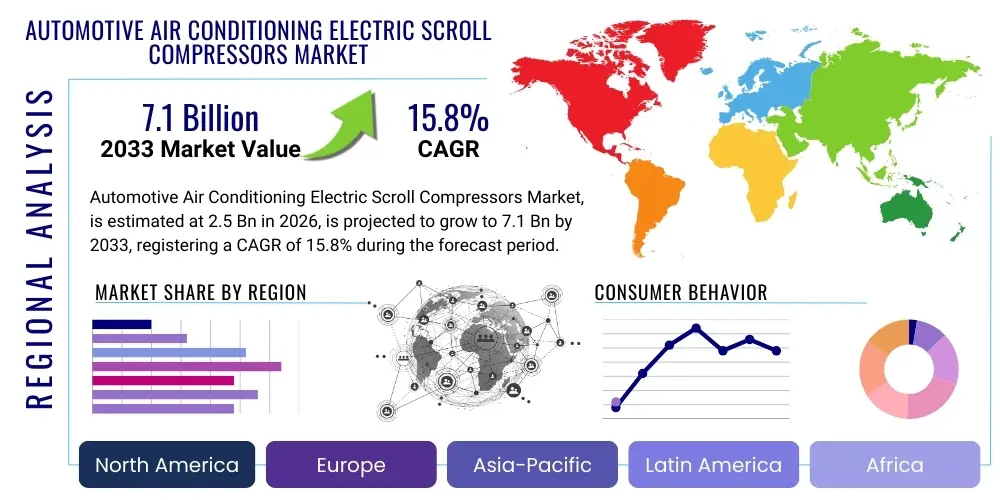

Automotive Air Conditioning Electric Scroll Compressors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441484 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Automotive Air Conditioning Electric Scroll Compressors Market Size

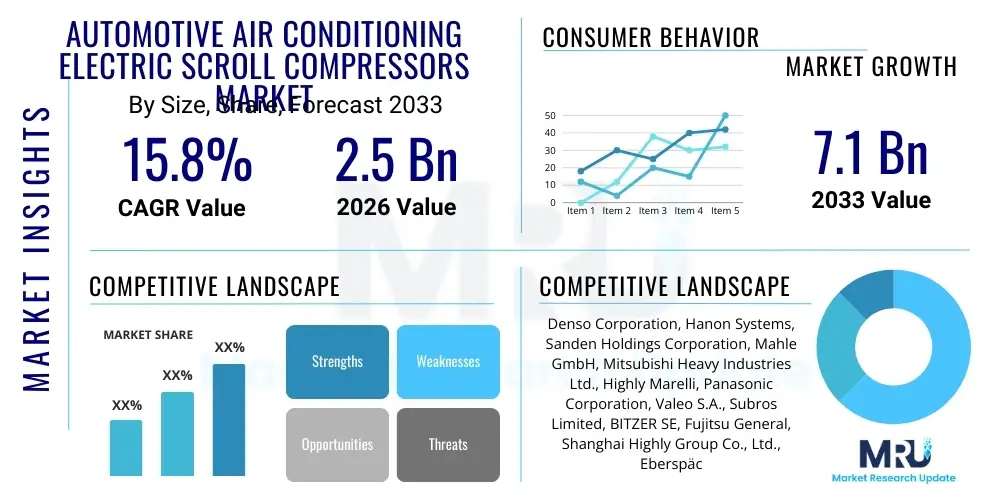

The Automotive Air Conditioning Electric Scroll Compressors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 15.8% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 7.1 Billion by the end of the forecast period in 2033.

Automotive Air Conditioning Electric Scroll Compressors Market introduction

The Automotive Air Conditioning Electric Scroll Compressors Market is experiencing unprecedented growth driven primarily by the profound global shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs), fundamentally altering the thermal management paradigm in the transportation sector. Unlike traditional belt-driven compressors used in internal combustion engine (ICE) vehicles, which rely on mechanical power derived from the engine's operation, electric scroll compressors function independently, drawing high-voltage power directly from the vehicle's battery pack. This independence is not merely a convenience but a necessity for maintaining consistent cabin cooling and, more importantly, precise thermal management efficiency within critical electric drivetrain components, such as the battery and power electronics. Since energy consumption directly affects the driving range of an EV, the efficiency of the electric compressor is a primary design consideration. The intrinsic design benefits of electric scroll technology, including inherently low noise generation, minimal vibration transmission, and superior coefficient of performance (COP) relative to conventional mechanical compressors, position them as indispensable components in the complex thermal loops of modern electrified vehicles, fostering rapid and sustained adoption across all major global automotive manufacturing regions, particularly in markets with aggressive electrification goals like the European Union and China. The regulatory landscape, marked by increasingly stringent mandates aimed at substantial reductions in fleet average CO2 emissions and fuel consumption, further compels automakers to expedite the transition from mechanically coupled thermal systems to optimized, electrified solutions.

Electric scroll compressors are sophisticated positive displacement devices characterized by their unique scroll mechanism, which comprises a stationary spiral scroll and an orbiting spiral scroll. As the orbiting scroll moves eccentrically around the stationary scroll, it continuously traps pockets of refrigerant gas, forcing them into a progressively smaller volume until they are discharged at high pressure. This smooth, continuous compression process delivers a nearly pulsation-free flow of refrigerant, a significant advantage over reciprocating or piston compressors, enhancing system lifespan and reducing operational noise. Key product specifications emphasize variable speed control enabled by integrated inverter technology, allowing the cooling capacity to be precisely matched to the load demand, optimizing energy use under diverse conditions. Furthermore, compatibility with new generation, environmentally benign refrigerants such as R1234yf is standard, while research into natural refrigerants like R744 (CO2) is rapidly maturing. These compressors serve dual roles: ensuring optimal occupant comfort by cooling or heating the cabin air, and critically, managing the temperature of high-voltage battery packs through dedicated chilling circuits within the Battery Thermal Management System (BTMS). Maintaining the battery within a narrow, ideal temperature window is vital for maximizing its power output, extending its lifespan, and enabling ultra-fast charging capabilities without degradation.

The synergistic benefits of electric scroll compressors translate directly into tangible competitive advantages for automotive OEMs. The immediate and most valued benefit is enhanced system efficiency, which directly mitigates the "range anxiety" often associated with EV ownership by minimizing auxiliary load penalties. This efficiency gain is coupled with dramatically improved noise, vibration, and harshness (NVH) characteristics, significantly elevating the perceived quality and luxury appeal of electric vehicles, particularly at lower speeds where engine noise is absent. Moreover, their ability to support rapid and precise heating and cooling cycles makes them essential for advanced heat pump integrated HVAC systems, which can scavenge waste heat from the battery and motor, further boosting thermal efficiency in colder climates. The market expansion is fundamentally driven by robust governmental emissions regulations demanding electrification, substantial capital investment by global OEMs in developing scalable, dedicated EV architectures (often referred to as 'skateboard' platforms), and the undeniable consumer shift towards vehicles prioritizing high comfort, technological integration, and minimized environmental impact. Ongoing technological refinement in high-power density motors and robust power electronics continues to improve the reliability and capacity-to-size ratio of these compressors, solidifying their status as a core foundational technology for the modern electric vehicle.

Automotive Air Conditioning Electric Scroll Compressors Market Executive Summary

The market for Automotive Air Conditioning Electric Scroll Compressors is undergoing intense competitive transformation and accelerated technological advancements, largely dictated by the sweeping global transition towards electric mobility platforms. Contemporary business trends indicate a strong pattern of strategic alignment, where Tier 1 thermal system suppliers are forming deep, long-term partnerships and securing multi-generational supply contracts with global automotive original equipment manufacturers (OEMs). This collaborative model ensures co-development of thermal modules optimized for new vehicle architectures, guaranteeing component compatibility and robust supply chain resilience. Core manufacturers are prioritizing vertical integration, particularly in the realm of power electronics, striving to design and manufacture their own high-efficiency inverter control units tailored precisely to their scroll mechanism. This strategy allows for optimization of control logic, leading to higher Coefficient of Performance (COP) ratios under real-world operating conditions—a critical factor in reducing energy consumption and maximizing EV range. Furthermore, in response to the overarching industry goal of vehicle lightweighting, material science innovation is focused on developing stronger, yet lighter, aluminum alloys for compressor bodies and optimizing motor design to minimize the package size and mass without compromising cooling capacity. Significant financial commitments are directed toward scaling global manufacturing footprint, especially within key high-growth regions like Southeast Asia and Central Europe, and investing in advanced R&D focused on next-generation high-voltage isolation and safety systems necessary for 800V and higher EV architectures.

From a regional perspective, the Asia Pacific (APAC) region, driven primarily by the massive electrification efforts and industrial capacity in the People's Republic of China, maintains an undisputed leadership position in terms of both production volume and consumption rate of Battery Electric Vehicles (BEVs). The conducive policy environment, coupled with unparalleled government support for battery manufacturing and the proliferation of domestic EV manufacturers and startups, creates an insatiable demand for electric scroll compressors. Following closely, the European market demonstrates high technological maturity, fueled by ambitious CO2 reduction mandates and a consumer base demanding premium and highly efficient EV solutions, with a particular emphasis on heat pump integration for cold weather performance. North America is emerging as the fastest-accelerating market segment, spurred by large-scale public and private sector investment aimed at establishing robust domestic supply chains and production capacity. The competitive environment across these regions is rapidly migrating from a purely cost-centric model to one centered on technological superiority, demonstrated system reliability, noise performance, and the ability to seamlessly integrate the compressor into complex vehicle energy management networks. This demands that suppliers differentiate themselves through verifiable engineering excellence, especially in managing the thermal and electrical challenges inherent in high-performance EVs.

Analysis of segment performance clearly underscores the profound market influence of the pure Battery Electric Vehicle (BEV) segment, which necessitates comprehensive, electric-only thermal solutions, far surpassing the proportional demand originating from Plug-in Hybrid Electric Vehicles (PHEVs), which often retain some legacy mechanical components. In terms of voltage architecture, 400V systems currently command the largest installed base due to their technical maturity, lower production cost, and widespread adoption across current-generation EVs. However, the 800V segment is forecast to achieve significantly higher Compound Annual Growth Rates (CAGR), aligning with the automotive industry’s commitment to premium, ultra-fast charging models. Regarding the displacement mechanism, although fixed displacement electric scrolls offer a competitive, straightforward solution for entry-level models, the industry trend strongly favors variable displacement compressors. Variable displacement units provide enhanced modulation capability, superior part-load efficiency, and the precise temperature regulation vital for advanced, multi-circuit heat pump systems that must simultaneously handle cabin comfort and critical powertrain component cooling. Furthermore, the integration of advanced smart electronics, including onboard diagnostic capabilities and communication interfaces, into the compressor unit represents a major technological trajectory, preparing these components for fully connected and autonomous vehicle ecosystems.

AI Impact Analysis on Automotive Air Conditioning Electric Scroll Compressors Market

Analysis of common user questions reveals significant interest in how artificial intelligence (AI) and machine learning (ML) optimize energy consumption and enhance the operational lifespan of electric scroll compressors within the context of EV thermal management. Users frequently inquire about the feasibility of AI-driven predictive maintenance to minimize compressor failure, the role of ML algorithms in dynamic climate control based on passenger load and external conditions, and how AI might integrate with route optimization software to pre-condition the battery for charging or performance. The key themes revolve around achieving maximum energy efficiency, enhancing system reliability, and leveraging data analytics for customized and intelligent thermal comfort. There is a strong user expectation that AI will transition the AC system from a reactive control mechanism to a proactive, predictive thermal management unit, directly contributing to extending the vehicle's effective driving range, which is a prime concern for EV owners. This shift moves the compressor control from simple thermostat regulation to complex optimization routines that anticipate future thermal needs based on driving patterns, minimizing instantaneous power spikes and balancing thermal requirements against propulsion energy needs, ultimately maximizing range and component longevity in a highly demanding operational environment.

- AI-driven Predictive Maintenance: Utilizing sensor data (pressure, temperature, current draw, vibration) and ML models trained on fleet data to identify subtle deviations indicative of potential scroll wear or motor degradation, allowing for timely servicing and minimizing catastrophic compressor failures, thus reducing warranty costs for OEMs.

- Dynamic Efficiency Optimization: Machine learning algorithms dynamically adjust compressor speed, refrigerant flow, and system setpoints based on real-time factors like interior solar load, precise cabin occupancy detection, external temperature forecasts, and driver-specific thermal preferences, maximizing the Coefficient of Performance (COP) under all operating loads.

- Integrated Energy Management: AI optimizes the distribution of high-voltage power resources between the essential propulsion system, high-speed charging requirements, and the electric AC system, prioritizing the preservation of driving range while ensuring essential safety protocols related to battery temperature are strictly maintained.

- Thermal Pre-conditioning Strategy: AI models anticipate the precise need for battery heating or cooling cycles based on navigation inputs (e.g., proximity to a planned DC fast charger or commencement of a high-load route segment), enabling proactive activation of the electric compressor to bring the battery into the optimal charging or performance temperature window ahead of time.

- Fault Diagnostics and Calibration: AI significantly enhances the speed and accuracy of identifying system anomalies through pattern recognition and automatically recalibrating inverter control parameters to compensate for measured component wear or minor system drift, thereby maintaining optimal performance and extending mean time between failures.

DRO & Impact Forces Of Automotive Air Conditioning Electric Scroll Compressors Market

The fundamental market trajectory is shaped by a compelling confluence of regulatory push factors and mature technological enablers, which act as dominant drivers, while significant financial and engineering hurdles impose measurable restraints, opening critical avenues for future market expansion. The overarching driver is the undeniable momentum of global automotive electrification, which mandates the replacement of mechanical AC systems with electric compressors as a core technology for all high-voltage vehicles, transforming this component from an auxiliary system into an essential, safety-critical subsystem. The primary restraints revolve around the inherently high capital expenditure required for high-voltage component manufacturing and the complex technical challenge of integrating a sophisticated thermal loop that must operate efficiently across extreme temperature ranges, minimizing the energy penalty on battery life. Nonetheless, substantial opportunities exist, particularly in leveraging the electric compressor for highly integrated, reversible heat pump systems capable of efficiently providing both heating and cooling, and in penetrating the rapidly electrifying heavy-duty commercial transport sector, which requires specialized, high-capacity electric solutions. These intersecting forces collectively enforce a substantial and sustained positive impact on the market's growth, pushing innovation toward more durable, efficient, and technologically integrated products compatible with future 800V standards.

A primary and non-negotiable driver stems from the necessity of effective Battery Thermal Management (BTM). Lithium-ion batteries function optimally and safely only within narrow temperature windows; overheating significantly degrades lifespan, while excessive cold severely limits charging speed and usable capacity. The electric scroll compressor provides the crucial mechanism for achieving rapid, precise temperature control necessary for BTM, ensuring optimal vehicle performance and longevity, thereby establishing a persistent and exponentially growing market demand. This is further supported by government policies globally, which utilize powerful financial incentives (e.g., tax credits, purchase subsidies) and severe regulatory penalties (e.g., non-compliance fines for CO2 emissions) to compel automakers toward achieving mass-market EV penetration. However, this powerful demand is constrained by the inherent complexity of high-voltage component engineering. Designing an electric compressor that is reliable over 150,000 miles, capable of handling rapid thermal cycling, and integrating seamlessly with multiple subsystems (BMS, ECU, Cabin HVAC) represents a significant engineering challenge. Furthermore, dependence on globalized supply chains for exotic materials, specifically rare earth magnets essential for high-power density motors and specialized insulation materials for 800V safety, represents a key logistical restraint that can impact production scalability and cost control for Tier 1 suppliers.

Key opportunities are focused on technological advancement that yields superior energy performance and opens new market segments. The growing feasibility of utilizing R744 (CO2) as a refrigerant presents a major opportunity, as R744 is highly environmentally friendly and offers unmatched heating performance in sub-zero climates, although it demands ultra-high pressure compressors, thus segmenting the market for advanced technology providers. Moreover, as autonomous driving technology matures, the demand for high-reliability cooling systems for the vehicle’s powerful onboard computing clusters (HPC) provides an entirely new adjacent application for robust, high-capacity electric compressors. The cumulative impact of these market forces—the relentless pressure from electrification mandates, the consumer demand for enhanced energy efficiency, and the technical hurdles related to cost and complexity—is catalyzing structural shifts within the automotive supply industry. This environment necessitates significant R&D investment, encourages strategic acquisitions and consolidation among smaller players, and fundamentally raises the barrier to entry, ensuring that market success is highly correlated with proven technical capability, robust quality assurance, and financial resilience to fund continuous innovation cycles.

- Drivers:

- Rapid global adoption of Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) necessitating dedicated electric thermal management systems.

- Strict governmental mandates worldwide enforcing substantial reductions in CO2 emissions and accelerating the transition to zero-emission vehicles across major economies.

- Critical necessity of electric compressors for efficient battery thermal management (BTM) systems, which directly impacts battery life, safety, and fast-charging capability in high-voltage vehicles.

- Increasing consumer preference for enhanced cabin comfort, rapid temperature conditioning, and superior Noise, Vibration, and Harshness (NVH) characteristics offered by modern electric systems.

- Restraints:

- Higher initial manufacturing and integration costs associated with complex high-voltage components, particularly the integrated power electronics (inverters) and specialized motors.

- The inherent challenge of minimizing the energy penalty of the thermal system on the overall EV driving range, requiring constant efficiency improvements.

- Vulnerability related to the global supply chain stability for strategic raw materials, including rare earth magnets and specialized silicon carbide (SiC) power semiconductors.

- Opportunities:

- Expansion into the heavy-duty commercial vehicle segment (electric buses, Class 8 trucks) which require large-capacity, high-durability electric scroll compressors.

- Technological specialization in high-efficiency, reversible heat pump architectures utilizing natural or extremely low-GWP refrigerants (e.g., R744/CO2).

- Development and mass production of 800V compatible electric compressors, enabling ultra-fast charging capability and supporting the premium EV segment growth.

- Potential integration into sophisticated cooling infrastructure for high-performance computing (HPC) platforms essential for highly autonomous driving functions within vehicles.

- Impact Forces:

- Electrification Mandate: The single strongest long-term force driving structural market transformation and component demand growth.

- Technological Complexity and Cost: Acts as a high barrier to entry, favoring established, highly capitalized Tier 1 suppliers with deep R&D resources.

- Efficiency Imperative: Continuous market pressure demanding improvement in Coefficient of Performance (COP) to reduce auxiliary power consumption and maximize EV range performance.

Segmentation Analysis

The Automotive Air Conditioning Electric Scroll Compressors market is meticulously segmented based on key criteria including the underlying vehicle technology, the voltage architecture employed, the type of displacement mechanism, and the end-use vehicle category. This detailed segmentation allows manufacturers and strategists to precisely target product development and market efforts towards the fastest-growing and most profitable niches within the electric vehicle landscape. The segmentation by vehicle type, for instance, clearly separates the distinct requirements of pure battery electric vehicles—which rely solely on the electric compressor for all thermal needs and are therefore the highest volume users—versus plug-in hybrids, which may utilize a supplemental or integrated mechanical compressor in certain operational modes. Understanding these differences is crucial for optimizing compressor size, power rating, and control logic for maximum efficiency in each specific application. The increasing focus on 800V systems highlights the divergence in technological pathways being pursued by premium and high-performance EV manufacturers who seek to minimize charging times and maximize high-speed driving range.

The segmentation by voltage is perhaps the most dynamic area, reflecting the industry's shift from established 400V platforms towards the nascent but highly promising 800V architectures. While 400V systems are currently standard and dominate the volume market due to cost-effectiveness, technical maturity, and widespread installation in most current-generation EV models, 800V systems are rapidly gaining momentum because they enable significantly faster charging times and require lower current levels for the same power output, permitting the use of lighter wiring harnesses and resulting in reduced thermal losses throughout the vehicle’s electrical system. Consequently, manufacturers are heavily investing in redesigning internal power electronics, insulation systems, and motor windings to safely and reliably operate their scroll compressors at these higher voltages, ensuring component reliability under the extreme electrical and thermal stress inherent to 800V operation. This voltage segmentation dictates component selection, specialized insulation requirements, and dictates the entire inverter design, making it a critical strategic determinant in the competitive supplier landscape.

Further granularity is provided by the displacement type, differentiating between fixed and variable displacement compressors. Fixed displacement compressors are characterized by their mechanical simplicity, resulting in lower manufacturing costs, and are typically suitable for smaller, entry-level EVs where price sensitivity is paramount and thermal requirements are simpler. However, variable displacement compressors offer vastly superior performance by continuously adjusting the internal displacement volume based precisely on the actual cooling load demand, providing highly accurate temperature control and significantly better efficiency, particularly during partial load operation which accounts for the majority of driving time. This modulation capability is absolutely paramount for complex heat pump systems that require continuous, precise balancing of capacity for simultaneous battery cooling, motor cooling, and cabin climate control. The necessary evolution across vehicle types, ranging from compact passenger cars to voluminous heavy-duty trucks, further necessitates segment-specific engineering, demanding increasingly robust, high-capacity electric scroll compressors tailored to the substantial and sustained thermal demands of large battery packs and extensive cabin spaces typical of commercial vehicle applications.

- By Vehicle Type:

- Battery Electric Vehicles (BEV): Largest and fastest-growing segment, relying entirely on electric compression.

- Plug-in Hybrid Electric Vehicles (PHEV): Often uses electric compression for low-speed/idle operation.

- Fuel Cell Electric Vehicles (FCEV): Utilizes electric compression for cabin cooling and stack thermal management.

- By Voltage Architecture:

- 400V Systems: Current market standard, widespread in mass-market EVs.

- 800V Systems: Fastest growing segment, used in premium, high-performance, and ultra-fast charging platforms.

- By Displacement Type:

- Fixed Displacement: Economical choice for entry-level models; constant capacity when running.

- Variable Displacement: Preferred for efficiency and precise control; capacity modulated based on load.

- By Application:

- Passenger Vehicles (Sedans, SUVs, Compacts)

- Commercial Vehicles (Light, Medium, Heavy-Duty Trucks & Buses): Requires specialized, high-capacity units.

- By Component:

- Compressor Unit (Scroll Mechanism, Housing, Bearings)

- Motor/Inverter Unit (Power Electronics, Motor Stator/Rotor, Controller)

Value Chain Analysis For Automotive Air Conditioning Electric Scroll Compressors Market

The value chain for Automotive Air Conditioning Electric Scroll Compressors is complex, spanning from primary raw material sourcing to final vehicle integration and subsequent aftermarket servicing, defined by highly specialized manufacturing stages and pronounced interdependence among market actors. The upstream segment initiates with the procurement and processing of fundamental raw materials, including high-grade aluminum and specialized alloys necessary for the high-strength, lightweight compressor housing and scroll components. Critically, this stage involves the sourcing of strategic materials such as rare earth elements (Neodymium, Dysprosium) essential for manufacturing the high-power density permanent magnets within the motor, and advanced power semiconductors (SiC, GaN) required for the integrated inverter control unit. The material cost and secure supply of these components profoundly influence the final product cost and manufacturing scalability. Companies specializing in the precision machining and surface treatment of the scroll sets, focusing intensely on achieving micron-level tolerances and superior sealing capabilities to minimize internal leakage and maximize thermal efficiency, represent a significant value-add function early in the chain.

The midstream focuses on the core manufacturing, assembly, and rigorous testing of the complete electric scroll compressor module, which encompasses the mechanical scroll mechanism, the integrated high-speed electric motor, and the sophisticated, liquid-cooled inverter control unit. Tier 1 suppliers, who dominate this stage, function primarily as advanced system integrators. They leverage extensive expertise in automotive thermal dynamics, power electronics integration, and control software development to deliver a validated, high-voltage component designed to meet stringent OEM performance specifications. The established distribution channel operates overwhelmingly through an indirect model, characterized by tightly controlled, just-in-time logistics where these Tier 1 suppliers deliver the final, tested compressor units directly to the Original Equipment Manufacturers (OEMs) assembly lines. The OEMs then integrate the compressor into the vehicle's complex high-voltage thermal management and HVAC circuits. Direct sales channels are minimal, typically restricted to highly specialized, low-volume vehicle builders or the replacement parts market, where procurement flows through authorized distributor networks to ensure parts authenticity and quality control.

Downstream activities encompass vehicle manufacturing, final consumer sales, and the subsequent lifecycle support, including warranty services and aftermarket maintenance. The reliability and energy performance of the electric scroll compressor directly influence the consumer's perception of the EV's quality, efficiency, and long-term operating costs, placing immense pressure on the entire supply chain to achieve zero-defect quality standards (e.g., IATF 16949 compliance). Furthermore, the highly specialized nature of high-voltage thermal systems mandates specific certification, diagnostic tools, and technician training for effective servicing, creating a technically demanding but profitable aftermarket sector focused on authorized service centers. Upstream value capture is maximized through effective cost management of raw materials and achieving economies of scale in component manufacturing, while downstream value is concentrated on delivering superior system integration capability, achieving high component reliability benchmarks, and providing comprehensive, long-term technical support to both the OEM and the eventual vehicle owner.

Automotive Air Conditioning Electric Scroll Compressors Market Potential Customers

The primary customer base for Automotive Air Conditioning Electric Scroll Compressors consists of Original Equipment Manufacturers (OEMs) across the global automotive sector. This diverse group includes established global automotive conglomerates (e.g., Volkswagen Group, General Motors, Toyota), highly specialized pure-play electric vehicle manufacturers (e.g., Tesla, Lucid, Nio), and niche commercial vehicle builders (e.g., electric bus and heavy-duty truck manufacturers like Proterra and Daimler Truck). These customers engage in high-volume procurement, integrating the electric scroll compressors as a fundamental, mission-critical component into their dedicated high-voltage vehicle platforms. The OEM procurement process is characterized by extremely strategic, long-term partnerships, involving extensive joint engineering activities and rigorous quality assurance protocols to ensure the compressor's full compatibility with the vehicle's specific electronic control units, chosen refrigerant type, and proprietary battery thermal management strategies. The scale and technical demands of these key customers necessitate that suppliers demonstrate not only manufacturing capability but also deep integration expertise.

A significant secondary customer segment includes large Tier 1 system integrators who specialize in delivering comprehensive thermal management modules, such as complete HVAC units or packaged Battery Thermal Management Systems (BTMS), directly to OEMs. These integrators source the core electric scroll compressors from specialist component manufacturers and subsequently package them with ancillary system components, including complex valve systems, heat exchangers, fluid pumps, and sophisticated electronic sensors, thereby providing a streamlined, ready-to-install solution. This segment values a supplier’s ability to provide standardized interfaces, robust technical documentation, and components that offer maximum ease of integration into larger, pre-validated systems, often under tight schedule constraints. Their focus is on minimizing complexity for the final vehicle manufacturer while ensuring the integrated module meets all performance targets, particularly around energy efficiency and thermal response time.

The tertiary, but expanding, customer segment is the automotive aftermarket channel, comprising authorized dealership service centers, certified independent repair facilities, and specialized automotive parts distributors. Although the volume of individual purch

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 7.1 Billion |

| Growth Rate | 15.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Denso Corporation, Hanon Systems, Sanden Holdings Corporation, Mahle GmbH, Mitsubishi Heavy Industries Ltd., Highly Marelli, Panasonic Corporation, Valeo S.A., Subros Limited, BITZER SE, Fujitsu General, Shanghai Highly Group Co., Ltd., Eberspächer Group, Concentric AB, Toshiba Corporation, Visteon Corporation, Calsonic Kansei, Bergstrom Inc., Xidian Heavy Industries, Aotecar New Energy Technology. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Air Conditioning Electric Scroll Compressors Market Key Technology Landscape

The technology landscape governing the Automotive Air Conditioning Electric Scroll Compressors market is defined by intensive research into high-efficiency material use, aerodynamic optimization, and advanced power electronics control, driven primarily by the need to minimize energy consumption and enable operational capability within the demanding 800V EV architectures. A fundamental technological focus is placed on the continuous optimization of the kinematic scroll set geometry and the material composition of the bearing systems and tip seals. Sophisticated analytical tools, including Computational Fluid Dynamics (CFD) simulations, are employed to model refrigerant flow dynamics and minimize internal leakage paths, while Finite Element Analysis (FEA) is crucial for validating structural integrity and noise reduction under high-speed operation, often reaching speeds up to 12,000 RPM. This engineering rigor aims to extract the maximum volumetric efficiency from the compressor, which directly correlates to an improved Coefficient of Performance (COP). Furthermore, the regulatory transition towards utilizing non-flammable, low-Global Warming Potential (GWP) refrigerants, such as R1234yf, and the exploratory use of natural refrigerants like R744 (CO2), mandates a complex redesign of internal components, seals, and lubrication systems to reliably handle the distinct thermodynamic properties and, in the case of R744, extremely high operating pressures.

The integration of the electric motor and its associated power electronics unit (inverter) represents the most technologically critical area of differentiation. Modern compressors overwhelmingly utilize high-efficiency Permanent Magnet Synchronous Motors (PMSMs) or Brushless DC (BLDC) motors, integrated seamlessly with compact, liquid-cooled inverters designed for high-power density. The breakthrough technology currently gaining massive adoption is the use of Silicon Carbide (SiC) and, to a lesser extent, Gallium Nitride (GaN) wide-bandgap semiconductors within the inverter modules. SiC components permit switching frequencies significantly higher than traditional Silicon (Si) IGBTs, dramatically reducing the size and mass of passive components (like inductors and capacitors), improving overall system efficiency by reducing switching losses, and importantly, mitigating Electromagnetic Interference (EMI) issues prevalent in high-voltage, high-frequency systems. The control algorithms embedded within these inverters are becoming increasingly complex, utilizing advanced field-oriented control (FOC) strategies to achieve precise, dynamic torque control and integrating sophisticated health monitoring capabilities that provide real-time diagnostics on motor load, vibration signatures, and thermal states, crucial for predictive maintenance strategies.

Beyond the core component, system-level integration capabilities dictate market readiness. The electric scroll compressor must communicate reliably and efficiently with the vehicle's central domain controller, the Battery Management System (BMS), and the thermal control unit (TCU) via high-speed automotive communication networks (CAN FD, Ethernet). This demands a high degree of interoperability and standardized communication interfaces. A growing trend involves developing fully integrated, modular thermal units that combine the compressor, expansion valve, heat exchangers, and associated sensors into a compact, pre-validated assembly—a strategy that simplifies the final vehicle assembly process for OEMs. Other emerging technologies include the adoption of oil-free or reduced-oil scroll designs to enhance compatibility with newer refrigerants and the implementation of advanced noise reduction techniques achieved through innovative motor isolation mountings and acoustic dampening within the compressor housing. The overall technological direction is firmly fixed on achieving maximum energy recuperation through highly optimized heat pump cycles and ensuring complete reliability and safety when operating under the extreme electrical and thermal stresses associated with next-generation 800V fast-charging platforms.

Regional Highlights

The regional market landscape for Automotive Air Conditioning Electric Scroll Compressors displays distinct patterns of growth, regulation, and technological adoption, reflecting the varied pace of electric vehicle transition globally. The dominance of electric vehicle adoption rates and local manufacturing capabilities heavily influence regional market size and growth trajectory, necessitating localized strategies for component suppliers.

- Asia Pacific (APAC): APAC, spearheaded by the immense automotive and EV manufacturing sector in China, represents the largest and fastest-growing market globally. China's market leadership is driven by ambitious national targets for new energy vehicles (NEVs), substantial domestic manufacturing capacity across the entire EV supply chain (batteries, motors, power electronics), and fierce competition among indigenous EV manufacturers (e.g., BYD, Nio, Xpeng). South Korea and Japan also contribute significantly, with established, high-tech automotive suppliers driving innovation in compact, highly efficient 800V systems and advanced integrated heat pumps. The sheer volume production potential and robust consumer demand for electrified mobility make this region the most critical strategic focal point for global component suppliers.

- Europe: Europe maintains a technologically robust and highly critical position, fundamentally driven by the world's most stringent emissions regulations (e.g., aggressive fleet average CO2 reduction targets and the pending Euro 7 standards) and high consumer willingness to adopt premium, technology-laden EVs. Countries like Germany, Norway, France, and the Netherlands lead in electrification efforts. The European market prioritizes high system efficiency, rigorous environmental sustainability (accelerated adoption of low-GWP refrigerants like R744/CO2), and extremely sophisticated system integration, particularly demanding optimization of electric compressors for use in highly efficient reversible heat pump applications, which are essential for mitigating battery range degradation in cold European winters.

- North America: The market is currently undergoing a rapid and transformative acceleration phase, substantially supported by massive federal investments (e.g., Inflation Reduction Act - IRA) designed to incentivize domestic EV production and establish localized supply chains for critical components like electric compressors. While historically slower than APAC and parts of Europe, the unwavering commitment of major US automakers (including Ford, GM, and Tesla) to transition their core fleets to pure electric platforms is generating immense, sustained demand. The focus in North America is balanced between supplying high-performance systems for larger vehicle categories (electric trucks and SUVs) and developing highly resilient, scalable domestic manufacturing capacity to service the burgeoning local EV production hubs.

- Latin America (LATAM), Middle East, and Africa (MEA): These regions are collectively categorized as emerging markets, characterized by foundational yet accelerating growth, often starting with public sector electrification initiatives (e.g., electric buses in major cities). Demand volumes are presently lower compared to the tripartite leading regions, but are expected to scale with increasing urbanization, improvements in charging infrastructure, and phased governmental adoption policies favoring electric public transit and fleet vehicles. Market penetration in these regions remains highly sensitive to favorable import tariffs, local regulatory frameworks, and the successful establishment of reliable domestic electric vehicle charging infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Air Conditioning Electric Scroll Compressors Market.- Denso Corporation

- Hanon Systems

- Sanden Holdings Corporation

- Mahle GmbH

- Mitsubishi Heavy Industries Ltd.

- Highly Marelli

- Panasonic Corporation

- Valeo S.A.

- Subros Limited

- BITZER SE

- Fujitsu General

- Shanghai Highly Group Co., Ltd.

- Eberspächer Group

- Concentric AB

- Toshiba Corporation

- Visteon Corporation

- Calsonic Kansei (now Marelli)

- Bergstrom Inc.

- Xidian Heavy Industries

- Aotecar New Energy Technology

Frequently Asked Questions

Analyze common user questions about the Automotive Air Conditioning Electric Scroll Compressors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for automotive electric scroll compressors?

The predominant driver is the global electrification of vehicles, specifically the large-scale production of Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs), which require high-voltage electric compressors for efficient cabin cooling and essential battery thermal management (BTM). This shift is mandated by global CO2 reduction targets.

How do 800V electric compressors differ from standard 400V units?

800V electric compressors operate at double the voltage, which minimizes current draw for the same power output. This allows for reduced thermal losses, thinner cabling, and enables significantly faster DC fast charging, positioning them for use in high-performance and luxury EV platforms requiring superior power delivery and efficiency.

What role does the electric compressor play in the EV's driving range?

The electric compressor is crucial for thermal management, particularly when integrated into a heat pump system. By efficiently controlling the temperature of the battery and cabin, it minimizes the auxiliary energy demand placed on the main battery pack, directly preserving and maximizing the vehicle’s effective driving range, especially under extreme ambient temperature conditions.

Which geographic region dominates the Automotive Electric Scroll Compressors Market?

The Asia Pacific (APAC) region, primarily led by the high volume of EV production and rapid consumer adoption in China, currently holds the largest market share. This dominance is due to strong governmental support for domestic EV supply chains and the massive scale of vehicle production in the region.

Are fixed displacement or variable displacement compressors more commonly used in modern EVs?

Variable displacement electric scroll compressors are increasingly favored in advanced EVs and heat pump systems. They offer superior energy efficiency, highly precise thermal modulation, and the flexibility needed to handle the complex, simultaneous thermal demands of the cabin and the high-voltage battery system, offering better performance than simpler fixed displacement units.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager