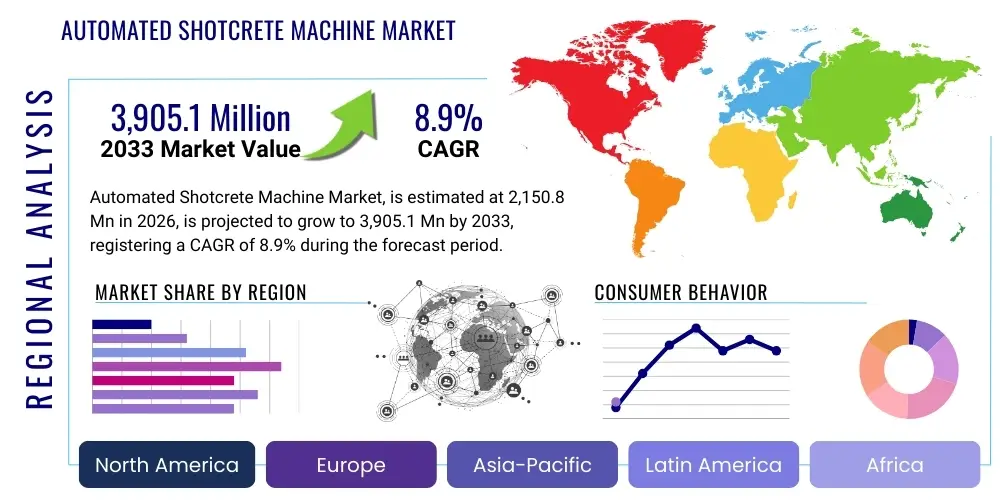

Automated Shotcrete Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443050 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Automated Shotcrete Machine Market Size

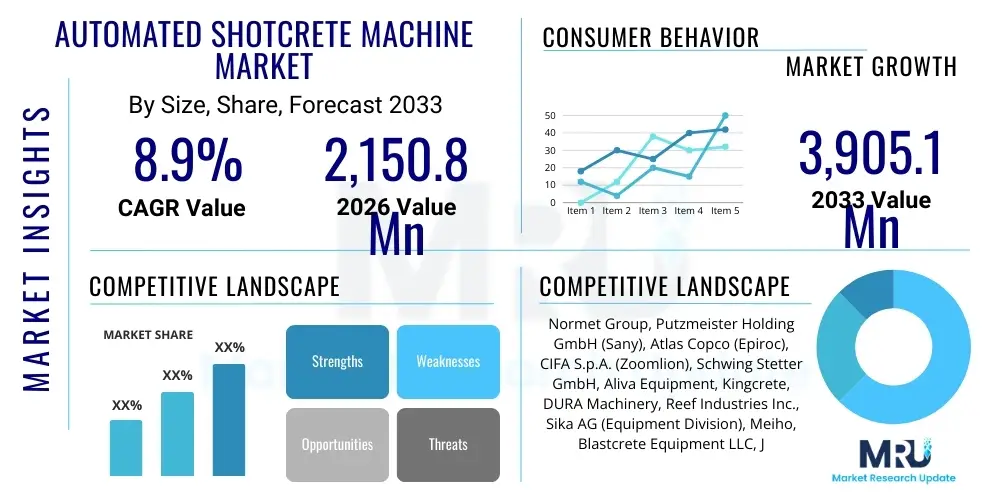

The Automated Shotcrete Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. The market is estimated at USD 2,150.8 Million in 2026 and is projected to reach USD 3,905.1 Million by the end of the forecast period in 2033.

Automated Shotcrete Machine Market introduction

The Automated Shotcrete Machine Market encompasses advanced equipment utilized for spraying concrete (shotcrete) onto surfaces, primarily in construction, mining, and tunneling activities. These machines integrate sophisticated robotic arms, remote control systems, and often, computer-aided application parameters to enhance safety, improve application quality, and significantly increase operational efficiency compared to traditional manual or semi-automated methods. Automated systems minimize material waste, ensure uniform thickness, and allow operators to manage the process from a safe distance, mitigating risks associated with working in volatile or confined underground environments.

The primary applications driving the adoption of automated shotcrete technology include ground support in tunnel boring projects (metros, railways, roadways), stabilization of rock slopes in open-pit mining operations, and the reinforcement of underground infrastructure such as hydroelectric power stations and sewer systems. These machines are increasingly crucial in large-scale infrastructure projects where speed and precision are paramount, contributing directly to faster project completion timelines and superior structural integrity. The market’s expansion is intricately linked to global investments in urban infrastructure development and the mandatory adoption of stringent industrial safety standards across developed and rapidly industrializing economies.

Key benefits driving market growth include enhanced worker safety by removing personnel from hazardous spray zones, consistent quality of the shotcrete layer which reduces rework and structural failure risks, and remarkable productivity gains due to higher pumping capacity and continuous operation capabilities. Furthermore, the integration of telematics and diagnostic features allows for predictive maintenance and optimized resource allocation. Driving factors include the global focus on deep tunneling and underground infrastructure projects, the necessity for robust ground support systems, and regulatory pressures enforcing higher levels of automation in hazardous operational settings.

Automated Shotcrete Machine Market Executive Summary

The Automated Shotcrete Machine Market is currently experiencing robust momentum, fundamentally driven by pervasive global trends toward infrastructure modernization and stringent worker safety mandates, particularly within the deep tunneling and resource extraction sectors. Business trends highlight a strong shift toward fully robotic and integrated systems featuring advanced teleoperation capabilities and real-time monitoring sensors, enabling operational consistency and superior material utilization. Strategic partnerships between traditional heavy equipment manufacturers and specialized robotics and software developers are shaping the competitive landscape, focusing on optimizing machine learning algorithms for spray pattern recognition and quality assurance.

Regionally, the Asia Pacific (APAC) market is projected to demonstrate the fastest growth rate, fueled by massive government investments in high-speed rail networks, urban metro expansions, and extensive mining operations in countries like China, India, and Australia. North America and Europe, characterized by mature markets, are focusing on adopting next-generation electric and hybrid automated machines to comply with increasingly strict environmental regulations regarding emissions and noise pollution. These mature markets prioritize retrofitting existing fleets with advanced automation kits and utilizing predictive maintenance platforms, supporting sustained demand for high-value technology upgrades.

In terms of segmentation, the market displays dominant trends favoring wet-mix shotcrete technology due to its superior consistency and reduced rebound losses compared to dry-mix methods, particularly for high-volume applications in tunnels. The fully automated segment, inclusive of robotic systems, is expected to capture the largest market share owing to its unparalleled precision, ability to handle complex geometries, and superior safety profile. Application-wise, the tunneling and infrastructure segment remains the largest consumer, though the specialized mining sector is showing accelerated growth rates, driven by the necessity for fast and reliable ground support in increasingly deeper and more challenging mine shafts.

AI Impact Analysis on Automated Shotcrete Machine Market

Common user questions regarding AI’s influence on the Automated Shotcrete Machine Market often revolve around operational autonomy, quality consistency, and cost savings. Users frequently inquire about the feasibility of autonomous spray pattern optimization, how AI improves material efficiency by reducing rebound, and the role of machine learning in predicting component failure (predictive maintenance). Concerns also center on the complexity of integrating sophisticated AI algorithms with rugged, heavy-duty machinery and the required skill upgrade for operators transitioning from remote control to supervisory roles over autonomous systems. There is high expectation that AI will standardize application quality across different sites and significantly reduce the reliance on highly specialized human expertise for complex spray tasks.

AI's primary transformative impact is focused on achieving 'first-time-right' application quality, moving away from post-application assessments to real-time feedback loops. AI-powered vision systems, utilizing high-resolution cameras and LiDAR, analyze surface topology and material flow properties instantly, adjusting pump pressures and nozzle trajectories autonomously to maintain the optimal distance and angle. This predictive and prescriptive control drastically minimizes human error, optimizes the thickness distribution of the shotcrete layer, and ensures adherence to structural engineering specifications across entire construction sections, particularly crucial in complex tunnel arches and cavern construction.

Furthermore, AI algorithms are revolutionizing the maintenance and operational lifespan of automated shotcrete machines. By continuously analyzing sensor data related to pump vibration, hydraulic system pressure, and engine performance, machine learning models can accurately forecast potential mechanical failures hours or even days before they occur. This transition from reactive maintenance to true predictive maintenance minimizes costly unplanned downtime, extends the life of critical components, and maintains high utilization rates—factors vital for large infrastructure projects operating under tight schedules and budget constraints. This enhanced reliability directly contributes to a lower total cost of ownership for end-users.

- AI-driven real-time material flow optimization reduces rebound waste by up to 15%.

- Predictive maintenance algorithms minimize unplanned downtime by forecasting critical component failures.

- Autonomous trajectory planning ensures uniform shotcrete thickness in complex geometries (AEO focus: consistency).

- Machine vision systems utilize AI for immediate, automated quality inspection and conformity checks.

- AI enhances operator safety by enabling fully autonomous operation in high-risk zones.

DRO & Impact Forces Of Automated Shotcrete Machine Market

The dynamics of the Automated Shotcrete Machine Market are dictated by a compelling confluence of market drivers, significant technical and financial restraints, and emerging growth opportunities, collectively modulated by internal and external impact forces. A primary driver is the accelerating global investment in major infrastructure development, specifically deep tunneling projects for transportation and utilities, which necessitate highly efficient and safe ground support mechanisms. Coupled with this is the increasing global emphasis on worker safety regulations, pushing construction and mining companies to adopt automated systems that remove personnel from hazardous spray environments, thereby achieving compliance and reducing liability risks. These factors combine to create a sustained demand foundation for advanced automation solutions.

However, the market faces significant restraints, chiefly the substantial initial capital investment required for high-end automated shotcrete equipment, which often presents a barrier to entry for smaller or regional contractors. Furthermore, the complexity of integrating and operating these advanced robotic systems necessitates specialized training and a higher skill set among the technical workforce, leading to challenges related to talent acquisition and operational expertise in certain geographical regions. Economic volatility and fluctuations in commodity prices, particularly steel and cement, also introduce uncertainty regarding project funding and execution timelines, potentially dampening procurement cycles for expensive machinery.

Opportunities for market expansion are predominantly centered on the penetration of emerging markets, particularly in Southeast Asia and Africa, where rapid urbanization and industrialization are just beginning to require modern ground support technology. The technological opportunity lies in the continuous development of battery-electric automated shotcrete machines, addressing the growing demand for zero-emission equipment in restricted underground environments, and integrating IoT and augmented reality (AR) for enhanced remote diagnostics and maintenance support. The critical impact forces include technological inertia (resistance to adopting new, complex systems) and competitive pricing pressure from manufacturers of semi-automated or traditional equipment, requiring automated solutions providers to consistently demonstrate superior Return on Investment (ROI) through enhanced efficiency and safety metrics.

Segmentation Analysis

The Automated Shotcrete Machine Market is strategically segmented based on key functional attributes, operational methodologies, power sources, and core applications to provide a granular view of market dynamics and adoption patterns. The segmentation allows stakeholders to analyze growth pockets related to technology adoption, regulatory compliance, and regional infrastructure needs. Understanding these divisions is crucial for manufacturers in tailoring product development, marketing strategies, and distribution networks to effectively meet the highly specialized requirements of sectors such as underground mining and large-scale public infrastructure projects.

The method of operation—specifically the distinction between wet-mix and dry-mix processes—forms a fundamental segmentation axis. Wet-mix shotcrete machines, which involve pre-mixing water and materials before pumping, dominate professional construction and tunneling applications due to their high output consistency and reduced particulate emissions, making them ideal for high-specification structural work. Conversely, the segmentation by power source reflects the industry's green transition, with battery-electric machines gaining significant traction over traditional diesel-powered units, especially in confined spaces where air quality is a major concern.

- By Type:

- Wet Mix Automated Shotcrete Machines

- Dry Mix Automated Shotcrete Machines

- By Automation Level:

- Semi-Automated Machines (Remote Controlled)

- Fully Automated Machines (Robotic Systems)

- By Application:

- Tunneling and Underground Construction (Metro, Road, Rail)

- Mining (Ground Support, Shaft Reinforcement)

- Hydropower and Water Infrastructure

- Slope Stabilization and Civil Construction

- By Power Source:

- Diesel Powered

- Electric Powered (Wired)

- Battery Electric Powered (BEV)

Value Chain Analysis For Automated Shotcrete Machine Market

The value chain for the Automated Shotcrete Machine Market begins with the upstream activities centered on the procurement and processing of highly specialized components, including high-pressure hydraulic systems, robotic arm assemblies, precision dosing units for admixtures, and specialized control software platforms. Key upstream suppliers include manufacturers of heavy-duty steel structures, electronic control units (ECUs), and advanced sensor technologies essential for precise trajectory control and material mixing accuracy. Success at this stage relies heavily on reliable supply chains for robust, durable components that can withstand the harsh and abrasive environment of shotcrete application, ensuring machine longevity and reducing total lifecycle costs.

Midstream activities encompass the core manufacturing, assembly, and rigorous testing of the automated shotcrete machines. Manufacturers focus on integrating sophisticated software for operational autonomy, designing user-friendly HMI (Human-Machine Interface) systems for remote operation, and engineering safety redundancies. Distribution channels for these high-value, specialized assets are typically bifurcated: direct sales channels handle large, custom orders for major international construction or mining conglomerates, providing extensive after-sales service and specialized training. Indirect channels, involving authorized regional distributors and dealers, manage sales and localized support for smaller contractors and specific regional projects, requiring inventory management and immediate parts availability.

Downstream activities involve machine deployment, operational utilization by end-users in tunneling or mining sites, and comprehensive post-sales support, including maintenance, spare parts supply, and software updates (often delivered wirelessly). The relationship between the manufacturer and the end-user is critical in this phase, as the effectiveness of the machinery heavily depends on expert operational training and rapid technical support to minimize downtime. The increasing trend toward machine-as-a-service (MaaS) and subscription models for predictive maintenance reflects the high criticality of these assets in ongoing infrastructure projects, influencing long-term profitability and customer retention within the market ecosystem.

Automated Shotcrete Machine Market Potential Customers

The primary customer base for Automated Shotcrete Machines comprises large-scale entities involved in complex, high-stakes civil engineering and subterranean operations where efficiency, safety, and structural integrity are non-negotiable prerequisites. This includes major multinational infrastructure development companies specializing in the construction of subterranean roadways, high-speed rail tunnels, and utility conduits in dense urban areas. These customers prioritize machines that offer high throughput, maximum automation, and robust quality documentation capabilities to meet stringent governmental and municipal specifications, thereby reducing construction time and ensuring compliance.

A significant segment of potential buyers are major mining organizations, both surface and underground, focusing on the extraction of high-value minerals and coal. For these entities, automated shotcrete is vital for ground support and ventilation sealing in shafts and drifts, particularly as operations move to greater depths where geological stresses are higher and conditions are more hazardous. Miners seek battery-electric variants that improve air quality underground and systems capable of rapid deployment and relocation across vast underground networks.

Additionally, governmental public works agencies and utility companies that manage existing tunnels, dams, and water transfer infrastructure represent a consistent customer segment for rehabilitation and reinforcement projects. Engineering and procurement firms (EPCs) acting on behalf of these owners often mandate the use of the latest automated technology to ensure long-term stability and cost-effectiveness in maintaining critical national infrastructure. These customers require reliability, longevity, and detailed certification of the applied shotcrete layer.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2,150.8 Million |

| Market Forecast in 2033 | USD 3,905.1 Million |

| Growth Rate | CAGR 8.9% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Normet Group, Putzmeister Holding GmbH (Sany), Atlas Copco (Epiroc), CIFA S.p.A. (Zoomlion), Schwing Stetter GmbH, Aliva Equipment, Kingcrete, DURA Machinery, Reef Industries Inc., Sika AG (Equipment Division), Meiho, Blastcrete Equipment LLC, Jacon Equipment, Turbosol S.p.A., Conjet AB, GEB Shotcrete Equipment, Shotcrete Technologies, Inc., Multicrete Systems Inc., Semmco, Inc., Messer Group GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Shotcrete Machine Market Key Technology Landscape

The technological landscape of the Automated Shotcrete Machine Market is defined by the convergence of heavy machinery design with advanced industrial robotics, sensor technology, and digital communication platforms. Central to this evolution is the implementation of precise electro-hydraulic systems that enable the smooth, accurate movement of the robotic spray arm, allowing for complex pattern application that is impossible with manual methods. These systems are often paired with high-performance pumping technologies optimized for handling various shotcrete mixes, minimizing pulsation and ensuring continuous flow rate, which is critical for structural consistency and strength development in the applied concrete layer.

A major advancement involves sophisticated sensor arrays and control software utilizing Inertial Measurement Units (IMUs) and laser scanners (Lidar) to create a three-dimensional map of the substrate surface in real-time. This digital feedback allows the automated system to dynamically adjust the spray nozzle position, distance, and angle relative to the surface contours. This process minimizes rebound—the wasteful practice of concrete bouncing off the surface—and guarantees uniform layer thickness even in challenging environments like sharply curved tunnel arches or irregular rock faces. Furthermore, integration with telematics ensures remote diagnostics, fleet management, and performance data logging, supporting preventive maintenance schedules.

The shift towards electric and hybrid propulsion systems represents another pivotal technological trend. Battery Electric Vehicles (BEVs) are gaining significant market share, especially for indoor and underground applications, due to their zero local emissions, reduced noise pollution, and lower operating costs compared to diesel counterparts. Coupled with this is the growing adoption of smart dosing technology for chemical admixtures (such as accelerators and retarders). These smart systems automatically inject precise quantities of additives based on environmental conditions (temperature, humidity) and desired setting times, ensuring optimal chemical reactions and high early-age strength of the shotcrete, which is a key performance indicator in rapid construction projects.

Regional Highlights

- Asia Pacific (APAC): The dominant and fastest-growing region, driven by unparalleled levels of urbanization and national infrastructure spending (e.g., China’s Belt and Road Initiative, India’s National Infrastructure Pipeline). High demand for rapid metro and rail tunneling projects dictates heavy investment in large-scale, automated wet-mix systems.

- North America: Characterized by high labor costs and stringent safety regulations, leading to early and high adoption rates of fully robotic, remote-controlled systems. Focus is on replacing aging infrastructure and leveraging AI for predictive maintenance and operational efficiency in mining operations.

- Europe: Mature market focused on sustainable technology adoption. Strong regulatory environment pushes demand for battery-electric shotcrete machines and solutions that minimize noise and carbon footprint, particularly in densely populated urban tunneling projects across Western Europe.

- Latin America (LATAM): Growth is primarily propelled by large mining investments, particularly in Chile and Peru, where automated shotcrete machines are essential for deep-level ground support. Economic instability remains a constraint, but infrastructure deficits fuel long-term potential.

- Middle East and Africa (MEA): Emerging market showing high volatility but significant potential driven by mega-project development in the GCC (e.g., NEOM in Saudi Arabia). Demand focuses on large-capacity, robust equipment suitable for extreme environmental conditions and rapid project execution timelines.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Shotcrete Machine Market.- Normet Group

- Putzmeister Holding GmbH (Sany)

- Atlas Copco (Epiroc)

- CIFA S.p.A. (Zoomlion)

- Schwing Stetter GmbH

- Aliva Equipment

- Kingcrete

- DURA Machinery

- Reef Industries Inc.

- Sika AG (Equipment Division)

- Meiho

- Blastcrete Equipment LLC

- Jacon Equipment

- Turbosol S.p.A.

- Conjet AB

- GEB Shotcrete Equipment

- Shotcrete Technologies, Inc.

- Multicrete Systems Inc.

- Semmco, Inc.

- Messer Group GmbH

Frequently Asked Questions

Analyze common user questions about the Automated Shotcrete Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of fully automated shotcrete technology?

The central driver is enhanced worker safety, achieved by enabling remote operation which removes personnel from hazardous environments such as recently excavated tunnel faces, significantly reducing risks associated with ground collapse and dust exposure. Increased productivity and material efficiency are also crucial secondary factors.

How do Battery Electric Vehicles (BEVs) impact underground shotcreting operations?

BEVs fundamentally improve underground operational health and compliance by eliminating combustion engine emissions (NOx, CO), reducing the requirement for expensive ventilation systems, and significantly lowering noise levels, making them the preferred choice for sustainable tunneling and mining projects.

What is the typical Return on Investment (ROI) period for a robotic shotcrete machine?

While the initial capital cost is high, the ROI period is generally favorable (often 3-5 years) due to substantial savings derived from reduced labor dependency, minimized material waste (less rebound), and drastically lower downtime achieved through the inherent precision and predictive maintenance capabilities of automated systems.

Which application segment currently holds the largest market share for automated shotcrete equipment?

The Tunneling and Underground Construction segment holds the largest market share. This includes major projects like urban metro systems, long-distance railway tunnels, and road conduits, where high volume, consistent quality, and rapid application speed are essential structural requirements.

How does AI technology help minimize material rebound in automated shotcreting?

AI utilizes real-time sensor data and vision systems to precisely monitor the nozzle-to-surface distance and angle. The AI algorithm dynamically adjusts the robotic arm trajectory and material pump pressure, ensuring the kinetic energy of the spray is optimal, thus minimizing the rebound of dry aggregate and cementitious material off the application surface.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager