Automated Sample Digestion System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442973 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Automated Sample Digestion System Market Size

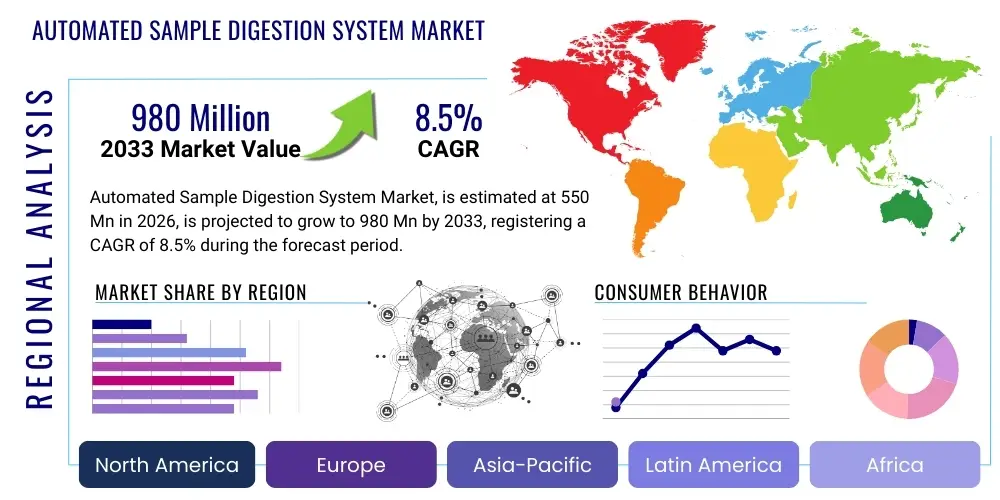

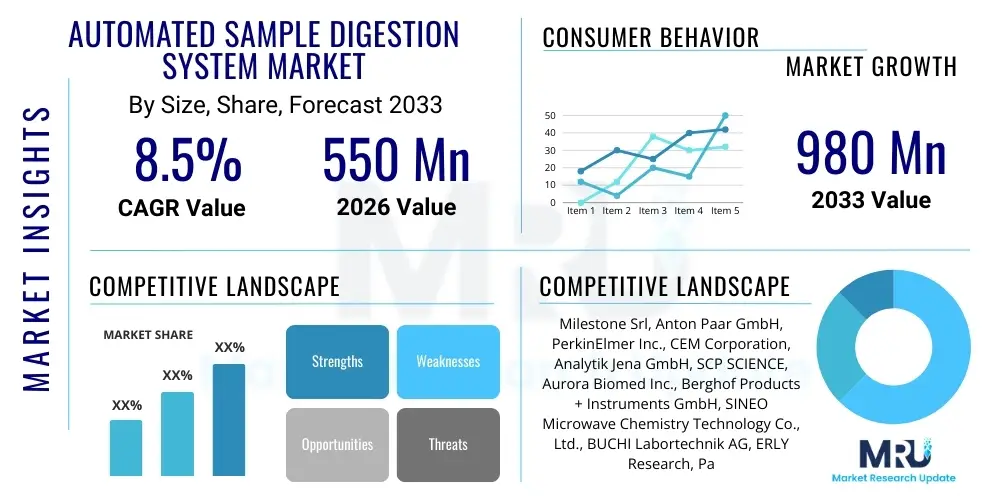

The Automated Sample Digestion System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 980 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the increasing global demand for high-throughput, accurate, and contamination-free sample preparation methods across critical sectors such as environmental testing, food safety analysis, and pharmaceutical quality control, necessitating advanced automation solutions.

Automated Sample Digestion System Market introduction

Automated Sample Digestion Systems are sophisticated laboratory instruments designed to prepare complex samples for subsequent elemental analysis using techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectrometry (AAS), or Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). These systems utilize controlled heat, pressure, and chemical reagents (acids) to completely dissolve or digest the sample matrix, transforming it into a homogenous solution suitable for highly sensitive analytical instrumentation. The primary types of automated digestion include microwave-assisted digestion, which offers speed and efficiency, and high-pressure block digestion, known for handling larger batches and simpler matrices.

The market landscape is characterized by continuous innovation aimed at enhancing throughput, safety, and reliability. Modern automated systems offer features such as integrated cooling mechanisms, automated reagent addition, and sophisticated pressure monitoring, significantly reducing manual intervention and the associated risks of human error or exposure to hazardous chemicals. These features are critical in regulated environments where documentation and repeatability are paramount. Major applications span trace metal analysis in environmental waters and soils, nutritional element profiling in food products, and purity testing in pharmaceutical ingredients, making the systems indispensable tools for quality assurance and regulatory compliance worldwide.

Key benefits driving the adoption of these systems include superior sample recovery, minimized cross-contamination, and substantial time savings compared to traditional manual digestion methods. The push for greater efficiency in contract research organizations (CROs) and large governmental testing laboratories, coupled with stringent global regulations regarding permissible levels of heavy metals and contaminants, acts as a pivotal driving factor. Furthermore, the integration of robotics and advanced software allows for seamless workflow management and compliance with standardized operating procedures (SOPs), positioning automation as the future standard in high-volume analytical laboratories.

Automated Sample Digestion System Market Executive Summary

The Automated Sample Digestion System Market is experiencing dynamic expansion, fueled by increasing stringency in environmental and food safety regulations globally, which necessitates highly precise and reproducible sample preparation. Business trends indicate a strong move toward consolidated, multipurpose systems capable of handling diverse matrices and implementing advanced software for compliance tracking and data integration. Key manufacturers are focusing their investment on developing microwave digestion units that offer increased pressure tolerance and temperature control, facilitating the digestion of highly complex, refractory materials while maintaining high safety standards. Strategic partnerships between instrumentation providers and reagent manufacturers are also shaping the competitive landscape, aiming to offer integrated, end-to-end analytical solutions to end-users.

Regional trends reveal North America and Europe as dominant markets, primarily due to established regulatory frameworks (e.g., EPA, FDA, REACH) and the presence of major pharmaceutical and contract testing laboratories. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth over the forecast period. This rapid expansion in APAC is attributable to accelerated industrialization, heightened public awareness regarding food quality and environmental pollution, and substantial governmental investment in developing modern analytical infrastructure across countries like China and India. The demand in APAC is particularly strong for robust, cost-effective block digestion systems used in high-volume routine testing.

Segment trends highlight the dominance of microwave digestion systems based on technology due to their speed and applicability for complex matrices, offering significant time reduction in preparation cycles. Application-wise, environmental testing remains the largest consumer segment, although the food and beverage industry is demonstrating accelerating growth driven by global export requirements and consumer demand for transparency in food content. End-user segmentation shows that analytical testing laboratories (including CROs and governmental labs) are the primary adopters, valuing automation for maintaining consistent quality and managing high sample volumes effectively.

AI Impact Analysis on Automated Sample Digestion System Market

Common user questions regarding AI’s impact on automated sample digestion systems revolve primarily around optimization, predictive maintenance, and data integrity. Users frequently inquire how AI can autonomously adjust digestion parameters (temperature, pressure, time, reagent ratio) based on real-time sample matrix feedback to ensure complete digestion and minimize method development time. Concerns also focus on using machine learning for fault detection in instrumentation, predicting when components might fail (such as pressure vessels or sensors), and integrating digestion results seamlessly into laboratory information management systems (LIMS) for compliance auditing. The consensus is that AI promises to transition sample digestion from a standardized, empirically developed process to a highly adaptive, optimized, and predictive stage in the analytical workflow, drastically improving efficiency and lowering operational risk.

- AI enables real-time optimization of digestion protocols based on sample matrix complexity, minimizing energy consumption and preparation time.

- Machine learning algorithms facilitate predictive maintenance by analyzing instrument performance data, reducing unexpected downtime and service costs.

- Integration of AI-driven data processing ensures automatic flagging of abnormal digestion cycles, enhancing quality control and audit readiness.

- Computer vision systems powered by AI can monitor sample loading and sealing processes, ensuring process consistency and safety.

- AI assists in developing robust, automated standard operating procedures (SOPs) for new or complex matrices with minimal manual expert intervention.

DRO & Impact Forces Of Automated Sample Digestion System Market

The market is critically influenced by a confluence of driving factors, regulatory constraints, available opportunities, and external competitive forces. The primary drivers include the mandatory global requirements for trace metal analysis stemming from environmental regulations (e.g., mercury, lead, cadmium detection) and consumer safety standards (food and pharmaceuticals). The perpetual industry challenge of managing high sample throughput while maintaining low detection limits is addressed effectively by automation, compelling laboratories to upgrade older manual systems. Restraints predominantly involve the significant initial capital investment required for high-end automated microwave digestion systems and the necessity of specialized technical expertise for operation and maintenance, which can be prohibitive for smaller laboratories or developing economies.

Opportunities in the sector are vast, particularly in integrating advanced robotics for complete end-to-end sample handling—from weighing and labeling to final transfer—eliminating almost all manual steps. Furthermore, the burgeoning demand in emerging economies for advanced laboratory equipment to support rapid industrial growth and adherence to global trade standards presents a lucrative growth avenue for manufacturers. The continued development of sophisticated software that offers full 21 CFR Part 11 compliance for pharmaceutical users and streamlined LIMS integration also constitutes a key opportunity for product differentiation and market penetration.

Impact forces significantly shape the market structure. The threat of new entrants remains relatively low due to high technological barriers and the rigorous certification required for reliable analytical equipment. However, the intensity of competitive rivalry among established players (such as Milestone, PerkinElmer, and Anton Paar) is high, focusing on superior safety features, digestion speed, and system modularity. Buyer power is moderate to high, especially for large analytical chains and governmental organizations that purchase in volume and demand specific performance guarantees and long-term service contracts. Supplier power is also moderate, dictated by the specialized nature of components like high-pressure quartz vessels and magnetron technology used in microwave systems.

Segmentation Analysis

The Automated Sample Digestion System Market is comprehensively segmented based on technology type, application area, and the specific end-user category. This multidimensional segmentation allows for precise market sizing and strategic targeting by manufacturers, reflecting the varied needs of different laboratory environments. The core technological distinction lies between microwave-assisted and traditional block digestion, each optimized for different sample volumes, matrix types, and throughput requirements. Application segmentation demonstrates where the most significant demand resides, highlighting the critical role these systems play in environmental monitoring, public health protection, and pharmaceutical quality assurance.

- By Technology:

- Microwave-Assisted Digestion System

- Block Digestion System (Hot Plate Digestion)

- High-Pressure/High-Temperature Digestion System

- By Application:

- Environmental Testing (Water, Soil, Air Filters)

- Food and Beverage Analysis

- Pharmaceutical and Biotechnology Analysis

- Forensics and Clinical Testing

- Geological and Mining Analysis

- Academic Research and Development

- By End-User:

- Analytical Testing Laboratories (Contract Research Organizations - CROs)

- Government and Academic Research Institutes

- Pharmaceutical and Biotechnology Companies

- Chemical and Petrochemical Industries

Value Chain Analysis For Automated Sample Digestion System Market

The value chain for Automated Sample Digestion Systems starts with upstream activities, which include the procurement and processing of highly specialized raw materials. Key inputs involve high-grade polymers and ceramics for reaction vessels and linings, sophisticated electronic components for control boards and sensors, and magnetrons crucial for microwave systems. Manufacturers rely on specialized suppliers for these components, where quality control and material purity are non-negotiable due to the extreme operating conditions (high temperature and pressure) inherent in the digestion process. Efficient sourcing and quality assurance in the upstream segment directly influence the final product's reliability and lifespan.

The core manufacturing and assembly stage involves the integration of these components, often utilizing proprietary software and precision engineering for automated handling and safety mechanisms. Midstream activities encompass rigorous internal testing, validation, and regulatory certification (e.g., CE, UL, ISO 9001) necessary for distribution globally. Direct and indirect distribution channels then facilitate the market reach. Direct channels are typically utilized for high-value or customized systems sold to major pharmaceutical firms or governmental bodies, allowing manufacturers to maintain tight control over installation and post-sale service. Indirect channels involve authorized regional distributors and specialized scientific equipment dealers, particularly prevalent in rapidly developing markets where local knowledge and rapid technical support are essential.

Downstream activities center on reaching the end-users, encompassing comprehensive pre-sale technical consultation, system installation, and extensive user training required for complex operations. Post-sale support, including calibration, preventative maintenance contracts, and timely access to spare parts and specialized reagents (digestion acids), forms a critical, high-margin component of the value chain. Customer feedback from large analytical labs is frequently integrated back into the research and development pipeline, ensuring continuous product improvement and optimization for real-world analytical challenges like handling difficult or complex sample matrices.

Automated Sample Digestion System Market Potential Customers

The primary consumers and buyers of Automated Sample Digestion Systems are highly regulated analytical entities requiring reliable and high-throughput sample preparation for elemental analysis. Analytical Testing Laboratories, including large Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs), form the core customer base. These organizations demand systems that offer rapid processing capabilities, high repeatability, and verifiable compliance documentation to meet strict client requirements across multiple industries, including environmental and food safety testing. Their procurement decisions are heavily influenced by system throughput (samples per hour) and compliance features (data logging, audit trails).

Governmental and academic research institutes represent another significant segment, particularly those involved in public health monitoring, geological surveys, and fundamental material science research. Government laboratories, such as EPA or FDA facilities, mandate highly accurate and standardized methods for regulatory enforcement, making automated systems essential for maintaining public safety standards. Academic labs focus on flexibility and adaptability, often requiring systems capable of handling novel or small-volume samples for method development and experimental research, often prioritizing technology that can accommodate high-pressure or unusual reagent combinations.

Furthermore, major players in the pharmaceutical and biotechnology sector are increasing their investment in these systems. Drug manufacturing requires rigorous testing for heavy metal contamination in raw materials and finished products, driven by global pharmacopeial standards (USP, EP, JP). Automation in digestion ensures that trace impurity analysis is performed consistently and efficiently, minimizing the risk of batch failure due to contamination. Similarly, the expanding global food processing industry, driven by international trade standards and consumer safety demands, relies on automated digestion to quickly and accurately quantify nutrients and contaminants in diverse food matrices, from raw agricultural products to highly processed consumer goods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 980 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Milestone Srl, Anton Paar GmbH, PerkinElmer Inc., CEM Corporation, Analytik Jena GmbH, SCP SCIENCE, Aurora Biomed Inc., Berghof Products + Instruments GmbH, SINEO Microwave Chemistry Technology Co., Ltd., BUCHI Labortechnik AG, ERLY Research, Parr Instrument Company, ISOLAB Laborgeräte GmbH, Katanax, Beijing Xiangyu Central Heating Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Sample Digestion System Market Key Technology Landscape

The technological landscape of the Automated Sample Digestion System Market is rapidly evolving, driven by the need for safer, faster, and more robust methods to handle increasingly complex matrices. Microwave digestion systems dominate the high-end market segment, characterized by closed-vessel technology that allows for extremely high pressures (up to 199 bar) and temperatures (up to 300°C). This capacity ensures rapid and complete digestion of difficult samples like polymers, petroleum products, and refractory geological materials. Modern microwave units feature fiber optic temperature sensors for real-time monitoring and advanced software for protocol storage and automated pressure release mechanisms, emphasizing operator safety and method reproducibility.

Block digestion systems, while older technology, remain relevant for routine, high-volume, and relatively simpler matrices, such as those found in standard water quality testing or certain agricultural applications. Recent technological advancements in block systems focus on improved temperature homogeneity across the heating block, minimizing variability between samples, and integrating automated features for acid handling and fume extraction. These systems are favored for their lower operational costs and simpler maintenance requirements compared to microwave units, catering primarily to budget-conscious laboratories or those focusing purely on high-volume standardized testing.

The most significant technological shift involves system connectivity and automation. Current generation systems are incorporating features such as wireless control, integration with LIMS for data logging and audit trails, and robotic arms for automated sample loading and unloading. This automation minimizes the operator's exposure to hazardous reagents and ensures consistent timing and handling. Furthermore, the development of specialized vessels, such as disposable or high-purity quartz vessels, aims to address the critical issue of cross-contamination, a key concern in ultra-trace elemental analysis, thereby expanding the applicability of these automated systems into highly sensitive research areas.

Regional Highlights

The adoption and market size of Automated Sample Digestion Systems vary significantly across global regions, dictated by regulatory maturity, industrial concentration, and investment in analytical infrastructure.

- North America: This region holds a significant market share, characterized by stringent environmental protection agency (EPA) standards and robust pharmaceutical manufacturing regulations (FDA). High demand stems from large CROs, governmental labs, and the established biotechnology sector, which prioritizes speed, automation, and compliance (e.g., 21 CFR Part 11). The market here is mature, focusing on replacing legacy equipment with the latest high-pressure microwave systems and integrated robotic workflows.

- Europe: Europe is a key market, driven by comprehensive legislation like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and strong investment in academic and environmental research. Germany, the UK, and France are major contributors, exhibiting a high demand for innovative, high-safety instruments. The European market shows a strong preference for sustainable and energy-efficient digestion technologies, aligning with the region's overall environmental policies.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, fueled by rapid industrialization, massive investments in analytical laboratories across China and India, and increasing scrutiny over food safety and water quality due to expanding urbanization. While price sensitivity exists, there is a burgeoning demand for reliable block digestion systems for high-volume routine testing, alongside increasing adoption of advanced microwave systems in export-focused pharmaceutical and food processing companies aiming for global compliance.

- Latin America (LATAM): Growth in LATAM is steady but concentrated, primarily driven by resource-based industries like mining and agriculture, which require frequent elemental analysis for quality control and export compliance. Brazil and Mexico are leading markets, where adoption is often focused on robust, easy-to-maintain block systems, although microwave adoption is rising in centralized governmental testing facilities.

- Middle East and Africa (MEA): This region is an emerging market, with growth concentrated in nations investing heavily in oil and gas, petrochemicals, and centralized environmental monitoring initiatives. Demand is often project-based, linked to large-scale infrastructure development and the establishment of new regulatory frameworks for water and soil quality control.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Sample Digestion System Market.- Milestone Srl

- Anton Paar GmbH

- PerkinElmer Inc.

- CEM Corporation

- Analytik Jena GmbH

- SCP SCIENCE

- Aurora Biomed Inc.

- Berghof Products + Instruments GmbH

- SINEO Microwave Chemistry Technology Co., Ltd.

- BUCHI Labortechnik AG

- ERLY Research

- Parr Instrument Company

- ISOLAB Laborgeräte GmbH

- Katanax

- Beijing Xiangyu Central Heating Technology Co., Ltd.

- Agilent Technologies, Inc. (via product portfolio)

- Thermo Fisher Scientific Inc. (via product portfolio)

- Metrohm AG

- TE Instruments

- Preekem Instruments Co., Ltd.

Frequently Asked Questions

What are the primary differences between microwave and block digestion systems?

Microwave digestion systems utilize closed vessels and microwave energy to achieve higher temperatures and pressures quickly, resulting in faster and more complete digestion of complex or difficult matrices. Block digestion systems use conduction heating in open or capped tubes, offering simpler operation, lower cost, and suitability for large batches of less complex, routine samples like water or agricultural soil extracts. Microwave systems are superior for trace metal analysis requiring ultra-low detection limits.

Which application segment drives the highest demand in the Automated Sample Digestion Market?

Environmental testing is currently the largest application segment driving the demand for automated sample digestion systems. This is due to increasingly stringent global regulatory mandates from agencies like the EPA and EU directives, requiring high-volume, reliable analysis of trace elements and heavy metals in water, soil, and air quality samples to monitor environmental health and compliance effectively.

How does automation improve laboratory efficiency in sample digestion?

Automation drastically improves laboratory efficiency by minimizing manual handling, which reduces the potential for human error and cross-contamination. Automated systems facilitate high-throughput processing, allow for unattended operation (e.g., overnight runs), and ensure method reproducibility through precise control over temperature, pressure, and reagent dosing, thereby shortening the overall sample turnaround time for analytical results.

What key safety features are integrated into modern automated digestion systems?

Modern automated digestion systems incorporate critical safety features, particularly in microwave units, including real-time pressure and temperature monitoring, automated pressure relief valves and burst discs to prevent over-pressurization, and robust shielding to contain microwave energy. Software controls also include interlocks that prevent accidental startup or opening of vessels before cooling, significantly enhancing operator protection against hazardous reagents and high-pressure steam.

Which geographical region is expected to show the fastest market growth through 2033?

The Asia Pacific (APAC) region is projected to exhibit the fastest Compound Annual Growth Rate (CAGR) due to rapid industrial growth, substantial government investment in modern analytical laboratories, rising public awareness regarding food and environmental safety, and the necessity for local manufacturers to comply with international quality and export standards, spurring demand for advanced analytical instrumentation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager