Automobile Spray Booth Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440997 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Automobile Spray Booth Market Size

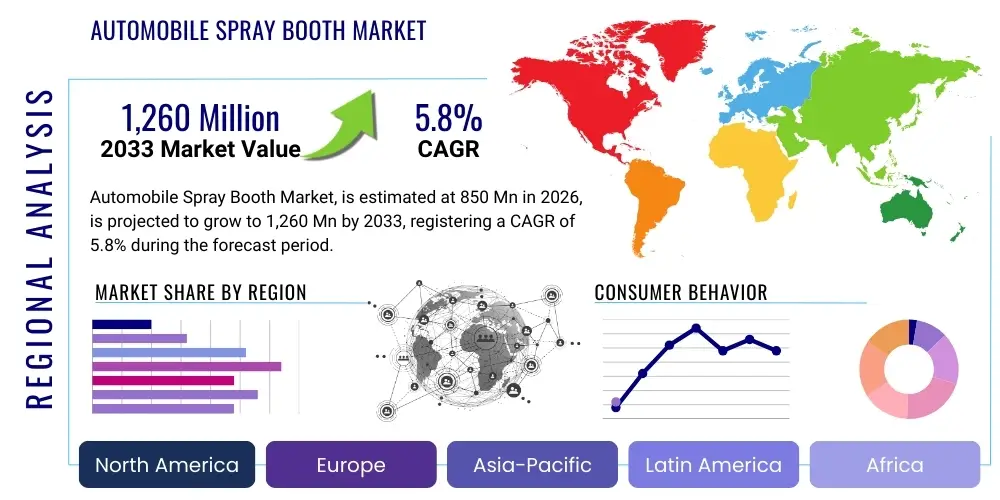

The Automobile Spray Booth Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,260 Million by the end of the forecast period in 2033.

Automobile Spray Booth Market introduction

The Automobile Spray Booth Market encompasses equipment and integrated systems designed to provide a controlled, contaminant-free environment for applying liquid coatings, such as paint, primers, and clear coats, to automotive parts and complete vehicles. These specialized enclosures are critical for achieving high-quality finishes, ensuring worker safety by controlling volatile organic compounds (VOCs) and overspray particulate matter, and complying with stringent environmental regulations. Modern spray booths incorporate advanced features such as heated air recirculation, sophisticated filtration mechanisms (e.g., dry filters, carbon filters), and pressurized ventilation systems (e.g., downdraft, cross-draft) to optimize paint adhesion and curing efficiency.

Major applications of automobile spray booths span the entire automotive lifecycle, from Original Equipment Manufacturer (OEM) assembly lines requiring massive, automated systems for mass production, to independent collision repair centers (body shops) focusing on restoration and repair, and specialized custom paint shops catering to high-end vehicles and modifications. The primary benefit derived from these booths is the creation of a dust-free environment essential for flaw-free finishes, dramatically reducing rework rates and increasing throughput. Furthermore, the contained environment ensures compliance with occupational safety standards regarding explosive atmospheres and air quality management.

Driving factors for this market include the global increase in vehicle production and sales, particularly in emerging economies, leading to higher demand for OEM installations. Simultaneously, the sustained requirement for collision repair services due to traffic accidents fuels the aftermarket segment. Technological advancements in paint curing methods, such as the adoption of UV and IR curing lamps, alongside the growing emphasis on energy efficiency and reduced solvent emissions, compel body shops and manufacturers to upgrade to newer, highly efficient, and environmentally compliant booth models, thereby stimulating market growth across all geographical regions.

Automobile Spray Booth Market Executive Summary

The Automobile Spray Booth Market is experiencing robust growth driven primarily by stringent regulatory frameworks concerning VOC emissions and particulate matter, necessitating continuous technological upgrades across both manufacturing and aftermarket sectors. Business trends show a distinct pivot towards smart, energy-efficient solutions, including booths equipped with variable frequency drives (VFDs) for optimized airflow control and advanced curing technologies that reduce energy consumption and cycle times. Furthermore, consolidation among major collision repair networks is influencing purchasing decisions, favoring suppliers capable of providing comprehensive, standardized equipment packages and long-term maintenance services, pushing smaller, localized manufacturers to innovate specialized niche products or seek strategic partnerships to maintain market relevance.

Regional trends indicate that the Asia Pacific (APAC) region, spearheaded by China and India, remains the fastest-growing market due to rapid expansion in automotive manufacturing capacity and a burgeoning middle class driving vehicle ownership and subsequent demand for collision repair infrastructure. North America and Europe, while mature, are characterized by high regulatory pressure, driving demand for premium, high-efficiency booths focused on reducing energy footprints and maximizing throughput in labor-intensive environments. The Middle East and Africa (MEA) and Latin America are showing steady adoption, primarily focused on establishing reliable repair networks that prioritize durability and lower initial investment costs, though environmental compliance is slowly becoming a more significant factor in purchasing decisions.

Segmentation trends highlight the increasing dominance of downdraft spray booths due to their superior air movement dynamics, which minimizes overspray and dust contamination, ensuring the highest quality finish required by modern waterborne and high-solids paint systems. By application, the collision repair sector accounts for the majority of installations, emphasizing flexibility and efficiency for varied repair jobs, while the OEM segment focuses heavily on fully automated, integrated production lines. Technology-wise, heated spray booths (especially those using direct-fire heating systems for rapid temperature achievement) dominate over non-heated counterparts, reflecting the global requirement for fast, reliable curing processes compatible with modern paint chemistry.

AI Impact Analysis on Automobile Spray Booth Market

User queries regarding the intersection of Artificial Intelligence and the Automobile Spray Booth Market largely center on three primary themes: enhancing paint application precision, automating quality control inspection, and optimizing energy consumption in the booth operation cycle. Users are highly interested in how AI-driven vision systems can detect microscopic defects or inconsistencies in paint thickness immediately after application, thereby minimizing the need for manual inspection and costly rework. Key concerns revolve around the integration cost and complexity of these sophisticated systems within existing booth infrastructure, particularly for smaller body shops, and the necessity for highly trained technicians to manage and calibrate AI-enabled robotic arms and diagnostic software. The overall expectation is that AI will transform the spray booth from a passive environmental enclosure into an active, intelligent system capable of predictive maintenance and adaptive process control.

The analysis reveals a strong anticipation that AI will revolutionize the paint preparation and application phases. Specifically, machine learning algorithms can analyze data streams from humidity sensors, temperature controls, and air flow monitors to dynamically adjust booth parameters in real-time based on the specific paint formulation being used and ambient conditions. This level of optimization promises significant savings in energy, particularly in the curing phase, and ensures consistent quality regardless of external environmental fluctuations. Furthermore, AI-powered robotics are expected to handle complex, repetitive painting tasks with unmatched consistency, leading to material savings and reduced human exposure to hazardous materials.

While full automation through AI-integrated robotics is primarily anticipated in large-scale OEM facilities, the collision repair sector is looking forward to AI tools for digital color matching and defect detection. Predictive maintenance, another critical AI application, uses historical operational data to forecast equipment failures (e.g., filter saturation, fan motor issues), allowing for proactive servicing that maximizes booth uptime—a crucial factor in profit-driven body shops. However, data privacy and cybersecurity surrounding proprietary paint formulation data handled by these intelligent systems remain an underlying concern for industry stakeholders.

- AI-driven automated quality inspection (AQI) systems reduce post-paint defect rates by detecting micro-imperfections instantly.

- Machine learning algorithms optimize booth operating parameters (temperature, humidity, airflow) in real-time for maximum energy efficiency and material usage.

- Robotic paint application systems, guided by AI, ensure unparalleled consistency and thickness uniformity for complex automotive geometries.

- Predictive maintenance schedules enabled by AI analytics minimize unscheduled downtime and extend the operational life of filtration and heating components.

- Integration of AI tools for digital color matching and spectroscopy improves accuracy in repair painting, especially critical for complex metallic or pearl finishes.

DRO & Impact Forces Of Automobile Spray Booth Market

The dynamics of the Automobile Spray Booth Market are significantly influenced by a synergistic interplay of market drivers, operational restraints, and long-term opportunities, collectively shaping the direction and pace of growth. Key drivers include stringent governmental regulations globally regarding the control of VOCs and particulate emissions, compelling continuous investment in compliant, high-efficiency filtration and ventilation systems. Simultaneously, the persistent demand for high-quality, durable automotive finishes, driven by consumer expectations and manufacturer warranties, necessitates the use of controlled environments offered by advanced spray booths. The main restraints involve the high initial capital investment required for installing modern, compliance-ready spray booths, which poses a barrier, particularly for smaller independent repair facilities, coupled with the rising operational costs associated with energy consumption for heating and ventilation. Opportunities emerge from the accelerating adoption of smart booth technologies, including integrated IoT sensors for real-time monitoring and energy management, and the increasing market acceptance of advanced curing technologies like UV and LED systems that drastically reduce processing times and energy usage. These forces result in an impact characterized by rapid technological innovation focused on sustainability, countered by the inherent cost pressures of specialized capital equipment.

Segmentation Analysis

The Automobile Spray Booth Market is analyzed across various critical segments, including booth type, application, structure, technology, and geography, providing a granular view of market dynamics and adoption trends. Segmentation by booth type is fundamental, differentiating between cross-draft, side-draft, and the increasingly popular downdraft systems, each offering varying levels of air quality control and efficiency suitable for different operational requirements and budget constraints. The application segment divides the market into OEM paint shops, which require highly automated, continuous flow systems, and the aftermarket segment (collision repair and custom shops), which demands flexible, batch-processing capabilities. Analyzing these segments helps stakeholders understand where investment is most concentrated and how technological adoption differs based on scale and operational purpose.

Further analysis focuses on structure types, contrasting stationary booths, which are the traditional standard, against movable or retractable booths, offering flexibility in space utilization, especially valuable in multipurpose workshops. Technology segmentation is vital, addressing heating and curing methods (e.g., heated vs. non-heated, conventional gas/electric vs. infrared/UV curing), reflecting the industry's shift towards faster cycle times and lower energy costs. The complexity of modern paint chemistry, particularly the shift to waterborne coatings, inherently necessitates heated booths capable of maintaining precise temperature and humidity profiles for effective solvent evaporation and curing, thus driving the growth of sophisticated technological solutions across all market verticals.

- By Booth Type:

- Downdraft Spray Booths (Dominant due to superior contamination control)

- Cross-draft Spray Booths

- Side-draft Spray Booths

- Semi-Downdraft Spray Booths

- By Application:

- OEM Paint Shops (High automation, mass production)

- Aftermarket (Collision Repair Centers, Independent Body Shops)

- Custom and Specialized Shops

- By Structure:

- Stationary/Fixed Booths

- Movable/Retractable Booths

- By Technology (Heating/Curing):

- Heated Booths (Gas, Electric, Direct-fired)

- Non-Heated Booths

- IR Curing Systems Integrated Booths

- UV Curing Systems Integrated Booths

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy)

- Asia Pacific (China, Japan, India, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (UAE, Saudi Arabia, South Africa)

Value Chain Analysis For Automobile Spray Booth Market

The Value Chain for the Automobile Spray Booth Market begins with the upstream suppliers responsible for providing critical raw materials and components, which include specialized sheet metal (often galvanized or powder-coated steel), high-efficiency filtration media (both intake and exhaust filters), heating elements (gas burners or electric coils), and complex electronic control systems (PLCs, VFDs, sensors). The quality and cost of these foundational inputs directly influence the final performance and pricing of the spray booth system. Manufacturers then undertake the highly engineered process of designing, fabricating, assembling, and testing the complex structures and integrated machinery. Successful manufacturers leverage proprietary designs focused on maximizing energy efficiency, optimizing airflow dynamics, and ensuring compliance with multiple global safety and environmental standards (e.g., NFPA, OSHA, EPA standards).

The downstream flow involves the distribution channel, which is typically bifurcated into direct sales for large, complex OEM installations and indirect channels utilizing authorized distributors or dealers for the fragmented aftermarket segment. Direct channels allow manufacturers to offer comprehensive project management, customization, and integration services specific to large production lines. Conversely, the indirect channel, managed by specialized equipment dealers, provides local presence, quick installation, financing options, and crucial after-sales support, including spare parts and routine maintenance services, which are vital for body shops dependent on minimal operational downtime. The effectiveness of the downstream distribution network, particularly the availability of trained technicians for maintenance and repair, significantly impacts customer satisfaction and market reach.

Furthermore, post-installation services represent a significant value-add opportunity. This includes mandatory regular filter changes, calibration of air balancing systems, and compliance inspections. Direct relationships with end-users, fostered through maintenance contracts, enable manufacturers to gather valuable operational data, which informs future product development focused on predictive maintenance and enhanced efficiency features. The value chain, therefore, emphasizes engineering precision upstream, logistical efficiency through distribution, and robust service capabilities downstream to ensure the long-term optimal performance of these capital-intensive systems.

Automobile Spray Booth Market Potential Customers

The primary customers for automobile spray booth systems span three major categories, each with distinct requirements influencing purchasing decisions and technology adoption rates. The largest segment comprises collision repair centers, ranging from independent, family-owned body shops to large, nationally franchised MSOs (Multiple-Site Operators). These customers prioritize versatility, energy efficiency (to manage overhead costs), and high throughput capabilities to process a large volume of varied repair jobs quickly. Their purchasing decisions are often heavily influenced by financing options, ease of maintenance, and compliance certification necessary for insurance-mandated repairs. The rapid consolidation in the collision repair industry favors suppliers offering standardized, networked booth solutions capable of integration across multiple repair sites.

The second critical customer group is the Original Equipment Manufacturers (OEMs). These automotive manufacturers require highly specialized, large-scale, automated paint lines integrated directly into their assembly processes. Their focus is on extreme precision, high production volume, complete environmental isolation, and seamless integration with robotic application systems. Purchasing criteria for OEMs emphasize longevity, customization for specific vehicle models, advanced control systems for data reporting, and maximum energy recuperation technology to meet corporate sustainability goals. These projects typically involve multi-million dollar contracts and long-term service agreements directly with the manufacturing supplier.

The third group includes specialized customers, such as commercial vehicle manufacturers (trucks, buses), custom vehicle modification shops, and aviation/aerospace component coaters who utilize automotive-grade booths or customized variants. These niche buyers seek booths capable of handling oversized components or requiring specialized curing processes (e.g., high-temperature baking for industrial coatings). While smaller in volume compared to collision repair, this segment often demands unique modifications regarding booth size, access points, and ventilation capacity, providing opportunities for specialized manufacturers to serve high-margin projects requiring tailored engineering solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,260 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Global Finishing Solutions (GFS), PPG Industries, Accudraft, Blowtherm, Dalby, Sima, Nova Verta, Standard Tools and Equipment, Col-Met, USI ITALIA, SprayTech/Junair, Todoroki Kogyo, AFC Finishing Systems, Jingzhongjing (JZJ), Hengst Filtration, CELETTE, Garmat USA, Rohner, Saico, Iron Man Spray Booths |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automobile Spray Booth Market Key Technology Landscape

The technological landscape of the Automobile Spray Booth Market is characterized by continuous innovation focused on optimizing energy consumption, reducing operational cycle times, and ensuring environmental compliance. A core technology is the advanced ventilation system, specifically the high-efficiency downdraft configuration, which utilizes variable frequency drives (VFDs) to precisely control airflow volume and pressure. VFDs not only maintain optimal booth environment conditions but also significantly reduce electricity usage compared to traditional single-speed fans, achieving substantial long-term cost savings. Furthermore, sophisticated air make-up units (AMUs) are crucial, incorporating advanced heat recovery and recirculation technology to reduce the energy load required for heating incoming air, especially in cold climates, thereby improving the sustainability profile of the operations.

Another major technological advancement involves curing methodologies. While conventional gas-fired heating systems remain prevalent, there is a strong shift toward accelerated curing technologies such as Shortwave Infrared (IR) and Ultraviolet (UV) light curing systems. IR curing penetrates the coating quickly, dramatically reducing drying times and boosting throughput, particularly for large sections. UV curing, integrated primarily for specialized UV-curable primers and clear coats, offers near-instantaneous drying without the need for high heat, making it extremely energy efficient and ideal for spot repairs. The integration of these curing technologies often requires specialized booth modifications and enhanced safety protocols due to the specific spectrums of light utilized.

Finally, the proliferation of IoT (Internet of Things) and smart controls is defining the modern booth. These systems integrate various sensors (temperature, humidity, pressure differential, filter saturation) that feed data into a central PLC or HMI interface. This allows operators to monitor performance in real-time, implement adaptive control strategies, and facilitate predictive maintenance scheduling. Modern booths are often equipped with digital monitoring features that generate compliance reports automatically, streamlining adherence to strict local environmental regulatory bodies and providing verifiable proof of VOC capture and particulate control, which is essential for audit preparedness.

Regional Highlights

- North America (U.S., Canada, Mexico): North America represents a mature and technologically advanced market. The US market is heavily influenced by large MSOs in the collision repair sector that prioritize high throughput, energy efficiency, and low-VOC compliance (driven by state-level regulations like California’s CARB). Demand here is focused on replacing older equipment with VFD-equipped, downdraft booths featuring integrated curing technologies (IR/UV). Canada follows similar trends but with a stronger focus on heating efficiency due to colder climate demands. Mexico is rapidly expanding its OEM and aftermarket presence, increasing demand for standard and semi-downdraft systems to support burgeoning vehicle manufacturing hubs.

- Europe (Germany, UK, France, Italy): Europe is defined by extremely strict environmental standards (e.g., EU Solvent Emissions Directive), driving mandatory upgrades to booths capable of handling waterborne paints efficiently and recovering solvents effectively. Germany and the UK lead in adopting sophisticated, high-end automated booths in both OEM and premium body shops. Innovation in energy recovery systems (recuperators) and compliance monitoring tools is high. The market is fragmented but highly sensitive to long-term operational costs and environmental accreditation.

- Asia Pacific (APAC) (China, Japan, India, South Korea): APAC is the fastest-growing region, fueled by massive expansion in vehicle production (OEM) and a rapidly growing aftermarket sector driven by increasing vehicle density. China dominates the regional market both in terms of manufacturing capacity and consumption, demanding a wide range of booths, from basic cross-draft systems for smaller shops to state-of-the-art, large-scale automated lines for multinational OEMs. Japan and South Korea focus on precision, demanding highly specialized, clean-room environments for premium vehicle coating, often integrating robotics and advanced air purification systems. India shows significant potential due to infrastructural upgrades in its automotive service sector.

- Latin America (Brazil, Argentina): This region exhibits steady growth, primarily driven by the expansion and modernization of existing collision repair infrastructure. Price sensitivity is a key factor, favoring cost-effective, durable booth solutions. Adoption of advanced features like full downdraft systems and high-efficiency heating is gradually increasing, spurred by foreign investment and the establishment of global service chain standards, particularly in Brazil.

- Middle East & Africa (MEA) (UAE, Saudi Arabia, South Africa): The MEA market is marked by rising demand, especially in the Gulf Cooperation Council (GCC) countries, supported by high demand for luxury automotive services and increasing investments in localized vehicle assembly operations. Climate considerations (high temperatures and humidity/dust) necessitate specialized filtration and cooling systems, sometimes requiring custom engineering solutions to ensure quality finish in harsh environments. South Africa acts as a regional hub for both manufacturing and aftermarket repair, driving stable demand for medium-to-high quality booths.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automobile Spray Booth Market.- Global Finishing Solutions (GFS)

- PPG Industries (Through equipment division partnerships)

- Accudraft

- Blowtherm

- Dalby

- Sima

- Nova Verta

- Standard Tools and Equipment

- Col-Met

- USI ITALIA

- SprayTech/Junair

- Todoroki Kogyo

- AFC Finishing Systems

- Jingzhongjing (JZJ)

- Hengst Filtration (Component Supplier)

- CELETTE

- Garmat USA

- Rohner

- Saico

- Iron Man Spray Booths

- Beilite Group

- Jianbo Spray Booth Manufacturing

- Epcon Industrial Systems

- Binks (ITW Industrial Spray)

Frequently Asked Questions

Analyze common user questions about the Automobile Spray Booth market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using a downdraft spray booth over a cross-draft system?

Downdraft spray booths offer superior air filtration and flow dynamics, pulling contaminated air and overspray downward and away from the vehicle surface. This results in cleaner paint finishes, minimized risk of particulate contamination, and improved compliance with regulatory standards, making them the preferred choice for high-quality refinishing.

How do modern spray booths improve energy efficiency and reduce operational costs?

Modern booths utilize Variable Frequency Drives (VFDs) to modulate fan speeds based on operational requirements, highly efficient heating systems (like direct-fired gas or heat recovery), and accelerated curing technologies (IR/UV). These features collectively minimize energy consumption during ventilation and drastically cut down the time and fuel required for the critical baking cycle.

What impact are stricter VOC emission regulations having on the Automobile Spray Booth Market?

Stricter VOC regulations, particularly those promoting waterborne paints, necessitate spray booths with highly precise temperature and humidity controls to ensure proper flash-off and curing. This drives demand for mandatory upgrades to advanced, sealed, and often heated downdraft systems equipped with effective exhaust filtration and solvent capture mechanisms.

Is it financially viable for independent body shops to adopt advanced curing technologies like UV or Infrared (IR)?

Yes, while the initial investment is higher, advanced curing technologies are financially viable due to significantly reduced cycle times, allowing body shops to process more vehicles daily. IR and UV systems also offer substantial savings on natural gas or electricity required for traditional full-baking cycles, providing a fast return on investment through increased throughput and lower energy bills.

What maintenance practices are most critical for ensuring optimal performance and compliance of a spray booth?

Critical maintenance includes the mandatory, timely replacement of intake and exhaust filters to maintain optimal airflow balance and filtration efficiency. Regular calibration of air pressure sensors, inspection of heating elements, and cleaning of internal surfaces are also essential to prevent contamination and ensure consistent regulatory compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager