learning algorithms, enhancing the precision and predictive capabilities of these systems, moving beyond simple defect detection to anomaly prediction and process optimization. Consolidation among key players, driven by strategic acquisitions and partnerships, is reshaping the competitive landscape, aiming to offer more comprehensive solutions and expand market reach. Furthermore, the market is witnessing a surge in demand for customizable and modular systems that can adapt to diverse printing processes and specific end-user requirements, pushing manufacturers to innovate in flexibility and scalability. The emphasis on user-friendly interfaces and robust data analytics platforms is also a critical business trend, empowering operators with actionable insights for continuous improvement.

Regionally, the market exhibits varied growth trajectories and adoption rates. Asia Pacific (APAC) is projected to be the fastest-growing region, fueled by rapid industrialization, expansion of manufacturing bases, particularly in packaging and electronics, and increasing investments in advanced printing technologies in countries like China, India, and Japan. North America and Europe represent mature markets, characterized by high adoption rates, stringent quality standards, and a strong focus on innovation in AI-powered solutions and IoT integration. These regions often lead in the development and early adoption of cutting-edge inspection technologies. Latin America, the Middle East, and Africa are emerging markets, showing substantial potential due to growing industrial output, increasing awareness of quality control benefits, and developing infrastructure, although adoption rates here are still gaining momentum compared to more developed economies.

Segmentation trends within the Automated Print Quality Inspection System Market highlight specific areas of high growth and technological advancement. The packaging industry, including food & beverage, pharmaceuticals, and consumer goods packaging, remains the dominant application segment, driven by the critical need for defect-free labels and packaging to ensure product safety, regulatory compliance, and brand integrity. The electronics sector is also showing significant growth, particularly for inspecting printed circuit boards (PCBs) and flexible electronics, where microscopic defects can lead to critical failures. From a component perspective, software solutions, especially those incorporating AI/ML for advanced defect classification and predictive maintenance, are gaining considerable traction. Furthermore, there is a clear trend towards inline inspection systems over offline solutions, as real-time feedback and immediate defect correction are becoming increasingly vital for maintaining high production efficiency and reducing waste in high-speed printing environments.

AI Impact Analysis on Automated Print Quality Inspection System Market

User inquiries concerning the impact of AI on the Automated Print Quality Inspection System Market frequently revolve around the tangible benefits AI brings to accuracy, speed, and overall operational intelligence, alongside concerns about implementation complexity and data requirements. Users often ask how AI can reduce false positives, improve defect classification beyond human capability, and contribute to predictive maintenance. There's also significant interest in AI's role in process optimization, understanding how it can learn from defects to suggest improvements in the printing process itself. Concerns typically touch upon the cost of integrating AI, the need for extensive training data, and the availability of skilled personnel to manage and optimize AI-driven systems. Expectations are high for AI to deliver truly autonomous and self-optimizing quality control, fundamentally transforming traditional inspection methodologies.

- Enhanced accuracy and reduced false positives through sophisticated pattern recognition and deep learning algorithms, leading to more reliable defect detection.

- Automated defect classification, allowing systems to precisely categorize flaws (e.g., ink splatter, misregistration, scratches) and prioritize corrective actions.

- Predictive analytics capabilities that can anticipate potential printing errors based on historical data and real-time process parameters, enabling proactive adjustments.

- Real-time process optimization suggestions, where AI learns from defect patterns and recommends adjustments to print settings or machinery for improved output.

- Accelerated inspection speeds without compromising precision, enabling higher throughput and greater efficiency in high-volume production environments.

- Reduced reliance on human intervention for subjective quality judgments, leading to more consistent and objective inspection outcomes.

- Improved data utilization and insights, transforming raw inspection data into actionable intelligence for continuous improvement initiatives.

- Facilitation of adaptive learning, allowing systems to self-improve over time by analyzing new defect types and evolving quality standards.

- Lower operational costs over the long term by minimizing waste, reducing rework, and optimizing material usage through superior defect prevention.

- Development of intelligent, self-calibrating systems that minimize setup times and maintenance requirements.

DRO & Impact Forces Of Automated Print Quality Inspection System Market

The Automated Print Quality Inspection System Market is shaped by a complex interplay of drivers, restraints, opportunities, and external impact forces. Key drivers include the escalating demand for high-quality, defect-free printed products across various industries, necessitated by stringent regulatory standards, brand reputation concerns, and increased consumer expectations. The global shift towards automation and Industry 4.0 paradigms further propels market growth, as manufacturers seek to enhance efficiency, reduce labor costs, and achieve higher throughput. Additionally, the imperative to minimize waste and optimize resource utilization, driven by both economic considerations and sustainability goals, strongly encourages the adoption of automated inspection solutions capable of detecting flaws early in the production cycle. These drivers collectively create a robust foundation for market expansion.

Despite strong growth drivers, the market faces several significant restraints. The high initial capital investment required for automated print quality inspection systems can be a considerable barrier, particularly for small and medium-sized enterprises (SMEs) with limited budgets. The complexity of integrating these advanced systems into existing legacy production lines also presents technical challenges, demanding specialized expertise and potentially leading to downtime during implementation. Furthermore, a shortage of skilled personnel capable of operating, maintaining, and troubleshooting these sophisticated vision systems can hinder widespread adoption. Data management and cybersecurity concerns related to the vast amounts of data generated by these systems, especially in cloud-connected environments, also pose challenges that need to be addressed by manufacturers and end-users alike.

Opportunities within the market are abundant and promising. The ongoing technological advancements, particularly in artificial intelligence, machine learning, and high-resolution imaging, continue to unlock new capabilities and improve the performance of inspection systems, creating avenues for innovative product development. Emerging economies, especially in Asia Pacific, Latin America, and Africa, represent untapped markets with rapidly industrializing sectors and growing adoption of advanced manufacturing techniques, offering significant growth potential. The increasing demand for customized and flexible inspection solutions tailored to specific niche applications, such as security printing or specialized electronics, also provides avenues for market players to differentiate and expand their offerings. Moreover, the convergence of print inspection with broader smart factory ecosystems, leveraging IoT for predictive maintenance and real-time process control, offers substantial opportunities for integrated solutions.

Impact forces influencing the market are multifaceted. Technological advancements, particularly in sensor technology, AI algorithms, and data processing capabilities, directly influence system performance, cost-effectiveness, and new application development. Economic factors, such as global GDP growth, industrial output trends, and investment in manufacturing infrastructure, dictate the overall demand for automation solutions. The competitive landscape, characterized by both established global players and innovative startups, drives continuous innovation and pricing strategies. Regulatory and compliance frameworks, especially those pertaining to product quality, safety, and traceability in industries like pharmaceuticals, food & beverage, and automotive, significantly shape the requirements and adoption rates of inspection systems, making adherence to these standards a critical market influence.

Segmentation Analysis

The Automated Print Quality Inspection System Market is broadly segmented based on several key parameters, each reflecting distinct technological approaches, application needs, and end-user industries. This segmentation provides a granular view of the market dynamics, helping to understand specific growth pockets and competitive landscapes within different niches. The primary segmentation criteria typically include component type, system type, application, and end-use industry, offering a comprehensive overview of where demand is concentrated and how technological solutions are tailored to meet diverse industrial requirements. Analyzing these segments is crucial for stakeholders to identify strategic investment areas and adapt product development to evolving market needs.

- By Component

- Hardware (Cameras, Sensors, Lighting, Processors, Frame Grabbers)

- Software (AI/ML Algorithms, Image Processing Software, Control Software, Reporting & Analytics)

- Services (Installation, Maintenance, Training, Technical Support)

- By System Type

- Inline/Online Systems (Integrated into the production line for real-time inspection)

- Offline Systems (Used for batch inspection post-production)

- By Application

- Packaging (Flexible Packaging, Rigid Packaging, Cartons, Bags)

- Labels (Pharmaceutical Labels, Food & Beverage Labels, Industrial Labels, Security Labels)

- Commercial Printing (Magazines, Books, Brochures, Posters)

- Security Printing (Banknotes, Passports, Tickets, ID Cards)

- Textile Printing

- Electronics Printing (PCBs, Flexible Electronics, Displays)

- Decorative Printing

- Others (e.g., Pharmaceutical Blisters, Metal Decoration)

- By End-Use Industry

- Food & Beverage

- Pharmaceutical & Healthcare

- Consumer Goods

- Automotive

- Electronics & Semiconductors

- Textile

- Print Shops & Commercial Printers

- Industrial Manufacturing

- Others

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Automated Print Quality Inspection System Market

The value chain for the Automated Print Quality Inspection System Market is a complex ecosystem, starting with upstream suppliers and extending through manufacturers, integrators, and distribution channels to the ultimate end-users. The upstream segment is critical, involving providers of specialized components that form the core of these advanced systems. This includes manufacturers of high-resolution industrial cameras, advanced optical lenses, sophisticated sensors (e.g., hyperspectral, multispectral), powerful processors and computing units, and frame grabbers that convert analog signals to digital data. Additionally, software developers providing image processing algorithms, AI/ML frameworks, and user interface platforms constitute a vital part of the upstream supply, ensuring the intelligence and functionality of the inspection systems. Strong partnerships and reliable supply chains at this stage are crucial for the quality and innovation of the final product.

The midstream of the value chain involves the design, manufacturing, and assembly of the complete automated inspection systems by market players. These manufacturers integrate the various hardware and software components, develop proprietary inspection algorithms, and engineer the mechanical structures required for inline or offline operation. This phase includes extensive research and development to incorporate cutting-edge technologies like deep learning, advanced optics, and real-time data processing capabilities. Furthermore, system integrators play a significant role here, often customizing standard systems to meet the unique requirements of specific client applications or integrating the inspection systems seamlessly into existing complex production lines. Their expertise ensures that the solution is optimized for the client's specific printing process and environmental conditions, adding significant value.

Downstream activities focus on the distribution, sales, and post-sales support, directly interacting with the end-users. Distribution channels can be both direct and indirect. Direct sales involve manufacturers selling directly to large enterprises or key accounts, often with dedicated sales teams providing extensive technical consultation and custom solutions. This approach allows for closer relationships with clients and a deeper understanding of their specific needs. Indirect channels involve a network of distributors, resellers, and value-added partners who market and sell the systems, particularly to SMEs or in regions where the manufacturer does not have a direct presence. These partners often provide local support, installation, and training services, extending the manufacturer's reach. Post-sales support, including maintenance contracts, software updates, and technical assistance, is a critical component of the downstream value chain, ensuring system longevity, optimal performance, and high customer satisfaction, thereby reinforcing brand loyalty and driving repeat business.

Automated Print Quality Inspection System Market Potential Customers

The potential customers for Automated Print Quality Inspection Systems span a broad spectrum of industries where print quality, precision, and defect-free output are paramount. At the core, any enterprise involved in industrial-scale printing or manufacturing processes that rely on printed components represents a key demographic. This includes commercial printing houses that produce magazines, books, brochures, and marketing materials, where brand image and aesthetic consistency are crucial. Packaging manufacturers, supplying to the food & beverage, pharmaceutical, and consumer goods sectors, are also significant buyers. For these companies, ensuring the integrity of labels, cartons, and flexible packaging is not only about aesthetics but also about product safety, regulatory compliance, and brand protection, making automated inspection indispensable for avoiding costly recalls and maintaining consumer trust.

Beyond traditional printing, the market extends to specialized manufacturing sectors. Electronics manufacturers, for instance, utilize these systems to inspect printed circuit boards (PCBs), flexible electronics, and display components for microscopic defects that could impact device functionality. The automotive industry also increasingly relies on printed elements for dashboards, interior components, and even functional surfaces, requiring rigorous quality checks. Pharmaceutical and healthcare companies, with their extremely strict regulatory environments, are critical end-users, requiring flawless printing on drug packaging, labels, and medical devices to ensure correct dosage information, traceability, and patient safety. Furthermore, companies engaged in security printing, such as those producing banknotes, passports, and high-security documents, represent a niche but highly demanding customer segment, where counterfeit detection and intricate print integrity are non-negotiable requirements, thereby driving significant investment in the most advanced inspection technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,595 Million |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Baldwin Technology Company Inc., AVT - Advanced Vision Technology, BST eltromat International GmbH, Graphic Packaging Holding Company, Heidelberg (Heidelberger Druckmaschinen AG), Konica Minolta Inc., Nilpeter A/S, Quad/Graphics Inc., Koenig & Bauer AG, Bobst Group SA, SCREEN Holdings Co., Ltd., Canon Inc., HP Inc., Fujifilm Holdings Corporation, X-Rite, Incorporated, ISRA VISION AG, Lake Image Systems Ltd., Futec Corporation, MAVIX Inc., Microscan Systems, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Print Quality Inspection System Market Key Technology Landscape

The technological landscape of the Automated Print Quality Inspection System Market is characterized by continuous innovation and the integration of cutting-edge solutions designed to enhance accuracy, speed, and intelligence. At its core, the technology relies heavily on advanced machine vision systems, which include high-resolution industrial cameras (e.g., line scan cameras, area scan cameras) capable of capturing detailed images at high production speeds. These cameras are often paired with specialized lighting techniques, such as strobe lighting, dark-field illumination, or LED arrays, to optimize contrast and highlight specific defects on various substrates. Sophisticated optics and lens systems ensure image clarity and minimal distortion, which are critical for detecting minute imperfections.

Complementing the hardware, powerful image processing software and algorithms form the brain of these systems. These algorithms are designed to analyze captured images in real-time, identify deviations from pre-defined master images or quality parameters, and classify defects. The evolution of artificial intelligence (AI) and machine learning (ML) has profoundly impacted this area, enabling systems to learn from vast datasets of good and bad prints, significantly improving defect classification accuracy and reducing false positives. Deep learning models, in particular, are now being employed for complex pattern recognition, allowing systems to detect subtle flaws that might be missed by traditional rule-based algorithms. This AI integration moves inspection beyond simple comparison to intelligent anomaly detection and even predictive quality control.

Further technological advancements include the incorporation of Internet of Things (IoT) connectivity, enabling seamless integration of inspection systems with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. This connectivity facilitates real-time data exchange, remote monitoring, and comprehensive reporting, supporting Industry 4.0 initiatives. Cloud computing and edge computing are also gaining traction, allowing for scalable data storage, advanced analytics, and distributed processing, which is particularly beneficial for managing large volumes of inspection data. Robotic integration is another emerging trend, especially for offline inspection or handling of materials, enhancing automation and precision in quality control workflows. These combined technologies enable automated print quality inspection systems to deliver unparalleled levels of performance, efficiency, and reliability in modern printing and manufacturing environments.

Regional Highlights

- North America: This region is a mature market characterized by early adoption of advanced printing technologies, stringent quality standards, and a strong presence of key market players and innovation hubs. The demand here is driven by the need for high-precision printing in packaging, pharmaceuticals, and security documents, along with significant investment in R&D for AI-powered vision systems and Industry 4.0 integration. The United States and Canada are leading contributors, focusing on automation to combat rising labor costs and maintain a competitive edge.

- Europe: Europe is another significant market, propelled by robust manufacturing industries, particularly in Germany, Italy, and the UK, with a strong emphasis on high-quality packaging, labels, and commercial printing. Strict regulatory frameworks, especially in the pharmaceutical and food sectors, drive the adoption of sophisticated inspection systems. The region is also at the forefront of sustainable manufacturing, with automated quality control playing a crucial role in reducing waste and optimizing resource efficiency.

- Asia Pacific (APAC): APAC represents the fastest-growing market globally, fueled by rapid industrialization, expanding manufacturing capabilities, and increasing investments in automation across countries like China, India, Japan, and South Korea. The booming packaging industry, growth in electronics manufacturing, and rising consumer demand for quality products are key drivers. The region benefits from a lower cost of production, making automated systems attractive for improving quality consistency and scaling output.

- Latin America: This region is an emerging market with significant growth potential, particularly in countries like Brazil and Mexico, due to expanding manufacturing sectors and increasing foreign investment. The demand for automated print quality inspection systems is gradually rising as industries seek to modernize production lines, improve product quality to meet international standards, and enhance export capabilities.

- Middle East & Africa (MEA): The MEA region is also an emerging market, driven by diversifying economies, growing industrial infrastructure, and increasing awareness regarding the benefits of automation in sectors such as packaging, food processing, and pharmaceuticals. Investment in new manufacturing facilities and the adoption of modern technologies are contributing to the steady growth of the automated print quality inspection market in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Print Quality Inspection System Market.- Baldwin Technology Company Inc.

- AVT - Advanced Vision Technology (A subsidiary of Baldwin Technology Company Inc.)

- BST eltromat International GmbH (Part of EMERYS)

- Graphic Packaging Holding Company (Utilizes inspection systems, also a potential customer)

- Heidelberg (Heidelberger Druckmaschinen AG)

- Konica Minolta Inc.

- Nilpeter A/S

- Quad/Graphics Inc. (Utilizes inspection systems, also a potential customer)

- Koenig & Bauer AG

- Bobst Group SA

- SCREEN Holdings Co., Ltd.

- Canon Inc.

- HP Inc.

- Fujifilm Holdings Corporation

- X-Rite, Incorporated (A Danaher Company)

- ISRA VISION AG (Part of Atlas Copco)

- Lake Image Systems Ltd.

- Futec Corporation

- MAVIX Inc.

- Microscan Systems, Inc. (Part of Omron Corporation)

Frequently Asked Questions

Analyze common user questions about the Automated Print Quality Inspection System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an Automated Print Quality Inspection System and why is it important?

An Automated Print Quality Inspection System is a technology that uses cameras, sensors, and software to automatically detect and identify defects in printed materials during the production process. It is crucial for ensuring consistent print quality, reducing waste, meeting regulatory standards, and protecting brand reputation across industries like packaging, pharmaceuticals, and commercial printing by providing objective and real-time defect detection.

How does AI impact the performance of these inspection systems?

Artificial intelligence (AI) significantly enhances automated print quality inspection systems by enabling more precise defect classification, reducing false positives through advanced pattern recognition, and facilitating predictive analytics. AI-driven systems can learn from vast datasets, identify complex anomalies, and even suggest process optimizations, leading to higher accuracy, greater efficiency, and more intelligent quality control over traditional methods.

What are the primary benefits of implementing an Automated Print Quality Inspection System?

Implementing an automated system offers numerous benefits, including significantly improved product quality and consistency, substantial reduction in material waste and rework costs due to early defect detection, increased production efficiency by maintaining high operational speeds, and enhanced compliance with industry-specific quality regulations. It also provides objective data for continuous process improvement and strengthens brand integrity by ensuring flawless products reach the market.

What are the main challenges faced when adopting these systems?

Key challenges in adopting Automated Print Quality Inspection Systems include the high initial capital investment, which can be a barrier for smaller businesses. Integration complexity with existing legacy printing machinery often requires significant technical expertise and can lead to production downtime. Additionally, a shortage of skilled personnel to operate and maintain these sophisticated systems, along with concerns regarding data management and cybersecurity, are common hurdles that need to be addressed for successful implementation.

Which industries are the largest end-users of Automated Print Quality Inspection Systems?

The largest end-users of Automated Print Quality Inspection Systems primarily include the packaging industry (for food & beverage, pharmaceutical, and consumer goods), which relies heavily on defect-free labels and containers for safety and branding. Other significant sectors are commercial printing (for magazines, books), electronics (for PCBs and flexible displays), and pharmaceuticals & healthcare, where stringent quality and traceability requirements make automated inspection an indispensable part of their manufacturing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager